Method for preparing high-purity resorcinol through melt crystallization

A technology of pure resorcinol and resorcinol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of affecting product quality, difficulty in industrial production, low refining yield, etc. The effect of improving the working environment, protecting the health of employees, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

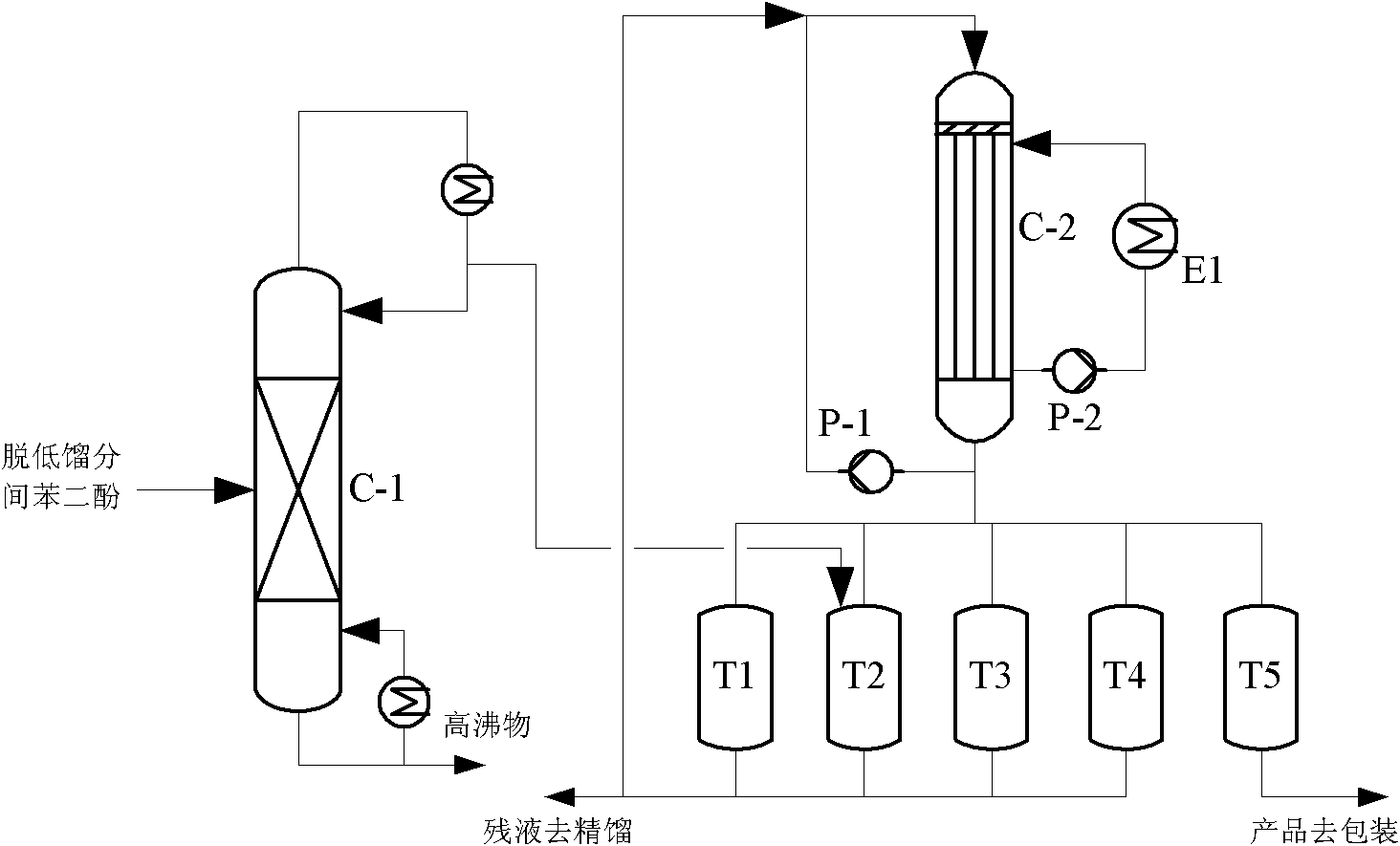

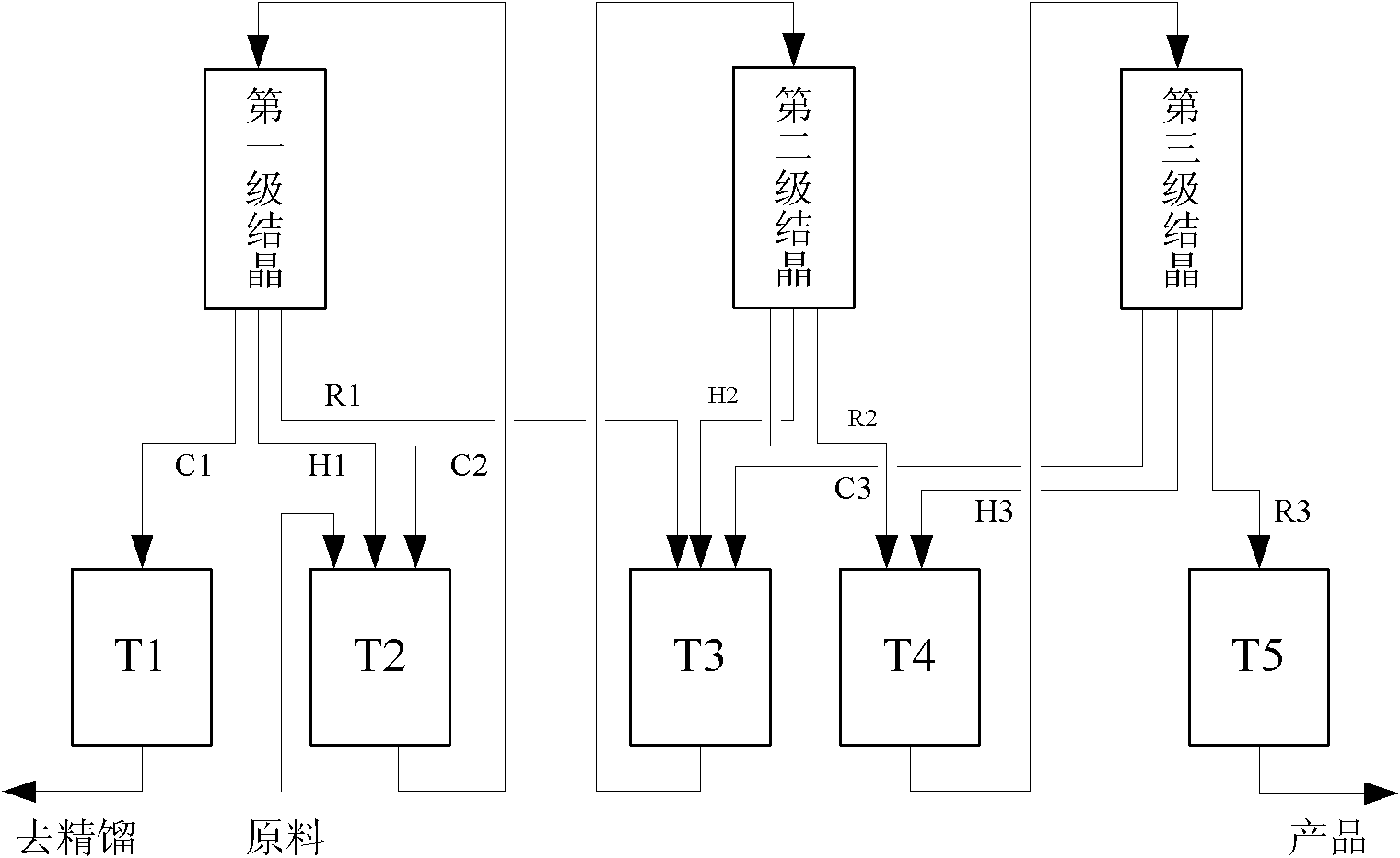

[0044] Prepare hydrolyzate with m-phenylenediamine, sulfuric acid, and water. The molar ratio of m-phenylenediamine, sulfuric acid, and water is 1:2.0:80. The temperature of the hydrolyzed liquid is 220-240°C. The reaction residence time is 3-6 hours. Cool down to normal temperature, extract with organic solvent butyl acetate, recover butyl acetate, water and low boilers from the extract by distillation, and remove the crude resorcinol from low boilers at 15~50mmHg, 160~190℃ Pressure