Patents

Literature

65 results about "Extrusion cooking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion cooking is a short time process in which food (feed) material is cooked by a combination of temperature, moisture, mechanical shear and pressure, as it is forced through a die. 1 As products exit the die, the release of pressure causes them to expand in different shapes, based on the die geometry.

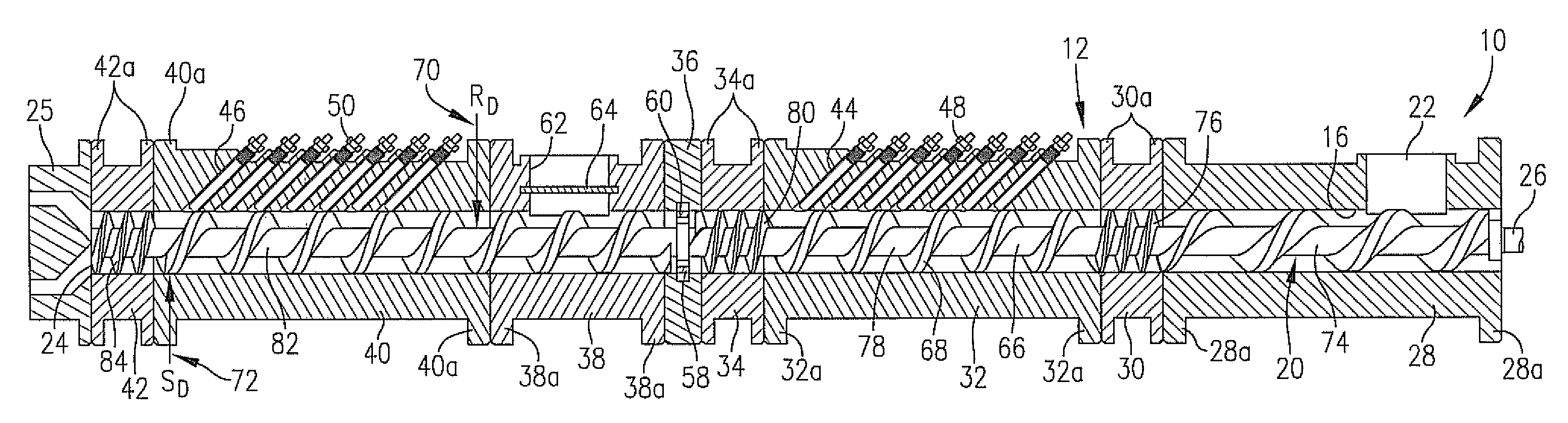

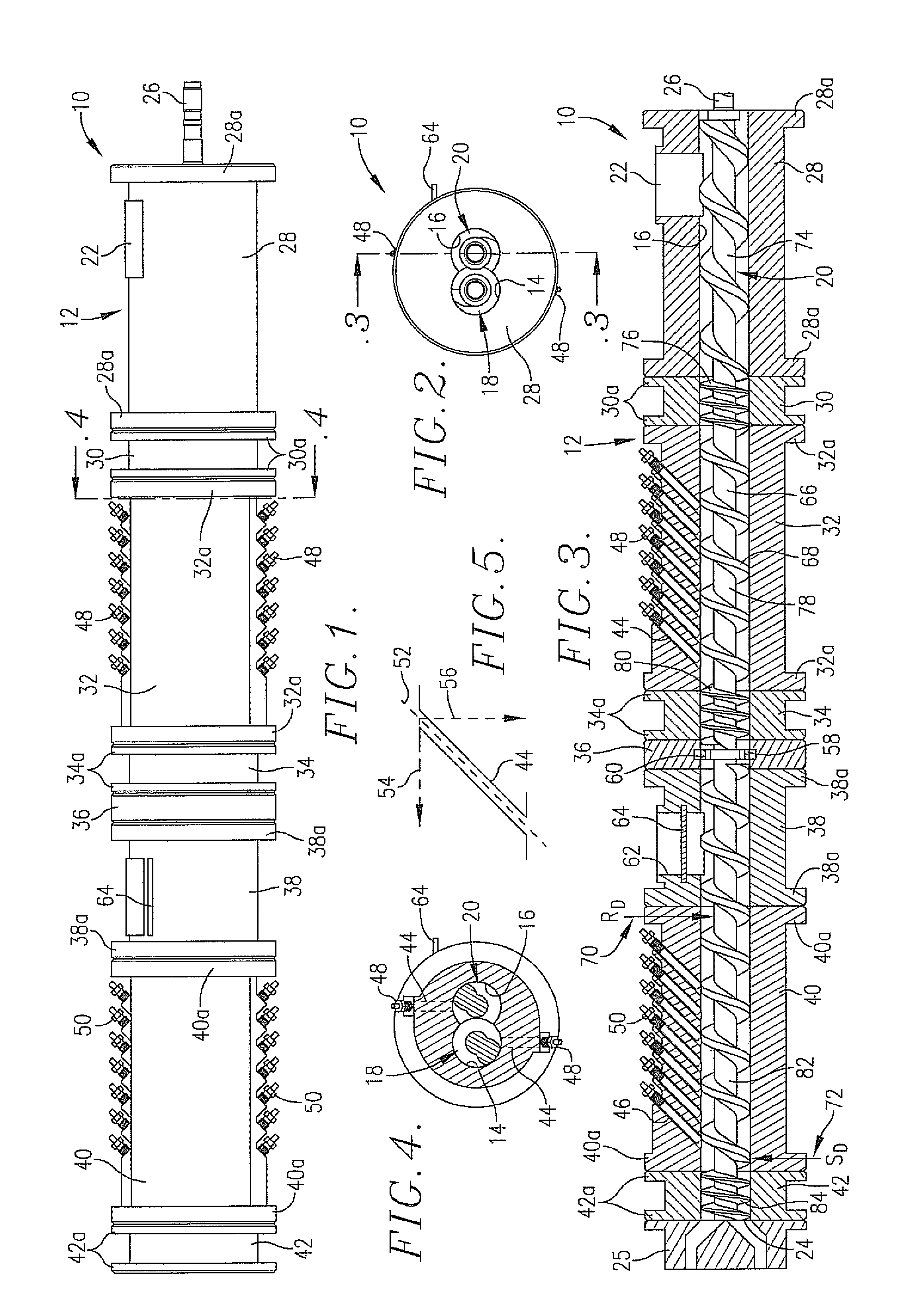

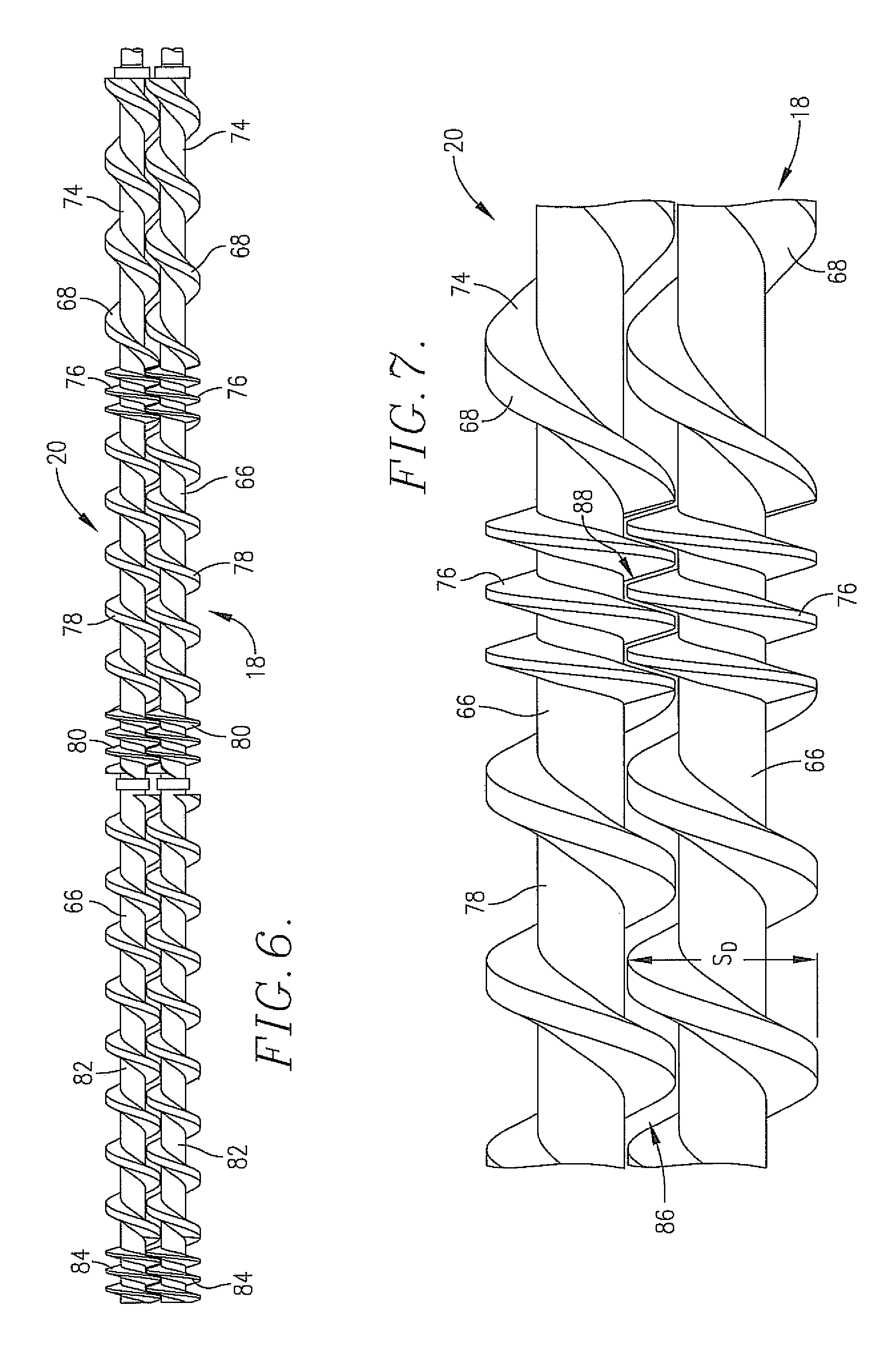

