An automatic gear welding mechanism

A welding mechanism and gear technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficulties in the field of automatic welding, achieve flexible and diverse welding methods, and improve positioning accuracy and repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

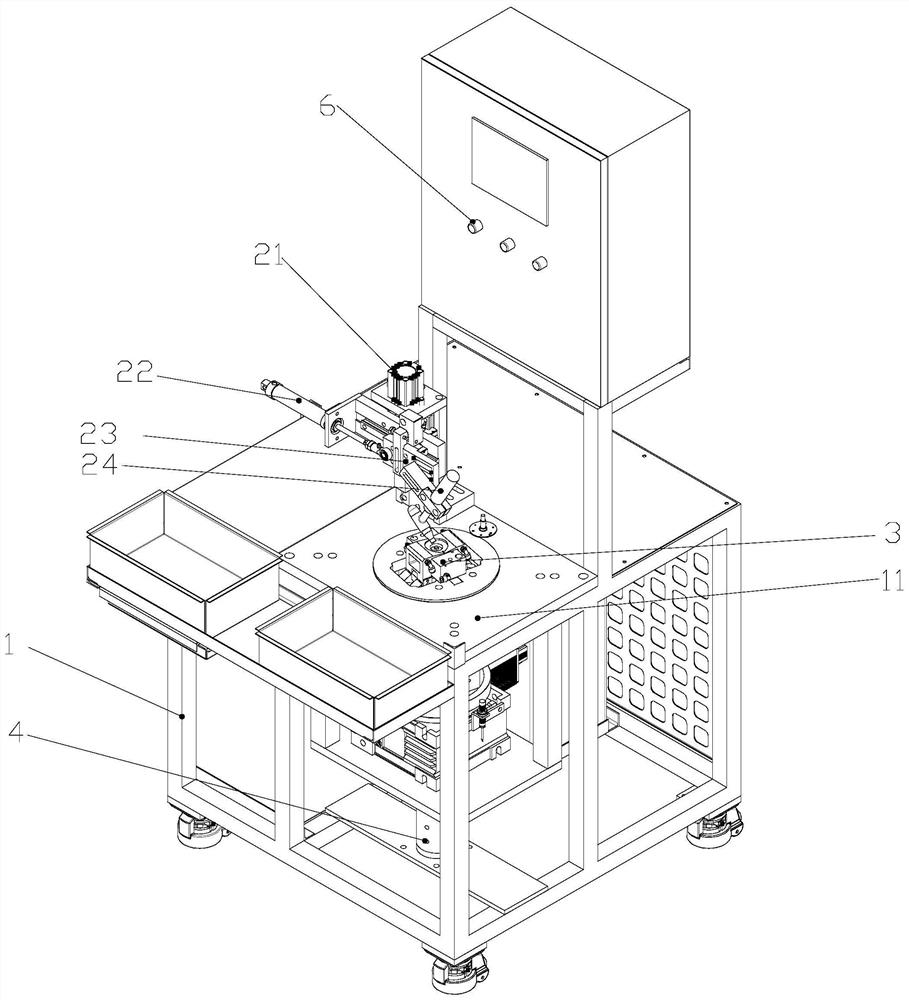

[0030] Such as Figure 1~5 An automatic gear welding mechanism is shown, including:

[0031] A frame 1, the frame 1 is provided with a cavity A and a cavity B, the cavity A is located above the cavity B, and the first platform 11 is between the cavity A and the cavity B;

