Machining machine and machining production line with machining machine

A technology of machining and production line, applied in the direction of metal processing machinery parts, manufacturing tools, metal processing, etc., can solve the problems of low efficiency and waste of machining operations, and achieve the effect of easy control and reduction of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

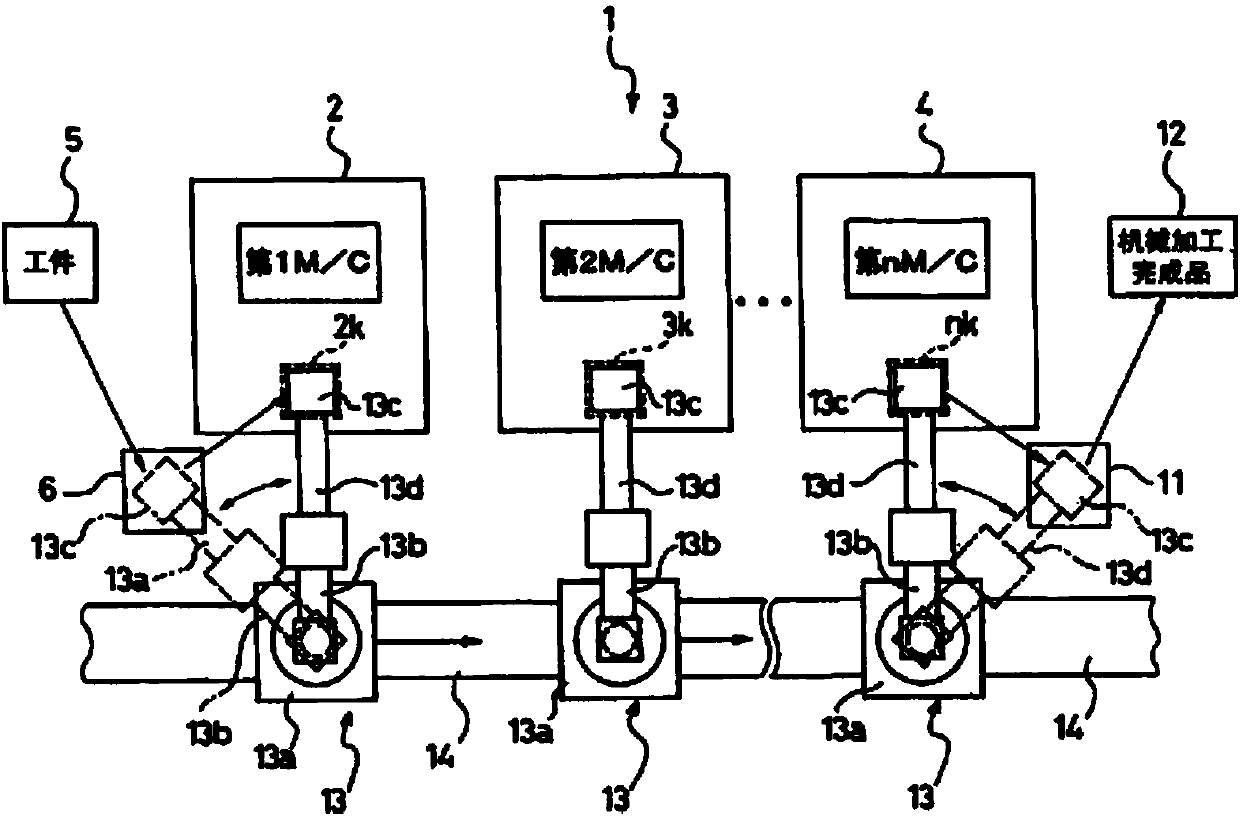

[0047] figure 1 It is a diagram schematically showing an example of a machining line having an example of an embodiment of the machining machine of the present invention. Also, with the above Figure 7 The same structural parts of the machining machine shown are represented by the same symbols, and detailed descriptions thereof are omitted.

[0048] Such as figure 1 As shown, in the machining production line 1 of this embodiment, there is no Figure 7 The temporary storage places 7, 8, 9, 10 of the workpiece 5 in the machining production line 1 are shown.

