Glass-metal heat sealing material and method of heat-pipe evacuated solar collector tube

A technology of vacuum heat collecting tube and sealing material, which is applied in the field of heat pipe type vacuum heat collecting tube glass-metal hot-pressing sealing material, which can solve the problems of difficult atomic-level sealing of solder metal and poor matching of Fe atoms, and achieve extension Improve performance, prolong service life and reduce air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When the welding wire is composed of metal single substance Ni, the heat pipe type vacuum heat collector glass-metal hot-press sealing method is as follows:

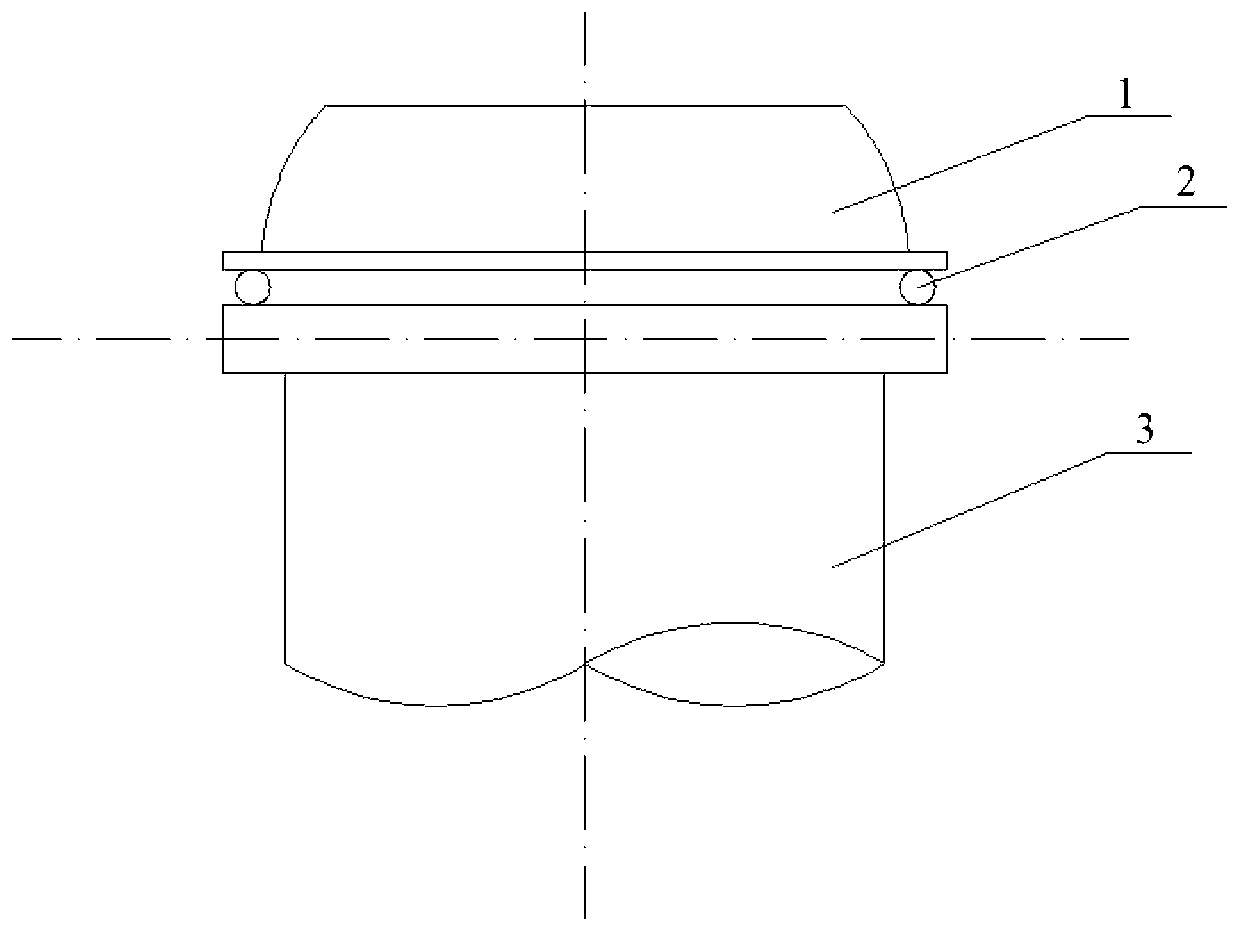

[0022] Burn one end of the Φ100mm glass tube into a glass flange 3, clean and degrease the end face of the flange and the surface of the iron-nickel expansion alloy end cover 1, sandwich a ring-shaped welding wire 2 with a diameter of 0.1mm in the middle, and heat the sealing part to 700 ℃, the sealing temperature is 0.6 times the melting point of the welding wire, and 70kg / cm is applied to the end face 2 impact pressure, the impact time is 0.5s, and the air leakage rate of the obtained sealing surface can be less than 1×10 -11 Torr.L / sec, meeting sealing requirements.

[0023] When the composition of the welding wire is any one of the metal elements Mg, Be, V, and Co, a good sealing effect can also be obtained by pressing and sealing according to the above-mentioned process.

Embodiment 2

[0025] When the composition of the welding wire is an alloy of Ni and Si added in the V base metal, the mass fraction of nickel in the metal alloy is 1%, and the mass fraction of silicon is 1%. The heat pipe type vacuum heat collector glass-metal hot pressing The sealing method is as follows:

[0026] Burn one end of the Φ100mm glass tube into a glass flange 3, clean and degrease the end face of the flange and the surface of the iron-nickel expansion alloy end cover 1, sandwich a ring-shaped welding wire 2 with a diameter of 10mm in the middle, and heat the sealing part to 650°C , the sealing temperature is 0.7 times the melting point of the welding wire, and 200kg / cm is applied to the end face 2 The impact pressure is 1min, and the air leakage rate of the obtained sealing surface can be less than 1×10 -11 Torr.L / sec, meeting sealing requirements.

[0027] The base metal V in the welding wire can be replaced by one of Mg, Be, and Co, and a good sealing effect can also be obt...

Embodiment 3

[0029] When the composition of the welding wire is an alloy of Ni and Si added in the V base metal, the mass fraction of nickel in the metal alloy is 15%, and the mass fraction of silicon is 15%. The sealing method is as follows:

[0030] One end of the Φ100mm glass tube is fired into a glass flange 3, the end face of the flange and the surface of the iron-nickel expansion alloy end cover 1 are cleaned and degreased respectively, and a ring-shaped welding wire 2 with a diameter of 15mm is inserted in the middle, and the sealing part is heated to 800°C , the sealing temperature is 0.8 times the melting point of the welding wire, and 300kg / cm is applied to the end face 2The impact pressure, the impact time is 1.5min, and the air leakage rate of the obtained sealing surface can be less than 1×10 -11 Torr.L / sec, meeting sealing requirements.

[0031] The base metal V in the welding wire can be replaced by one of Mg, Be, and Co, and a good sealing effect can also be obtained by p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com