Cable connector component and manufacturing method thereof

A technology for cable connectors and manufacturing methods, which is applied to parts of connecting devices, parts of lines/collectors, connections, etc., which can solve the problem of increasing connector costs, increasing welding time, and the inability to realize printed circuit boards and cables. Fast welding and other issues, to save welding time, reduce costs, and shorten assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

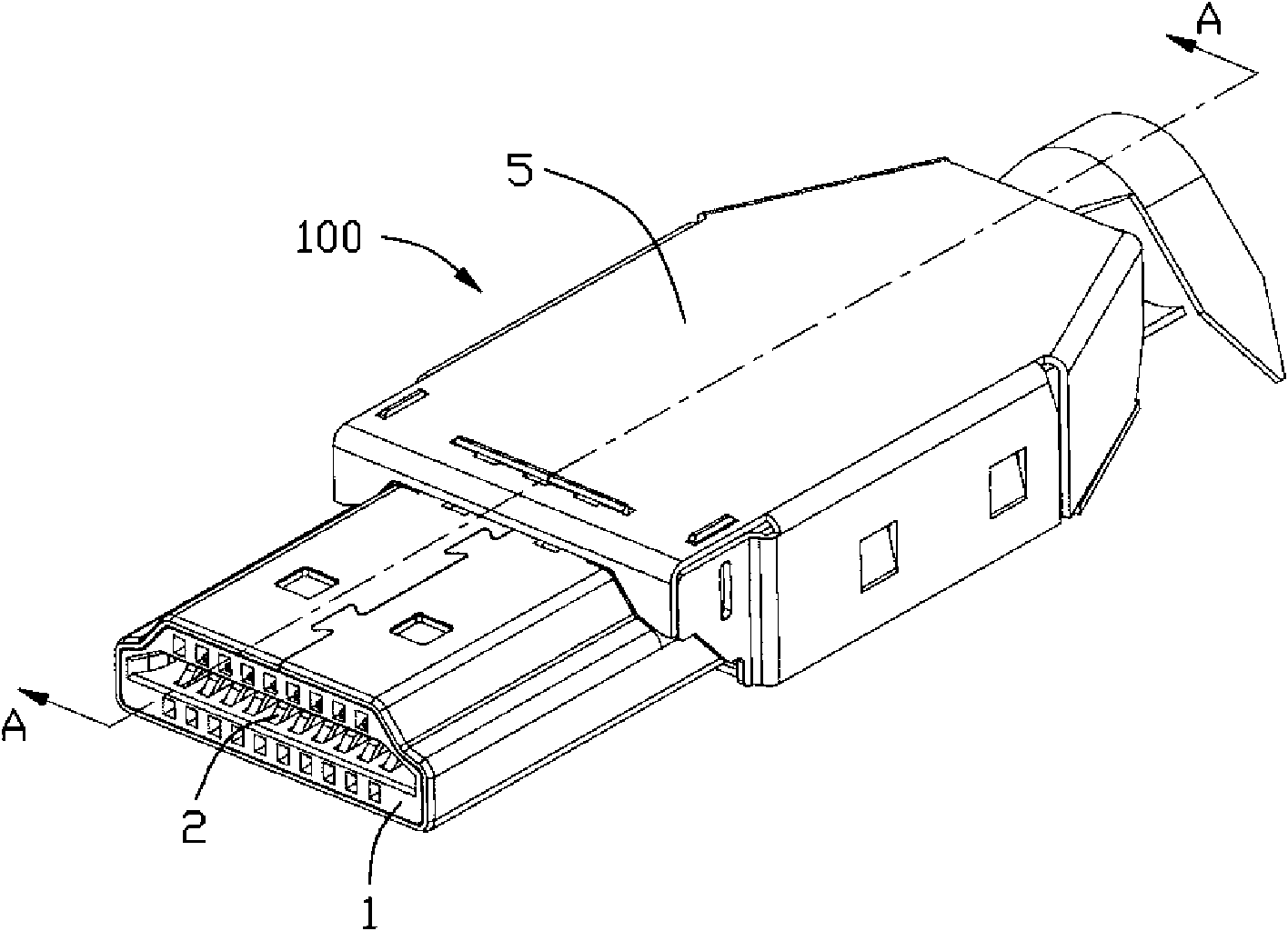

