Roller rotary alignment welding device

A technology of welding device and drum rotation, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of high labor load and slow manual welding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

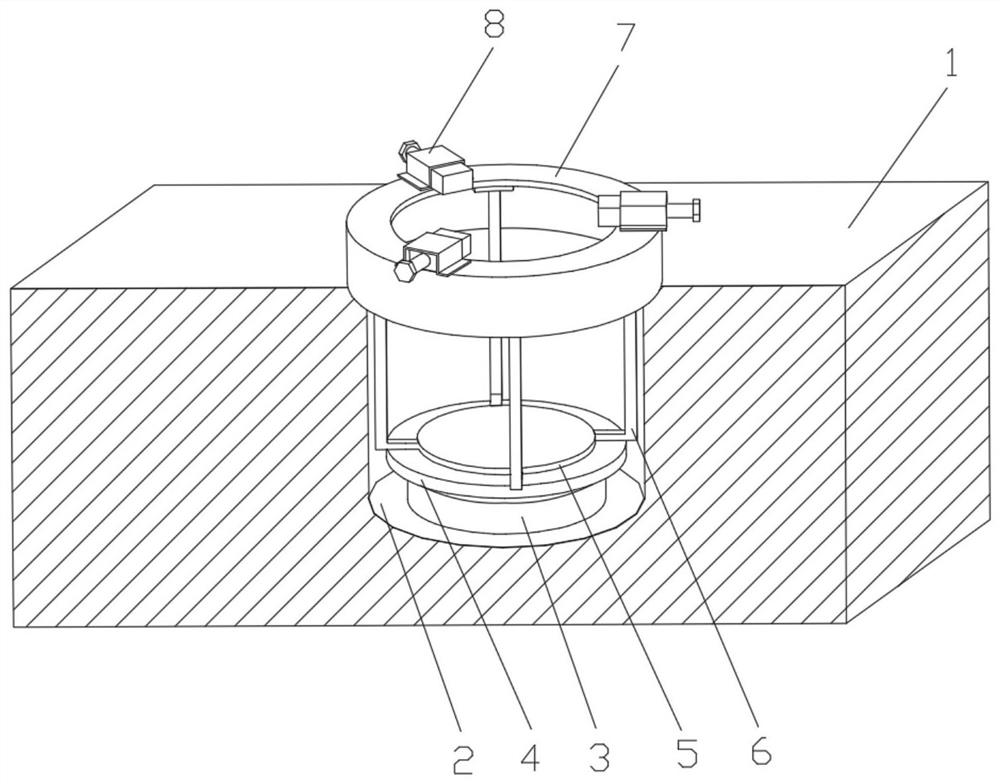

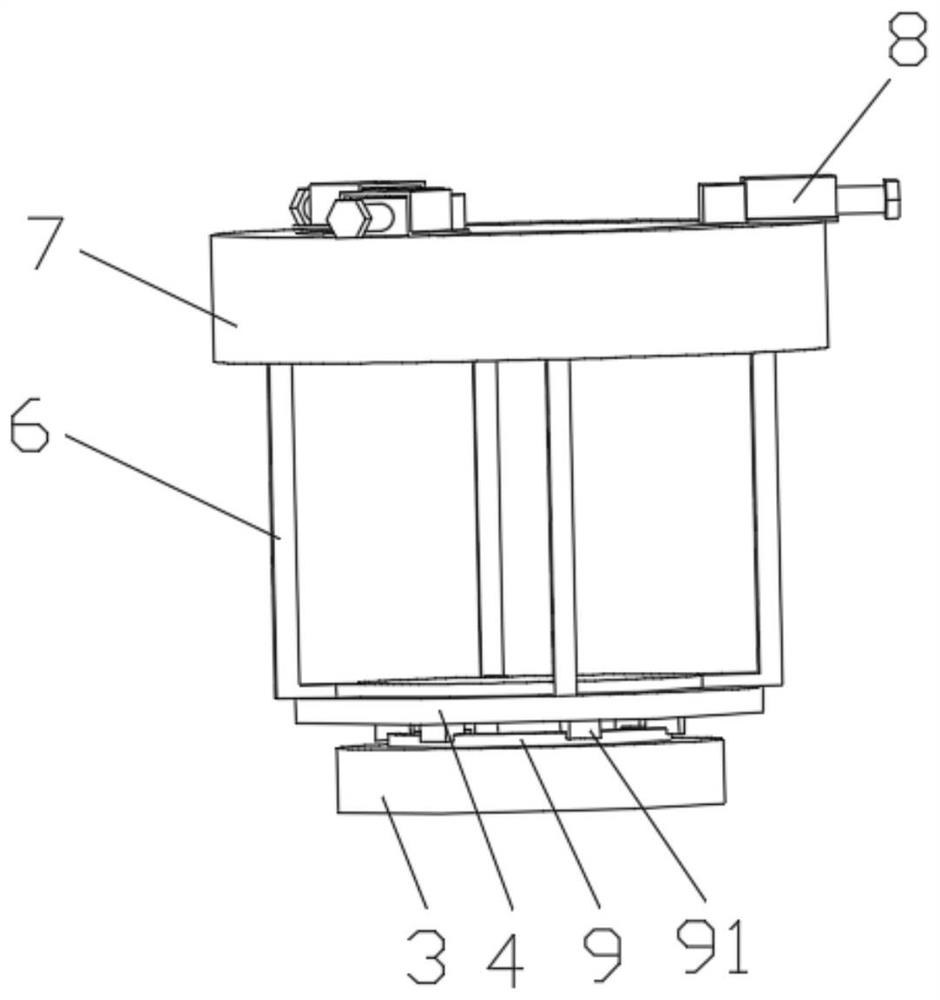

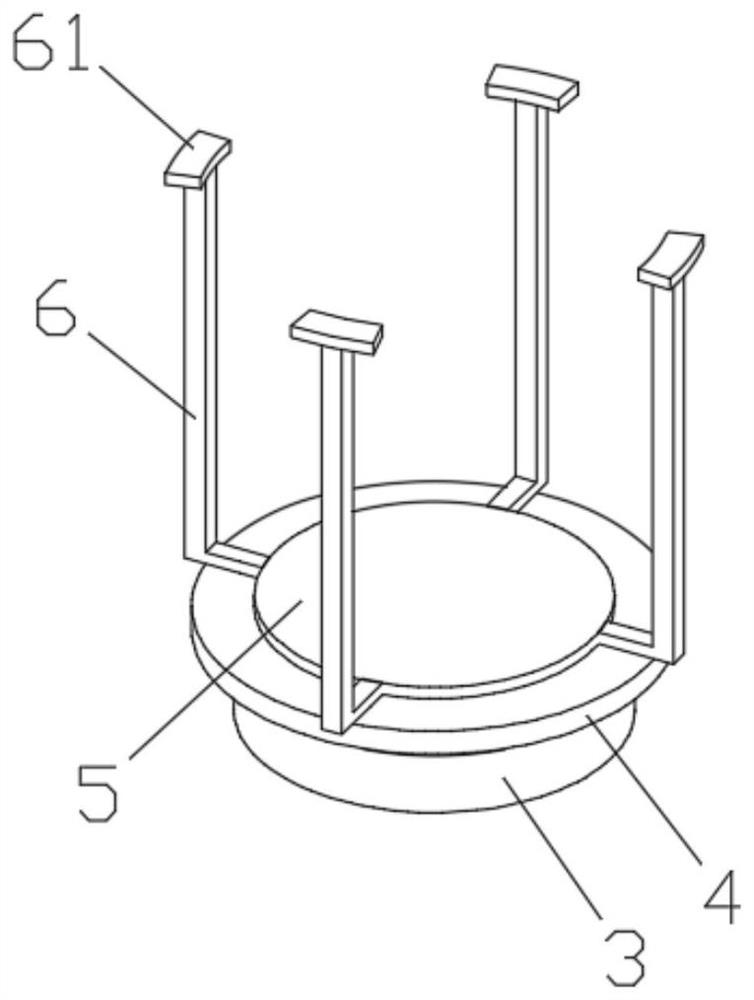

[0037] Such as figure 1 , 2 As shown in and 3, the drum rotation alignment welding device provided in this specific embodiment includes an operating platform, a rotatable rotating support mechanism arranged below the operating platform, a rotating support 7 arranged above the operating platform, and a rotating support arranged on the operating platform. One side of the welding machine used for welding drums, the upper part of the rotating support mechanism can be rotatably passed through the operating platform to connect with the rotating support 7, the rotating support 7 rotates with the rotation of the rotating supporting mechanism, and there is a place in the rotating supporting mechanism In the space of the drum, the rotating support 7 is provided with a relief hole for the roller to pass through, and the rotating support 7 is provided with a clamping and aligning mechanism, and the clamping and aligning mechanism is set on the rotating support 7 outside the relief hole, ...

Embodiment 2

[0053] The present invention also provides another drum rotation alignment welding device. In this embodiment, the drum rotation alignment welding device is substantially the same as the drum rotation alignment welding device in Embodiment 1, the difference is: the operating platform It is the ground 1, a pit 2 is set on the ground 1, the rotary support mechanism is placed in the pit 2, the rotary support 7 is located above the ground 1, and there is a gap between the rotary support 7 and the ground 1 for the rotary support 7 to rotate , the pit 2 is a cylindrical pit 2, and baffles are arranged around the pit 2. The setting of the baffles ensures that the humidity of the pit 2 is appropriate, and prevents the motor located in the pit 2 from getting damp and rotating the support mechanism. Corrosion, prolong the service life of the device. Placing the rotating support mechanism in the pit 2 saves the setting of the operating platform and reduces the cost, and the operator can ...

Embodiment 3

[0055] The present invention also provides another drum rotation alignment welding device. In this embodiment, the drum rotation alignment welding device is substantially the same as the drum rotation alignment welding device in Embodiment 2, the difference is: There are no ring guide rails and sliders, and a plurality of universal wheels are arranged on the lower part of the rotating disk. The universal wheels rotate on the base with the rotating disk, and the universal wheels play a supporting role on the rotating disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com