Phase-change heat accumulation type heat flow sensor

A technology of heat flow sensor and phase change heat storage, which is applied in calorimeters, instruments, and thermometers using electric/magnetic elements that are directly sensitive to heat, etc. Head melting and other problems, to achieve the effect of long working time, extended working time and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

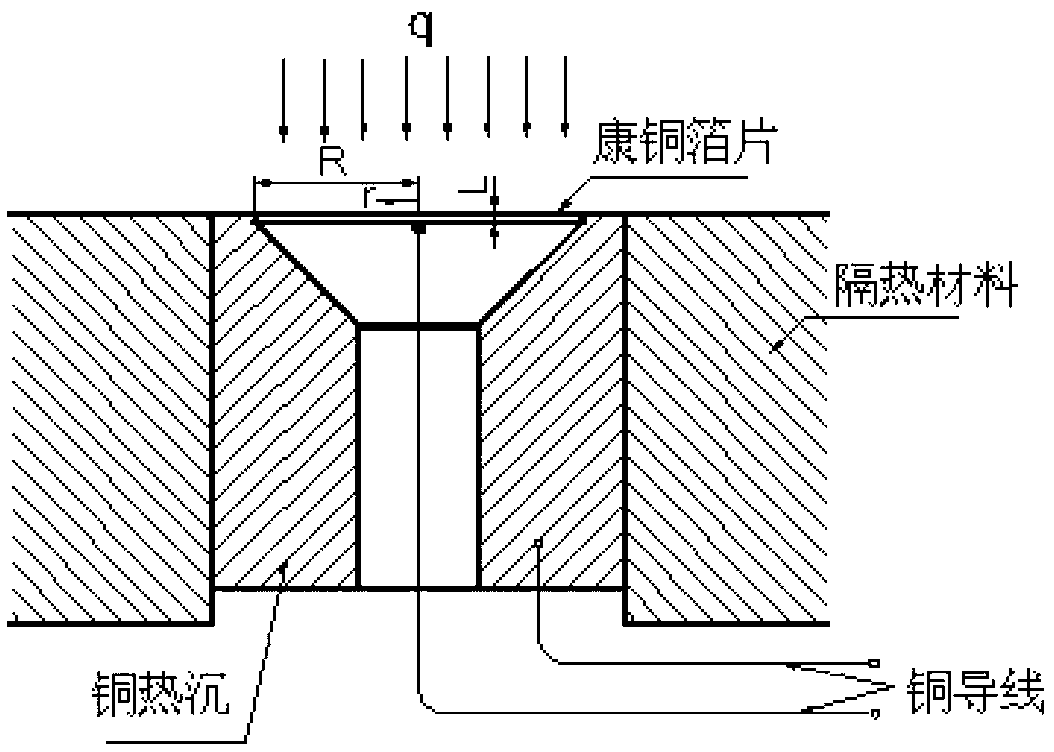

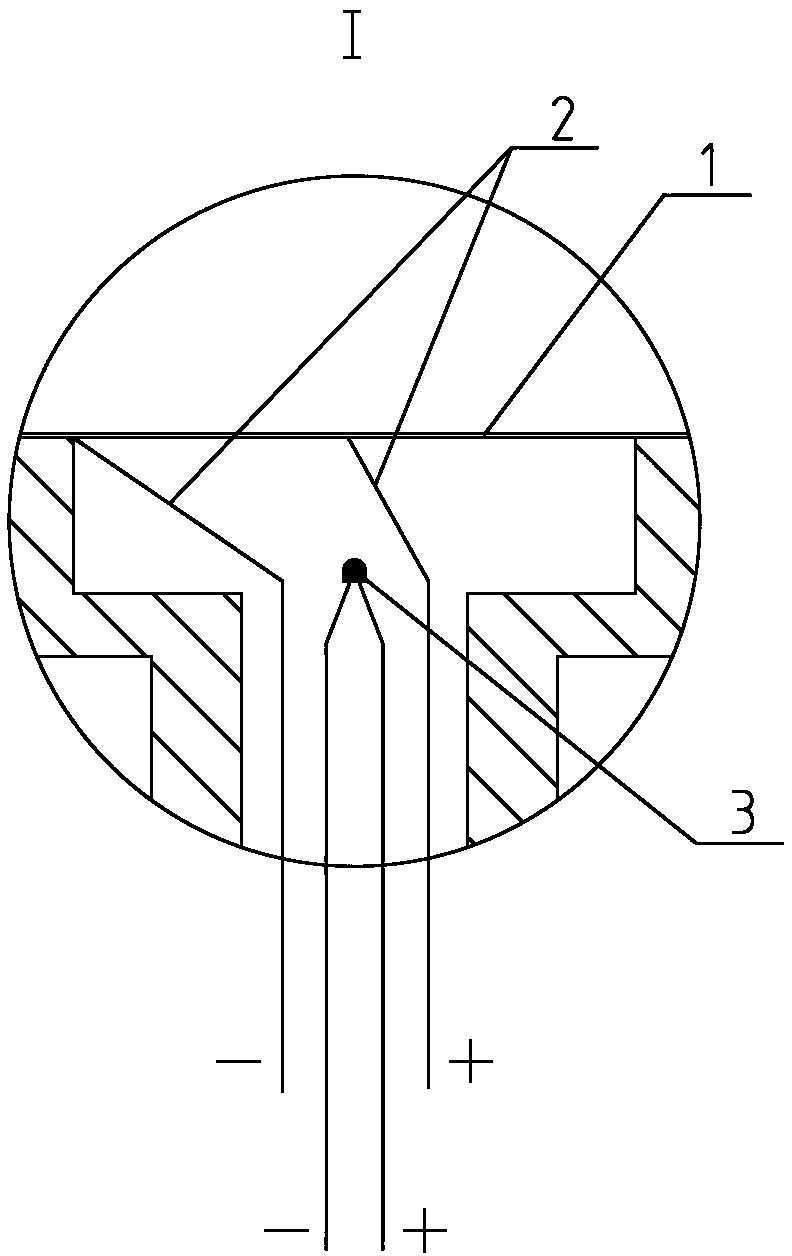

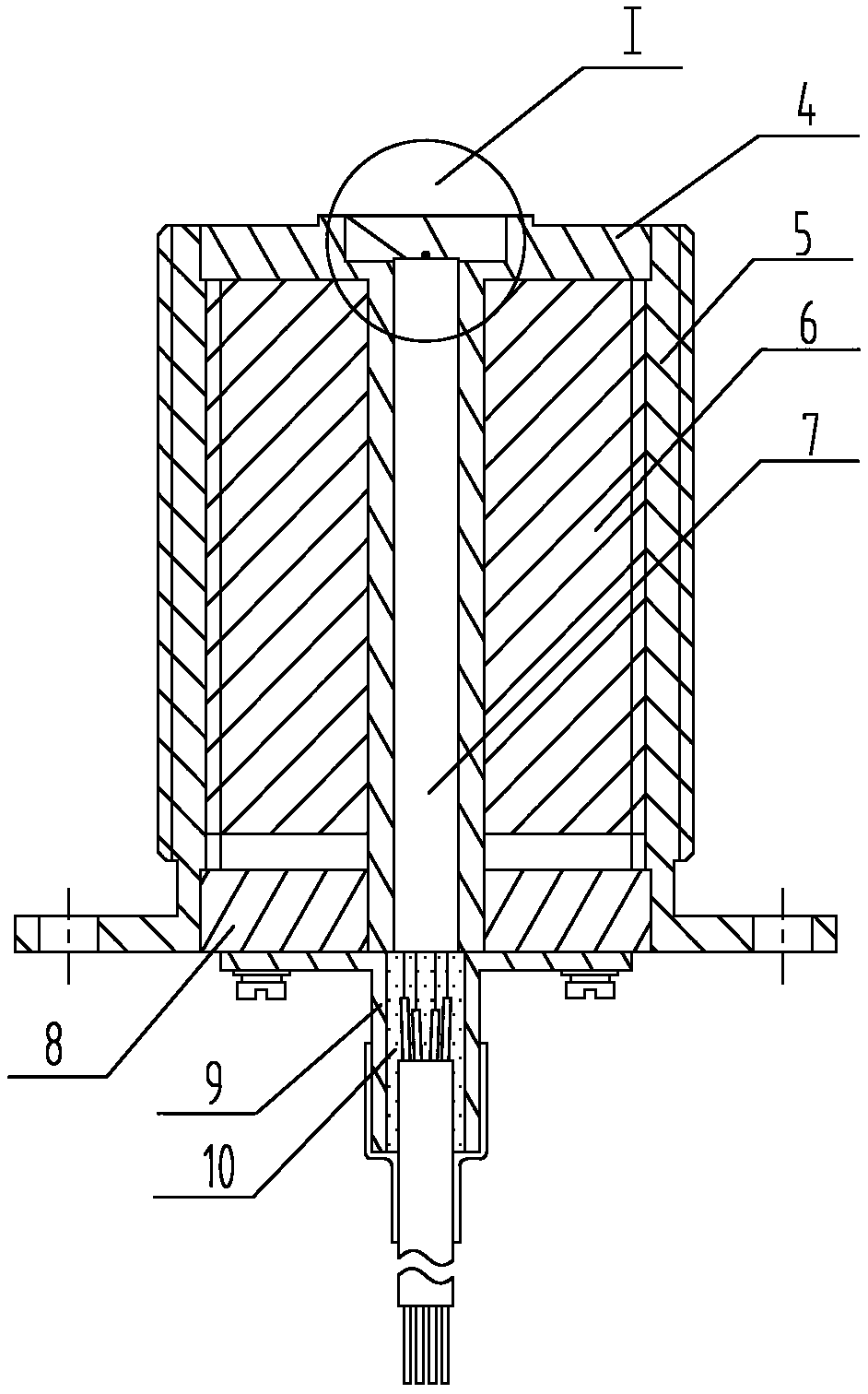

[0030] Such as image 3 Shown is the structural representation of sensor of the present invention, Figure 4 Shown is a partially enlarged view of the sensor of the present invention. It can be seen from the figure that the sensor of the present invention includes a constantan round foil 1 with a blackened surface, a nickel-chromium wire 2, a thermocouple 3, an upper cover 4, a housing 5, and a phase change heat storage Body 6, four-hole ceramic tube 7, lower cover 8, back cover 9 and high-temperature glue 10, wherein four-hole ceramic tube 7 and upper cover 4 are bonded and fixed by high-temperature glue 10, and thermocouple wire 3 passes through four-hole ceramic tube 7 Two of the holes, two nickel-chromium wires 2 pass through the remaining two holes of the four-hole ceramic tube 7, one of the nickel-chromium wires 2 is welded to the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com