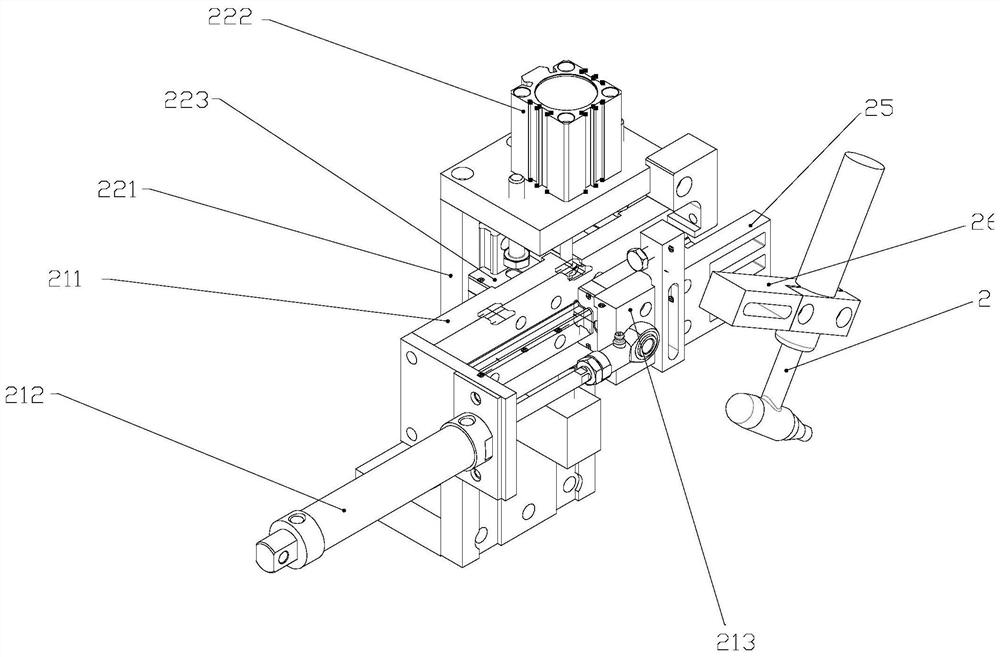

[0032] Device A includes a horizontal drive assembly 21, a vertical drive assembly 22, a fixing assembly 23 and a welding torch 24, the vertical drive assembly 22 is fixed on the first platform 11, and the horizontal drive assembly 21 is arranged on the vertical drive assembly 22, It can slide up and down, the fixed component 23 is set on the horizontal driving component 21, and can slide horizontally, and the welding torch 24 is set on the fixed component 23;

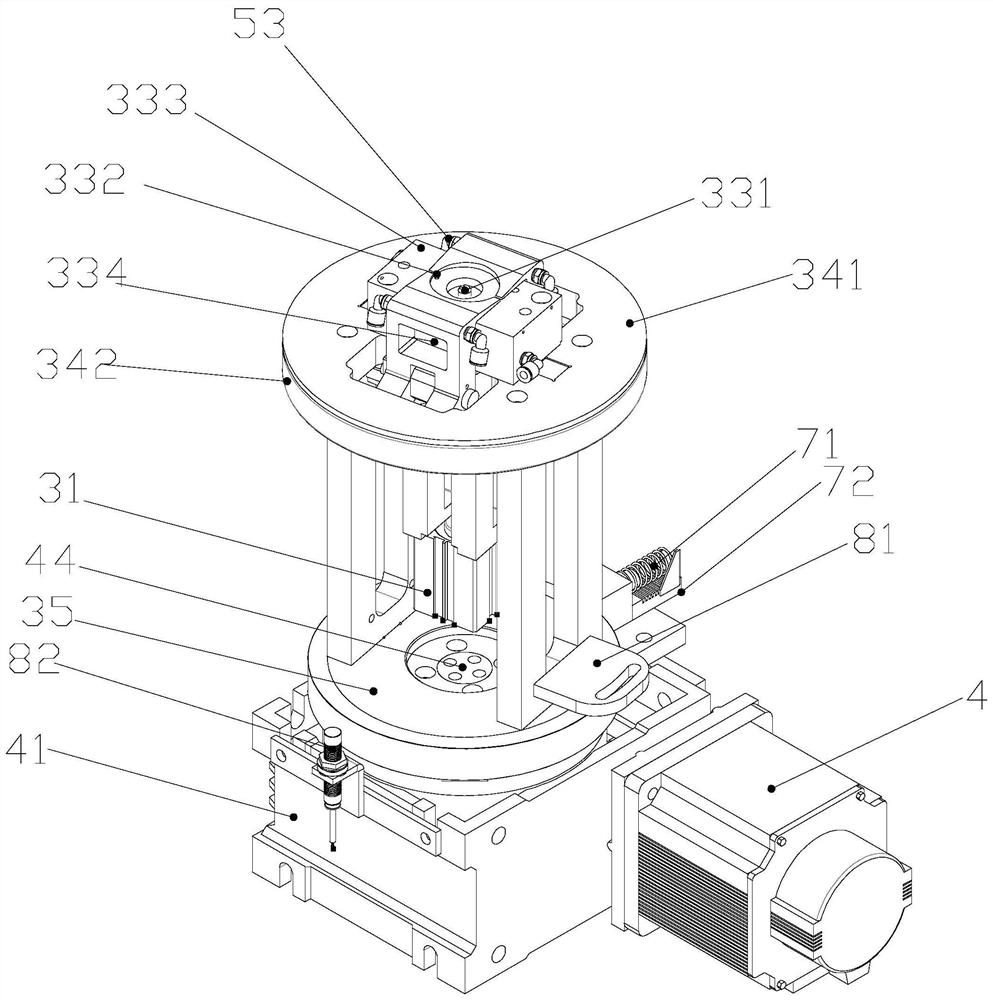

[0033] The device B includes a product holder 3 and a rotating assembly 4 , the product holder 3 is partly located on the first platform 11 , and the rotating assembly 4 is below the product holder 3 .

[0034] The device C includes a water tank 51...

Embodiment 2

[0049] The difference between this embodiment and the first embodiment is that the motor 42 can also provide stepping rotation, so this embodiment can also complete automatic spot welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com