rectification to remove high boiling impurities, the purity of crude resorcinol reaches 99.0-99.7%. The resorcinol melt condensed to ~122°C is used as the raw material for subsequent crystallization and refining, and is discharged into the raw material storage tank T2 for standby. see process figure 1 .

[0045] The falling film crystallizer used is composed of 3 vertical stainless steel tubes with a jacket, and the lower part is equipped with a liquid storage tank. The crystallizer, storage tan...

Embodiment 2

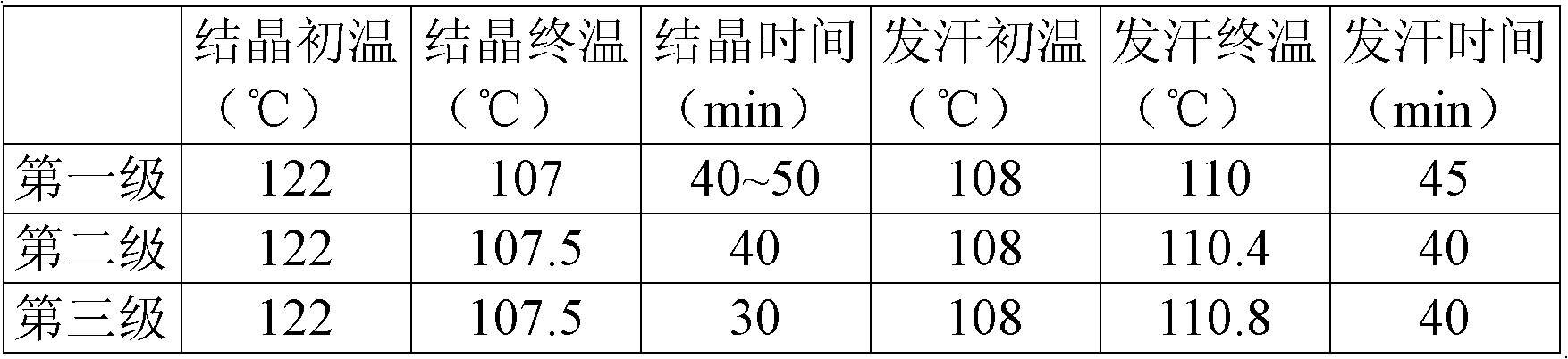

[0059] According to the method of Example 1, get 99.2% of the crude product resorcinol obtained by rectification and follow the same three-stage crystallization process to refine the crude product resorcinol, and the process conditions are as follows:

[0060]

[0061] The purity of the product obtained by the third stage crystallization reaches 99.999%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com