Hypertransparent Nanostructured Superhydrophobic and Surface Modification Coatings

a superhydrophobic and surface modification technology, applied in the field of hypertransparent nanostructured superhydrophobic and surface modification coatings, can solve the problems of low transmittance of hydrophobic coatings and inapplicability to windows and solar panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

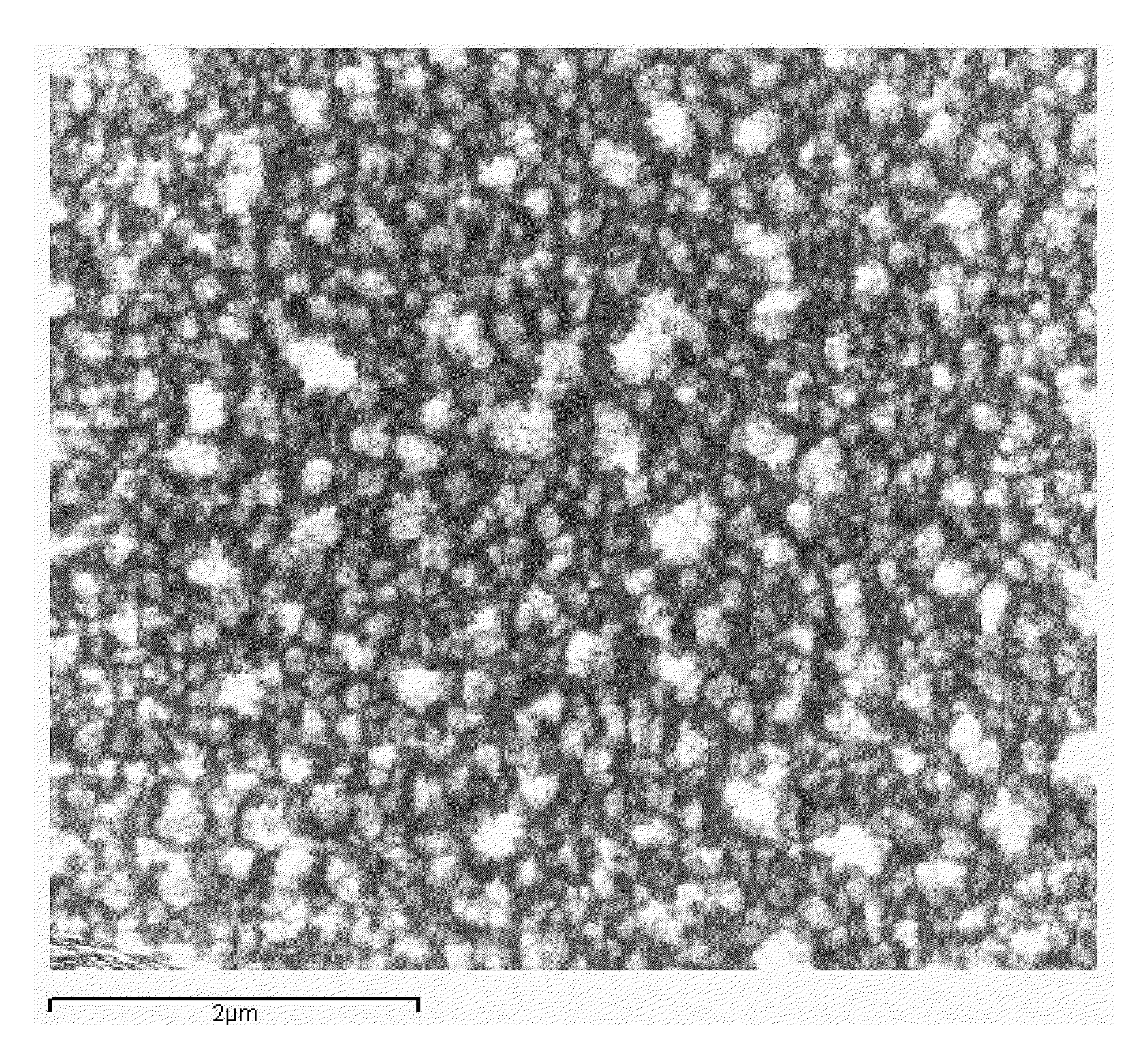