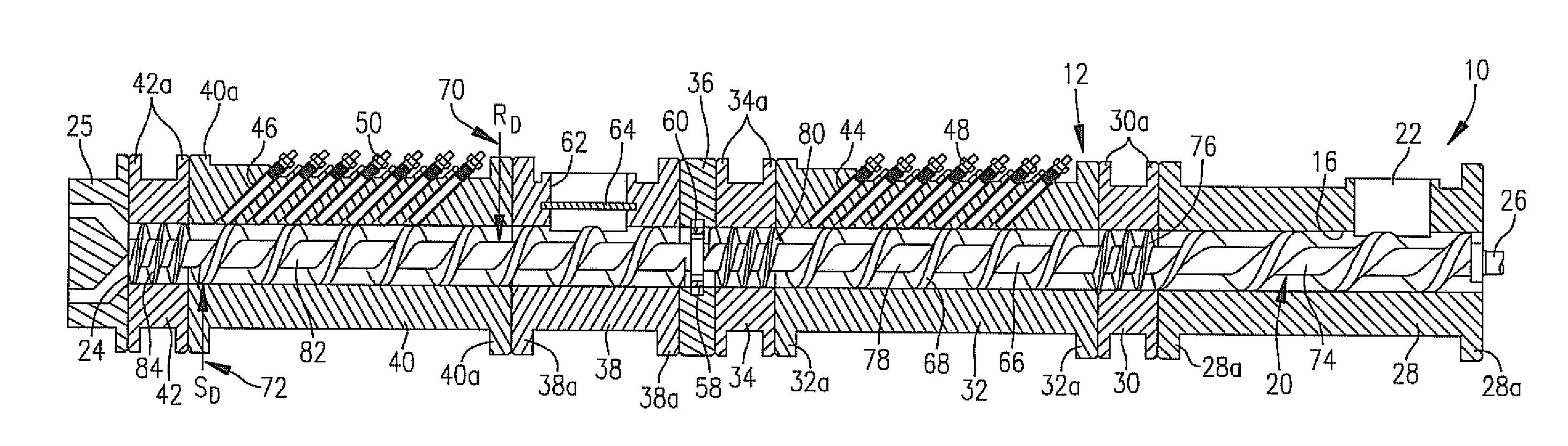

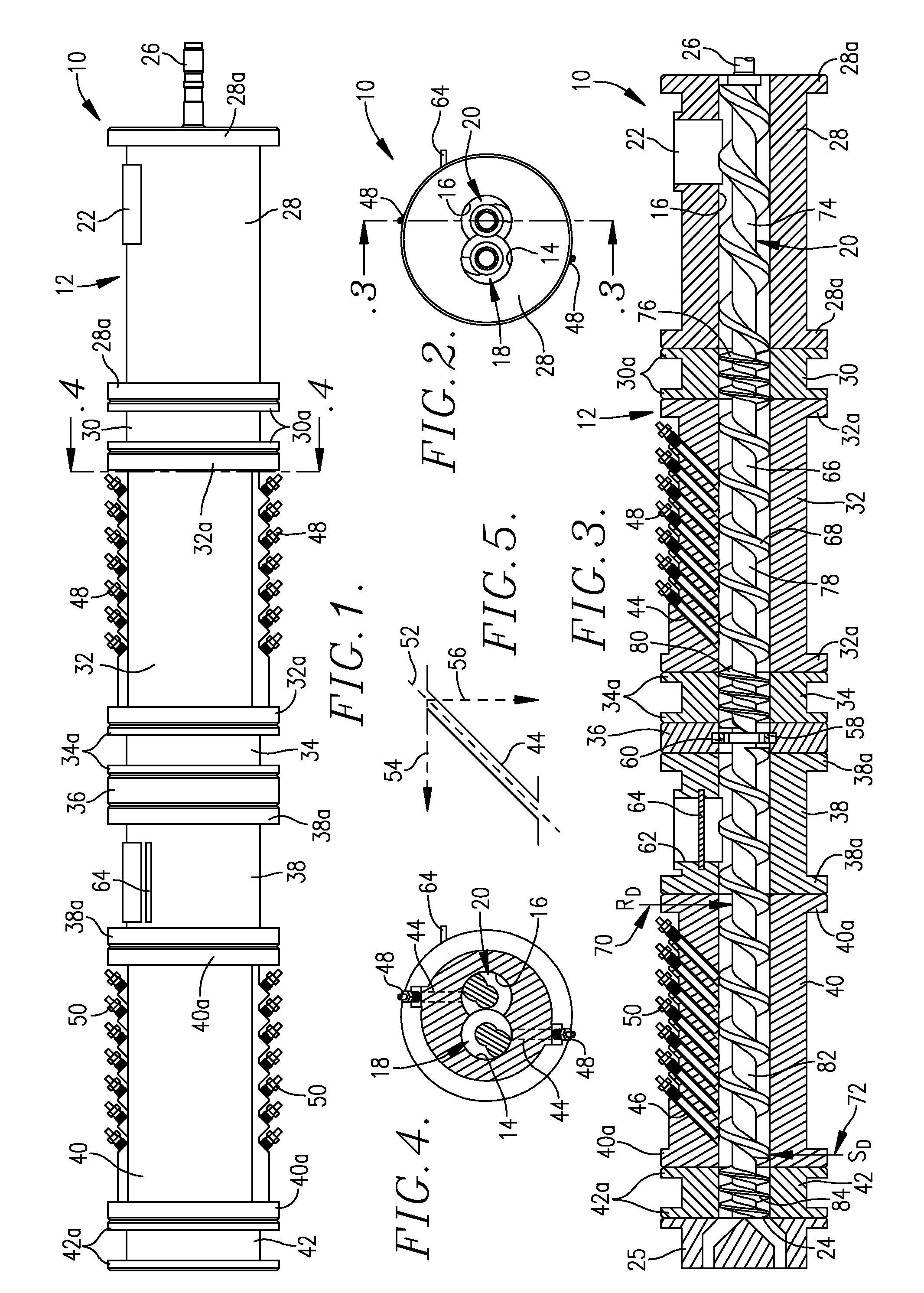

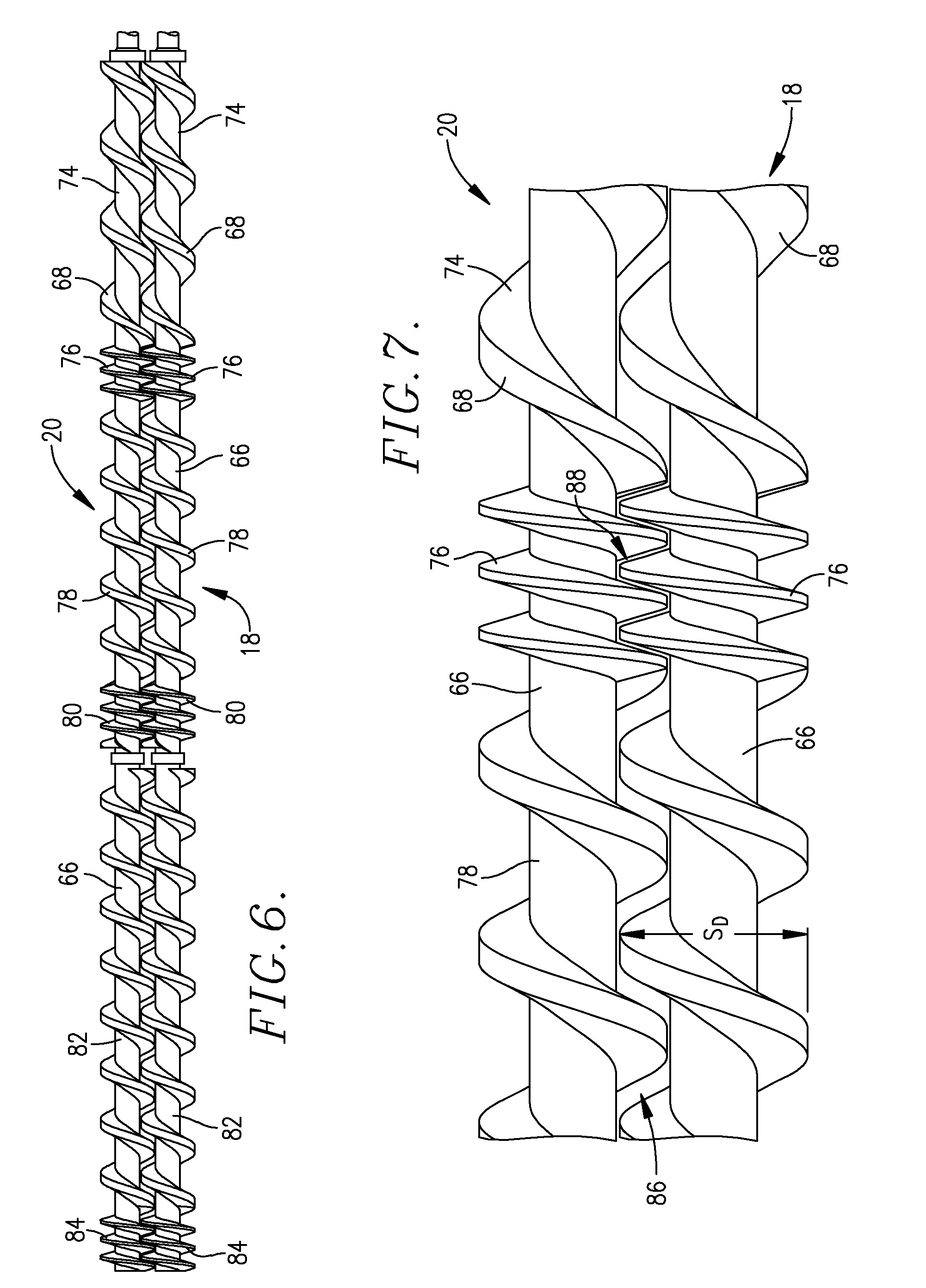

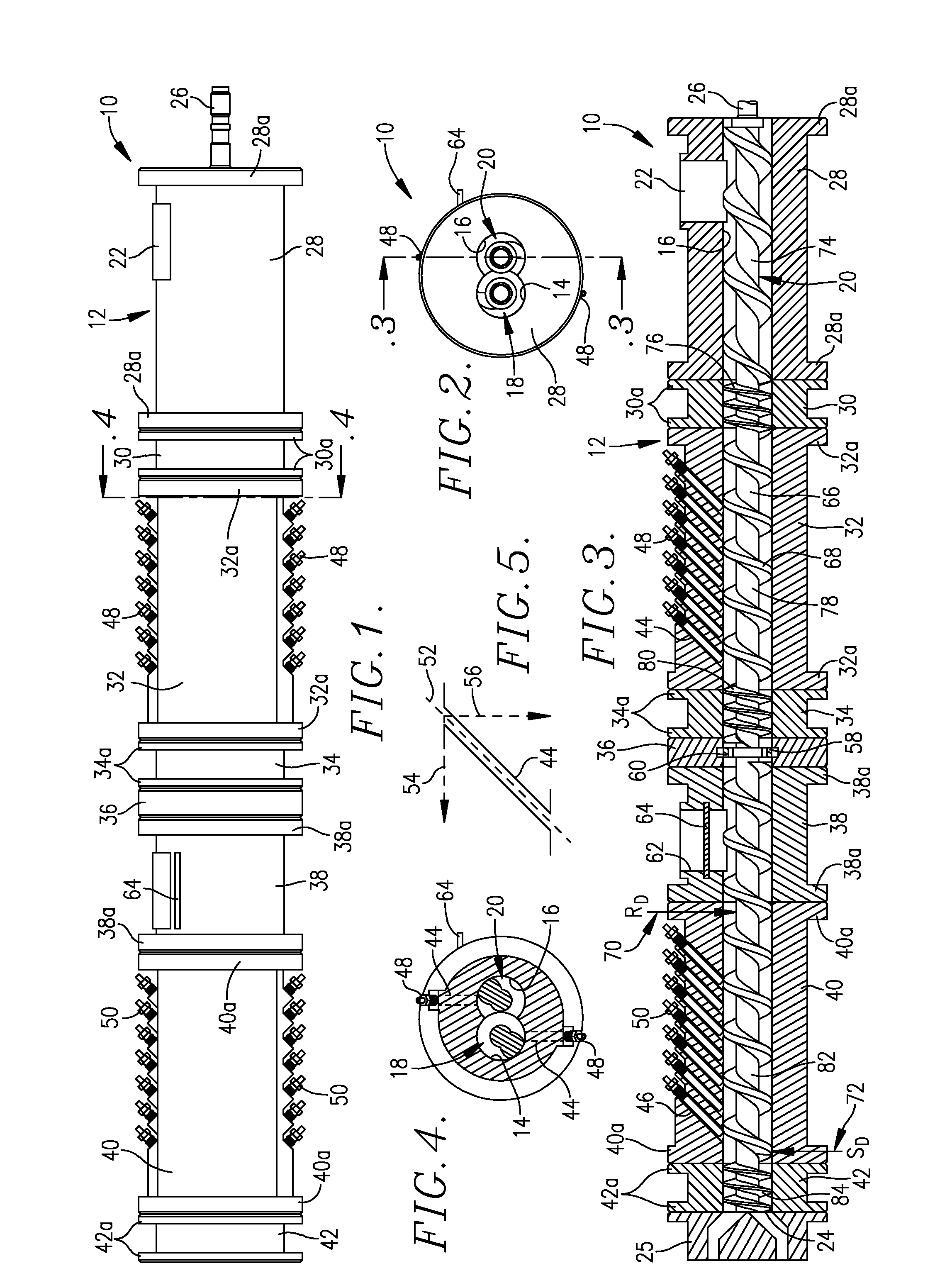

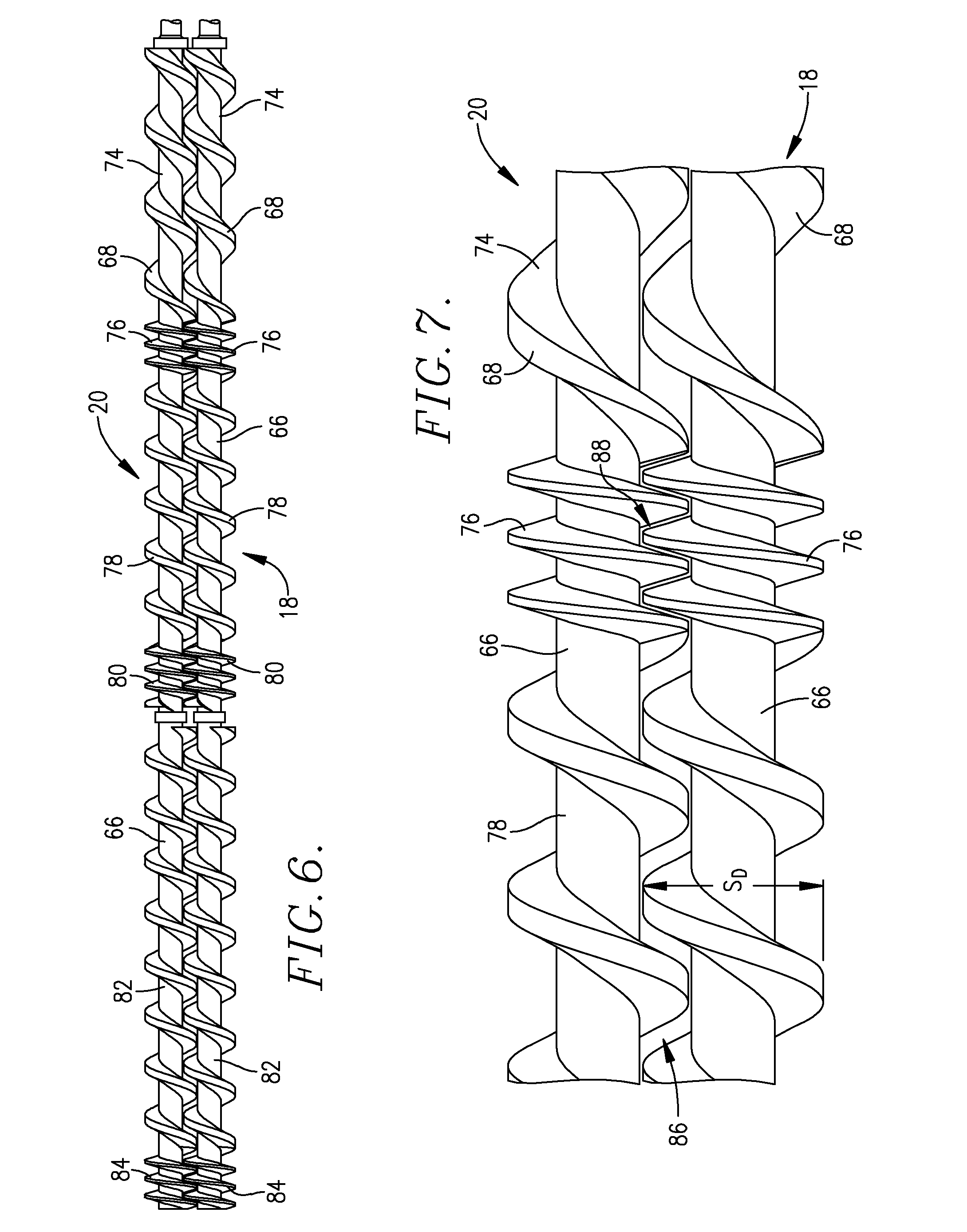

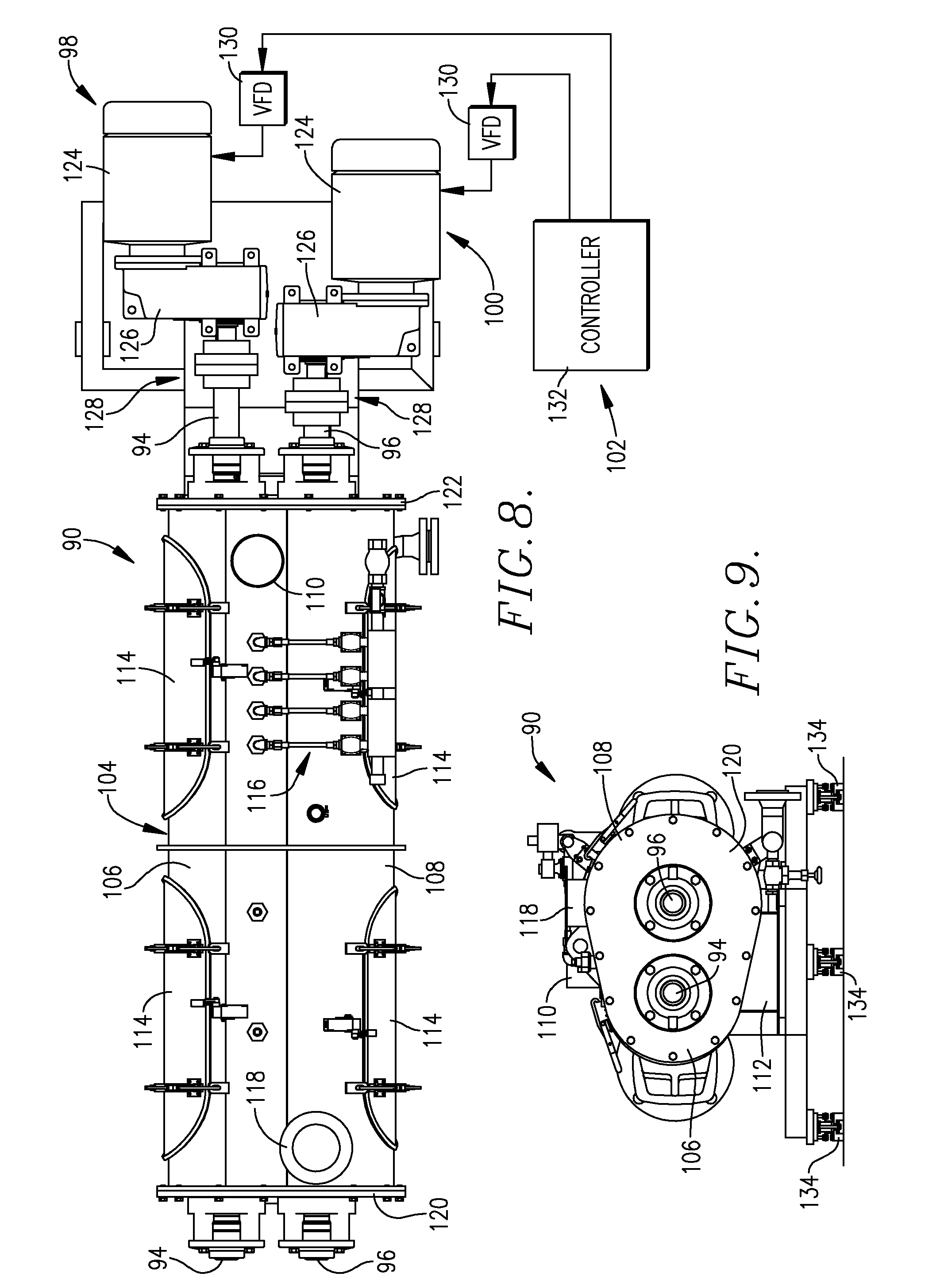

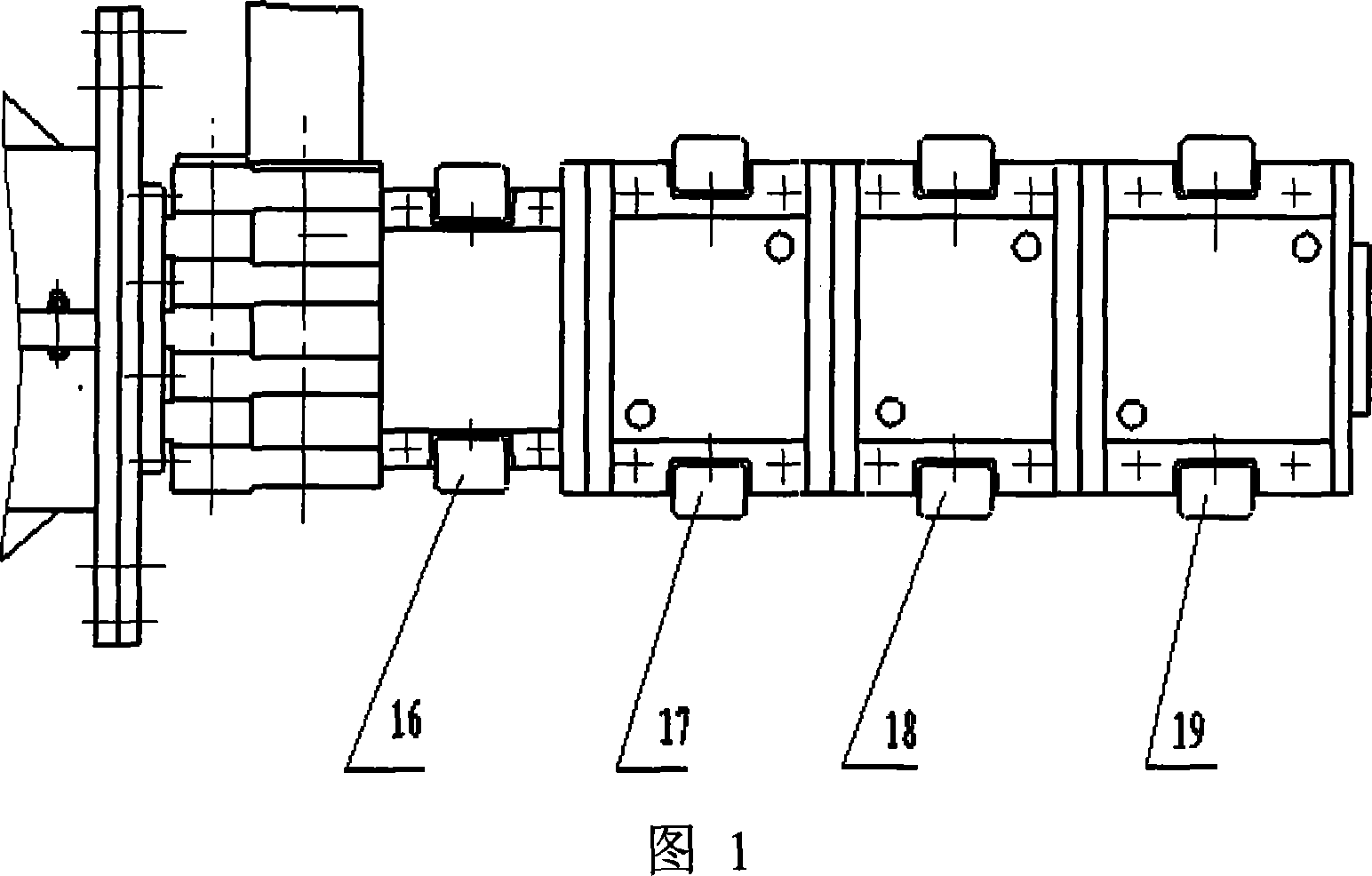

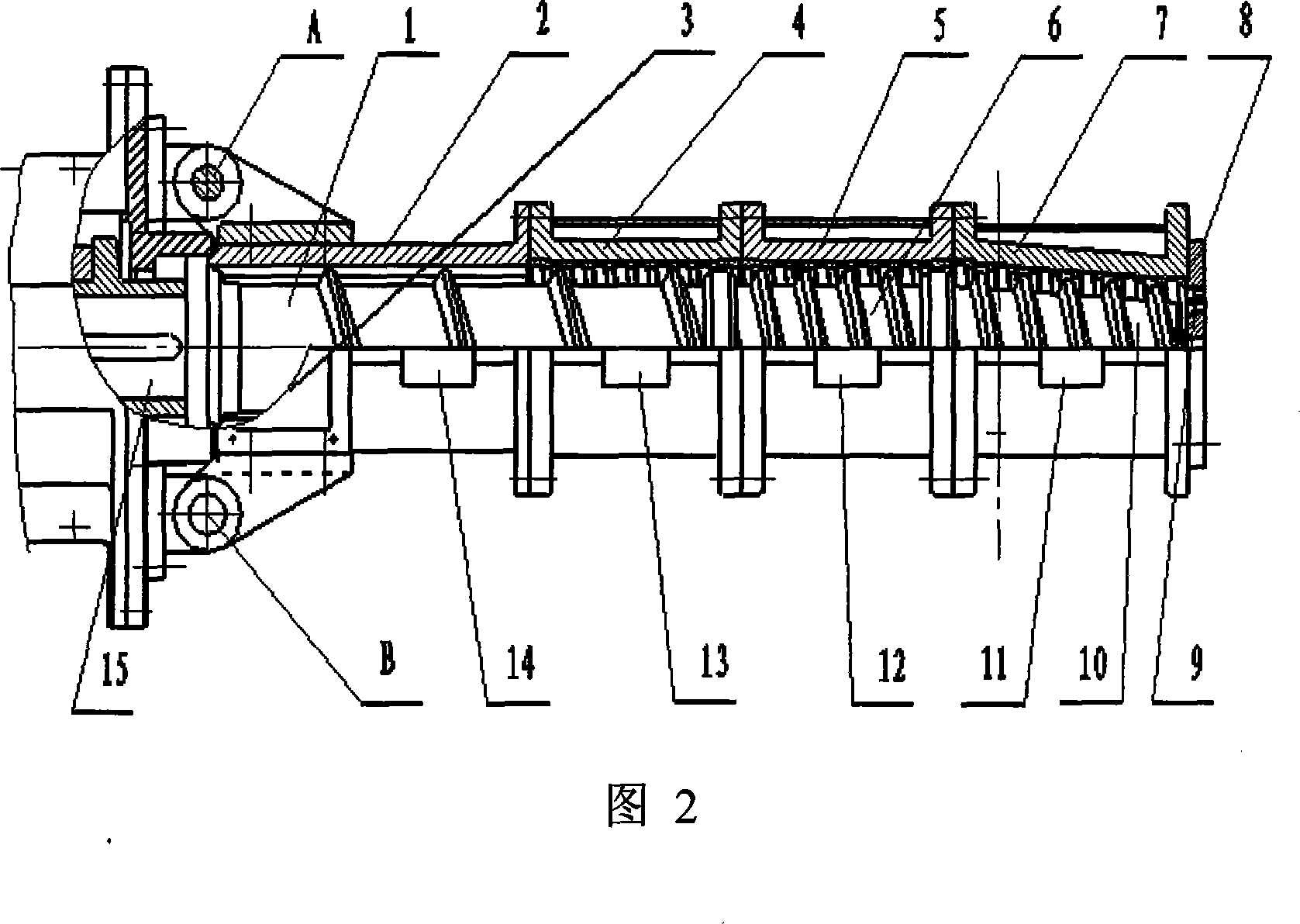

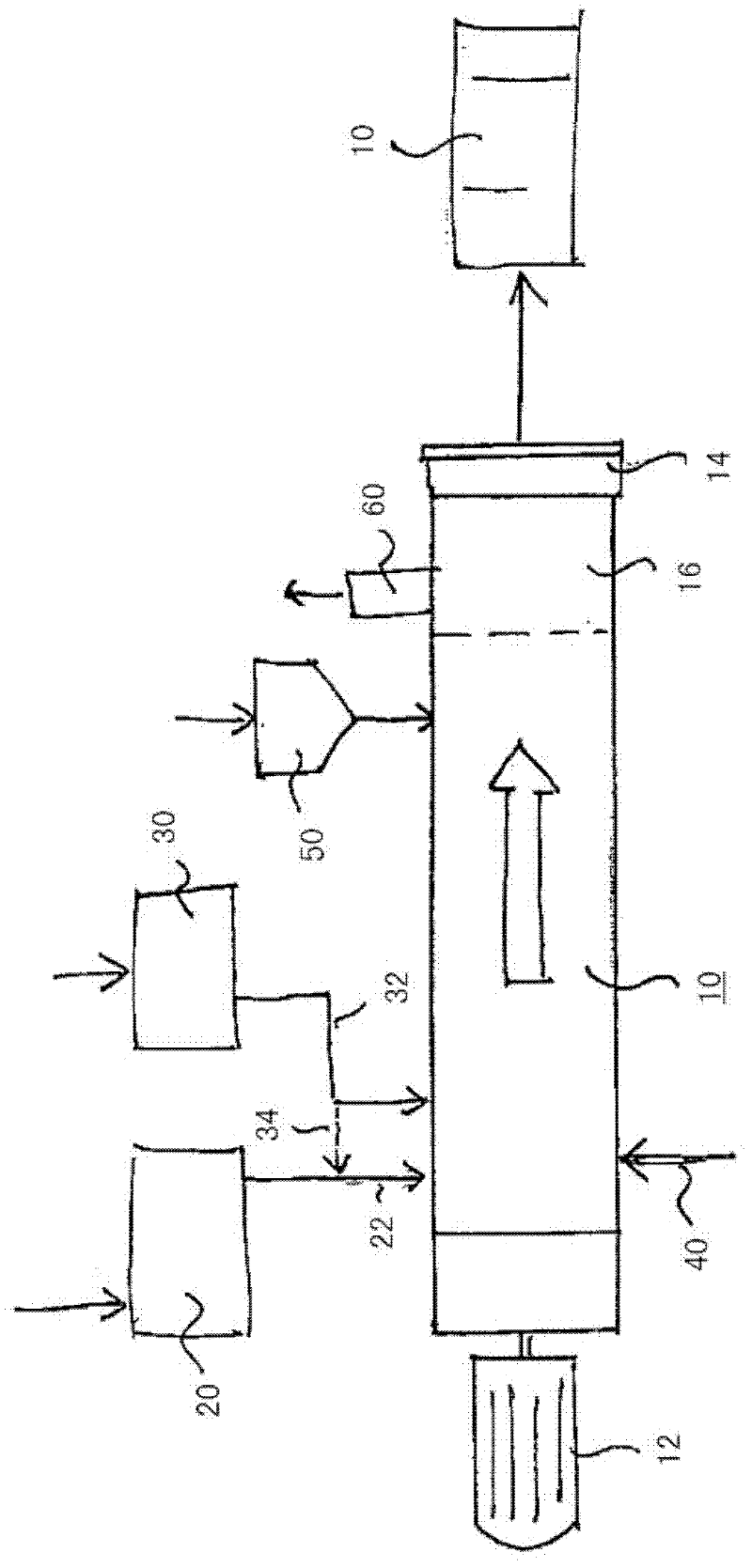

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

ActiveUS7521076B1The implementation process is simpleLow costMilk preservationFeeding-stuffEngineeringPreconditioner