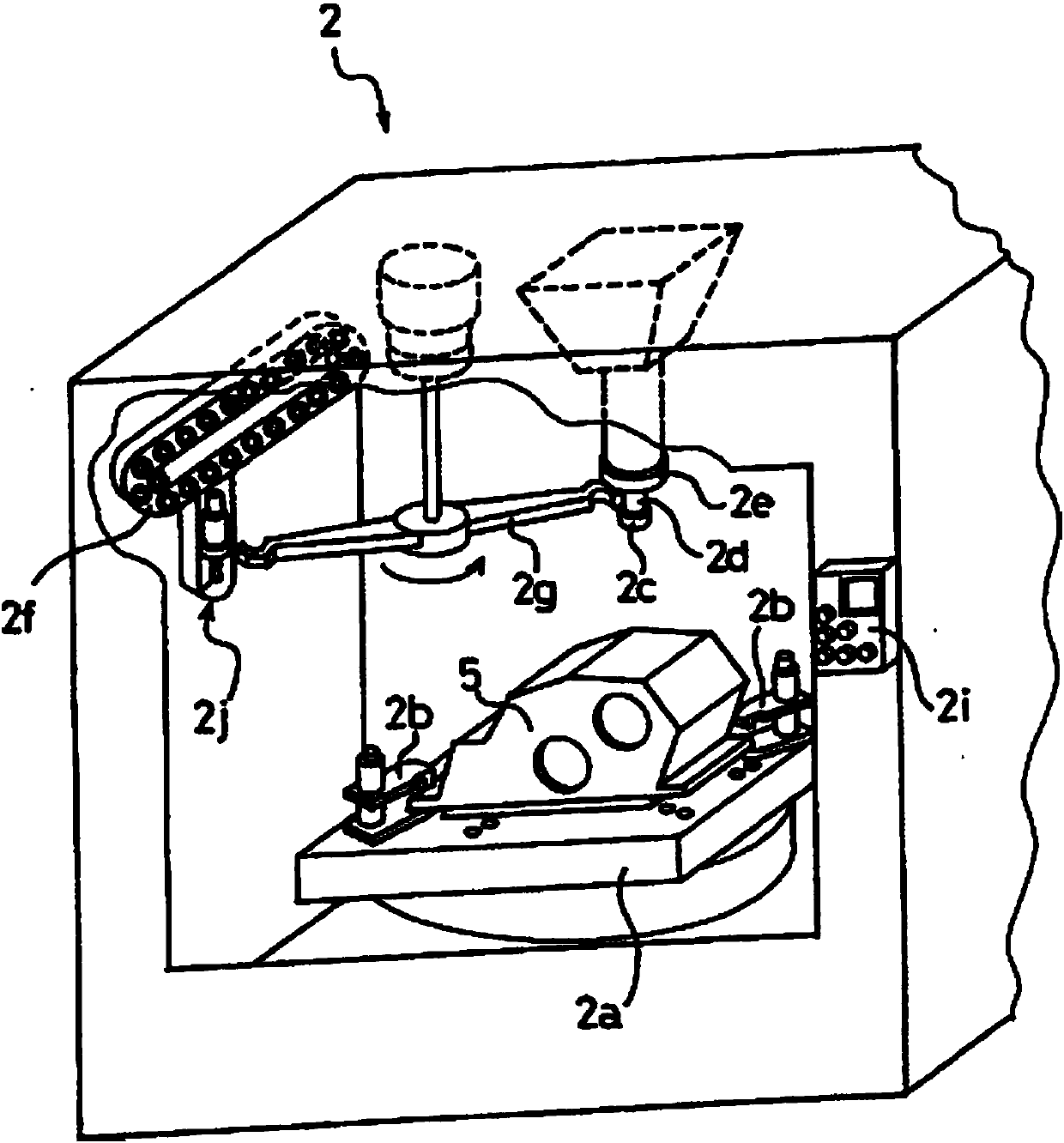

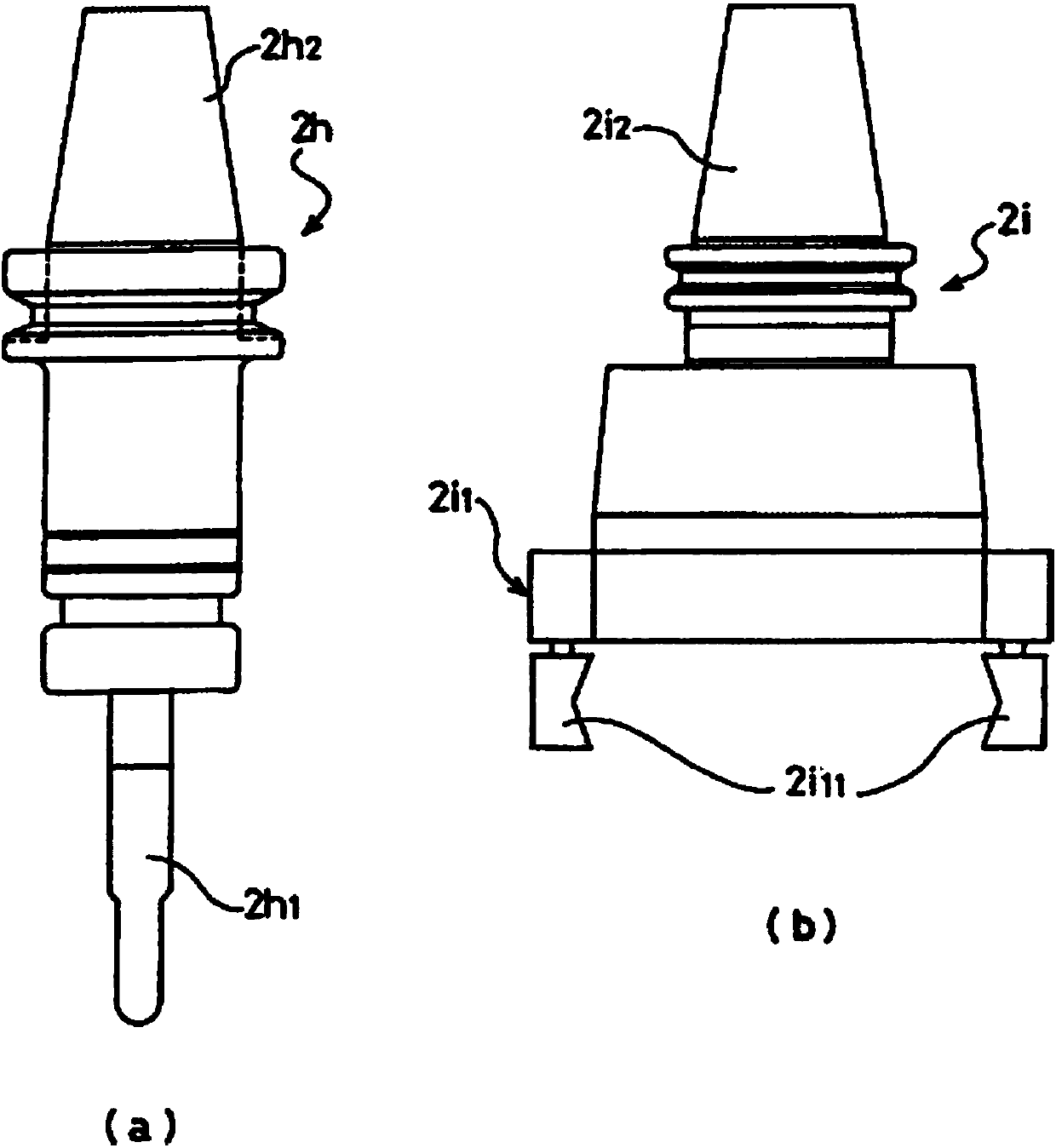

[0049] Such as figure 2 As shown, the first M / C2 of this embodiment has a workbench 2a that supports and fixes a workpiece 5, a clamp device 2b that fixes a workpiece 5 on the workbench 2a, and a connection portion (equivalent to The tool holding portion of the present invention) 2d, the spindle 2e operated by the tool 2c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com