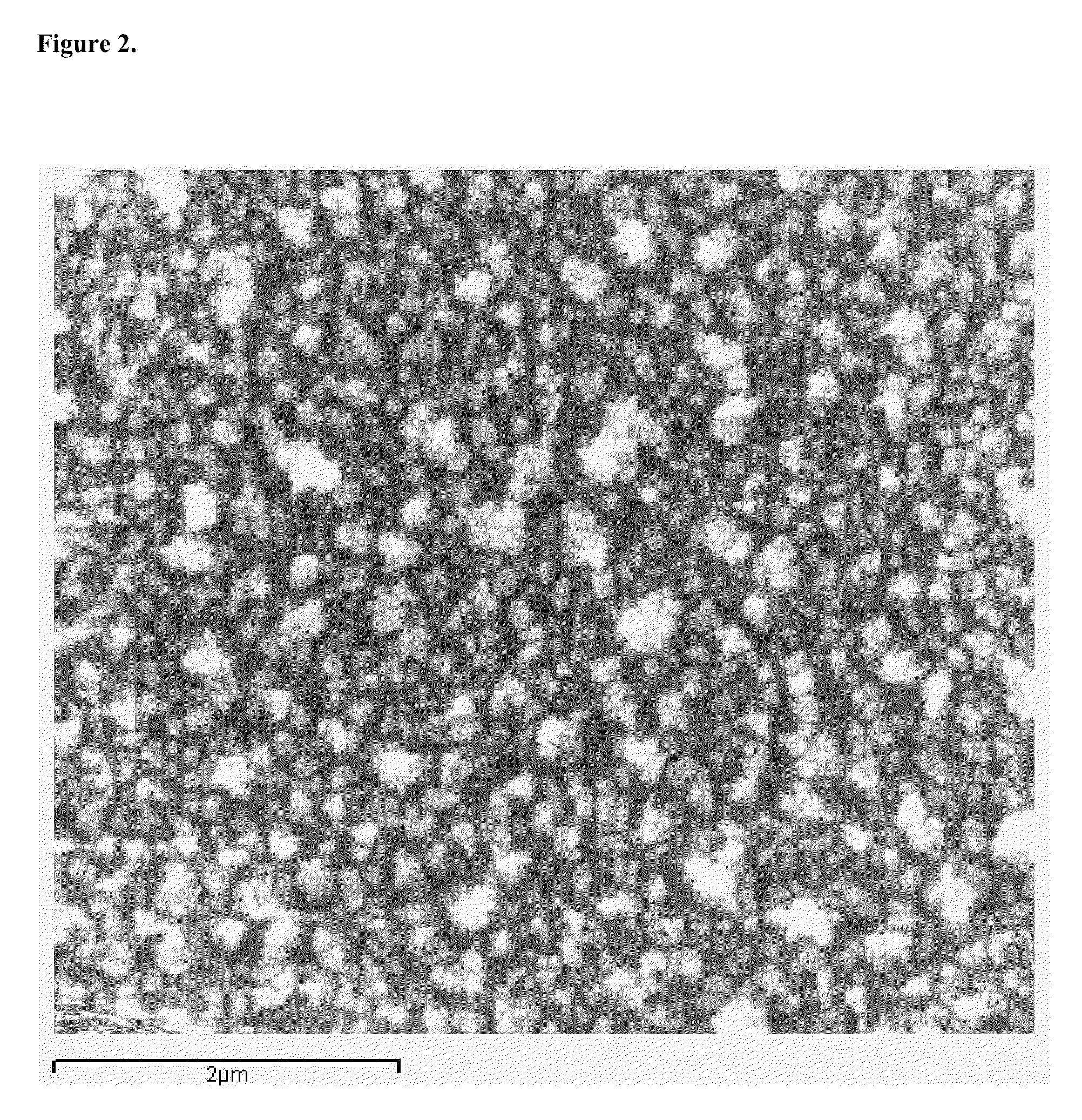

Image

Examples

Embodiment Construction

[0020]Superhydrophobic Coatings by the CCVD Process

[0021]Superhydrophobic and other surface modifying coatings have been grown by many techniques, such as CVD (Wu et al., Chem. Vap. Deposition 8, 47, 2002) and sol-gel (Shang et al., Thin Solid Film 472, 37, 2005). These techniques can require costly starting materials, be time consuming, and / or have low throughput.