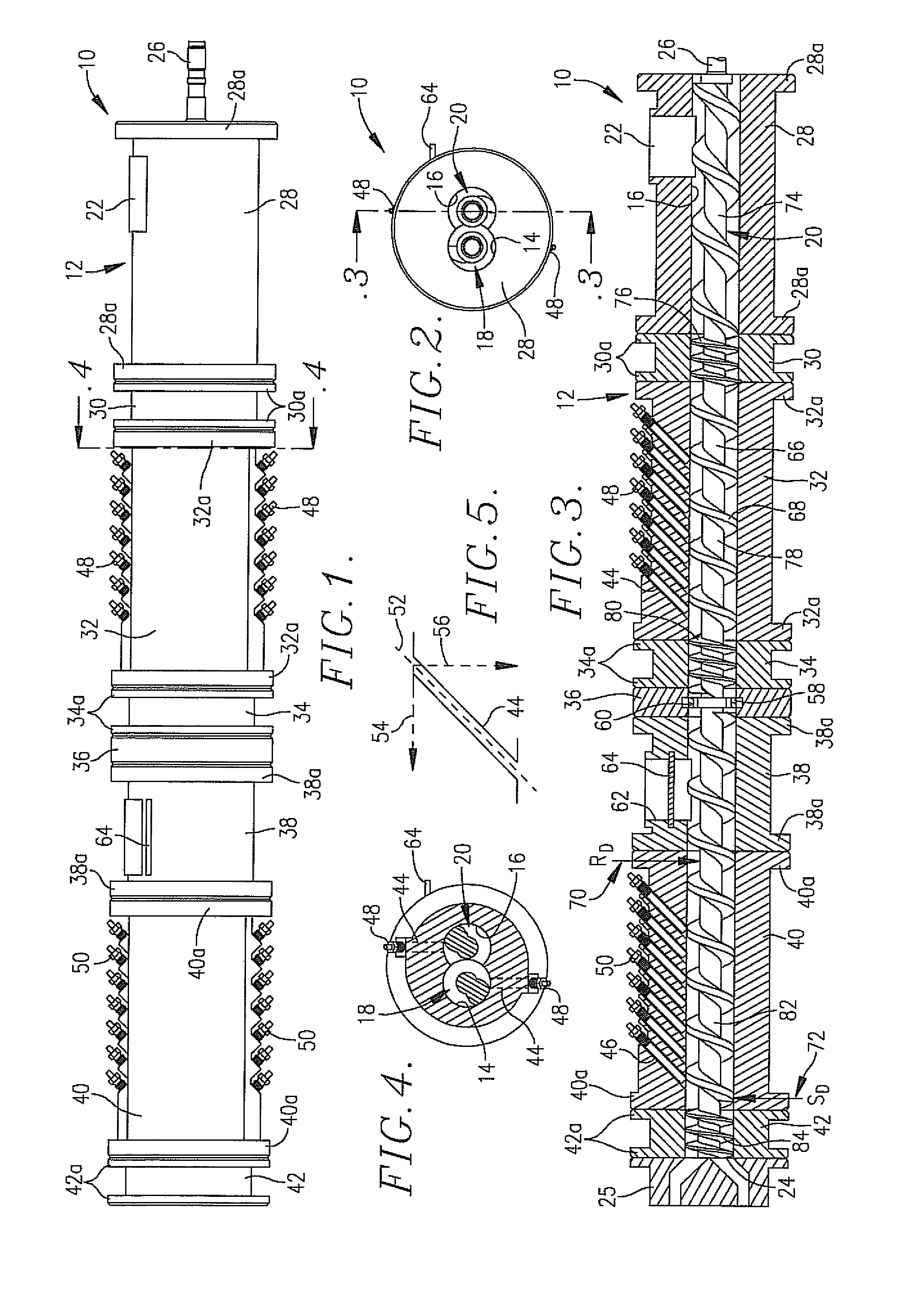

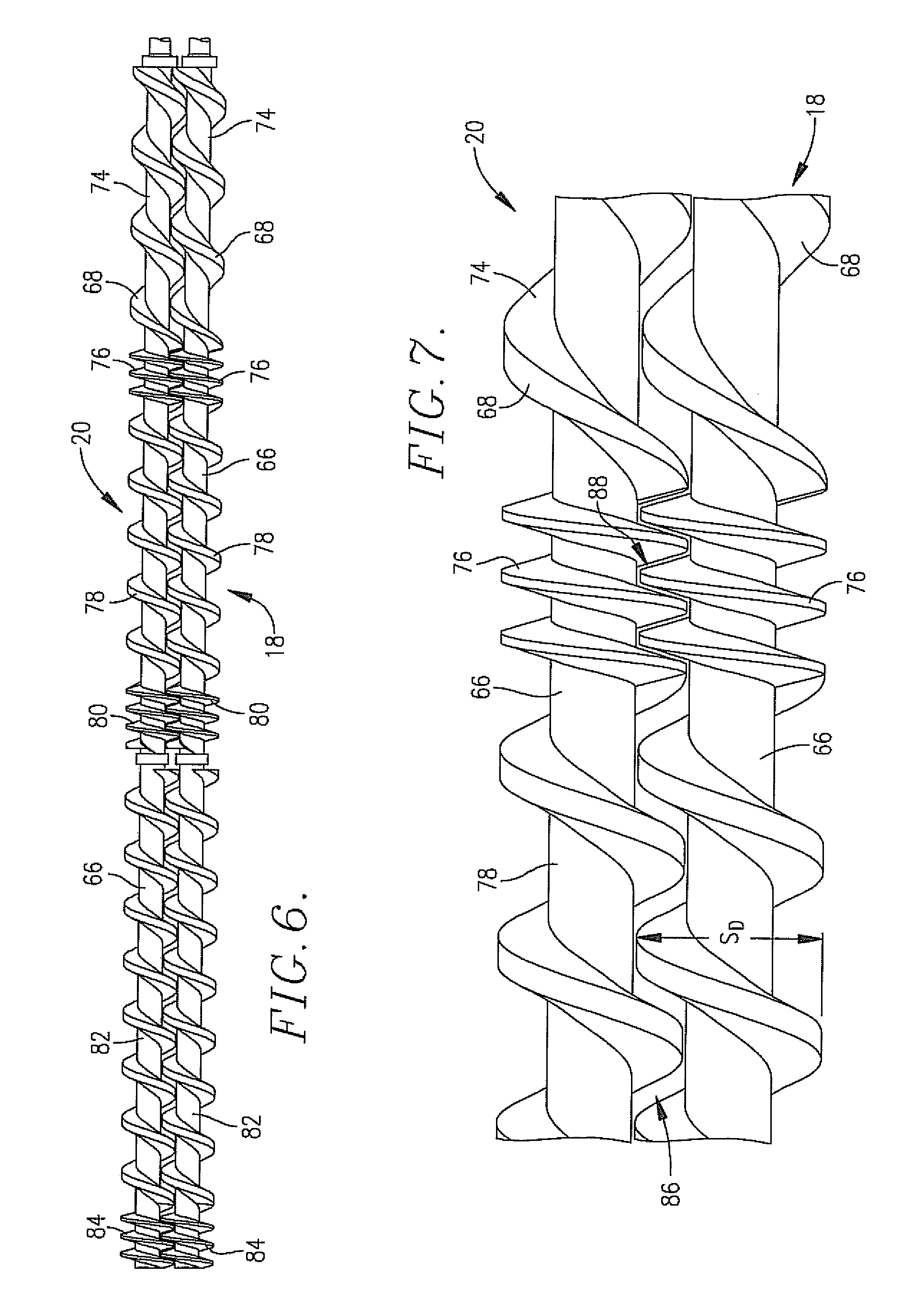

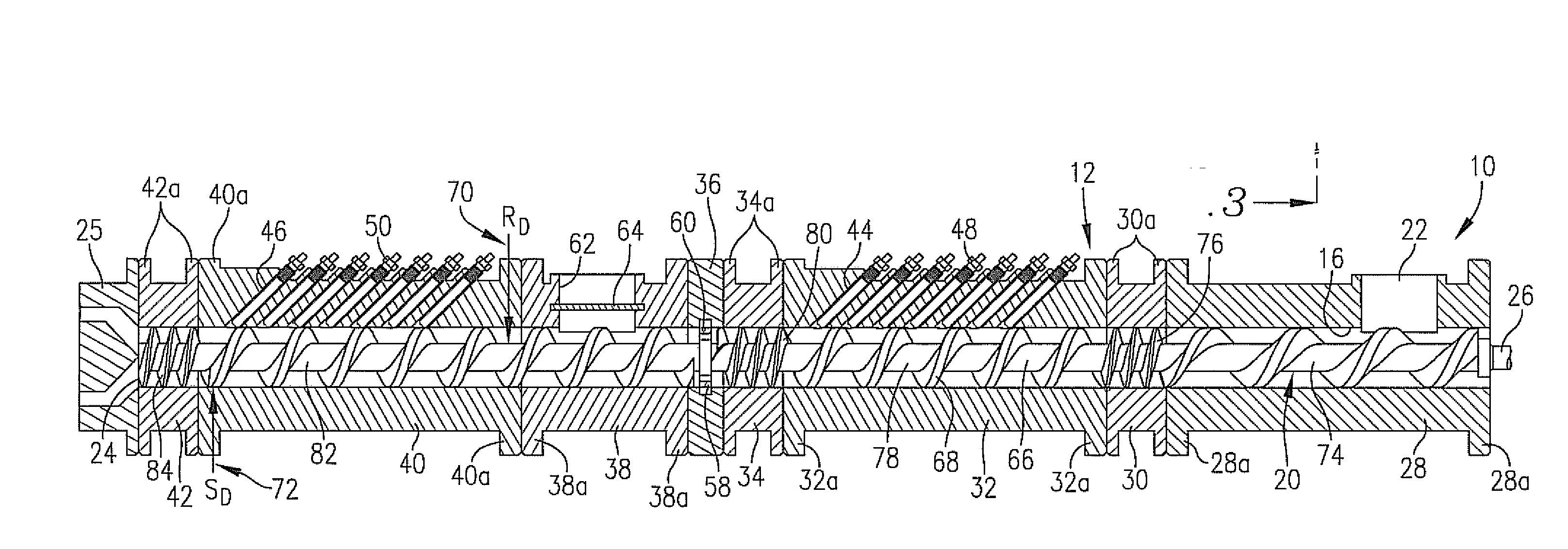

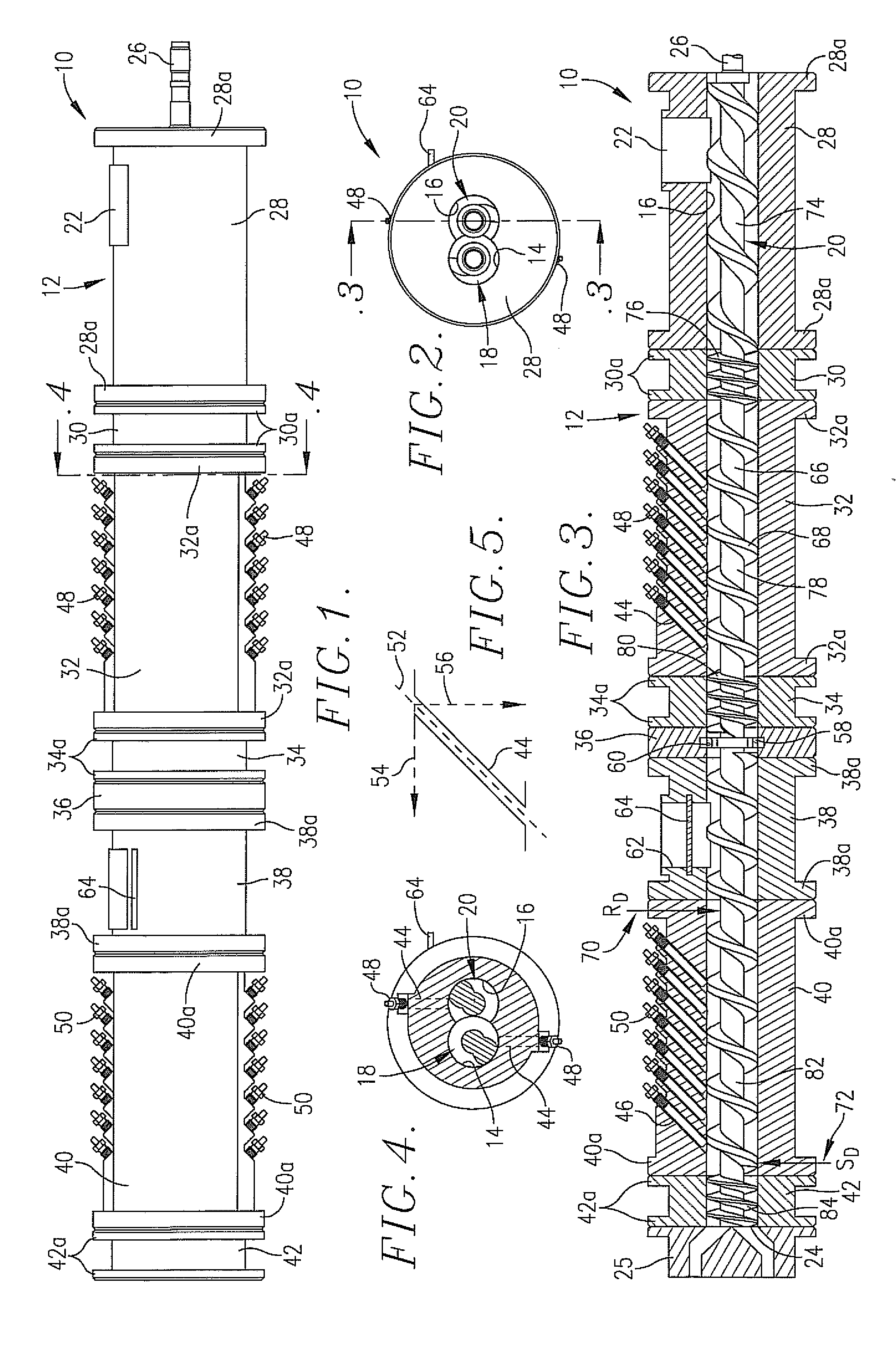

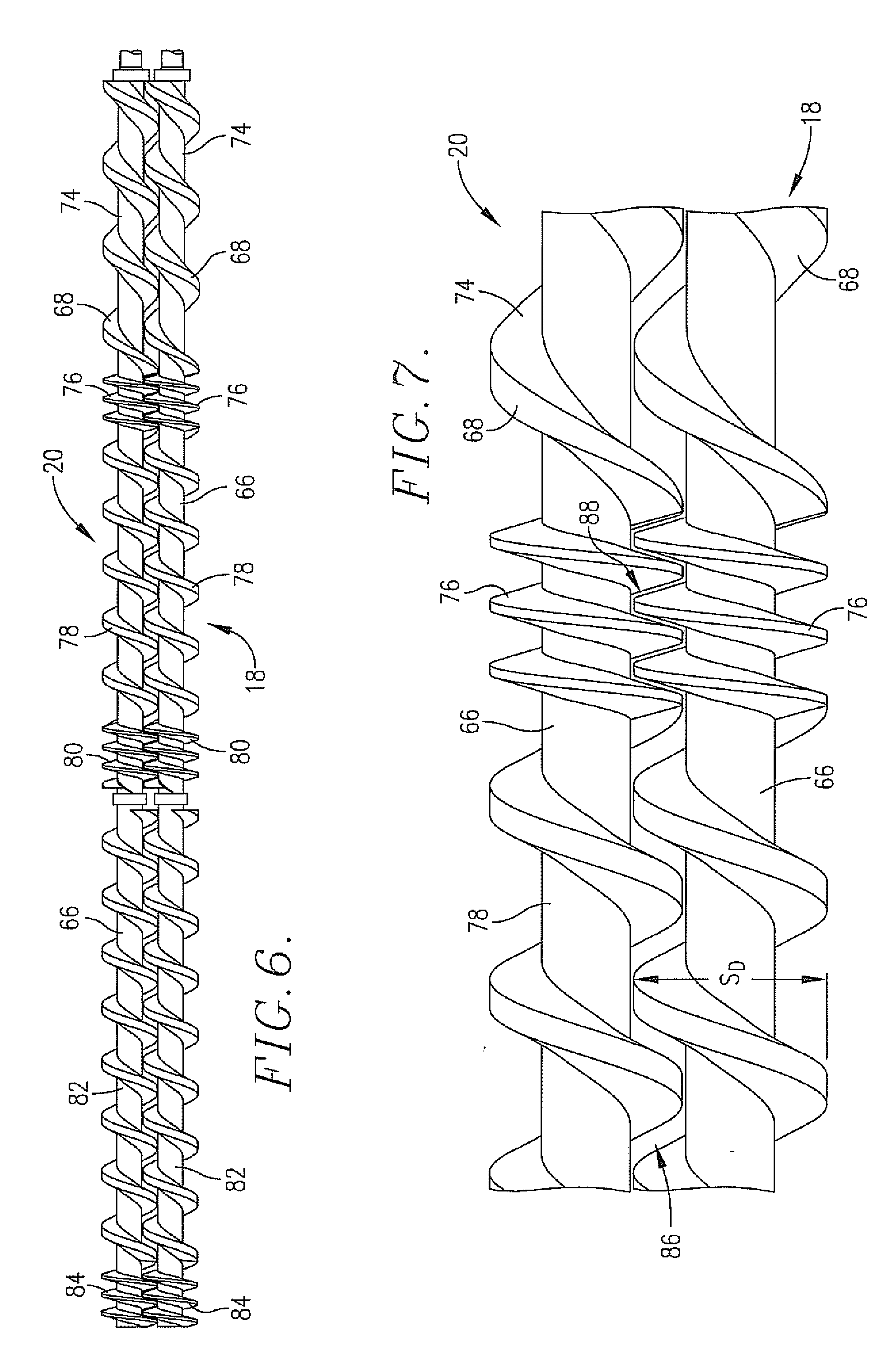

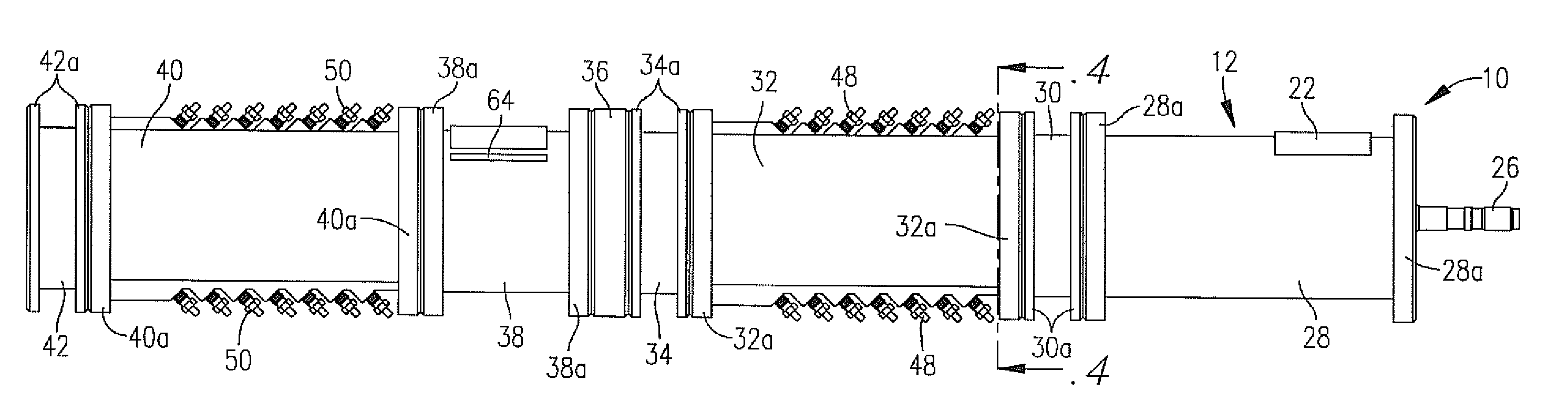

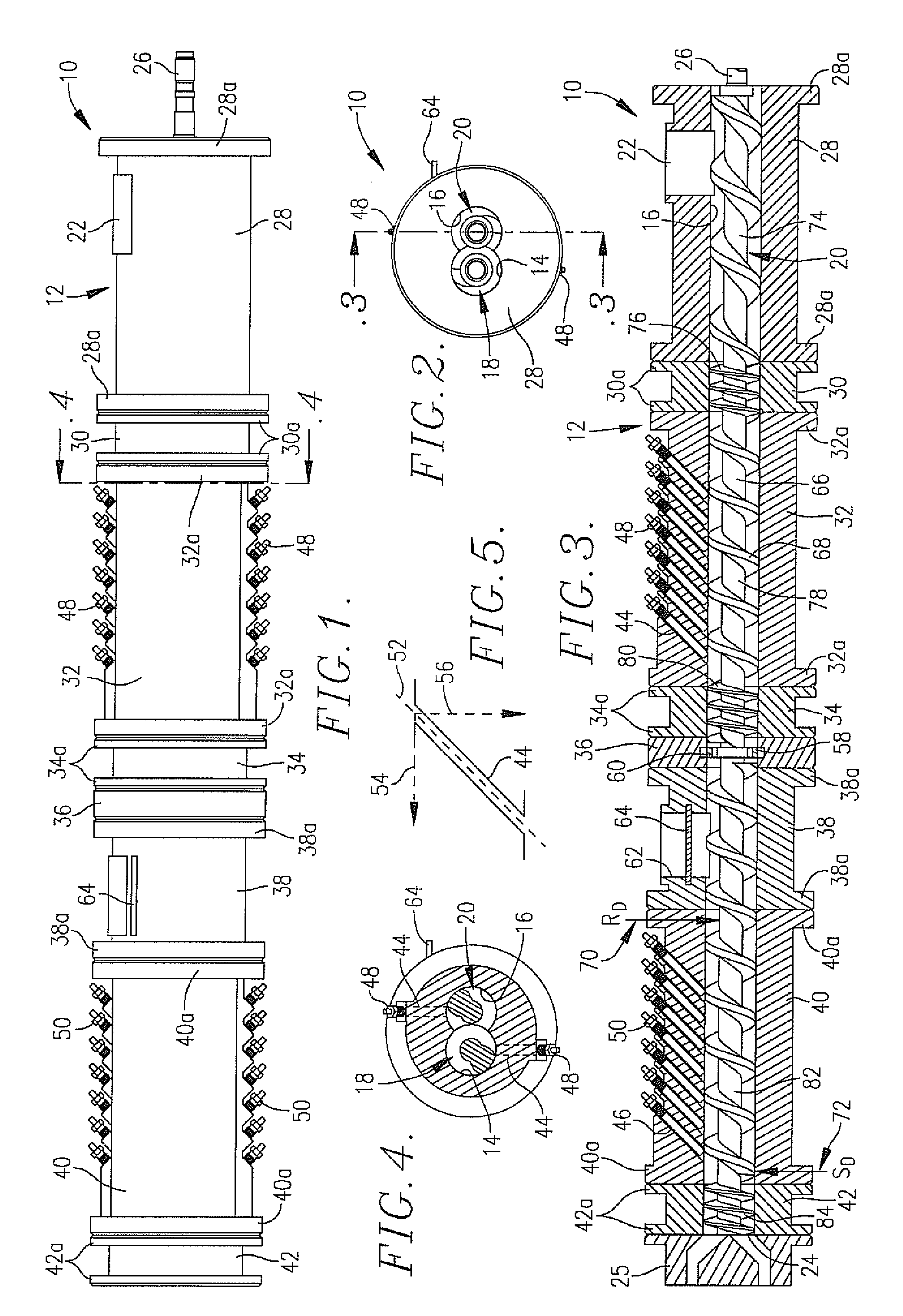

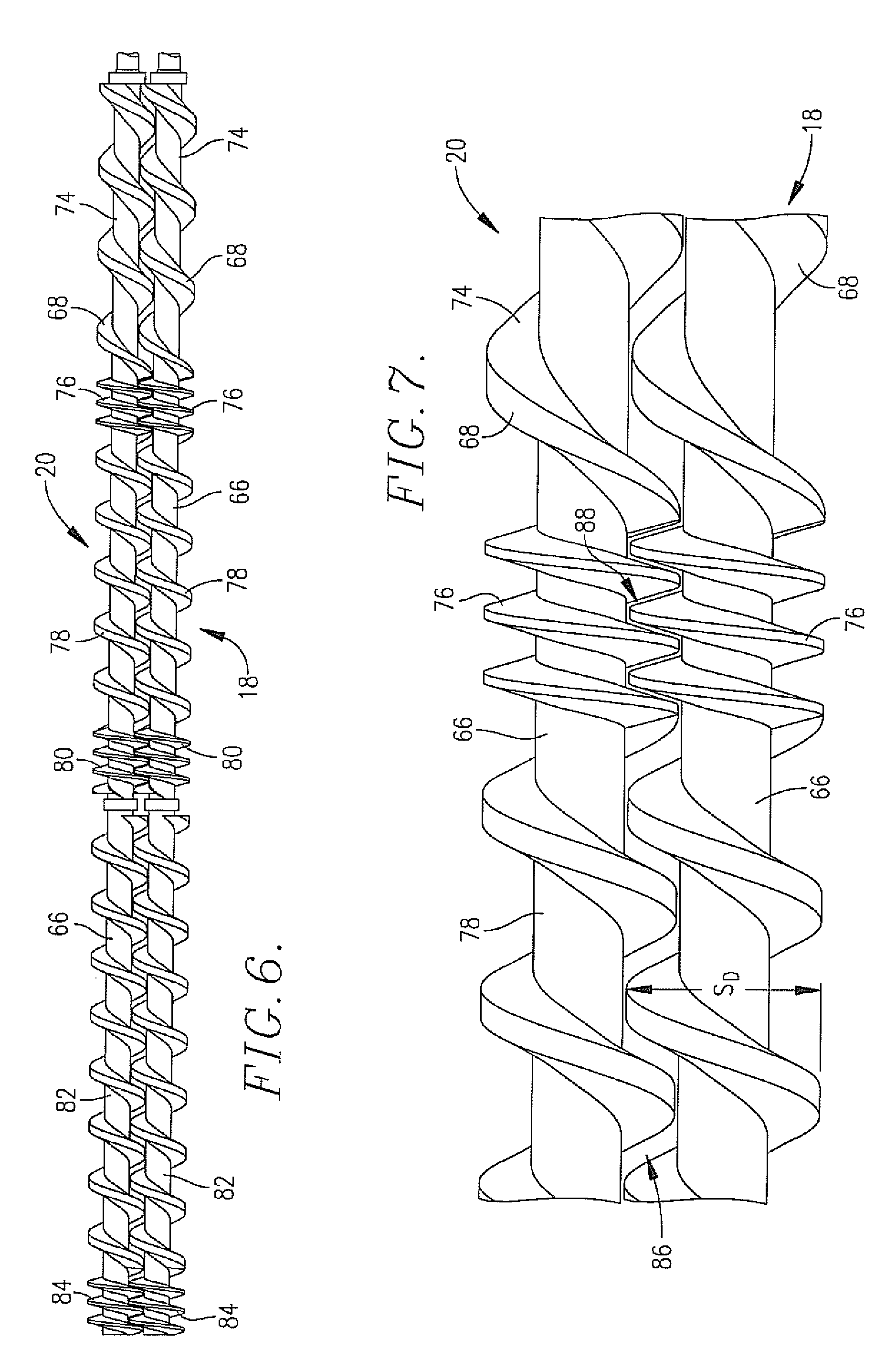

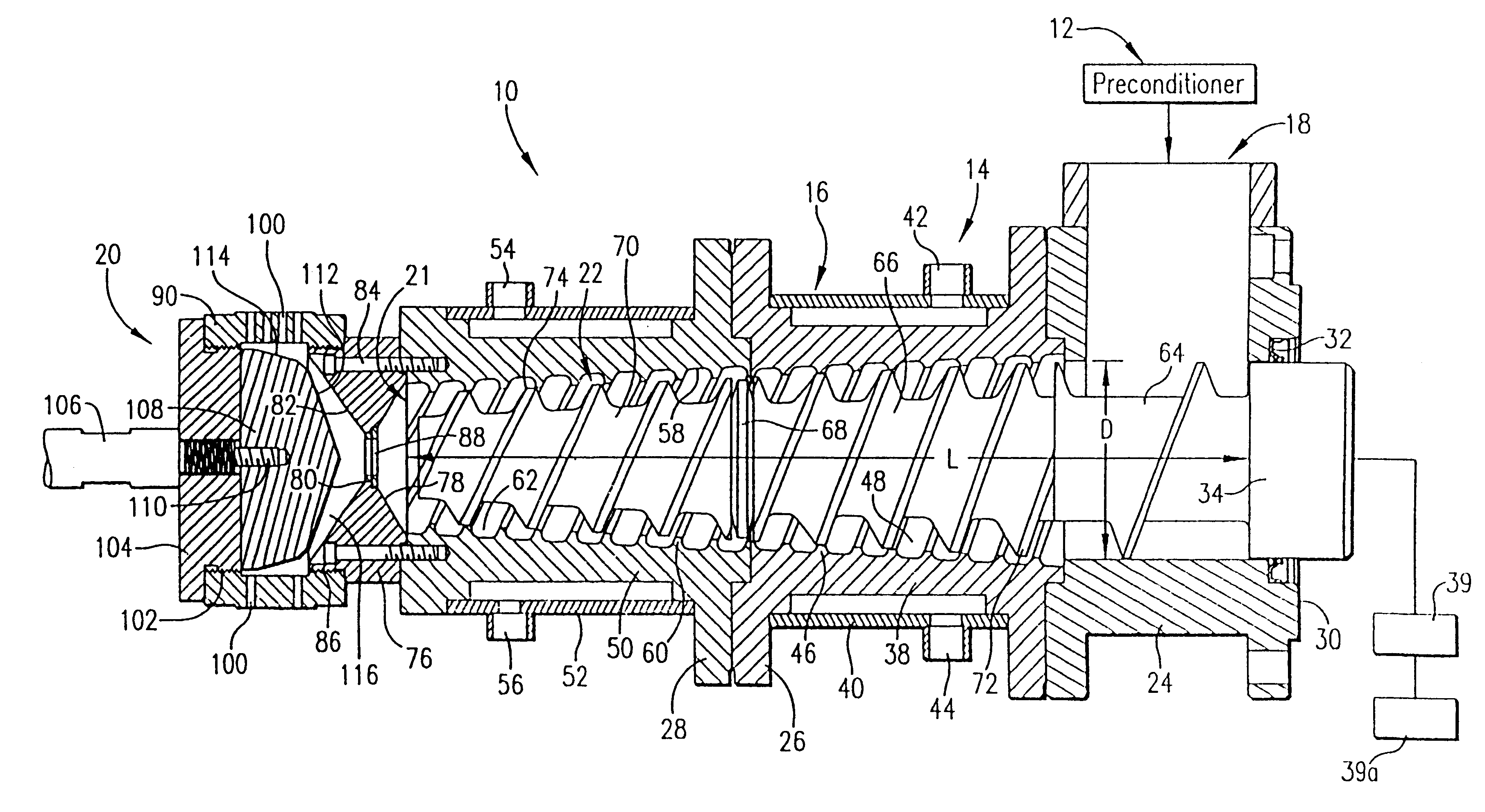

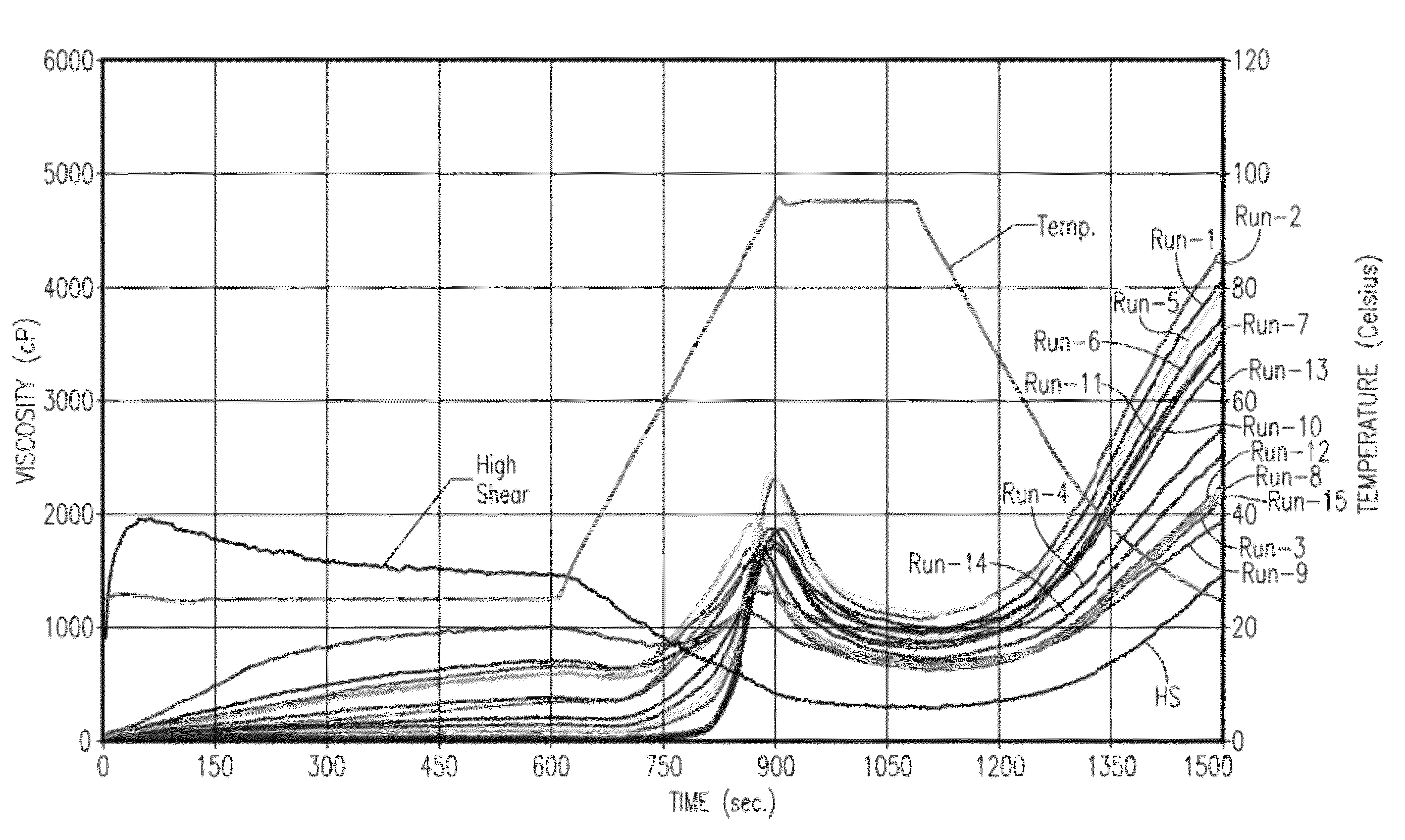

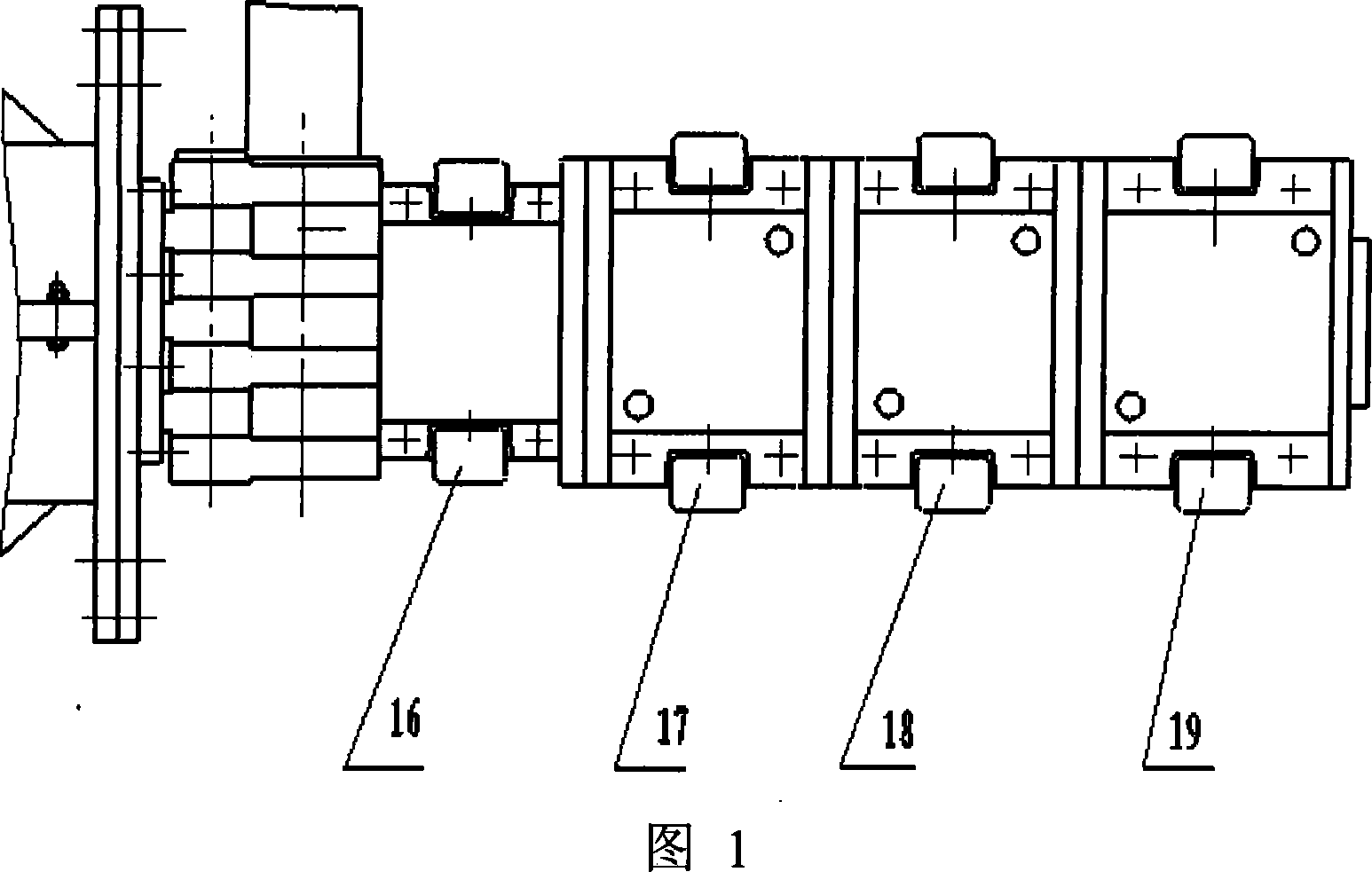

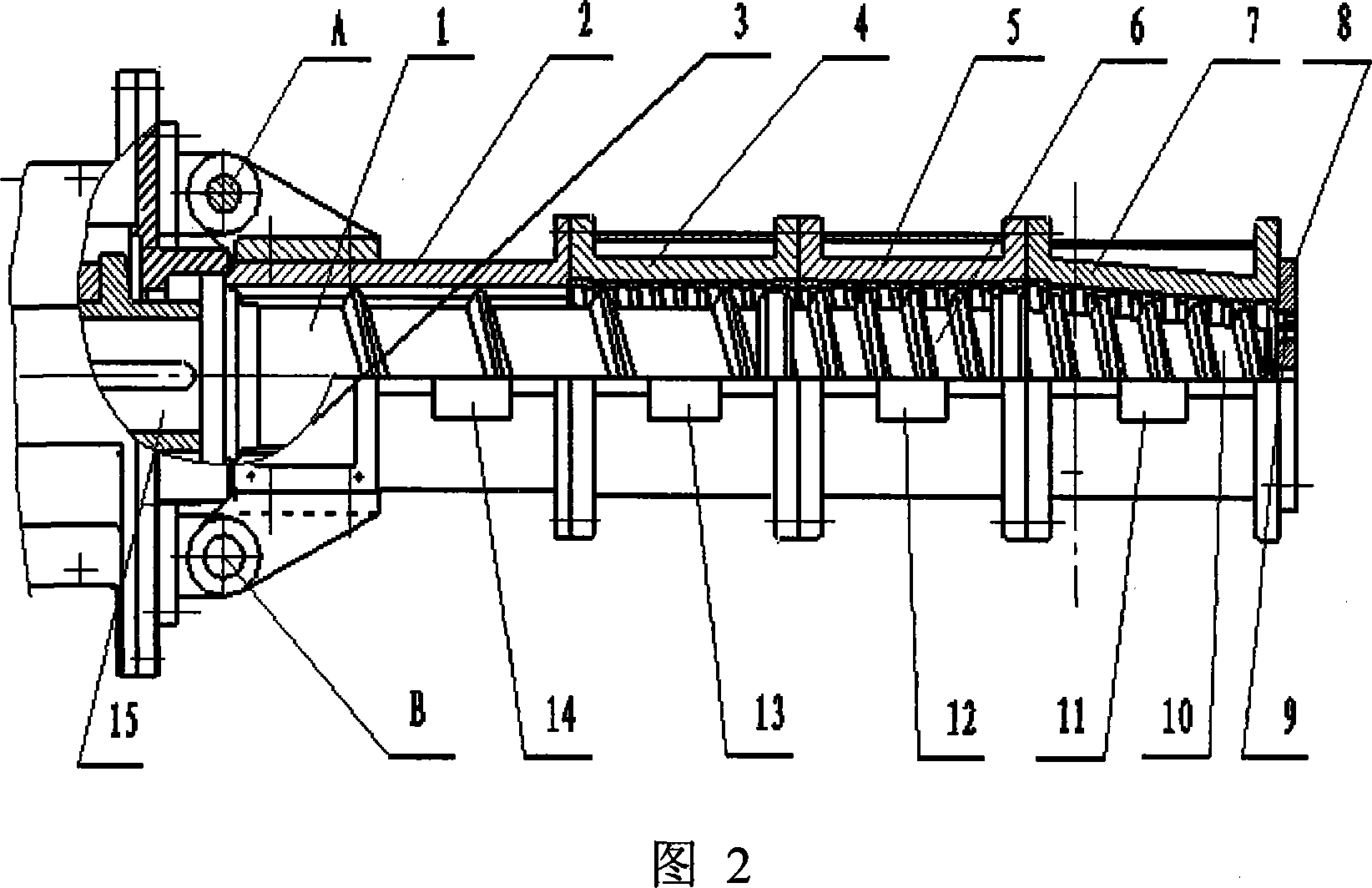

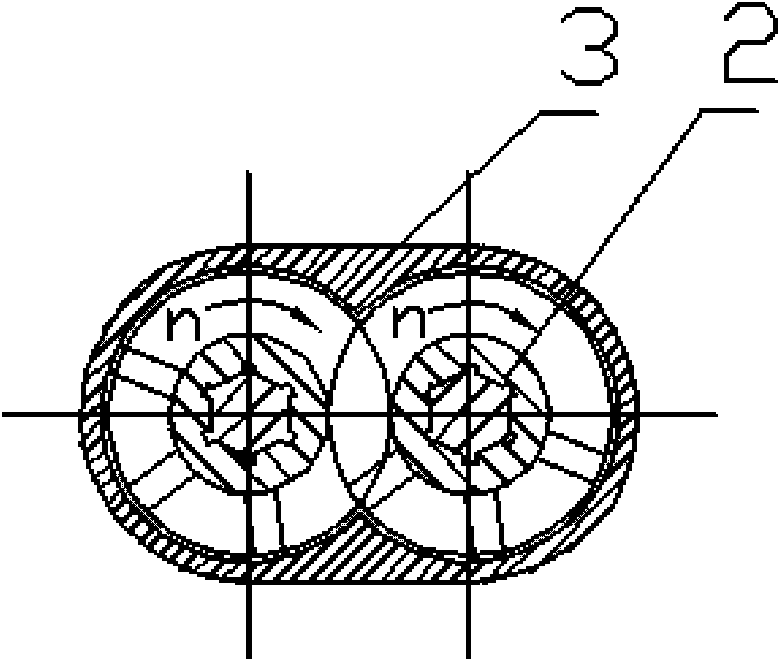

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MFG LLC

Extruded, highly cooked, non-sticky starch products

Owner:WENGER MANUFACTURING INC

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

InactiveUS20100062093A1Avoid excessive wearLow costTailstocks/centresFeeding-stuffEngineeringPreconditioner

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MANUFACTURING INC

Low-sodium salt composition

ActiveUS20090117254A1Preserves natural tasteGreat tasteDough treatmentFood preparationSalt substituteFood grade

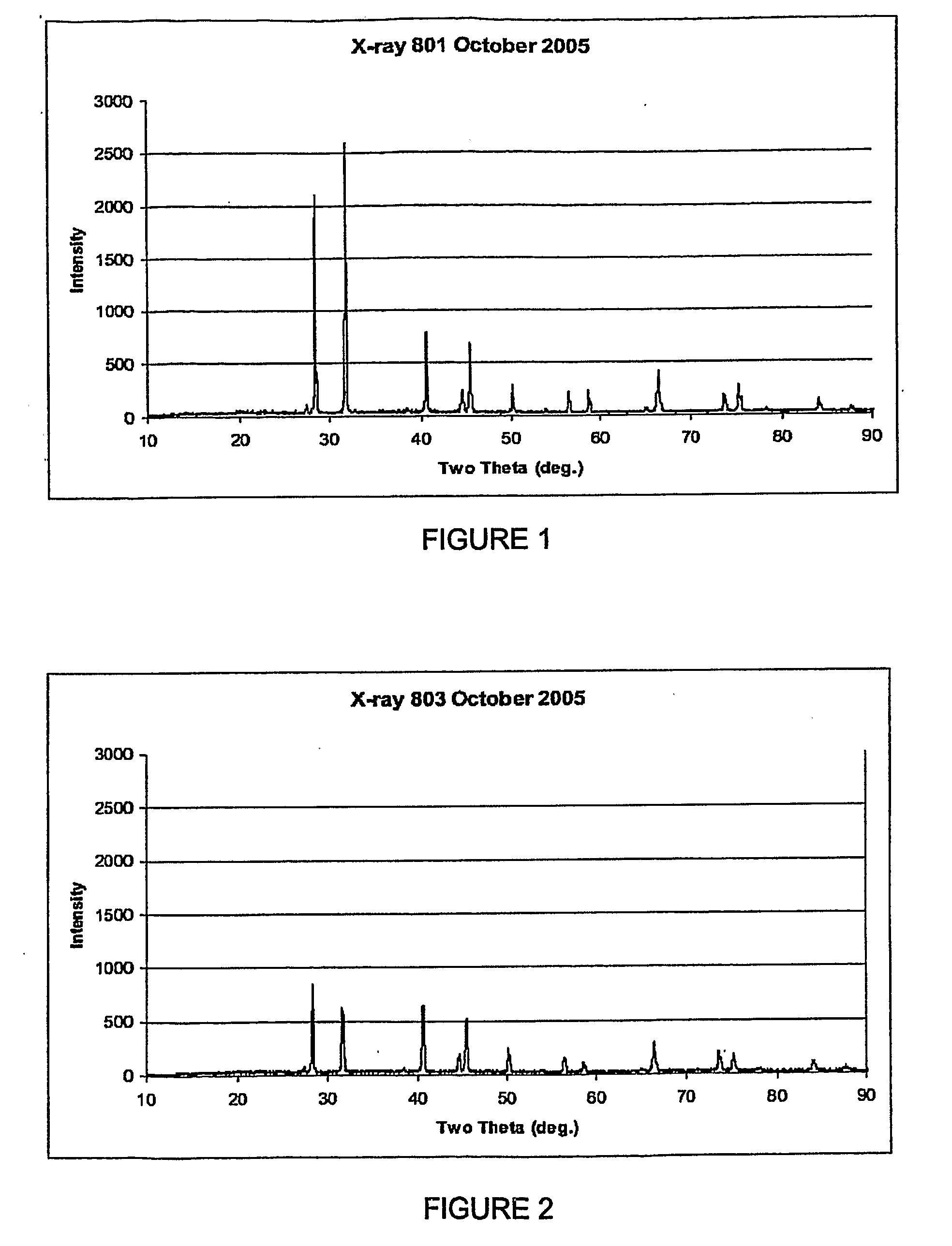

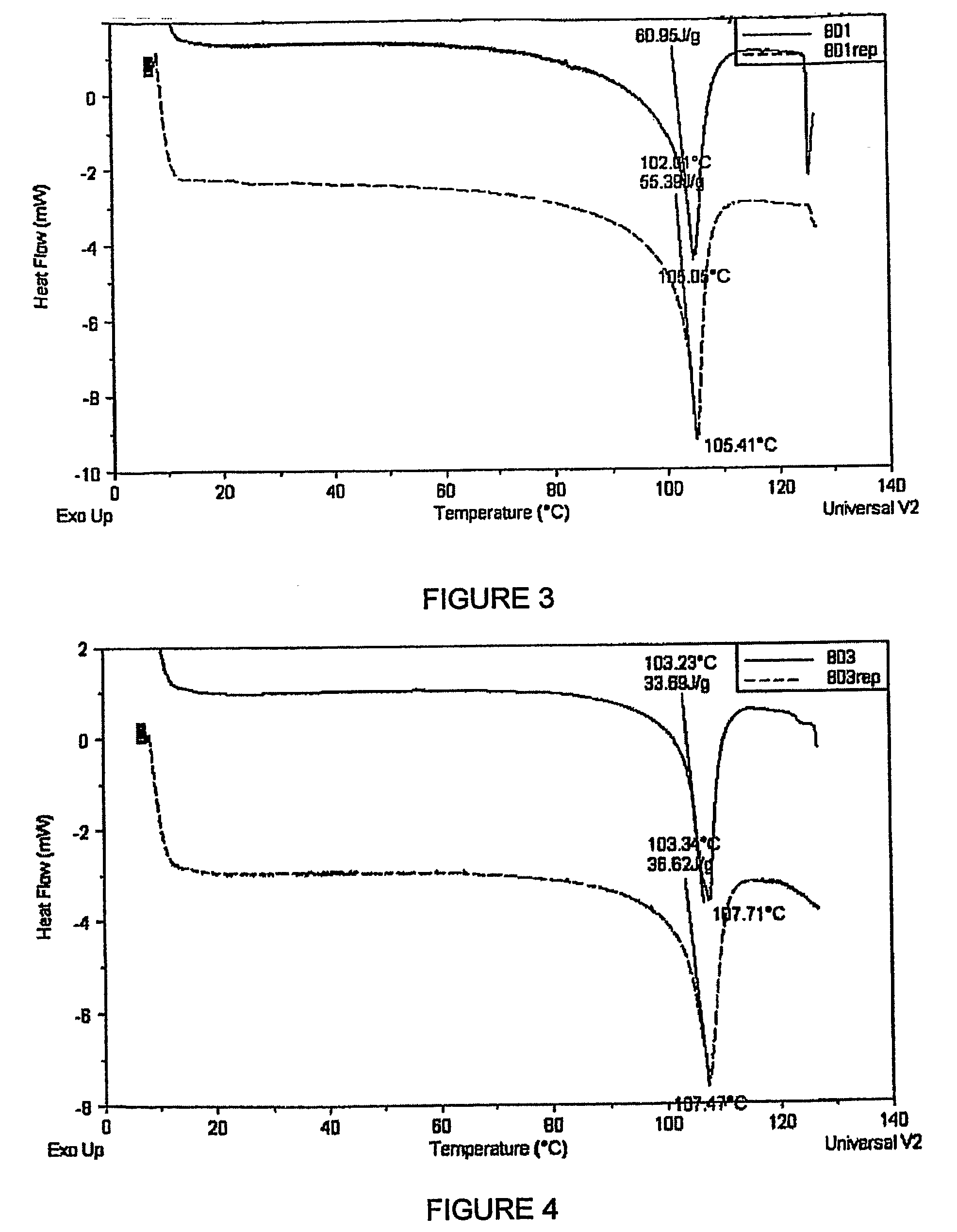

Low-sodium salt compositions / substitutes, Modified Potassium Chlorides (MPCs) and methods of making the same. The salt compositions / substitutes preferably include NaCl, KCl and a modifier(s), preferably a cereal flour such as rice flour. A food grade acidulant is preferably