Submerged-arc welding root welding and back chipping process of thick plate with K-type groove

A K-groove and submerged arc welding technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high labor intensity and heavy labor load, so as to improve welding efficiency, save welding time, and reduce welding time. Effects of noise and dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

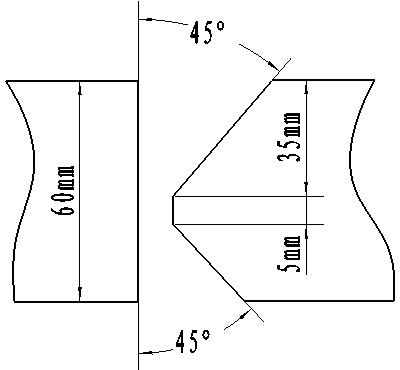

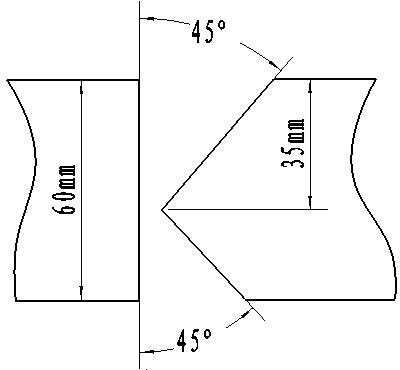

[0019] Select two pairs of steel plates with dimensions of 1000mm (length) × 500mm (width) × 60mm (thickness). One pair is welded by traditional submerged arc welding process; the other pair is welded by submerged arc welding after adopting the process of the present invention. Welding current, welding voltage and welding materials are consistent. Selection of test plate using traditional submerged arc welding process figure 1 For the middle groove type, the front groove welding is performed first, and after the front welding is completed, the carbon arc gouging is performed to clean the root, and then the reverse groove is welded after polishing. Adopt the test plate selection of technology of the present invention figure 2 The middle groove type, the root is welded, the root is cleaned, and then the submerged arc welding of the front and back grooves is performed. The mixed gas protection of argon and carbon dioxide is used during welding. The mixed gas is 80% argon + 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com