A welding process for super duplex stainless steel bars

A technology of duplex stainless steel and welding technology, which is applied in welding equipment, welding medium, welding equipment, etc., can solve the problems that hinder the popularization and application of super duplex stainless steel reinforcement, and the workload is large, so as to save the groove processing process and operation Convenience and guaranteed balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

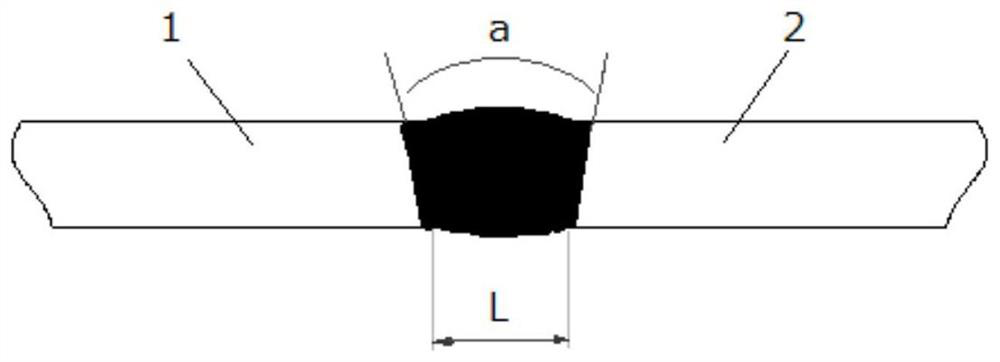

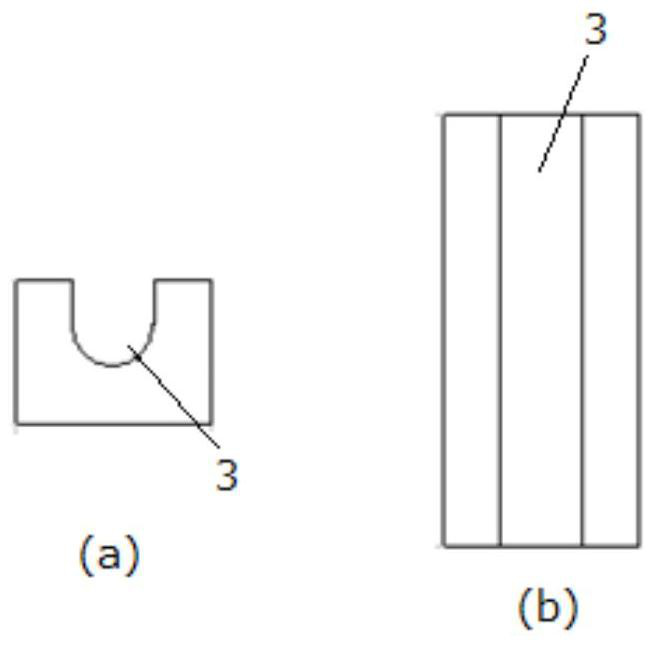

[0032] Use a solid core wire with a diameter of 1.2mm to press figure 1 Connector form shown, placed in figure 2 Welding is carried out in the mold shown, the groove angle is 30°, the welding gap is 15mm, the welding current is 200A, the welding voltage is 27V, the welding speed is 30cm / min, the welding heat input is 7.5kJ / cm, and the gas flow rate is 25L / min, the protective gas is 97%Ar+3%N 2 , to make welded joints.

Embodiment 2

[0034] Use a solid core wire with a diameter of 1.2mm to press figure 1 Connector form shown, placed in figure 2 Welding is carried out in the mold shown without groove, the welding gap is 15mm, the welding current is 180A, the welding voltage is 25V, the welding speed is 30cm / min, the welding heat input is 6.3kJ / cm, and the gas flow rate is 20L / min , the protective gas is 95% Ar+3% N 2 +2% He, made into welded joints.

Embodiment 3

[0036] Flux cored wire with a diameter of 1.2mm is used to press figure 1 Connector form shown, placed in figure 2 Welding is carried out in the mold shown, the groove angle is 30°, the welding gap is 15mm, the welding current is 200A, the welding voltage is 27V, the welding speed is 35cm / min, the welding heat input is 6.5kJ / cm, and the gas flow rate is 25L / min, the protective gas is 97%Ar+3%N 2 , to make welded joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com