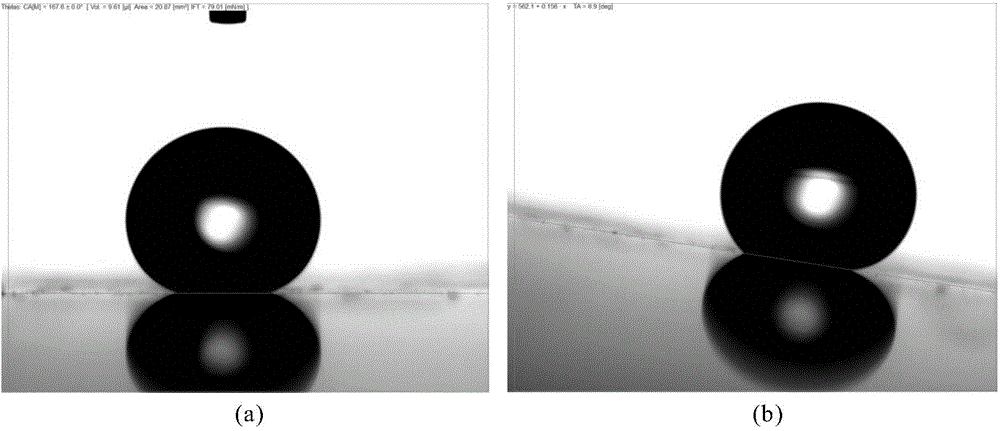

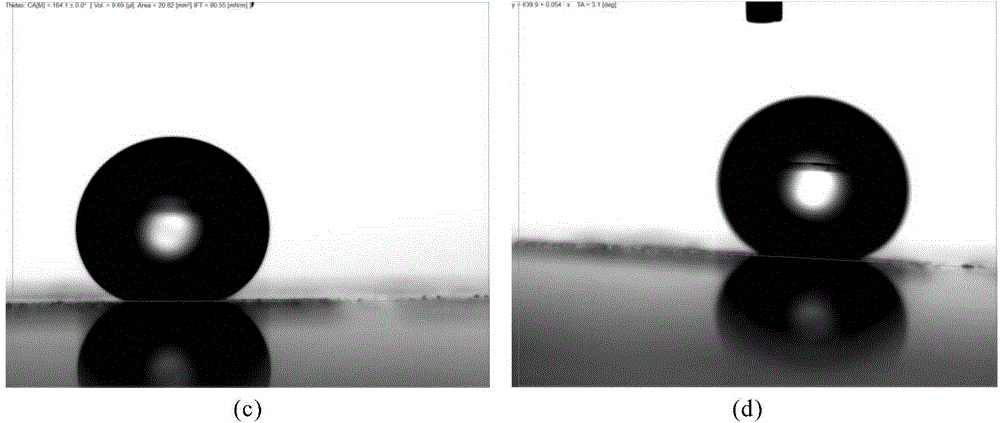

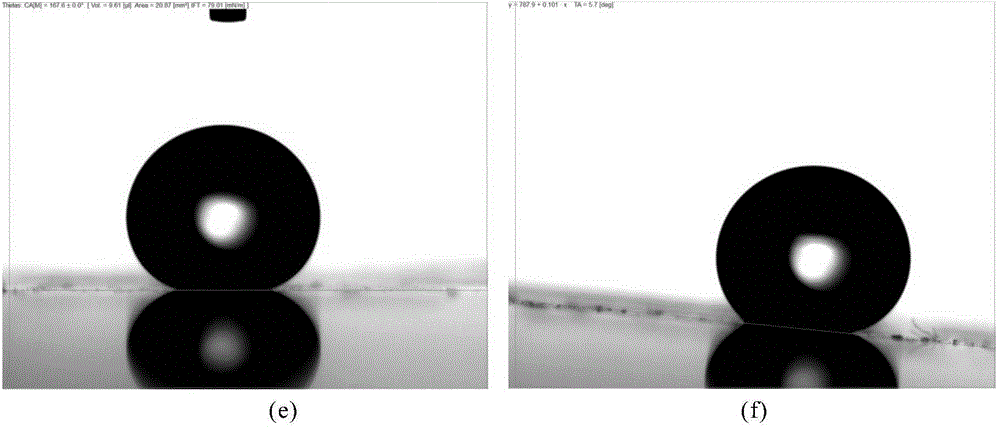

Method for preparation of aluminium alloy superhydrophobic self-cleaning surface by use of ultrafast laser

An ultrafast laser and aluminum alloy technology, which is applied in the field of surface modification of metal substrates, can solve the problems of being unsuitable for large-scale industrial production and high processing costs, and achieve the effects of easy control of process parameters, simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method of preparing an aluminum alloy superhydrophobic self-cleaning surface using an ultrafast laser in this embodiment includes the following specific steps:

[0043] Step 1: Polish the 2a12 aluminum alloy to be processed, select a metallographic sample pre-grinding machine with a power of 370W, a grinding disc rotation speed of 450 rpm, and a grinding disc diameter of 230 mm. The polishing process requires an auxiliary diameter of 200 mm and 1000 mesh SiC water sandpaper is used to polish the surface of the aluminum alloy, and the polishing range is 100cm 2 , the polishing time is 10 minutes, and the aluminum alloy sample after surface polishing is obtained;

[0044] Step 2: Clean the aluminum alloy sample after the surface polishing described in step 1 with an ultrasonic cleaner, the ultrasonic frequency of the ultrasonic cleaner is 40 kHz, submerge the surface of the sample with deionized water with a resistivity of 18.25 megohm, and clean continuously at room te...

Embodiment 2

[0052] A method of preparing an aluminum alloy superhydrophobic self-cleaning surface using an ultrafast laser in this embodiment includes the following specific steps:

[0053] Step 1: Polish the 2a12 aluminum alloy to be processed, select a metallographic sample pre-grinding machine with a power of 370W, a grinding disc rotation speed of 450 rpm, and a grinding disc diameter of 230 mm. The polishing process requires an auxiliary diameter of 200 mm and 1000 mesh SiC water sandpaper is used to polish the surface of the aluminum alloy, and the polishing range is 100cm 2 , the polishing time is 10 minutes, and the aluminum alloy sample after surface polishing is obtained;

[0054] Step 2: Clean the aluminum alloy sample after the surface polishing described in step 1 with an ultrasonic cleaner, the ultrasonic frequency of the ultrasonic cleaner is 40 kHz, submerge the surface of the sample with deionized water with a resistivity of 18.25 megohm, and clean continuously at room te...

Embodiment 3

[0062] A method of preparing an aluminum alloy superhydrophobic self-cleaning surface using an ultrafast laser in this embodiment includes the following specific steps:

[0063] Step 1: Polish the 2a12 aluminum alloy to be processed, select a metallographic sample pre-grinding machine with a power of 370W, a grinding disc rotation speed of 450 rpm, and a grinding disc diameter of 230 mm. The polishing process requires an auxiliary diameter of 200 mm and 1000 mesh SiC water sandpaper is used to polish the surface of the aluminum alloy, and the polishing range is 100cm 2 , the polishing time is 10 minutes, and the aluminum alloy sample after surface polishing is obtained;

[0064] Step 2: Clean the aluminum alloy sample after the surface polishing described in step 1 with an ultrasonic cleaner, the ultrasonic frequency of the ultrasonic cleaner is 40 kHz, submerge the surface of the sample with deionized water with a resistivity of 18.25 megohm, and clean continuously at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com