Tool capable of applying pressure to carry out electron beam auxiliary heat action connection

A technology of applying pressure and electron beam, which is applied in the direction of electron beam welding equipment, auxiliary welding equipment, auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

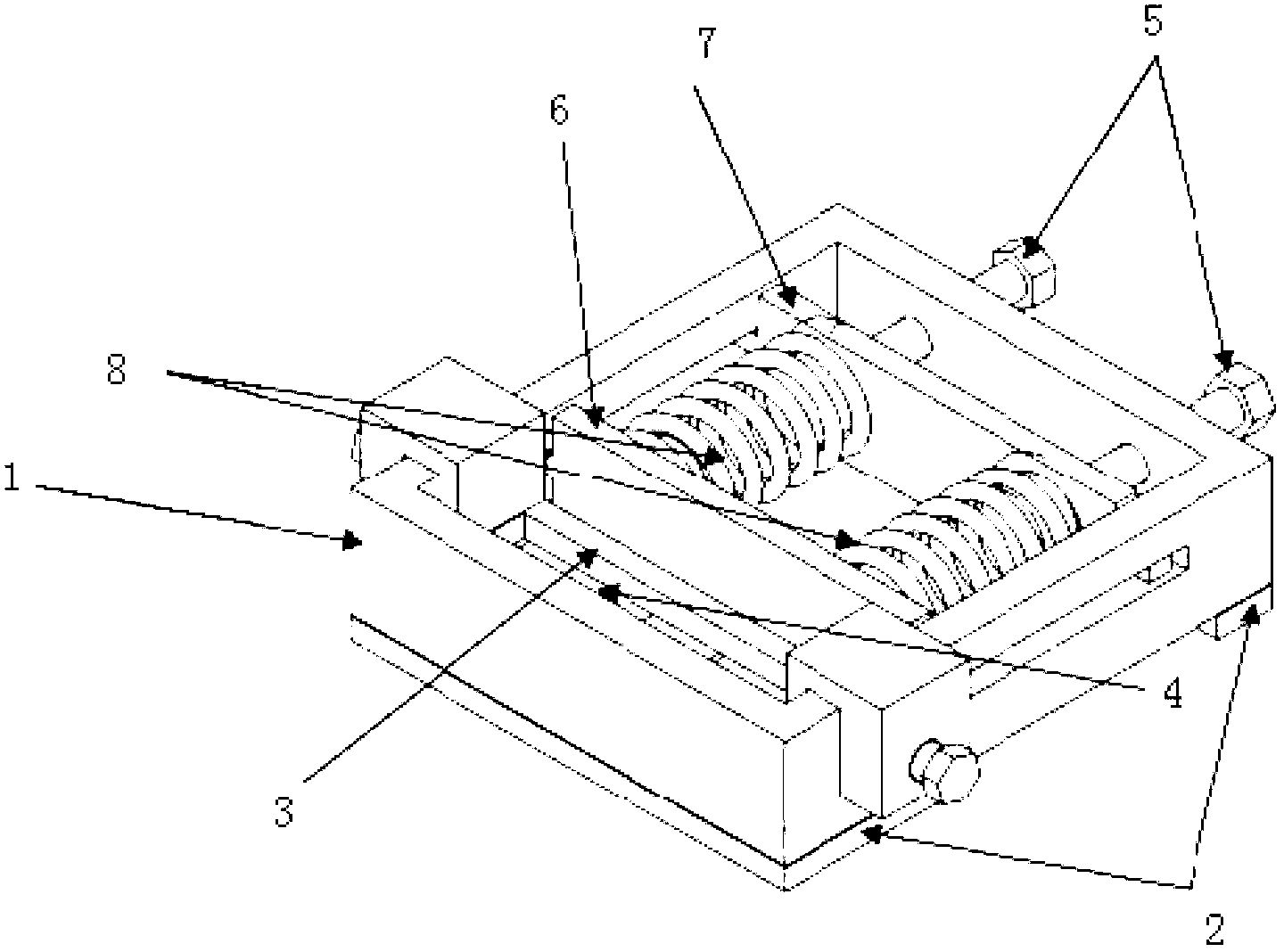

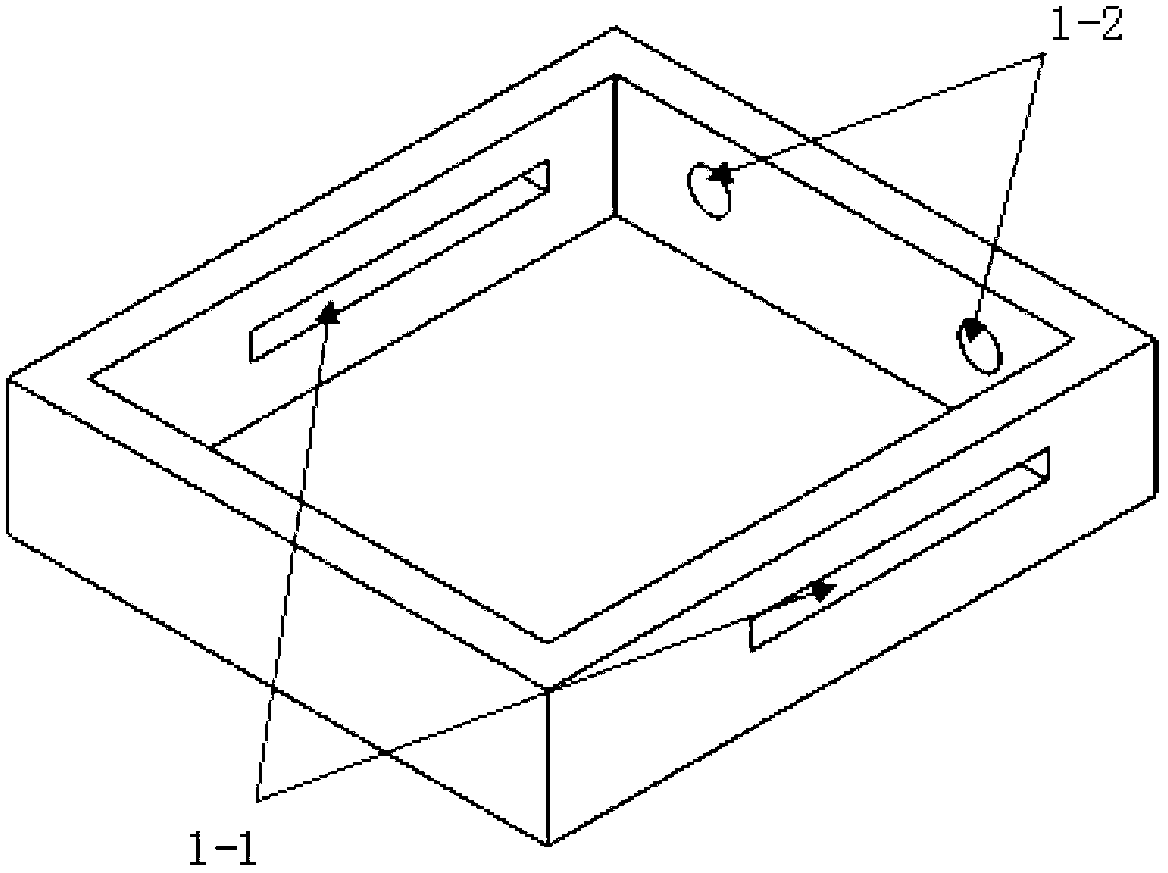

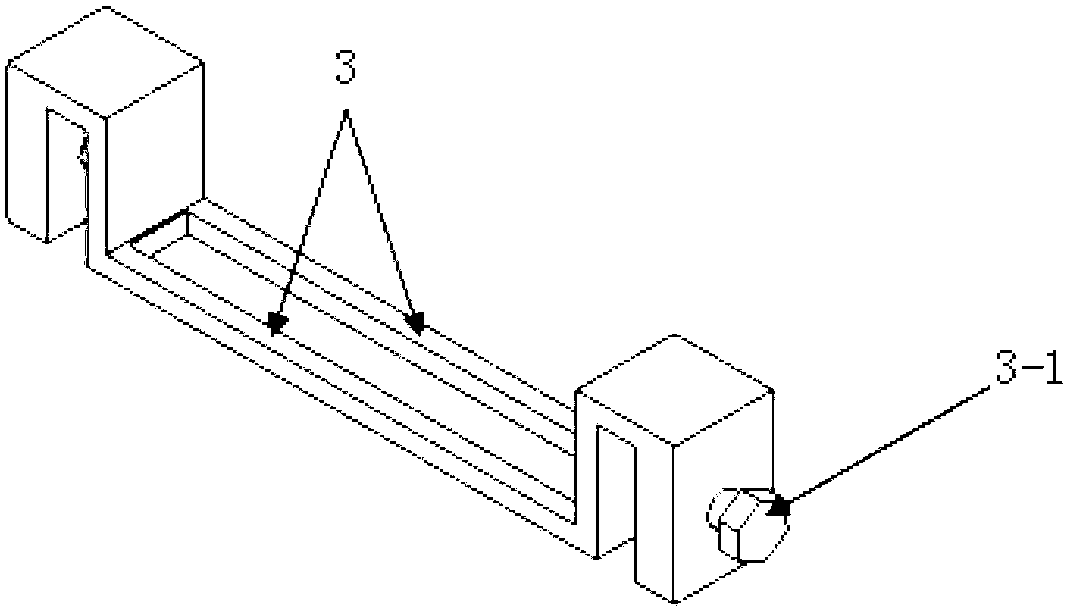

[0019] Embodiment 1: A tool capable of applying pressure for electron beam assisted thermal connection in this embodiment is composed of a clamp shell 1, a clamp base 2, a vertical fixing device and a horizontal fixing device, wherein the clamp shell 1 is fixedly connected On the fixture base 2, two opposite side walls of the fixture shell 1 are provided with sliding guide grooves 1-1, and the rear wall of the fixture shell 1 is provided with limiting holes 1-2, and the vertical fixing device is arranged on the fixture shell 1 The internal front end, the vertical fixing device is composed of a vertical fixing rod 3 and a bottom backing plate 4, the two ends of the vertical fixing rod 3 are engaged with the two side walls of the fixture shell 1 by fastening screws 3-1, and the bottom backing plate 4 is set Directly below the vertical fixing rod 3, wherein, the bottom backing plate 4 is provided with two raised fixing bars 4-1 and is opposite to the vertical fixing rod 3. The fi...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that: the main material of the fixture shell 1 is stainless steel without ferromagnetism. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the clamp base 2 is made of non-ferromagnetic 6061 aluminum alloy. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com