Ribbon pulling device and positioning and welding method for crystalline silicon solar cell module

A technology for solar cells and solar cells, applied in welding equipment, electrical components, laser welding equipment, etc., can solve the problems of the offset of the welding strip and the busbar, welding failure, difficult to fix, etc., so as to improve the welding efficiency and welding effect. , to ensure accurate positioning, convenient welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

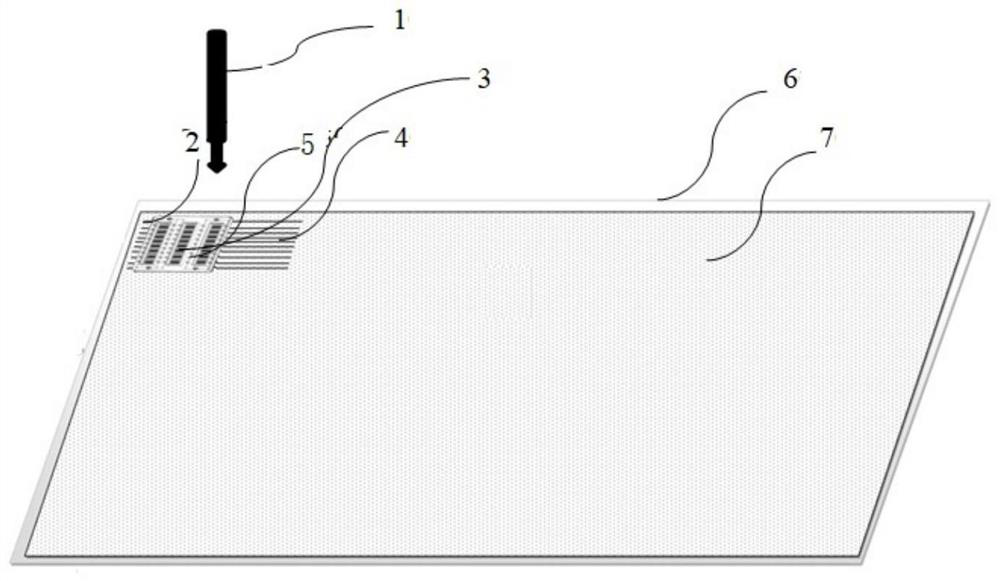

[0034] like figure 1 Shown, the present invention provides a kind of ribbon welding method of crystalline silicon solar cell module, comprises the following steps:

[0035] L1, place the bottom layer, the bottom layer includes a transparent rigid plate 6, such as flat glass, so that light is transmitted when laser welding is carried out, the bottom layer can also include a transparent elastic plate 7 arranged on the transparent rigid plate 6, such as an EVA sheet, the transparent The elastic plate 7 can make light transmittance during welding, and at the same time avoid fragments caused by the rigid pressure on the solar cells 3 after vacuuming.

