Circuit board welding method, circuit board and electronic equipment

A welding method and technology of electronic equipment, applied in welding equipment, metal processing equipment, printed circuit assembly of electrical components, etc., can solve the problems of increasing investment in welding production inspection, difficulty in finding and cleaning up, abnormal operation of equipment, etc., and achieve saving Equipment inspection and manual inspection links, providing reliability and service life, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0033] It should be noted that all expressions using "first" and "second" in the embodiments of the present invention are to distinguish two entities with the same name but different parameters or parameters that are not the same, see "first" and "second" It is only for the convenience of expression, and should not be construed as a limitation on the embodiments of the present invention, which will not be described one by one in the subsequent embodiments.

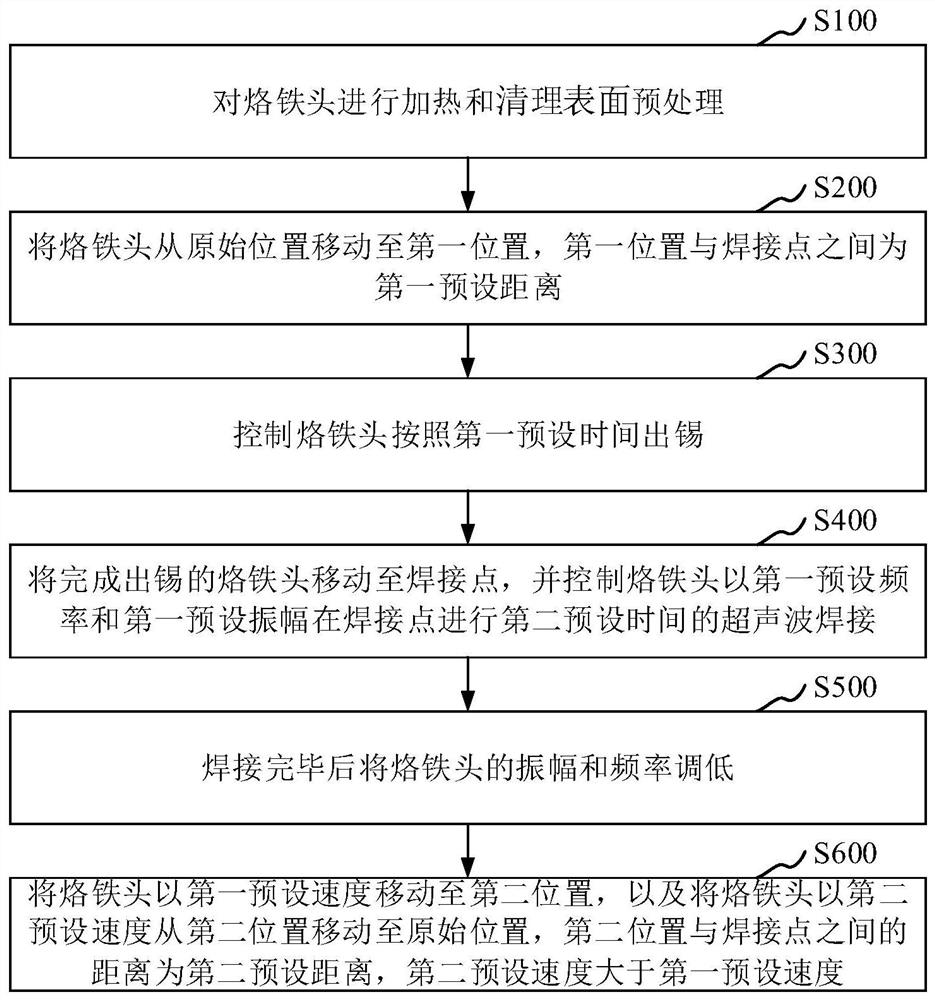

[0034] In one example, please refer to figure 1 As shown, the present invention provides a kind of circuit board welding method, and this method specifically comprises the following steps:

[0035] S100, pretreating the surface of the soldering iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com