Quick forming device for titanium alloy multi-layered plate and forming method thereof

A multi-layer board and titanium alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of complex forming process, long time-consuming single piece, high equipment requirements, etc., and achieve good welding quality, fast forming speed, The effect of fast diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

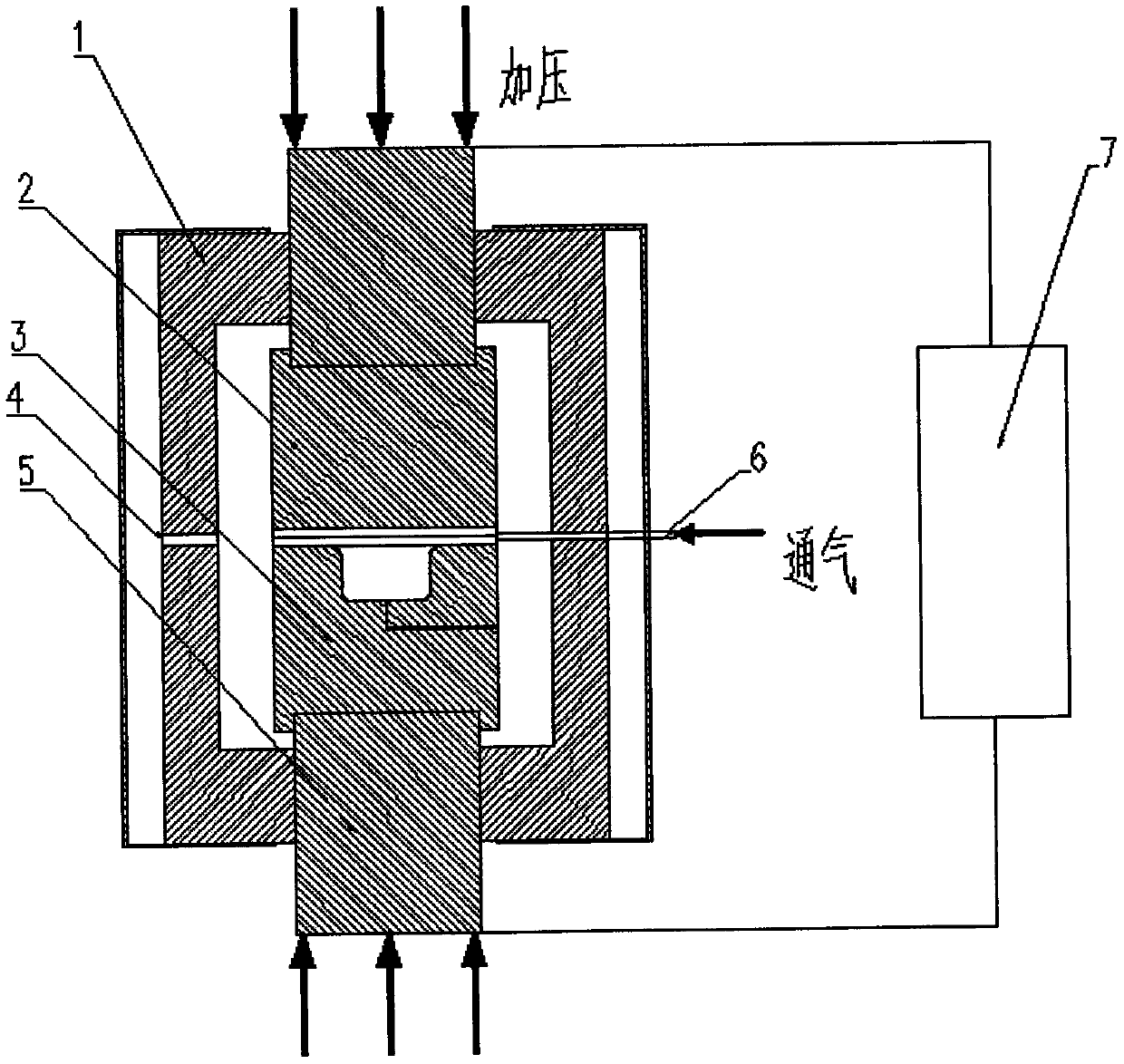

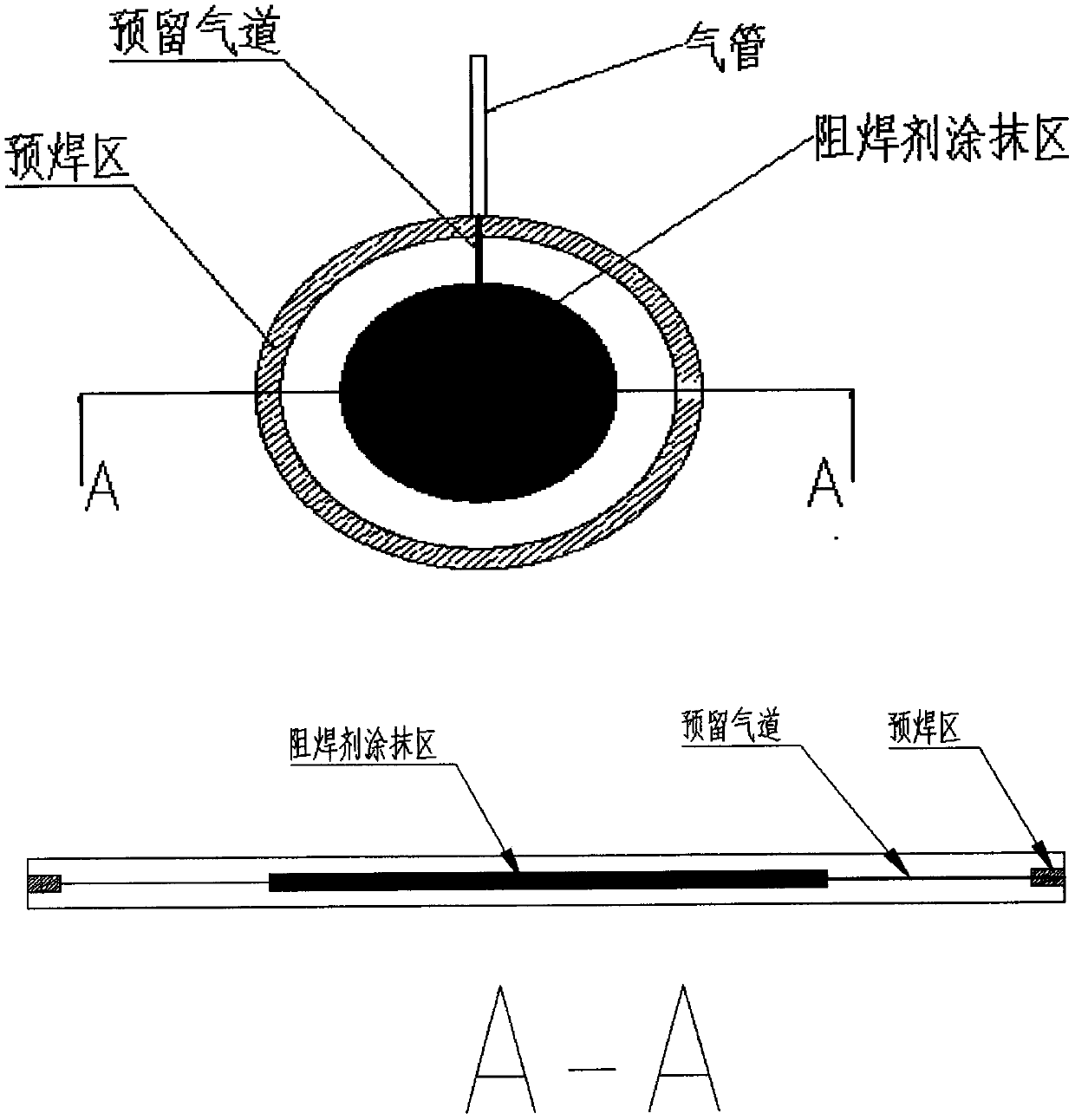

