Method for fixing printed circuit board (PCB) with mark point location function

A PCB board and point positioning technology, which is applied to the assembly of printed circuits with electrical components, auxiliary devices, auxiliary welding equipment, etc., can solve the problem of PCB board position deviation, poor soldering effect, affecting the practicability and operating efficiency of automatic soldering robots, etc. problems, achieve the effect of reducing welding time and increasing welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings.

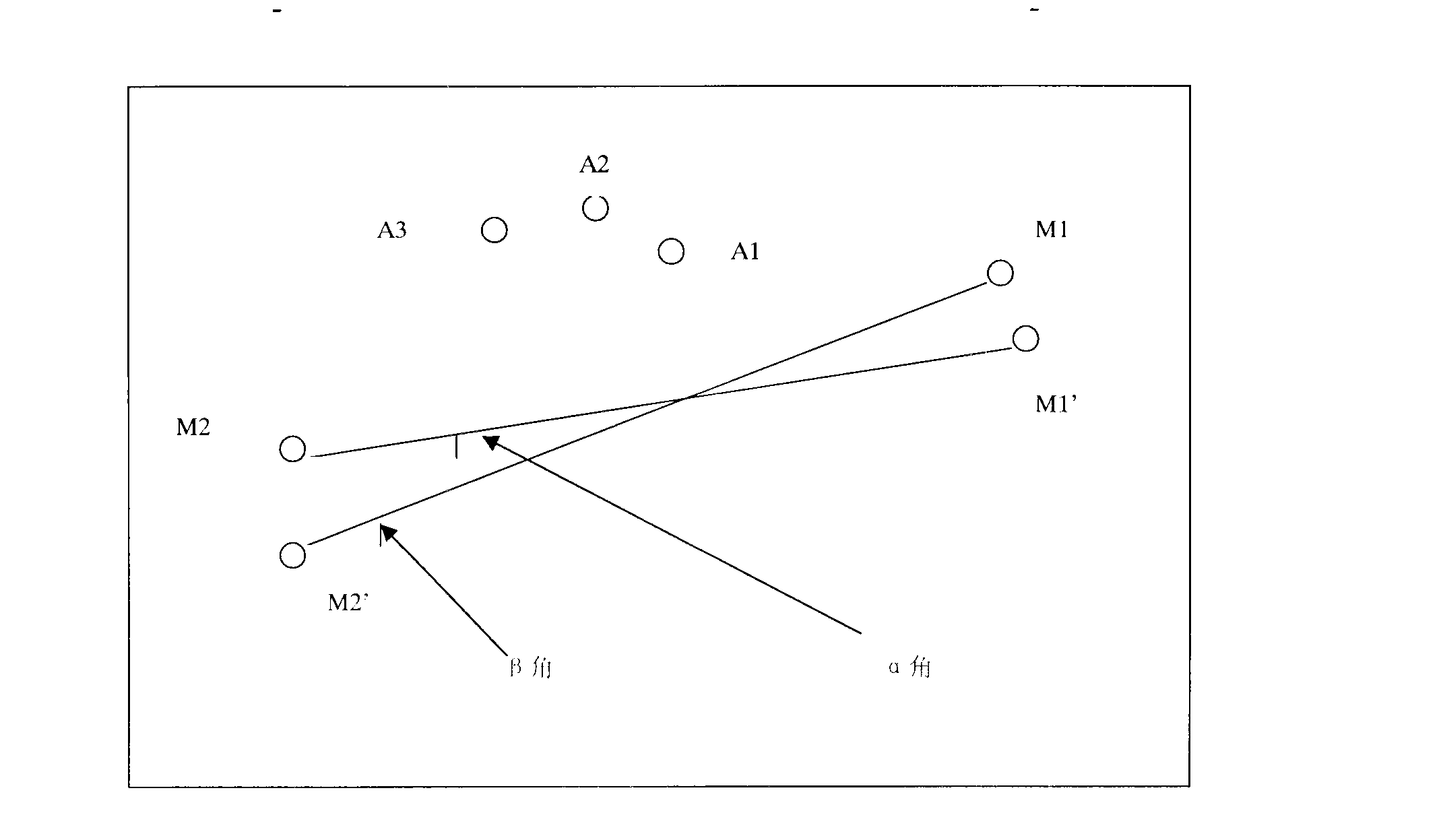

[0051] Such as figure 1 As shown, the Mark point is already done in the PCB board design stage. It is the position identification point where the PCB is applied to the automatic placement machine in the circuit board design. It is also called a mark point or a feature point. Points are generally circular markers. However, offsets often occur when the PCB board is placed. The present invention introduces the positioning function of the Mark point into the automatic soldering robot to fix the PCB board.

[0052] The general approach is:

[0053] 1. When doing the program, first place a reference PCB board on the fixture, take a picture of the Mark point on the PCB board with the camera, and display it on the computer screen, and then use the screenshot control that comes with the solder robot software on the Capture the image of the Mark point area in the current fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com