[0022]The inexpensive CCVD technology offers an attractive way to grow nanostructured superhydrophobic coatings on glass and plastic substrates with good yield and high throughput potential. While CCVD is the preferred method, other techniques, such as various vapor deposition methods, may be used to achieve the structures of the present invention. SiO2 was chosen as an example primary coating material because of its low cost, ease of preparation, and the refractive index match between the coating and many candidate substrates, which reduces reflectivity of the coated specimens.

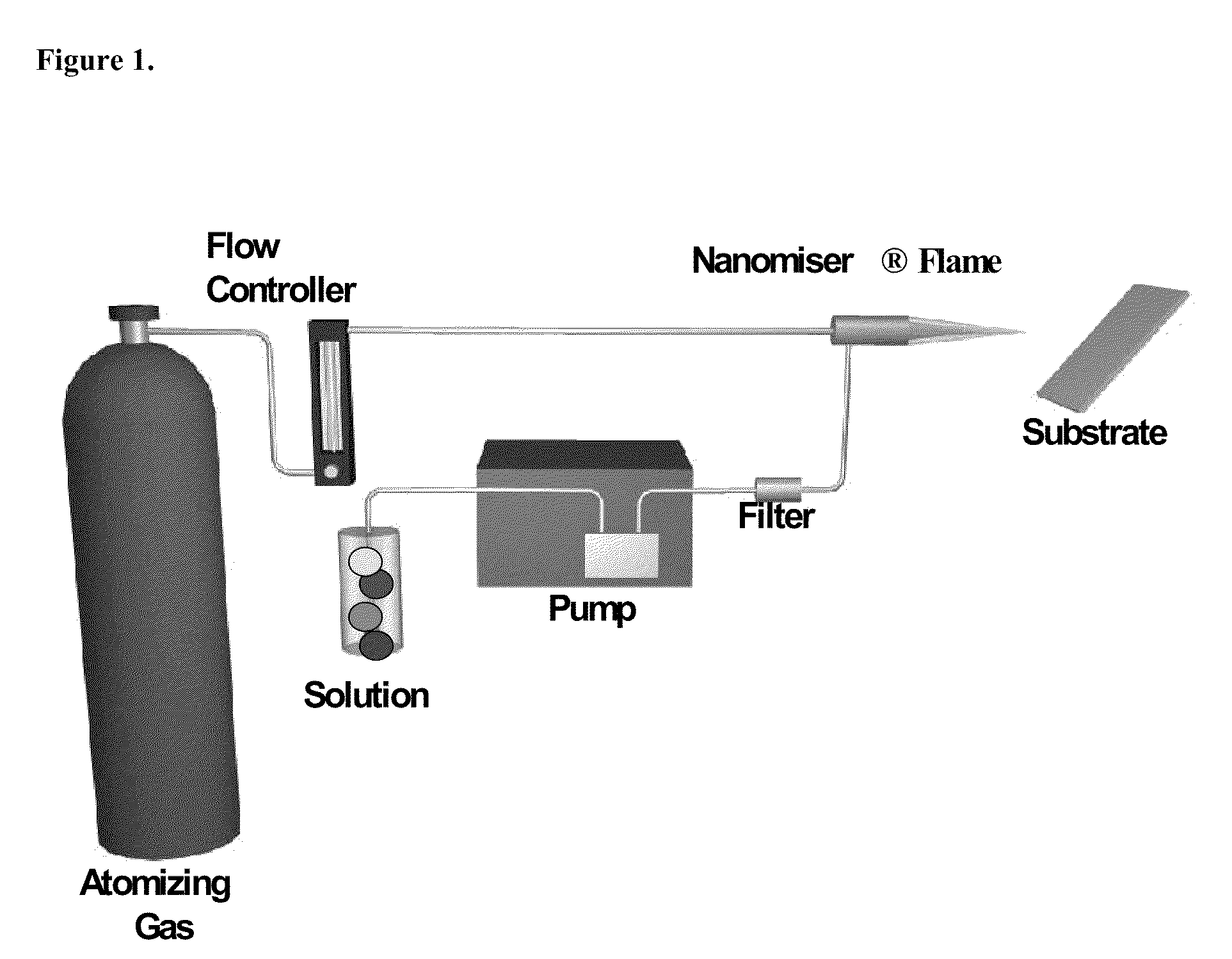

[0023]In the CCVD process (Hunt et al., App. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com