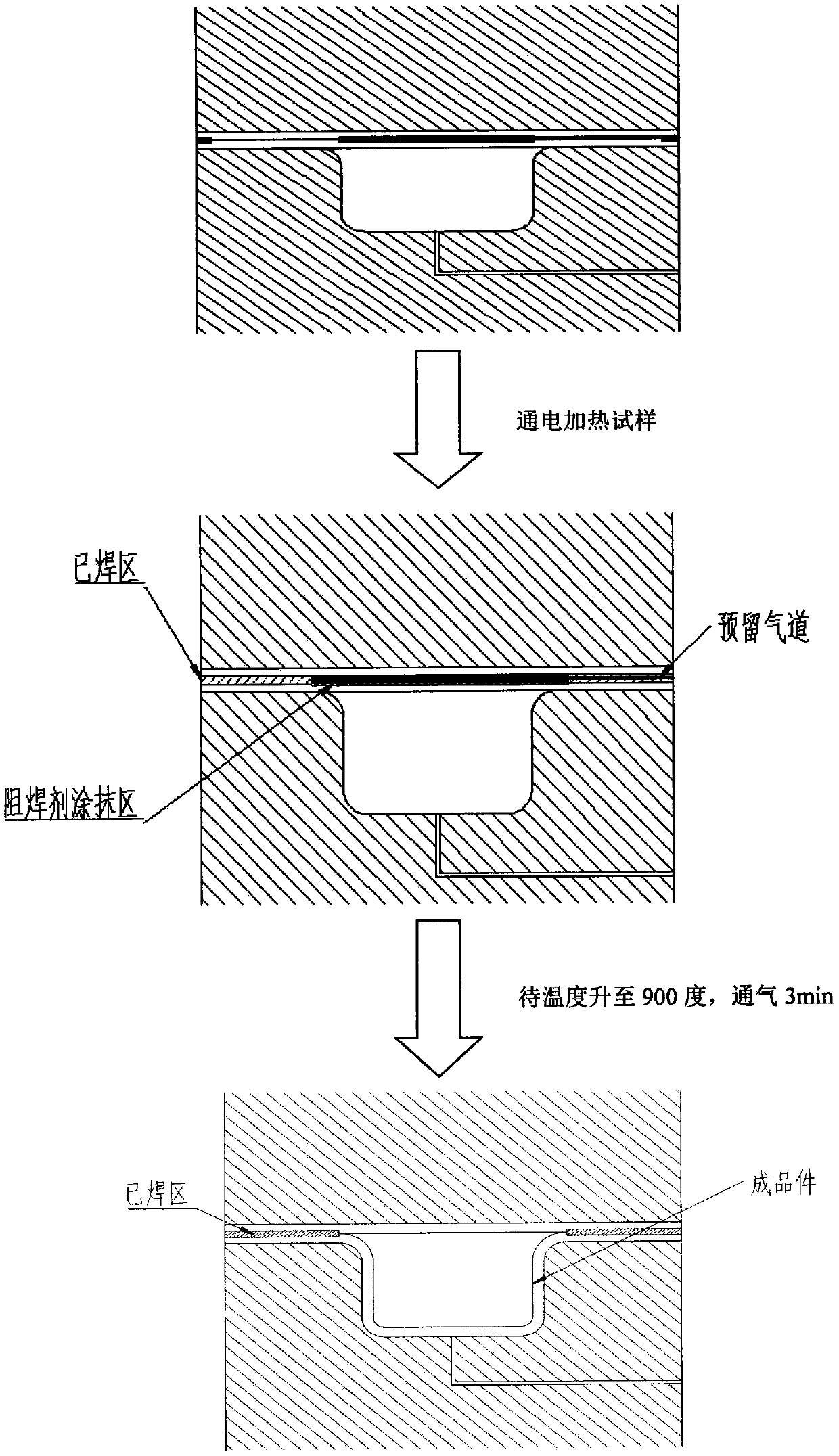

[0025] like figure 1 As shown, a rapid prototyping device of a titanium alloy multilayer plate of the present invention includes a thermal insulation sealed box 1, a graphite upper mold 2, a graphite lower mold 3, a temperature measuring hole 4, a graphite electrode 5, a ventilation pipe 6, and a DC pulse power supply 7 and the sample, the sample is two TC4 titanium alloy discs; the graphite electrode 5 is divided into the first electrode and the second electrode, the first electrode is connected to one end of the DC pulse power supply through a wire, and the second electrode is connected through a wire At the other end of the DC pulse power supply; the sample is located between the graphite upper mold 2 and the graphite lower mold 3, and the graphite upper and lower molds are respectively connected to the pulse power supply through two graphite electrodes 5; the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com