included. The composition / substitute will preferably have a Na / K ratio of from about 0.1 to about 9.0, most preferably about 1.0. MPCs preferably include KCl and a modifier(s), preferably a cereal flour such as rice flour. A food grade acidulant is preferably included. The salt compositions / substitutes and MPCs are preferably made by drum drying, extrusion cooking or agglomeration procedures. The MPC is preferably blended and / or co-ground with unmodified NaCl in any desired ratio, preferably 50 / 50, which gives a Na / K ratio of about 1 (i.e. 20% sodium and 20% potassium), to cost-effectively provide a salt substitute without modifying the NaCl.

Owner:S & P INGREDIENT DEV

Method for preparing homogeneous tomato sauce with high dietary fiber content

ActiveCN102028187AWith detoxificationPrevent constipationFood preparationCation-exchange capacityFiber

The invention discloses a method for preparing homogeneous tomato sauce with high dietary fiber content, which belongs to the technical field of comprehensive utilization of agricultural and sideline products. The method is implemented mainly by the steps of deodorizing bean dregs, and performing alkali liquor treatment, enzymolysis, decoloring, drying, extrusion cooking, drying and super micro milling to prepare super micro milled bean dreg dietary fiber flour for the preparation of the homogeneous tomato sauce with high viscosity and the high dietary fiber content. The method has the advantages that: 1, the high-activity soybean dietary fiber flour can be prepared from the bean dregs by performing the alkali liquor treatment, the enzymolysis, the extrusion cooking and the super micro milling, and has remarkably increased soluble dietary fiber content, remarkably improved water absorptivity and remarkably improved cation exchange capacity; 2, when used for preparing the tomato sauce,the soybean dietary fiber flour treated by the processes is homogenized by a 30 MPa homogenizer so as to make a sauce body more uniform and stable, increase the viscosity and health care value of thetomato sauce and improve the water absorptivity of the tomato sauce; and 3, the utilization of the bean dregs changes the conventional way of utilizing the bean dregs as feeds so as to reduce environmental stress at the same time of realizing reutilization.

Owner:JIANGNAN UNIV

Extruded, highly cooked, non-sticky starch products

ActiveUS7749552B1High degreeLow viscosityMilk preservationMeat/fish preservation by heatingPre treatmentViscosity

Improved extruded starch-bearing grain products (e.g., corn and wheat) are provided having relatively high cook values and low cold water viscosities. The products are prepared by initial preconditioning to partially cook the starting material(s), followed by low shear extrusion cooking, with a total STE / SME ratio of at least about 4.

