A friction stir welding device and method for realizing weld thickening

A friction stir, welding device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of limited welding seam thickening effect, large material removal, increased production cost, etc., to reduce input costs. , the effect of broadening the scope of application and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] In order to describe the technical content, structural features, and achieved goals and effects of the present invention in detail, the following will be described in detail in combination with embodiments and accompanying drawings.

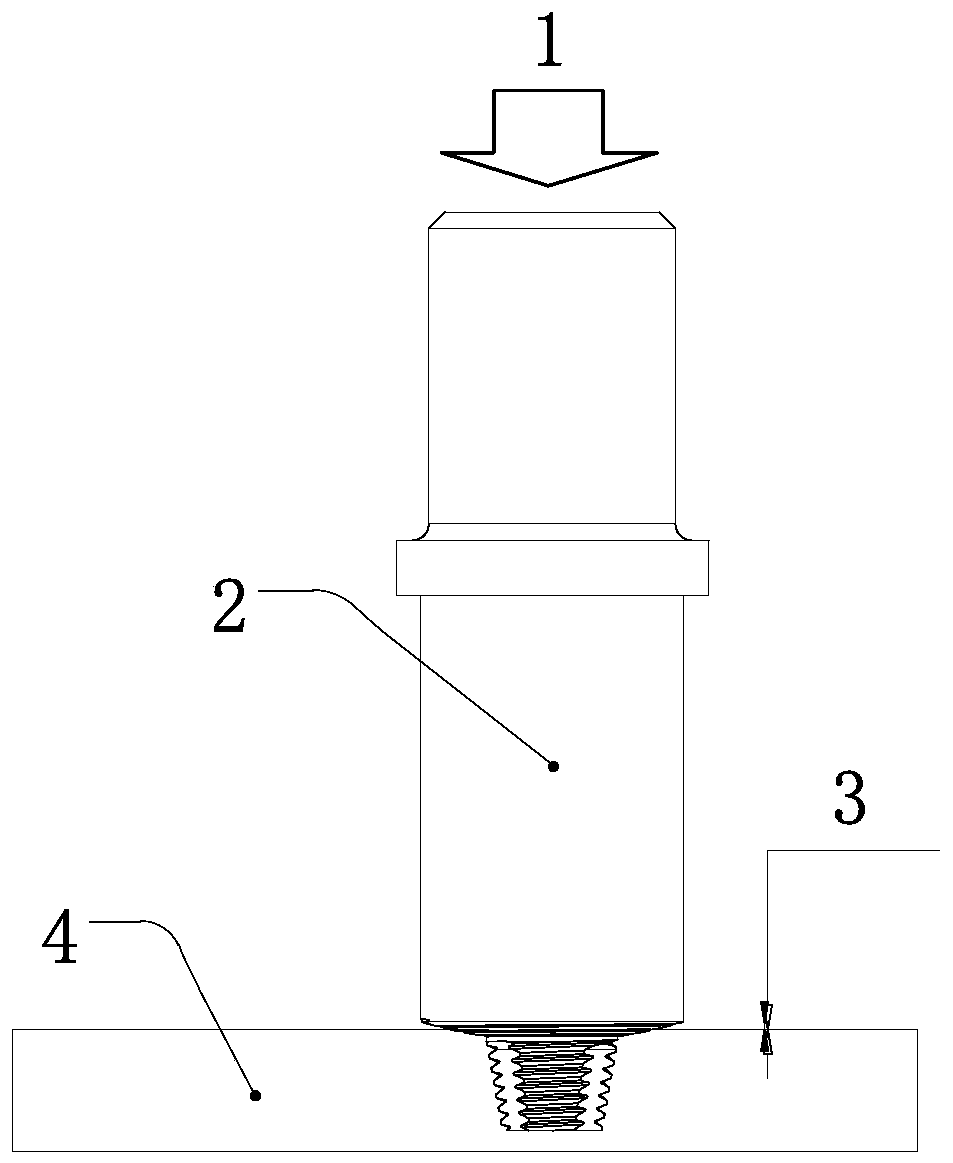

[0029] Such as figure 1 As shown, the friction stir welding device for thickening the weld according to the present invention is mainly realized by a zero-inclination welding module (3), a constant pressure control module (1) and a stirring tool module (2).

[0030] The zero-inclination welding module (3) ensures that the shaft shoulder is in contact with the surface of the workpiece at zero inclination during the welding process, and the constant pressure control module (1) ensures that the axial pressure of the stirring tool on the workpiece is constant during the welding process.

