Positioner tool for submerged arc welding

A technology of submerged arc welding and positioner, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., and can solve problems such as difficult arc welding bead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

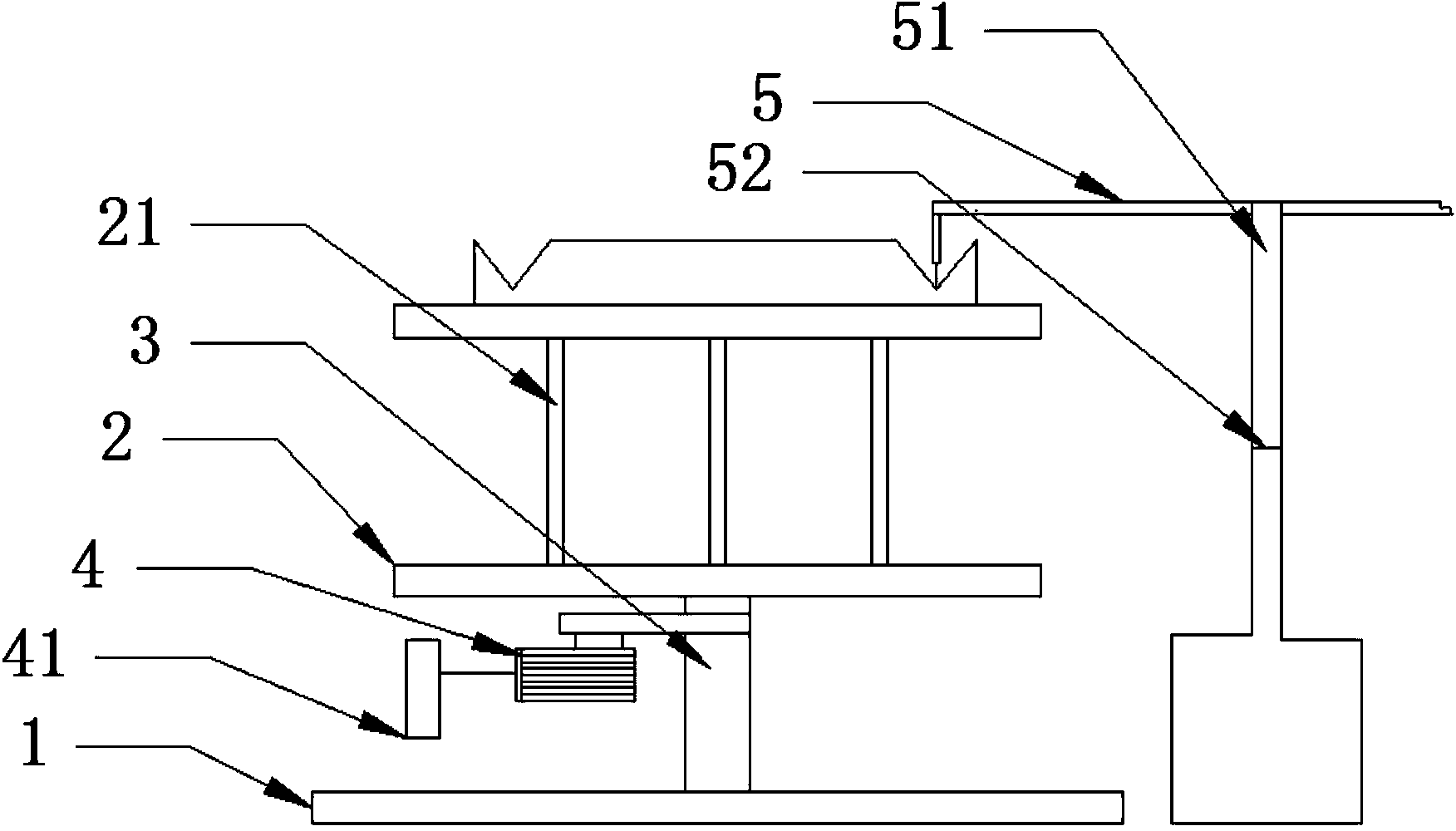

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] as attached figure 1 As shown, a positioner tooling for submerged arc welding is used for welding arc-shaped weldments, including a base 1, a workbench 2, a motor 4, a controller 41 and a submerged arc welding torch 5, and the working The table 2 is located above the base 1, and the two are connected by a rotating shaft 3, the rotating shaft 3 is connected to a motor 4, the motor 4 is a frequency conversion motor, and the frequency conversion motor is connected to a controller 41, and the controller 41 is a single-chip microcomputer. The workbench 2 is composed of two disks, the centers of the two disks and the center of the rotating shaft 3 are on the same straight line, and the two disks are connected by three support rods 21. The submerged arc welding torch 5 is located on the side of the workbench 2, and its switch Connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com