Owner:WENGER MFG LLC

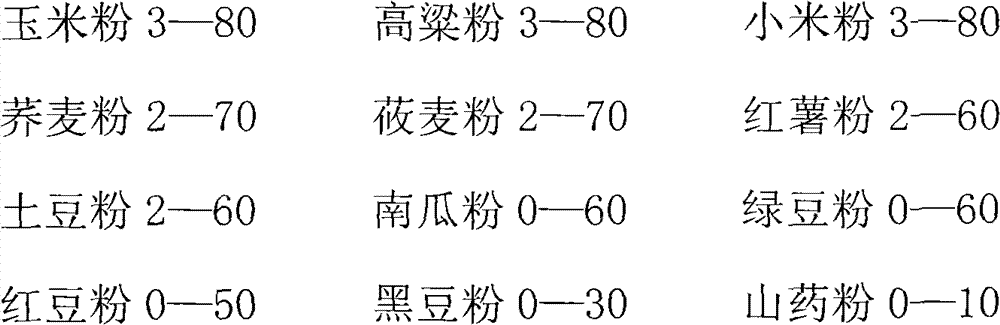

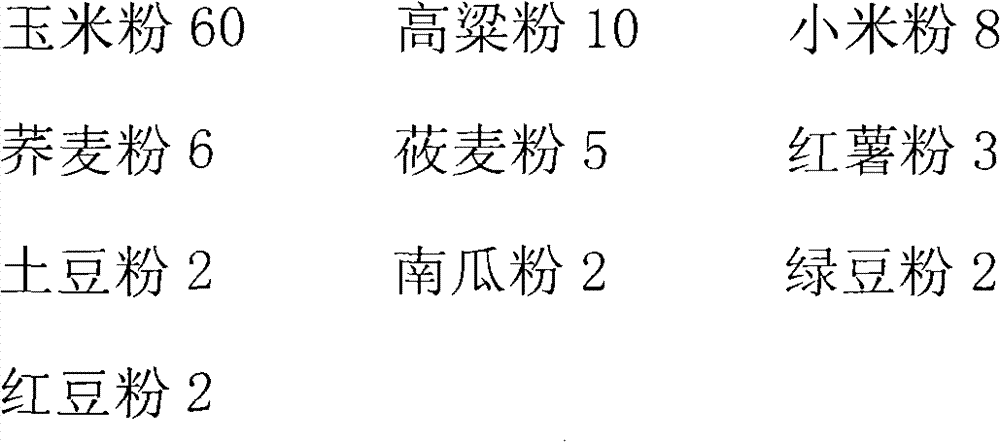

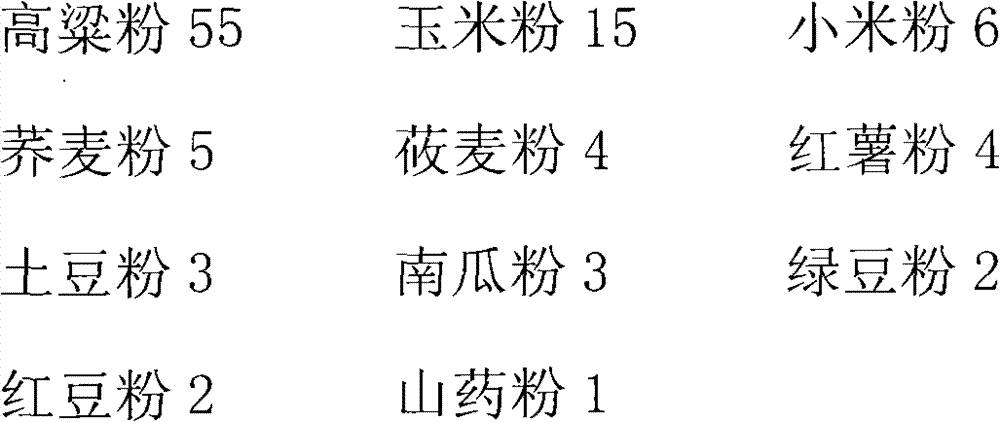

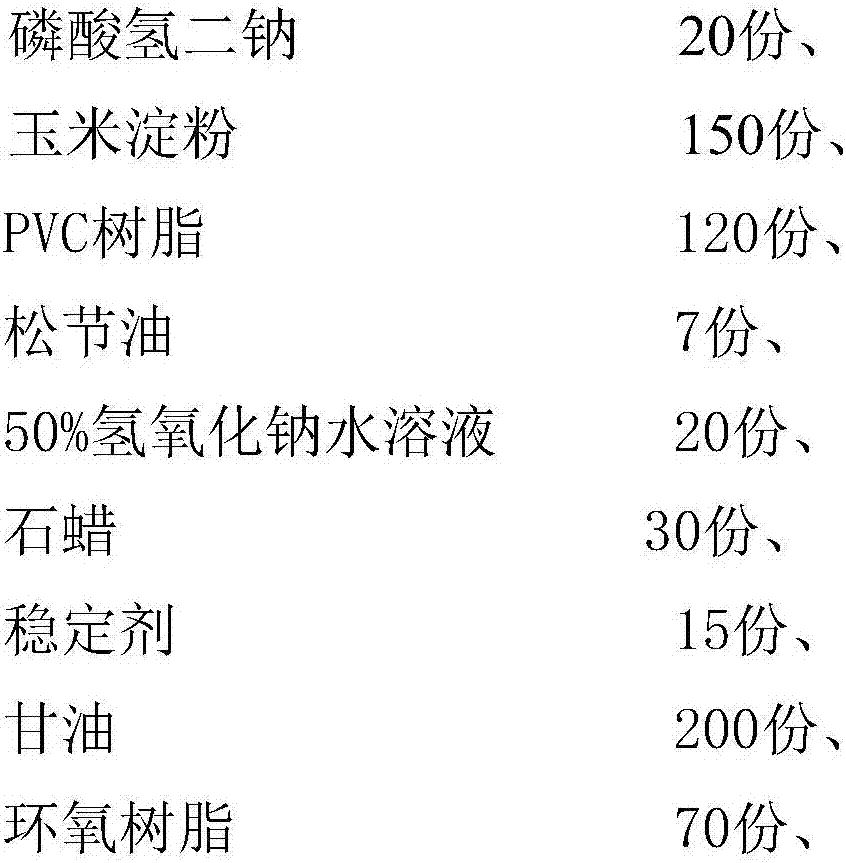

Staple food blend rice and its preparation method

The invention discloses staple food blend rice and its preparation method. The blend rice is characterized in that: it is composed of the following components by weight part. The method mainly includes the processes of: complete mixing, extrusion cooking, cutting granulation and the like. The staple food blend rice provided in the invention balances the nutrition of a variety of coarse cereals, improves the palatability of coarse cereal food, and is convenient to eat by co-cooking with rice, thus reflecting the new development trend of coarse cereal health food.

Owner:蒋佃水

Short length tapered extrusion cooking apparatus having peripheral die

InactiveUSRE37235E1Smooth transitionConfectioneryCeramic shaping apparatusVolumetric Mass DensityMechanical engineering

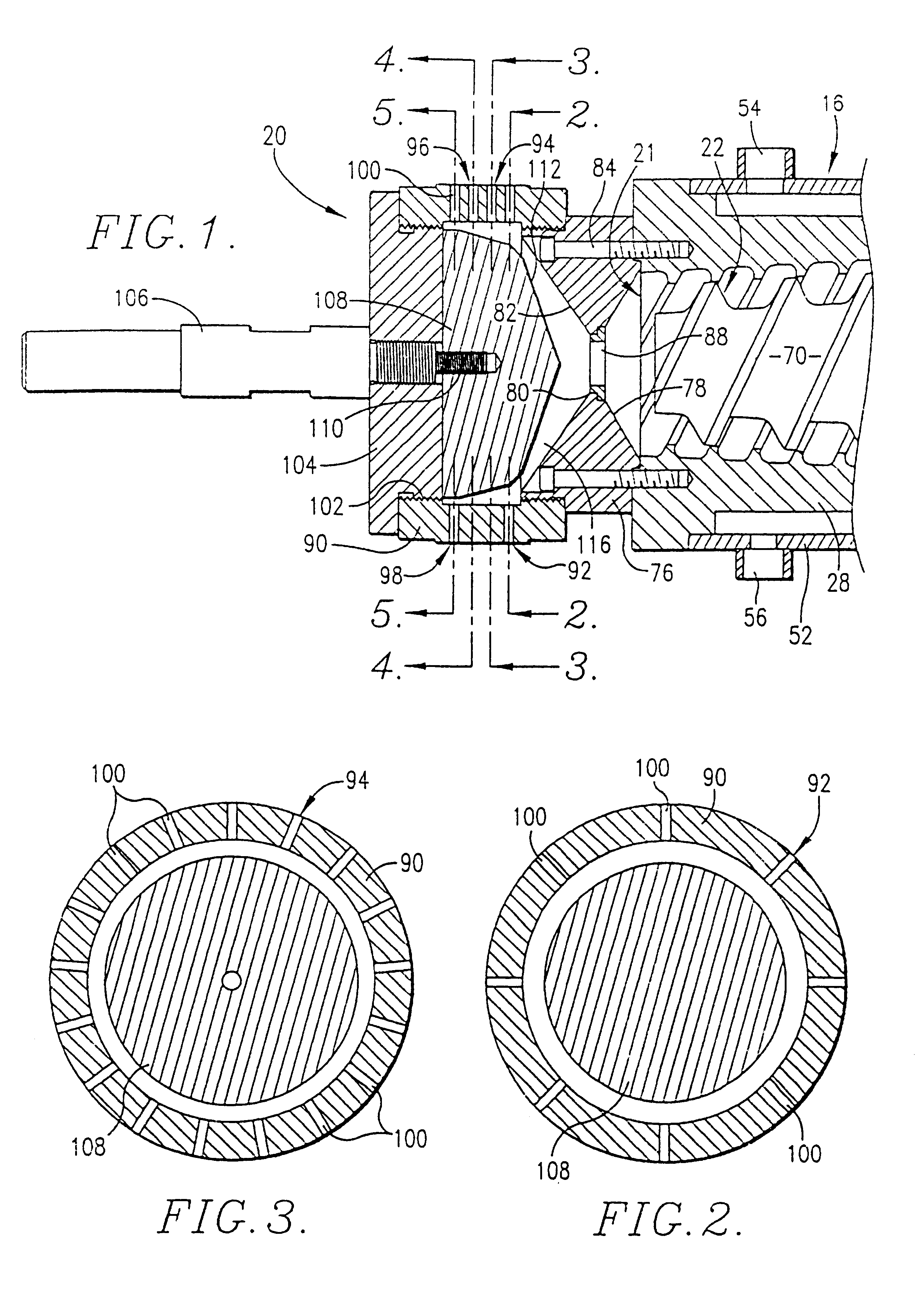

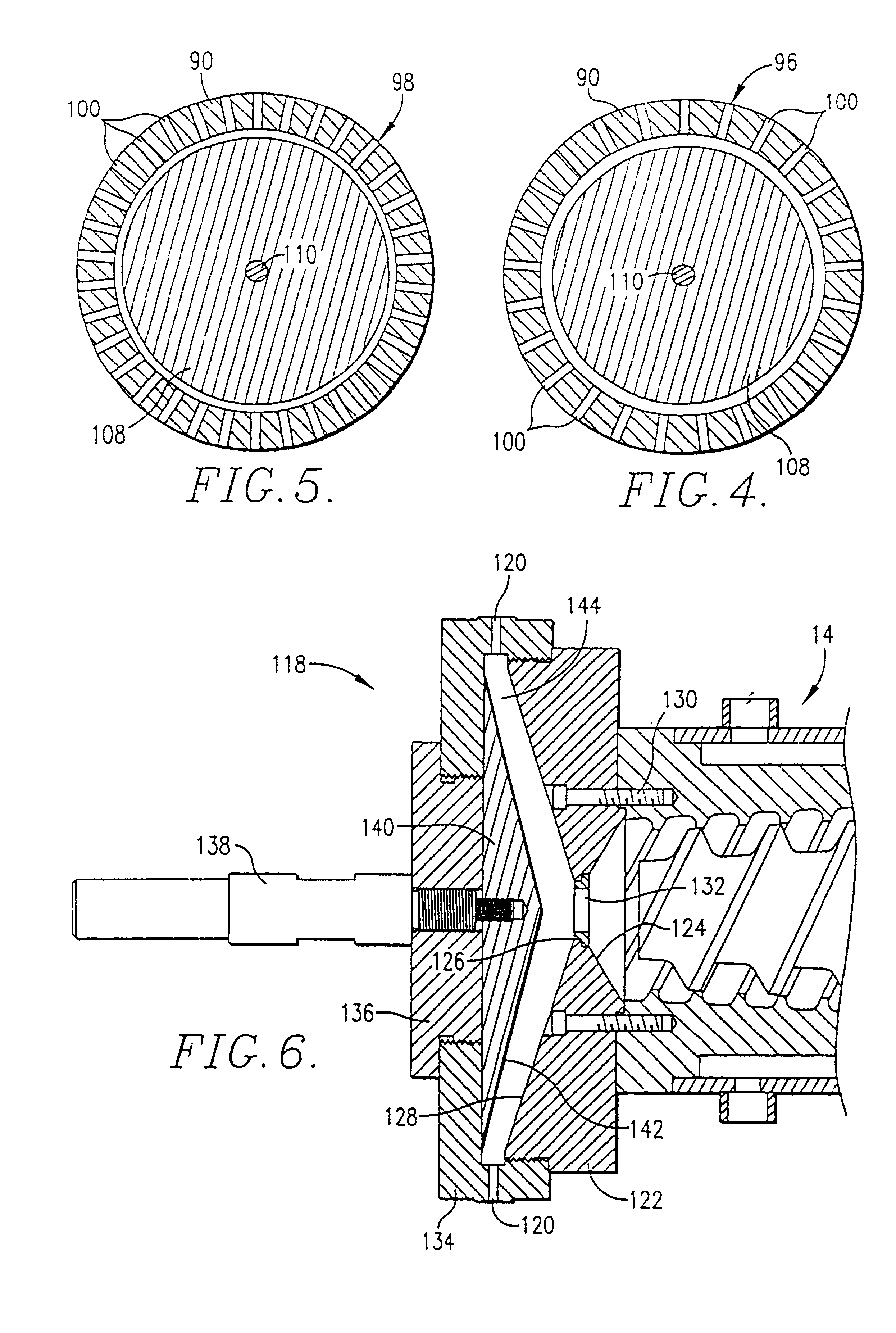

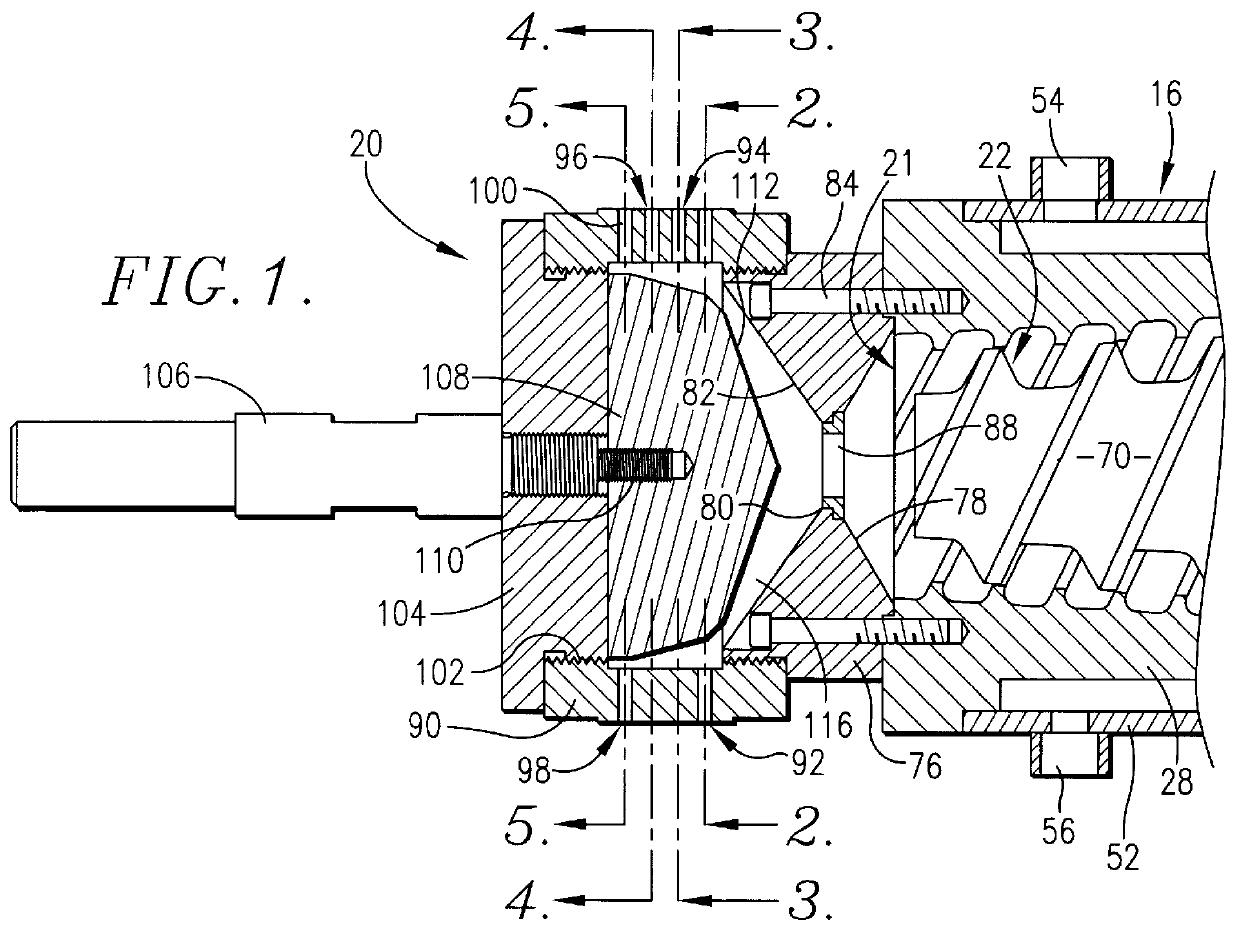

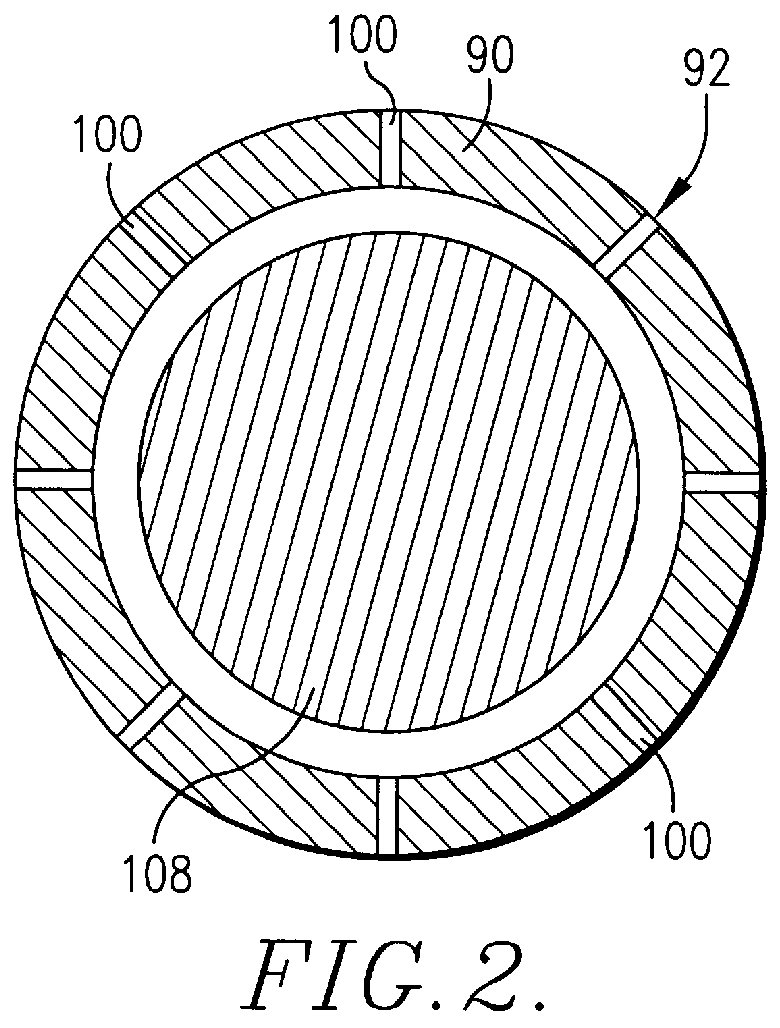

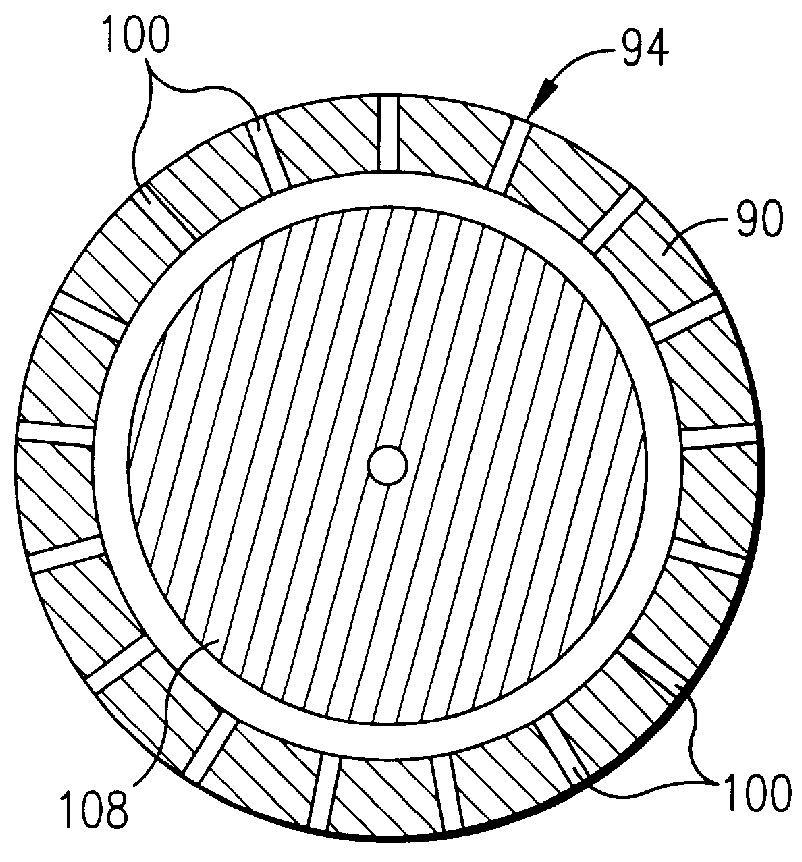

An improved short-length, high-speed extrusion device (10) is provided with having increased capacities and the capability of producing high quality extrudates with improved density and pellet integrity properties. The device (10) includes an extruder (14) equipped with a peripheral die (20,118), the latter having die outlet openings (100,120) oriented generally transverse to the longitudinal axis of the extruder barrel (16). The die (20) has a plurality of axially spaced series (92-98) of openings (100), wherein each series (92-98) has a different number of openings (100). Alternately, the die (118) is of radially enlarged design relative to the extruder barrel (16) and has only a single series of openings (120). In both instances, an internal flow-directing bullet (108,140) is positioned within the corresponding die (20,118) in order to smoothly direct flow of product from the outlet (21) of the barrel (16) to the transversely oriented die outlet openings (100,120).