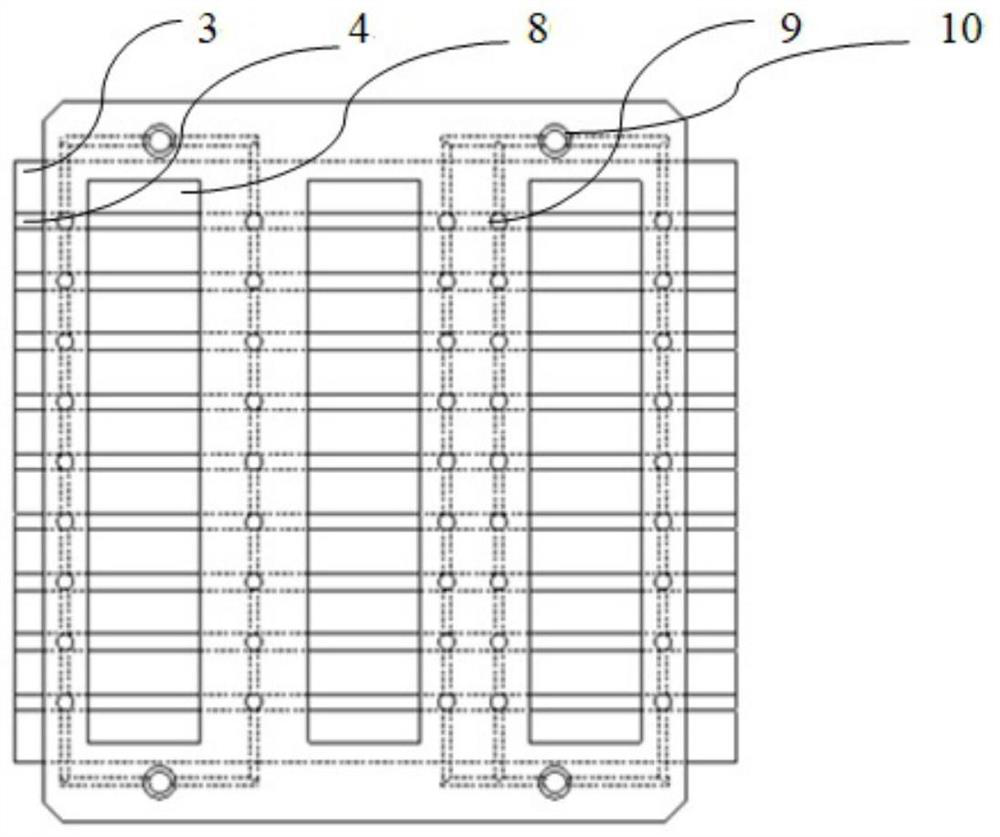

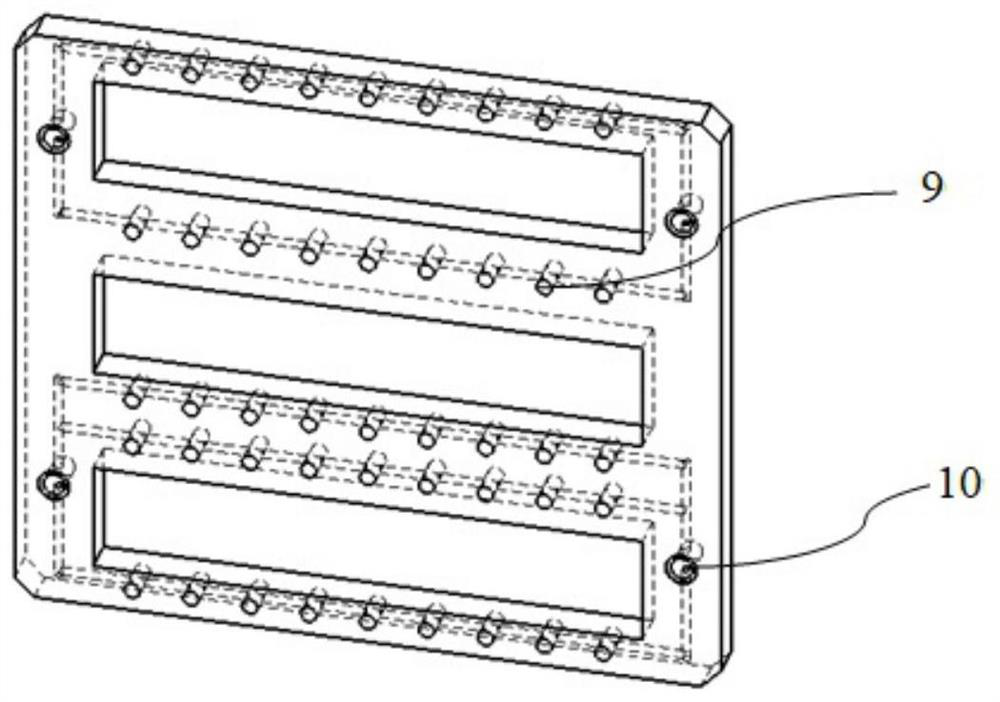

[0036] L2. Locate the bottom welding ribbon 2, the solar battery sheet 3 and the surface welding ribbon 4 according to the ribbon positioning method. The bottom welding strip 2 or the surface welding strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com