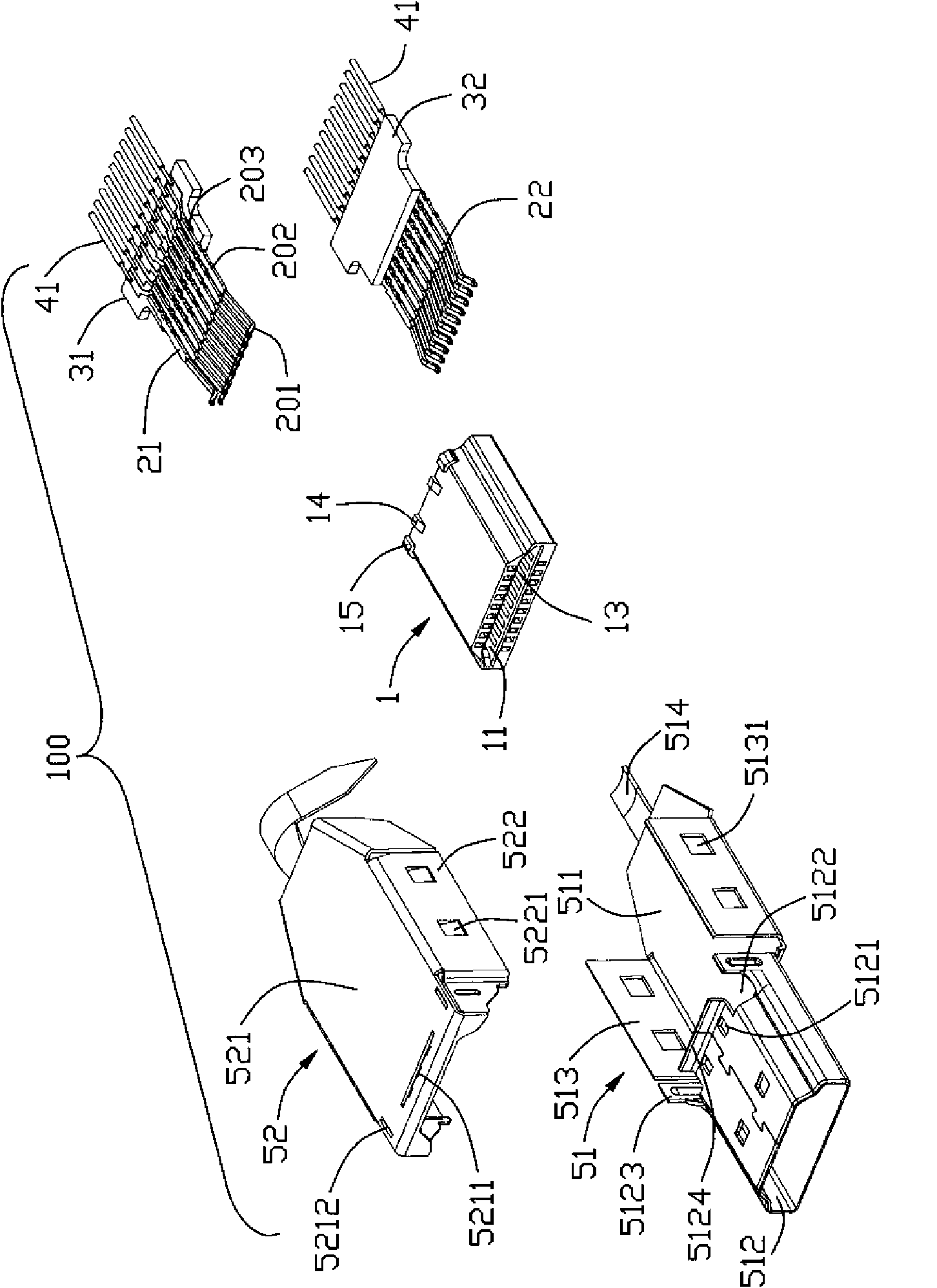

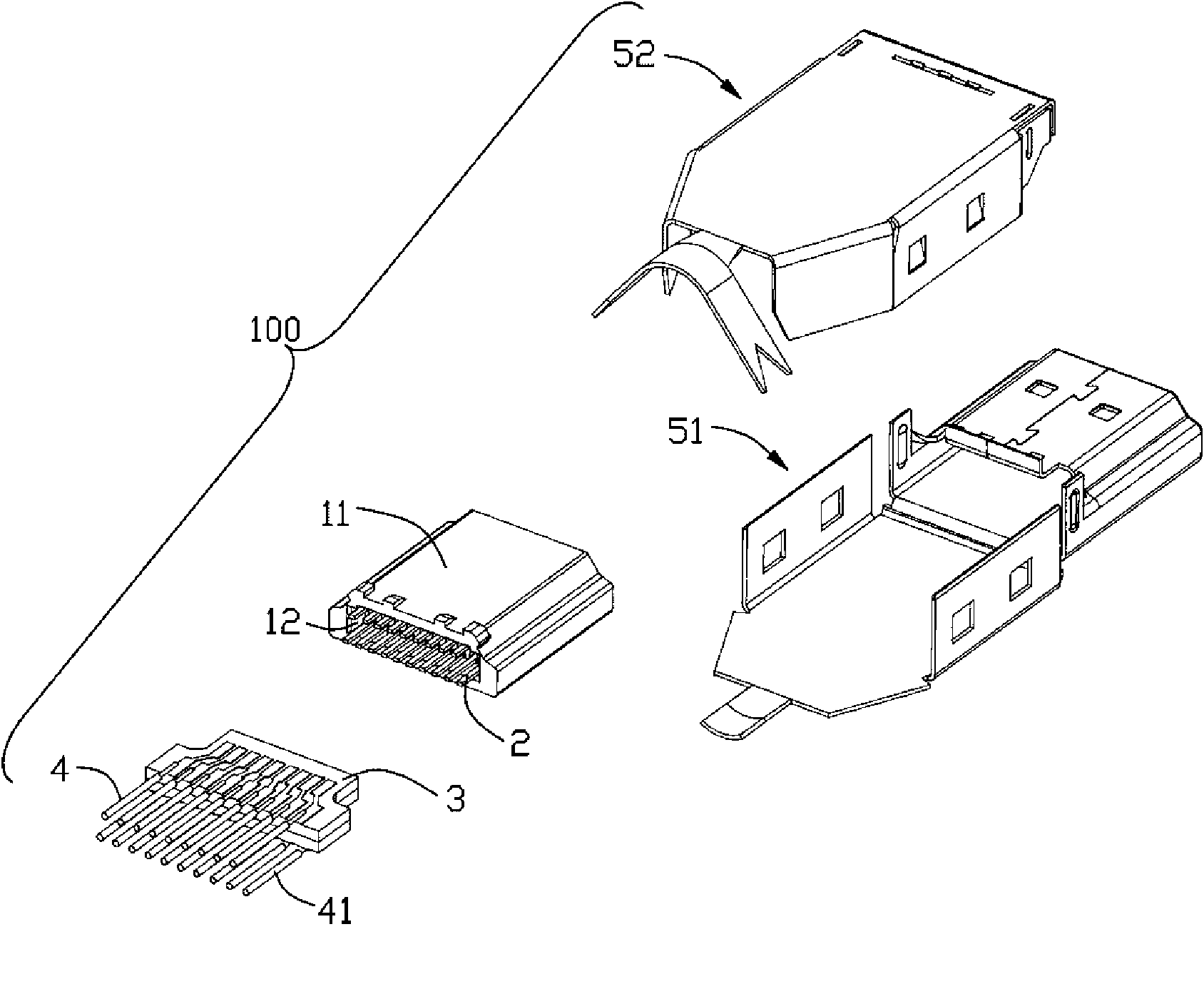

[0017] see Figure 1 to Figure 3 and Figure 5 As shown, the cable connector assembly 100 of the present invention includes an insulating body 1, a plurality of conductive terminals 2 housed in the insulating body 1, a printed circuit board 3 electrically connected to the conductive terminals 2, and a printed circuit board 3 electrically connected to the printed circuit board 3. The cable 4 and the metal shielding shell 5 covering the insulating body 1 and the printed circuit board 3 , wherein the printed circuit board 3 is composed of an upper circuit board 31 and a lower circuit board 32 .

[0018] see Figure 2 to Figure 4 The insulating body 1 has a front end face and a rear end face opposite to the front end face, a receiving chamber 11 is formed by inwardly recessing the front end face of the insulating body 1 , and a recessed cavity 12 is formed by inwardly recessing the rear end face of the insulating body 1 . Two rows of terminal receiving grooves 13 are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com