Owner:WENGER MANUFACTURING INC

Short length tapered extrusion cooking apparatus having peripheral die

InactiveUS6016742ASmooth transitionConfectioneryCeramic shaping apparatusVolumetric Mass DensityEngineering

An improved short-length, high-speed extrusion device (10) is provided with having increased capacities and the capability of producing high quality extrudates with improved density and pellet integrity properties. The device (10) includes an extruder (14) equipped with a peripheral die (20,118), the latter having die outlet openings (100,120) oriented generally transverse to the longitudinal axis of the extruder barrel (16). The die (20) has a plurality of axially spaced series (92-98) of openings (100), wherein each series (92-98) has a different number of openings (100). Alternately, the die (118) is of radially enlarged design relative to the extruder barrel (16) and has only a single series of openings (120). In both instances, an internal flow-directing bullet (108,140) is positioned within the corresponding die (20,118) in order to smoothly direct flow of product from the outlet (21) of the barrel (16) to the transversely oriented die outlet openings (100,120).

Owner:WENGER MANUFACTURING INC

Extruded, highly cooked, non-sticky starch products

Owner:WENGER MFG LLC

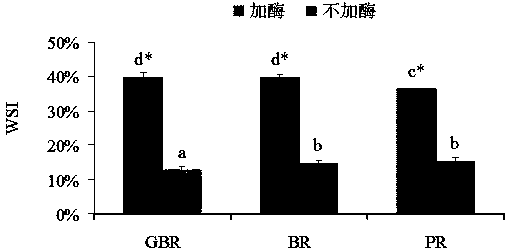

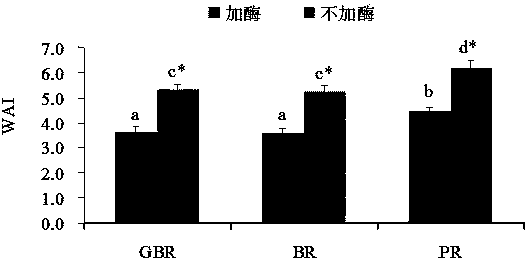

Processing method for improving digestibility and reconstituability of instant brown rice powder

The invention discloses a processing method for improving digestibility and reconstituability of instant brown rice powder. The processing method comprises the following steps: (1) germinating rice and then removing rich husk so as to obtain germinated brown rice; (2) crushing the germinated brown rice, sieving the crushed germinated brown rice with a 60-mesh sieve, sprinkling a high-temperature alpha-amylase weak solution into obtained brown rice powder, adjusting moisture content to 10 to 20%, carrying out uniform mixing, then carrying out sealing with a sealing bag, placing the sealing bag in a refrigerator with a temperature of 4 DEG C and balancing moisture for 10 to 20 h, wherein the sprinkling amount of the alpha-amylase weak solution is 40 to 60 U / g, i.e., 40 to 60 U units of the alpha-amylase weak solution is sprinkled into each g of the brown rice powder; and (3) after moisture balancing, carrying out extrusion cooking and crushing so as to obtain the instant brown rice powder. According to the invention, through effective combination of germination, enzymatic hydrolysis with high-temperature alpha-amylase and extrusion cooking, digestibility and reconstituability of the instant brown rice powder are improved to a greatest extent.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Extruded, highly cooked, non-sticky starch products

InactiveUS20120171346A1High degreeLow viscosityBaking mixturesAnimal feeding stuffPre treatmentViscosity

Improved extruded starch-bearing products (e.g., starches, starch-bearing legumes, starch-bearing grains and formulations containing any of the foregoing) are provided having relatively high cook values and low cold water viscosities. The products are prepared by initial preconditioning to partially cook the starting material(s), followed by low shear extrusion cooking, with a total STE / SME ratio of at least about 4.

Owner:WENGER MANUFACTURING INC

Processing method, device and saccharification method for starch syrup raw material by extruding and adding enzyme

The invention belongs to a processing method, a processing apparatus and saccharification method of starch sirup material of the extrusion cooking additive enzyme preparation in the starch sugar process. The main technical characteristics are: providing extrusion cooking apparatus of amylum sirup material of the additive enzyme preparation, the best parameter of the extrusion cooking system and glycation method of using the extrusion cooking starch sugar, smoothening the saccharification, and filtration of the saccharification liquid. Compared to present starch sirup production by using two kinds of enzyme not extrusion cooking starch sirup material, the invention reduces the saccharification time to 1 / 2 to 1 / 3 when achieving the same saccharification liquid DE value by not extrusion cooking starch sirup material.

Owner:SHANDONG UNIV OF TECH

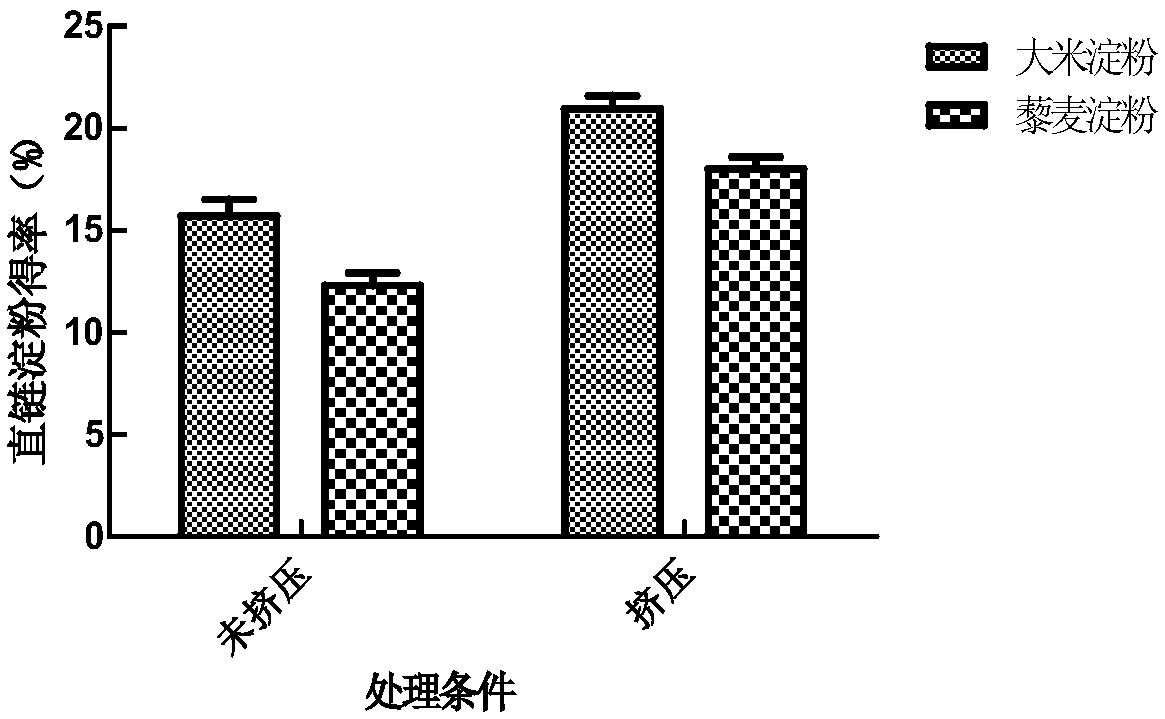

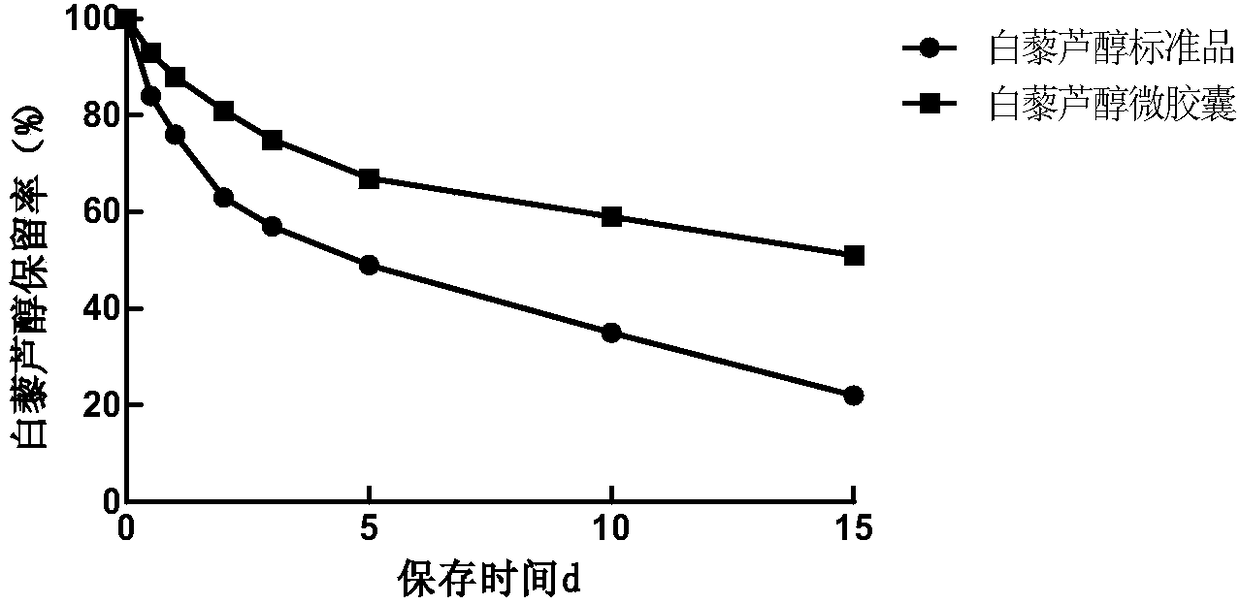

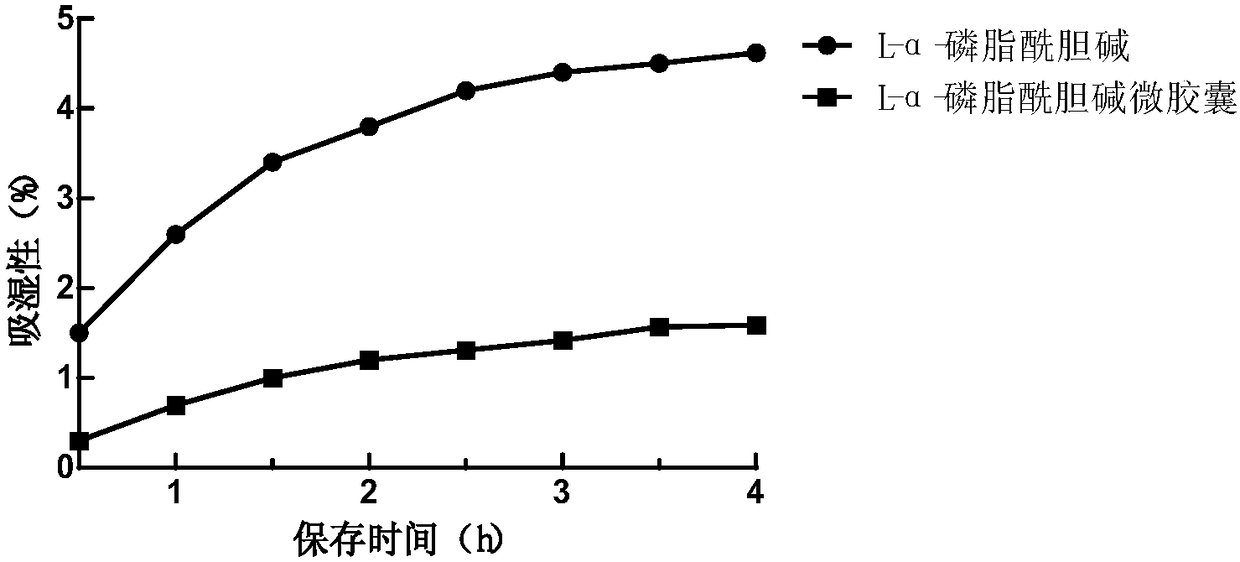

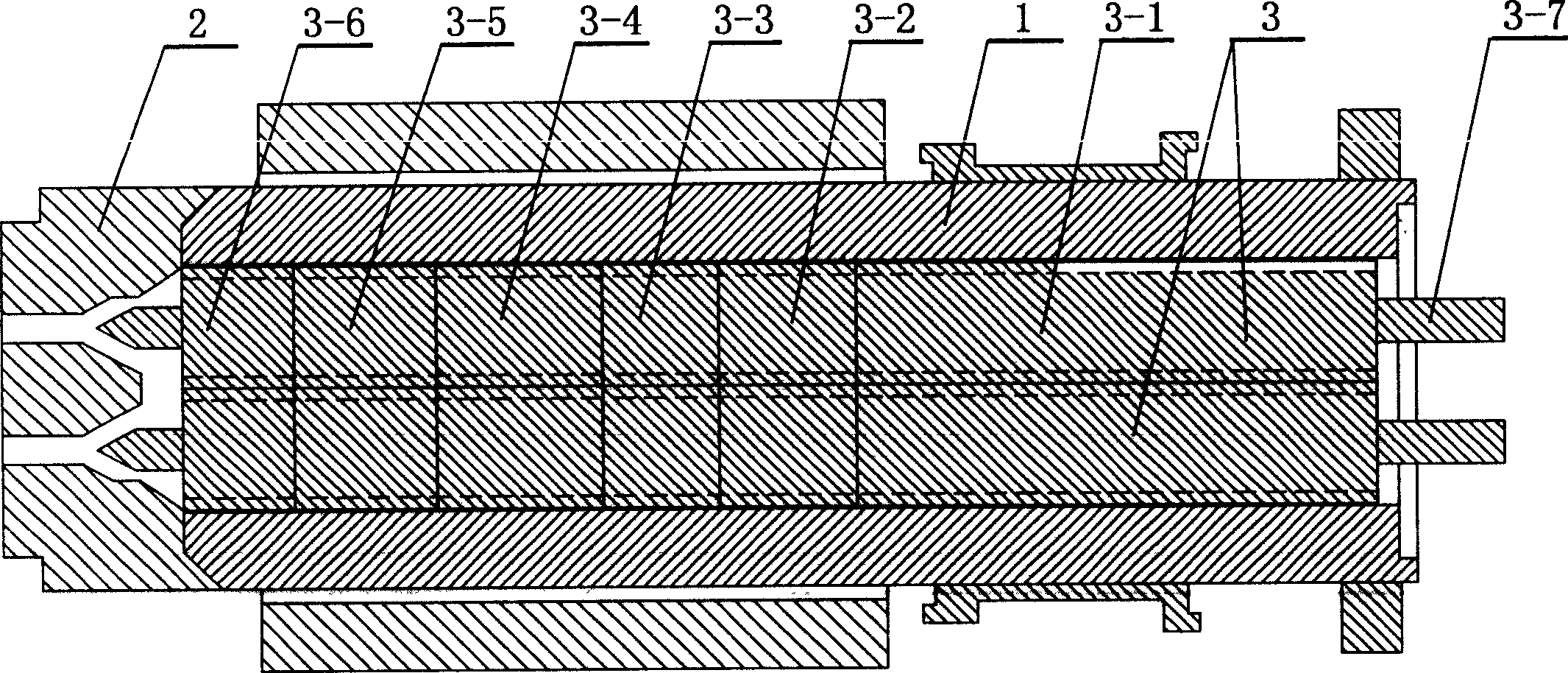

Method for preparing microcapsules from A-type crystalline structure starch entrapped resveratrol and L-alpha-phosphatidylcholine

InactiveCN108244626AEasy extractionImprove utilizationFood shapingNatural extract food ingredientsSolubilityWater baths

The invention discloses a method for preparing microcapsules from A-type crystalline structure starch entrapped resveratrol and L-alpha-phosphatidylcholine. The method comprises the following steps ofusing chenopodium quinoa will / rice as raw materials, activating the chenopodium quinoa will / rice by a twin-screw extrusion cooking machine, performing drying and crushing, extracting starch in activated chenopodium quinoa will / rice by an alkaline method, preparing chenopodium quinoa will / rice amylose by a repeated crystallization method, preparing the amylose into a solution, adding 20-40% of resveratrol and an L-alpha-phosphatidylcholine solution, adopting ultrasonic wave water bath for assisting in entrapping, and through spray drying, making the amylose microcapsules. The amylose microcapsules can restrain the oxidation of the resveratrol and the L-alpha-phosphatidylcholine, improves the stability of the resveratrol and the L-alpha-phosphatidylcholine, solves the problems of being poorin water solubility of the resveratrol and the L-alpha-phosphatidylcholine, sensitive to irradiation of light and low in biological availability, protects the resveratrol and the L-alpha-phosphatidylcholine to the greater extent, and increases the nutrient value.

Owner:SHENYANG NORMAL UNIV

Process for eliminating alkaloid and peculiar smell from fry starch of konjak

Owner:SOUTHWEST AGRICULTURAL UNIVERSITY

Method for preparing high activity alfalfa food fiber

InactiveCN1586306AChange the backward status of the preparation processImprove physiological activityFood preparationFiberEngineering

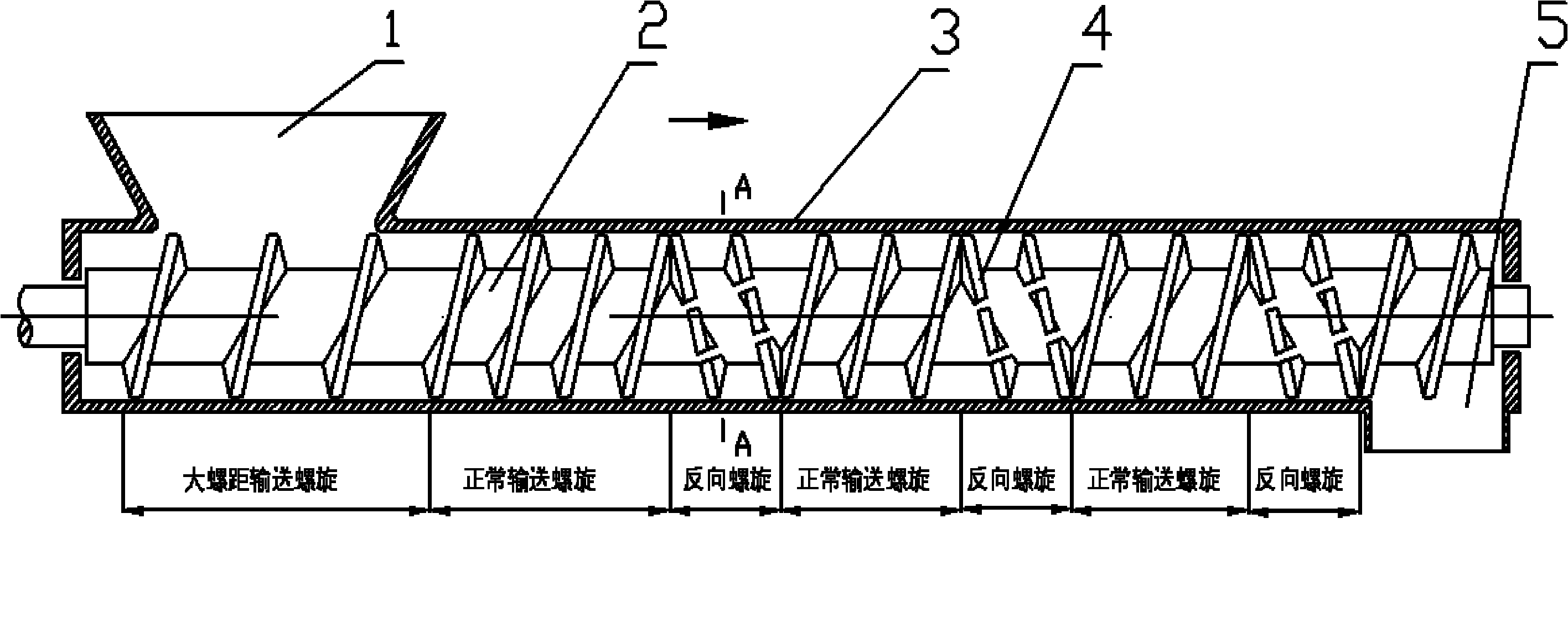

The present invention utilizes extrusion and steaming technology and superfine crushing technology in denaturing treatment of alfalfa food fiber. Especially, the screw structure in the double screw extruder is improved from available four section structure into six section distribution structure including material feeding section, smelting section, the first extruding section, homogenizing section, the second extruding section and reverse retarding section. The said technology can obtain alfalfa food fiber with high physiological activity and raise the technological stability of double screw extruder.

