Extruded, highly cooked, non-sticky starch products

a technology of high-cooked starch and non-sticky starch, which is applied in the field of extruded products, can solve the problems of little sme derived from preconditioning, and achieve the effect of low cold water viscosity and high cook degr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

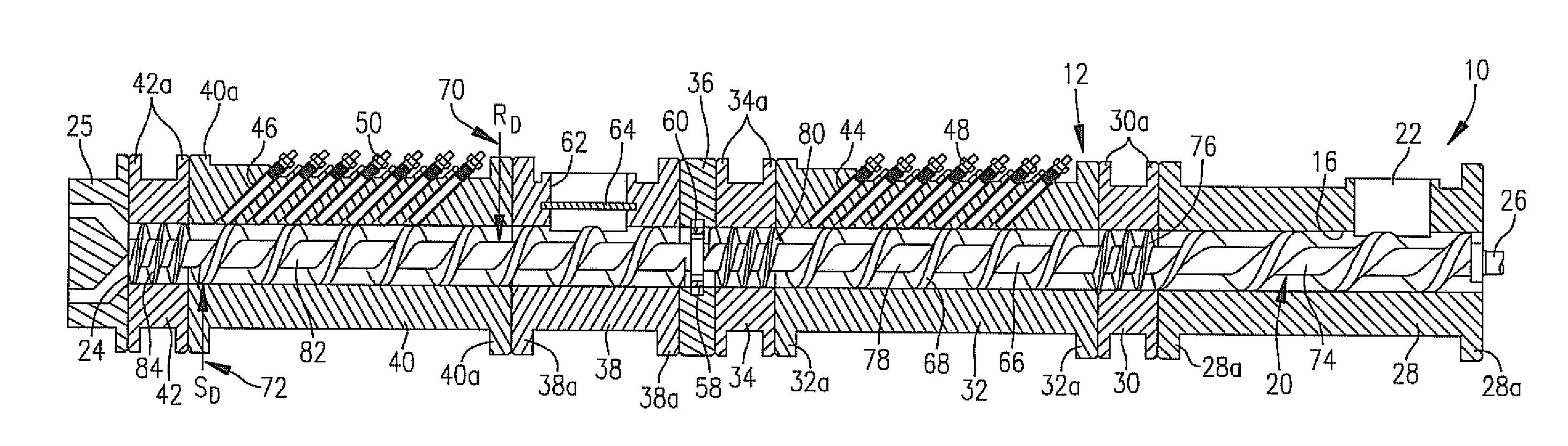

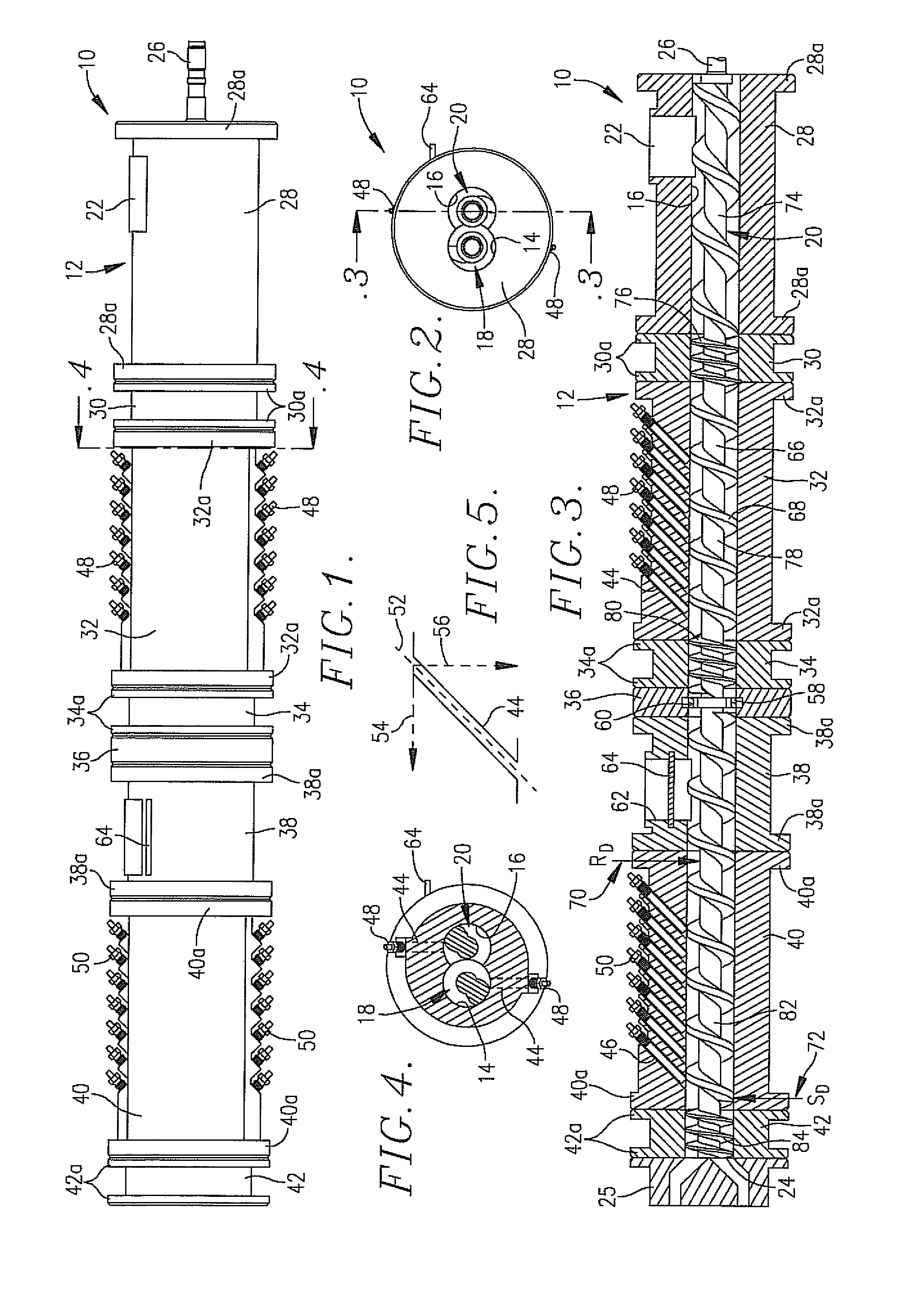

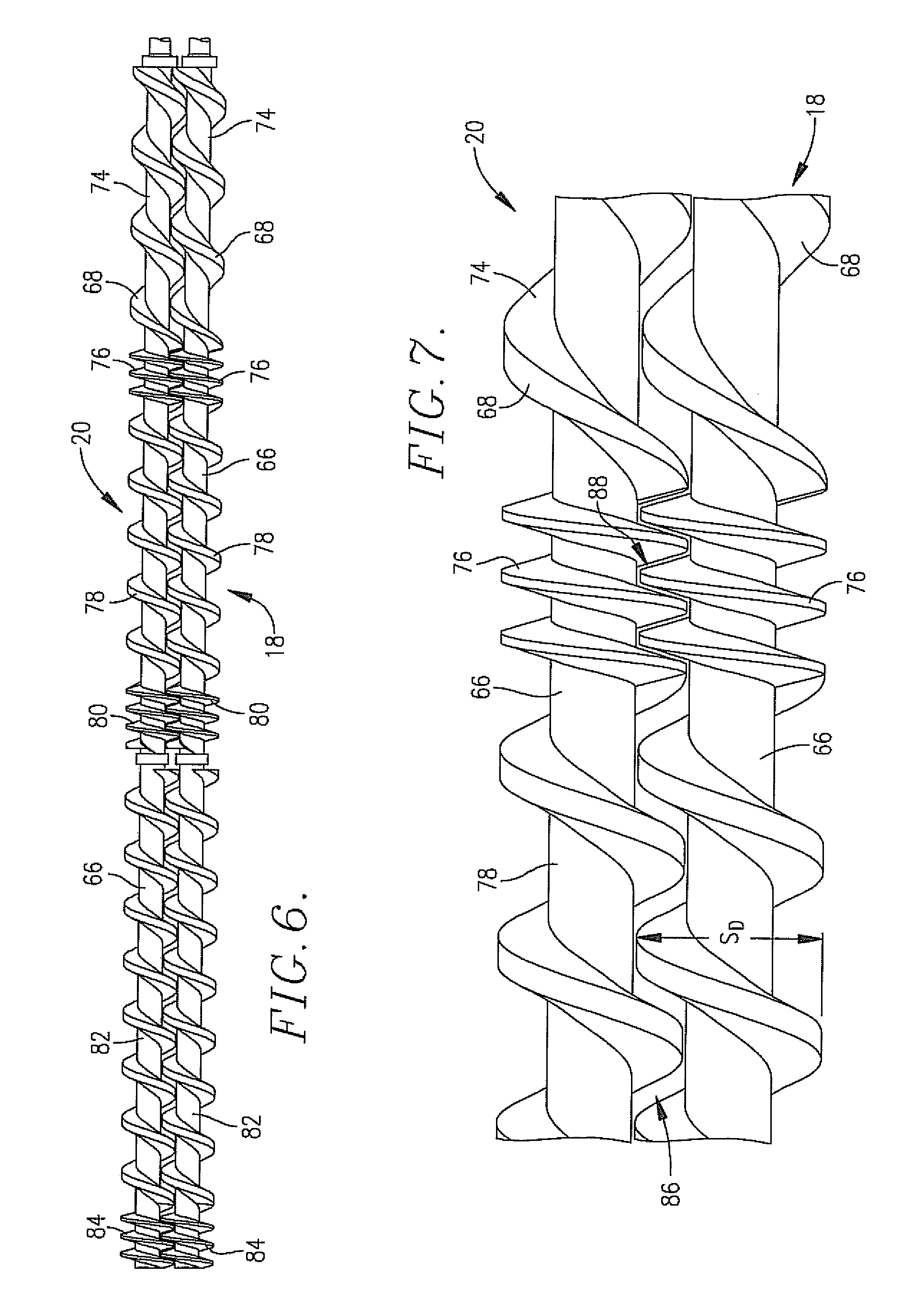

[0085]In this series of tests, commercially available ground corn was extruded using the equipment described above and illustrated in FIGS. 1-10, but without the adjustable valve 36 or outlet head 38. In all of the runs, the ground corn had a moisture content of 13.1% wb and a temperature of 20° C. The water added to the preconditioner had a temperature of 25° C.; no water was added to the extruder barrel. The smaller diameter side of the preconditioner was operated at 650 rpm in a reverse direction, whereas the larger diameter side was operated at 50 rpm in a forward direction. The extruder shaft speed in all cases was 500 rpm. SME values were determined by a direct load measurement from the extruder motor. The cook values were determined as described above.

