Hydrophilic modification method of polymer microporous film

A microporous membrane and polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of decay of effect with time, long time consumption of graft polymerization reaction, unsuitable for industrial production, etc. , to achieve the effect of simple equipment, widening the scope of application and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

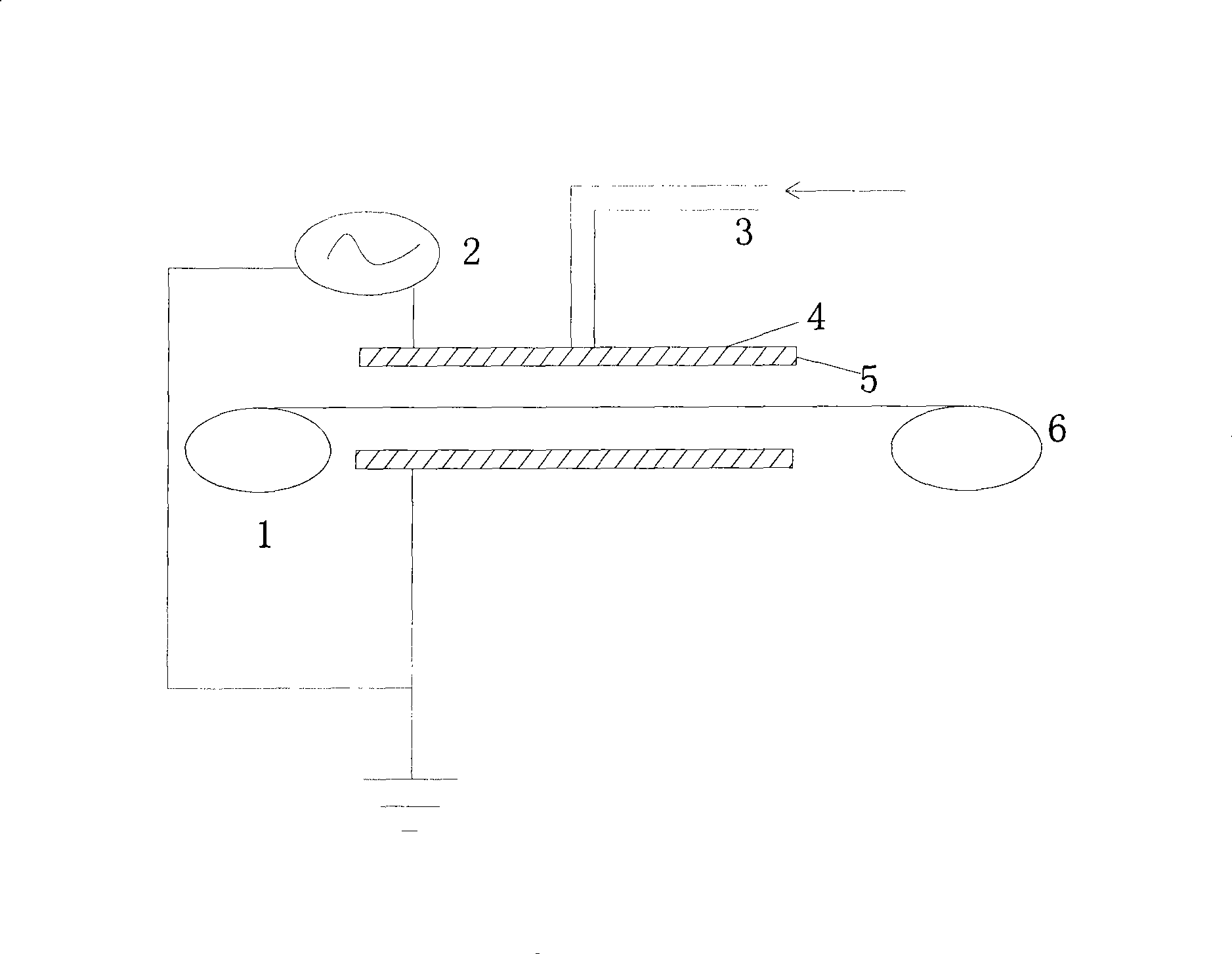

[0037] Embodiment 1: Atmospheric pressure plasma treatment polyethylene flat membrane modification process

[0038]Polyethylene flat film (film thickness 25 microns, average pore diameter is 0.4 microns, porosity 20%) is washed 3 times with acetone, to remove the impurity adsorbed on the film surface, then it is vacuum-dried at room temperature for 3 hours and is ready to use. Soak the above-mentioned cleaned and dried polyethylene flat film in an acetone solution containing 1% acrylic acid by mass percentage for 30 minutes to fully absorb acrylic acid monomer on its surface, and then dry it in the air.

[0039] Then carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polyethylene flat film after above-mentioned treatment, treatment condition is: the gap between discharge electrode is 2 millimeters; Mixed gas is argon and oxygen, and volume ratio is 99 / 1, The air intake speed is 4 liters / min; the plasma discharge power is 150 watts, the film lin...

Embodiment 2

[0041] Embodiment 2: Atmospheric pressure plasma treatment polyethylene flat membrane modification process

[0042] Polyethylene flat film (film thickness 200 microns, average pore diameter is 1 micron, porosity 60%) is washed 3 times with acetone, to remove the impurity that is adsorbed on the film surface, then it is vacuum-dried at room temperature for 3 hours stand-by. Soak the washed and dried polyethylene flat film in an acetone solution containing 8% N-vinylpyrrolidone by mass percentage for 30 minutes to fully absorb N-vinylpyrrolidone monomer on its surface, and then dry it in the air.

[0043] Then carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polyethylene flat film after above-mentioned treatment, treatment condition is: the gap between discharge electrode is 2 millimeters; Mixed gas is argon and oxygen, and volume ratio is 99 / 1, The air intake speed is 6 liters / min; the plasma discharge power is 120 watts, the film line speed i...

Embodiment 3

[0045] Embodiment 3: Atmospheric pressure plasma treatment polyethylene hollow fiber membrane modification process

[0046] The polyethylene hollow fiber membrane (inner diameter 100 microns, outer diameter 500 microns, average pore diameter 0.8 microns, porosity 50%) was washed 3 times with acetone to remove impurities adsorbed on the membrane surface, and then vacuum-dried at room temperature 3 hours to use. Soak the cleaned and dried polyethylene hollow fiber membrane in an acetone solution containing 10% acrylamide by mass percentage for 30 minutes to fully absorb acrylamide monomer on its surface, and then dry it.

[0047] Then carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polyethylene flat film after above-mentioned treatment, treatment condition is: the gap between discharge electrode is 2 millimeters; Mixed gas is argon and oxygen, and volume ratio is 99 / 1, The air intake speed is 4 liters / min; the plasma discharge power is 150 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com