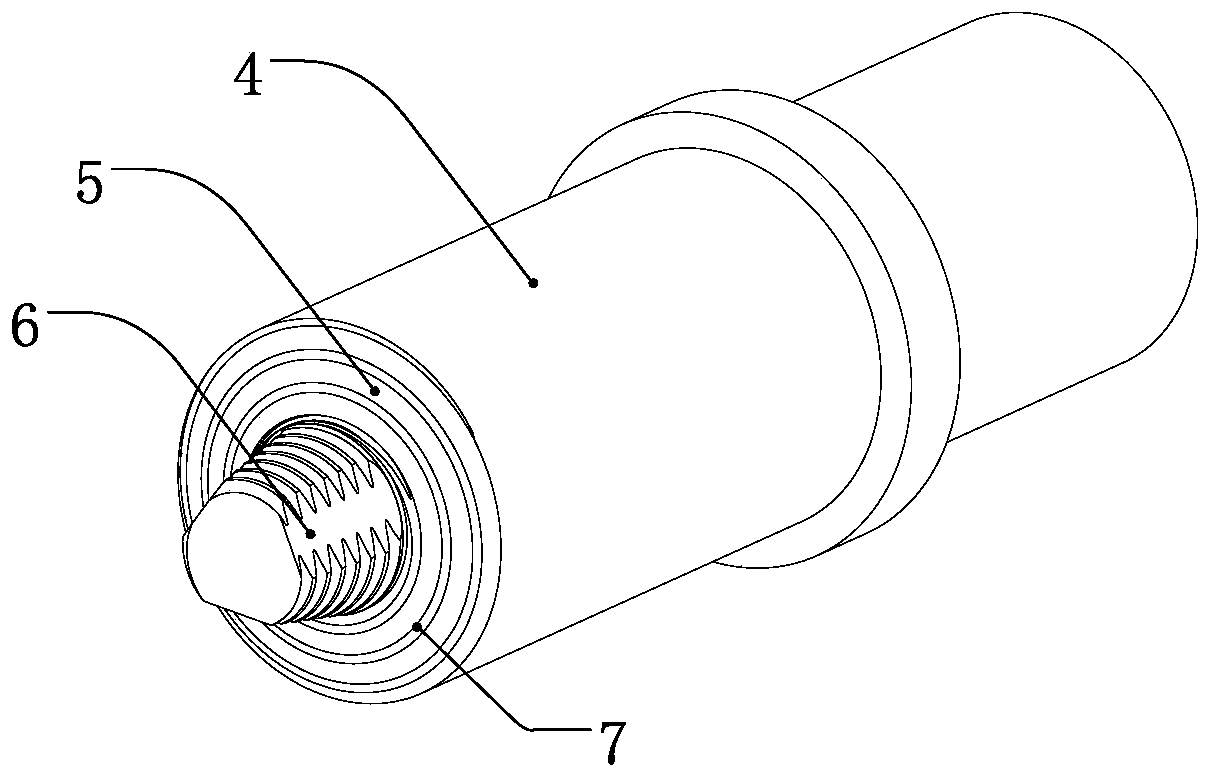

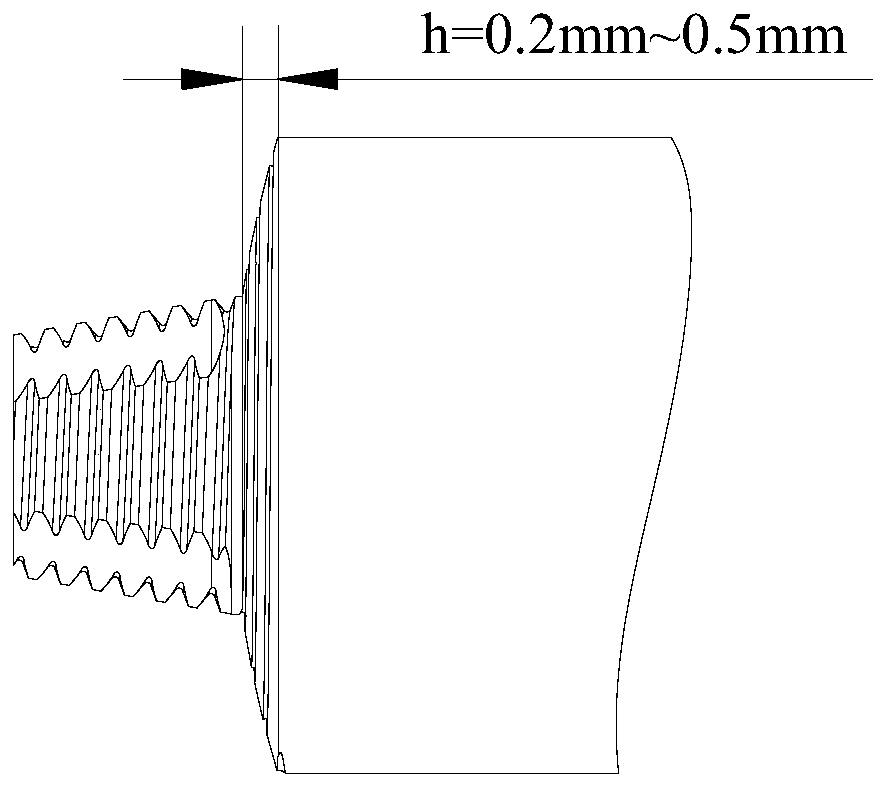

[0031] The stirring tool module (2) consists of a clamping end (4), a shaft shoulder (5) and a stirring pin (6), and the clamping end (4), the shaft shoulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com