[0086]The RVA curves for this set of runs are set forth in FIG. 12. The RVA profile used for these runs was:

Time (min)Temperature (° C.)Paddle Speed (rpm)02516010251601595160189516023251602525160

Each profile was generated using ...

example 2

[0088]In this series of tests, commercially available wheat flour was extruded using the equipment described in Example 1. In all of the runs, the flour had a moisture content of 11.83% wb and a temperature of 20° C. The water added to the preconditioner had a temperature of 25° C.; no water was added to the extruder barrel. The extruder shaft speed in all cases was 400 rpm. The cook values were determined as described above.

[0089]The RVA curves for this set of runs are set forth in FIG. 13. The RVA profile used for these runs was:

Time (min)Temperature (° C.)Paddle Speed (rpm)025160325160895160119516016251602025160

Each profile was generated using 3.5 grams of dry solids of the final extruded product mixed in 25 ml (or g) of water. The total dry solids concentration was thus 12.3% (3.5 g / 28.5 g). The first 3 minutes of each run gave the maximum cold water viscosity of the product.

[0090]The following Table 2 sets forth the preconditioning and extrusion conditions for all runs. The pro...

example 3

[0091]In this comparative example, ground corn was extruded in a conventional high-shear extruder with an upstream Wenger DDC preconditioner of the type illustrated and described in U.S. Pat. No. 4,752,139. The following Table 3 sets forth the conditions for this run.

TABLE 3RUN NUMBER26DRY RECIPE INFORMATIONDry Recipe Moisture Content (% wb)10Dry Recipe Temp (° C.)20Dry Recipe Rate (kg / hr)180PRECONDITIONING INFORMATIONSteam Flow to P / C (kg / hr)4.4Water Flow to P / C (kg / hr)8Process Water Temp (° C.)20Recorded P / C Discharge Temp (° C.)51EXTRUSION INFORMATIONExtruder Shaft Speed (rpm)321Motor Load (%)60Water Flow to Extruder (kg / hr)2.1Process Water Temp (° C.)20Extruder Motor Power (hp)50Rated Shaft Speed (rpm)508PRECONDITIONER CALCULATED CONDITIONSCalculated Moisture in P / C (% wb)15.8Product Mass Flow in P / C (kg / hr)192Thermal Energy Added in P / C (kJ / hr)12521Total Thermal Energy in P / C (kJ / hr)18889STE in P / C (kJ / kg)1105P / C Discharge Energy (kJ / hr)18885Calculated P / C Discharge Temp (° C.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com