Owner:张宁生

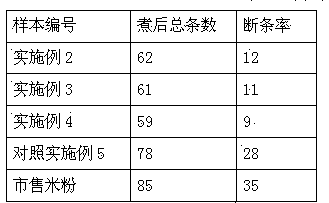

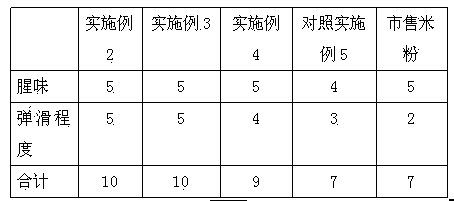

Fishy smell-free difficult-to-break fish rice noodles and production method for same

ActiveCN103689672AReduce fishy smellGreat tasteFood ingredient functionsFood preparationBiotechnologyAmylase

The invention discloses fishy smell-free difficult-to-break fish rice noodles and a production method for the same. Based on the total weight of raw materials, the rice noodles contain 10 to 30 percent of fish proteins, 30 to 60 percent of rice and 10 to 30 percent of water, wherein the rice is treated by alpha-amylases and cyclodextrin glycosyltransferase after being impregnated by the water. The production method comprises the following steps: 1, impregnating the rice for 10 to 48 hours at room temperature by using water; 2, grinding the completely impregnated rice by using a refiner; 3, treating rice milk for 1 to 4 hours under the conditions of 30 to 65 DEG C and pH of 5 to 8 by using the alpha-amylases, and enzymatically decomposing the treated rice milk for 10 to 300 minutes under the conditions of 55 to 65 DEG C and pH of 6 to 9 to obtain enzymatically-decomposed rice milk by using the cyclodextrin glycosyltransferase; 4, grinding the fish at 0 to 4 DEG C; 5, uniformly mixing the ground fish and the fermented rice milk by using a pulping machine, and extruding the mixture into strips at temperature of 80 to 90 DEG C by using an extrusion cooking type flour mill; 6, freezing the obtained strip-type rice noodles to 0 to -18 DEG C; 7, unfreezing the strip-type rice noodles; 8, processing the strip-type rice noodles to obtain dry or wet rice noodles for selling by using a conventional method.

Owner:抚州新天下知识产权咨询管理有限公司

Textured fish protein

InactiveCN101731447AFacilitate subsequent processingAdd flavorProteins working-up by texturisingAnimal proteins working-upSquidMixed materials

The invention belongs to the technical field of thermoplastic extruded food and particularly relates to textured fish protein using leftover materials of sleeve-fishes as a raw material. The textured fish protein is characterized in that: the textured fish protein uses the leftover materials of the sleeve-fishes as a main material and soy protein as an auxiliary material. A process for preparing the textured fish protein comprises the following steps: a raw material treating step for cleaning the leftover materials of the sleeve-fishes with water and stirring the cleaned leftover materials into slurry minced meat; a step for mixing the main material and the auxiliary material, namely, adding 1,200 to 1,300 parts by weight of soy protein into 6,000 parts by weight of slurry minced meat foruniform mixing; an extruding and steaming step for delivering the uniformly mixed material into a twin screw extruder for extrusion and steaming, wherein the temperature of a machine barrel at the tail end of the twin screw extruder is 150 DEG C and the rotational speed of a screw rod is 200 revolutions per minute; and a drying step for drying the extruded and steamed material at the temperature of 60 DEG C and under the normal pressure until the water content of the material is not over 15 percent to finally prepare the textured fish protein.

Owner:ZHEJIANG OCEAN UNIV

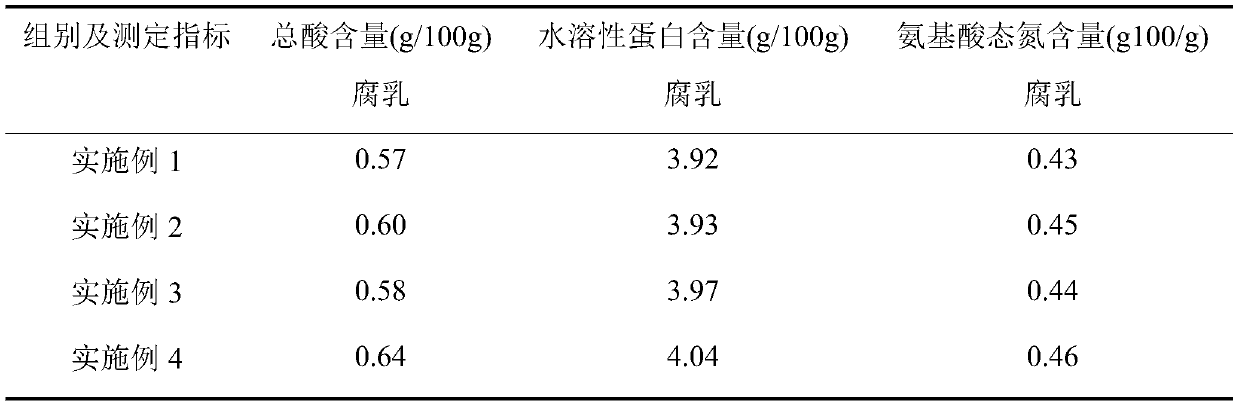

Method for preparing red and square probiotic fermented bean curds by using bean dregs as raw material

PendingCN110810530AGreat tastePromote absorptionCheese manufactureFood scienceBiotechnologySoybean product

The invention relates to a method for preparing red and square probiotic fermented bean curds by using bean dregs as a raw material, and belongs to the technical field of fermented food. The bean dregs and yellow slurry are adopted as raw materials to prepare the red and square probiotic fermented bean curds, an extrusion cooking technology and an ultra-fine crushing technology are utilized to improve the gel characteristics of protein in the bean dregs and refine dietary fiber in the bean dregs, and the technical problem of the rough texture of bean dregs fermented bean curds is solved; an ultrasonic pre-treatment technology and a glutamine transaminase cross-linking technology are combined so as to further enhance the gel properties of the protein and give a delicate sensory characteristic to blocks of the fermented bean curds, the formability of the bean dregs fermented bean curds is enhanced through the characteristic that mucopolysaccharide is produced by a starter strain, and meanwhile probiotic fermentation is utilized to give certain probiotic characteristics to the bean dregs fermented bean curds, so that a new product is obtained; and the problem of recycling of by-products which are produced during bean curd production is solved, high-value utilization of the bean dregs and yellow slurry is achieved, the added value of by-products of soybean products is improved, waste emission is reduced, environmental protection is achieved, and the production cost of the bean curds is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

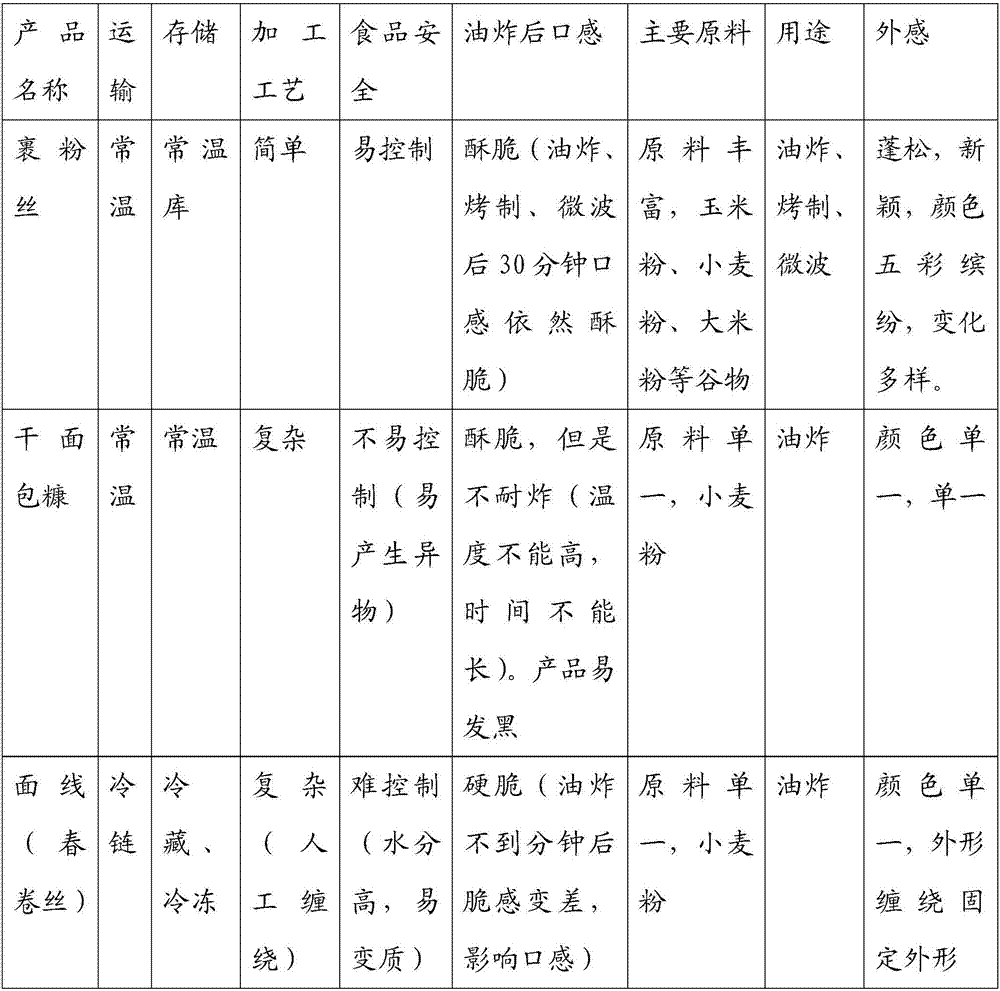

Coating vermicelli used for coating food, and production method thereof

InactiveCN106858344AReduce moisture contentCrispy tasteFood ingredient as taste affecting agentFood shapingFood additiveAquatic product

The invention discloses a coating vermicelli used for coating food, and a production method thereof. According to the production method, cereal powder or a mixture containing cereal powder and food additives is taken as a raw material; the raw material is subjected to extrusion cooking, is subjected to extrusion using a mould, and then is cut using a turning cut blade so as to obtain the coating vermicelli. The length of the coating vermicelli ranges from 5 to 50mm, the diameter of the coating vermicelli ranges from 0.1 to 6mm, and the water content of the coating vermicelli ranges from 8 to 16wt%. The length and the diameter of the coating vermicelli are preferable; the water content is low; room temperature transportation can be realized; the appearance of products coated with the coating vermicelli is novel, the mouthfeel is crisp, the kind is various, application range is wide, the coating vermicelli can be used for coating fried food, can be used for coating aquatic products, meat products, and vegetable products instead of conventional vermicelli products (spring roll vermicelli). Operation of coating of food with the coating vermicelli is simple; equipment production can be realized; and production efficiency is increased.

Owner:济南佳农食品有限公司

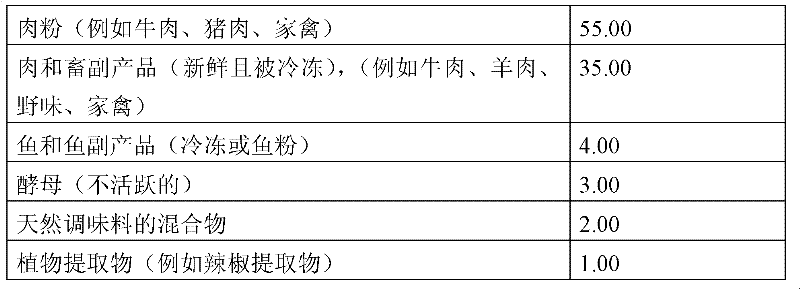

Meat-based semi-moist feed product and method for its production

A nutritionally suitable, semi-moist animal foodstuff which is similar to natural animal food meats and having a very high meat content is provided, which has good acceptance with the animal food animal and a corresponding structure. The semi-moist animal food product does not need cereal contents, cereal products and binders. The novel semi-moist animal food product is produced by extrusion cooking, wherein the extruder is charged at least with the following ingredients: a) at least one component of the group dry meat, meat meal, dry fish, fish meal, b) meat and / or fish, c) optionally water or steam, where not introduced by or in combination with a) or b). Components a), b) and c) together make up at least 80% by weight of the ingredient mass. In addition, additives, such as flavourings, probiotics and the like can be present.

Owner:VITAKRAFT VERKE VJURMANN & ZON GMBKH & KO

Method for squeezing auxiliary materials of enzyme added beer, processing installation, and saccharification method

InactiveCN101050406ACompletely degradedHigh reducing sugar contentWort preparationStarch degradationEnzyme

This invention discloses processing method, processing apparatus and saccharification method for beer adjunct added with enzyme preparation by squeezing and cooking. This invention provides squeezing and cooking apparatus for adding enzyme preparation to beer adjunct, reasonable parameters of squeezing and cooking system for adding enzyme preparation to beer adjunct, and saccharification method for beer adjunct added with enzyme preparation. During the saccharification process, the mash of beer adjunct added with enzyme preparation has such advantages as adequate starch degradation, short saccharification time, and high extract yield. Compared with the present double-mash saccharification method and enzyme addition saccharification method, the method in this invention omits beer adjunct cooking and pasting process and apparatus, and adds malt powder and beer adjunct powder or mince added with enzyme preparation into the water in the saccharification pot simultaneously for saccharification, which can save energy, lower cost, and increase beer productivity.

Owner:SHANDONG UNIV OF TECH

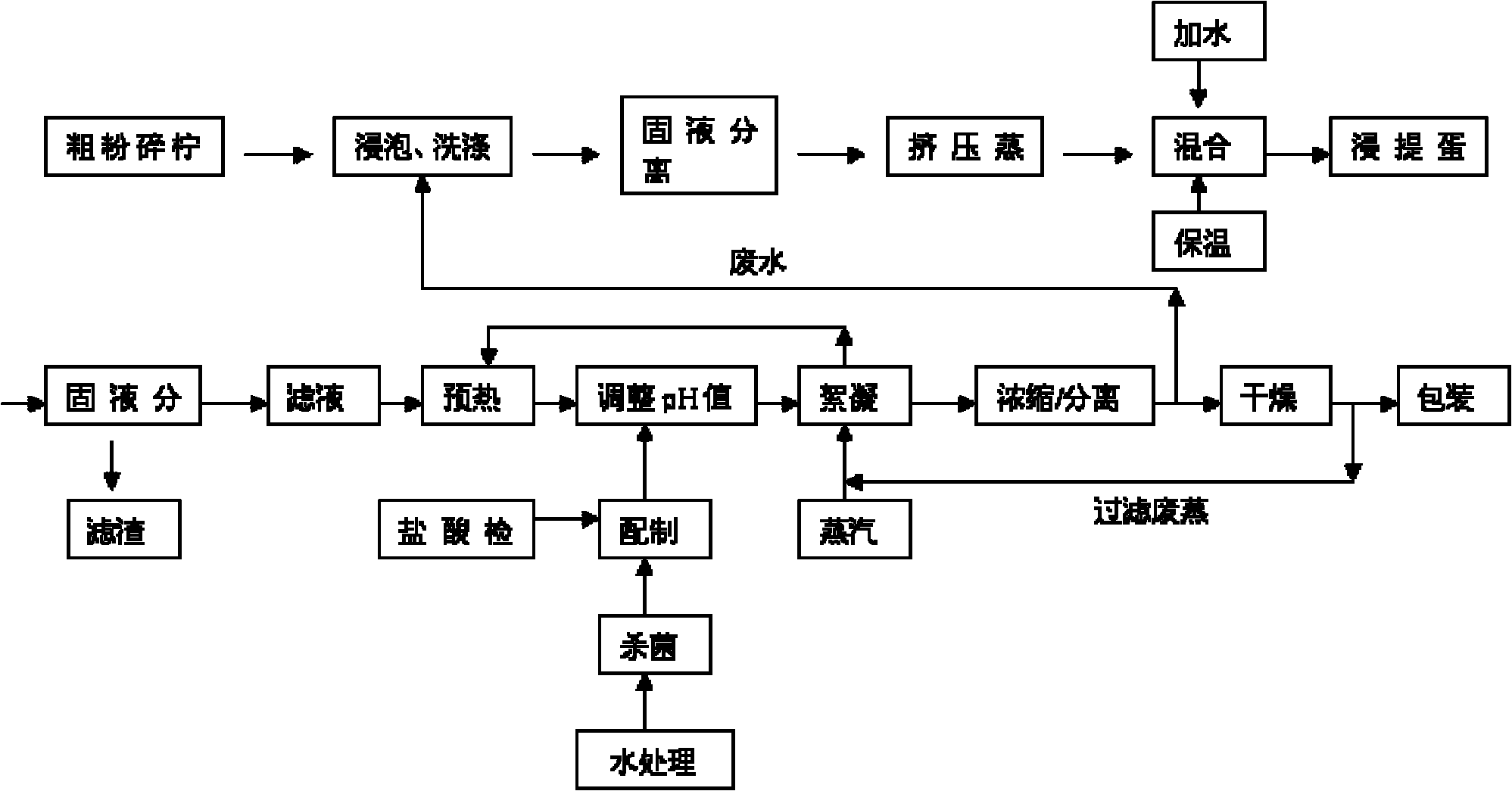

Extraction method of caragana microphylla proteins

The invention relates to an extraction method of caragana microphylla proteins, comprising the following steps of: preprocessing flowers and leaves or twigs of dry caragana microphylla; then washing; soaking; spirally conveying; carrying out extrusion cooking; carrying out mixed lixiviation; roughly filtering; finely filtering; flocculating; concentrating / separating; and drying so as to obtain the caragana microphylla proteins. The prepared caragana microphylla proteins have green color (as glycoprotein), extraction ratio of more than 80 percent and crude protein content of more than 90 percent, can not only be used as feeds, but also be used for industries, i.e. foods, pharmaceuticals, cosmetics, and the like, through further processing, and has very wide application prospect.

Owner:TIANJIN UNIV OF SCI & TECH

Process for processing novel concentrated fish protein synthetic food

The invention relates to a process for processing a novel concentrated fish protein synthetic food, which comprises the following steps of: a. putting raw material small trash fish or a fish product processing leftover material into a fish collecting machine for separating bones to obtain minced fish; b. processing the minced fish by a double-shaft extrusion cooking machine to form a base material, controlling the temperature of a cavity of the cooking machine to be between 150 DEG C and 170 DEG C and controlling the revolution of a screw rod of the cooking machine to be between 250rpm and 280rpm; c. leading the base material to stand for rehydration processing for one hour and then leaching for standby; d. cutting the base material into a block of 3mm<3>-5mm<3>; e. adding flavoring liquid into the block-shaped base material and uniformly mixing; f. bottling, sealing, sterilizing and cooling. The method can produce the novel food which has toughness texture and can be directly eaten by utilizing the residual fish or trash fish in the manufacture of fish products, utilizes fish resources at maximum and has simple process, easy operation and control and low production cost.

Owner:DALIAN FISHERIES UNIVERSITY

Sour paste fish meat rice noodles and preparation method thereof

ActiveCN103689370ASimple processReduce fishy smellFood ingredient functionsFood preparationBiotechnologyLactic acid bacterium

The invention discloses fish meat rice noodles which comprise the following raw materials by weight: 10%-30% of fish meat protein, 30%-60% of rice and 10%-30% of water, wherein the rice is fermented by lactic acid bacteria. The preparation method comprises the following steps: (1) soaking 30%-60% of the rice in 10%-30% of water at room temperature for 10-48 hours; (2) grinding the soaked rice by a grinding machine; (3) heating rice paste to 30-50 DEG C and inoculating the lactic acid bacteria under the pH value of 5-6.5 for fermenting until the pH value of the rice paste is 2-6; (4) mincing 10%-30% of fish meat at 0-4 DEG C; (5) uniformly mixing the minced fish meat with the fermented rice paste, and processing by a chopper for 30-300 minutes; (6) extruding chopped fish meat rice paste by an extrusion cooking type rice noodle machine at 80-90 DEG C to form strips, and ageing and drying by a conventional method.

Owner:抚州新天下知识产权咨询管理有限公司

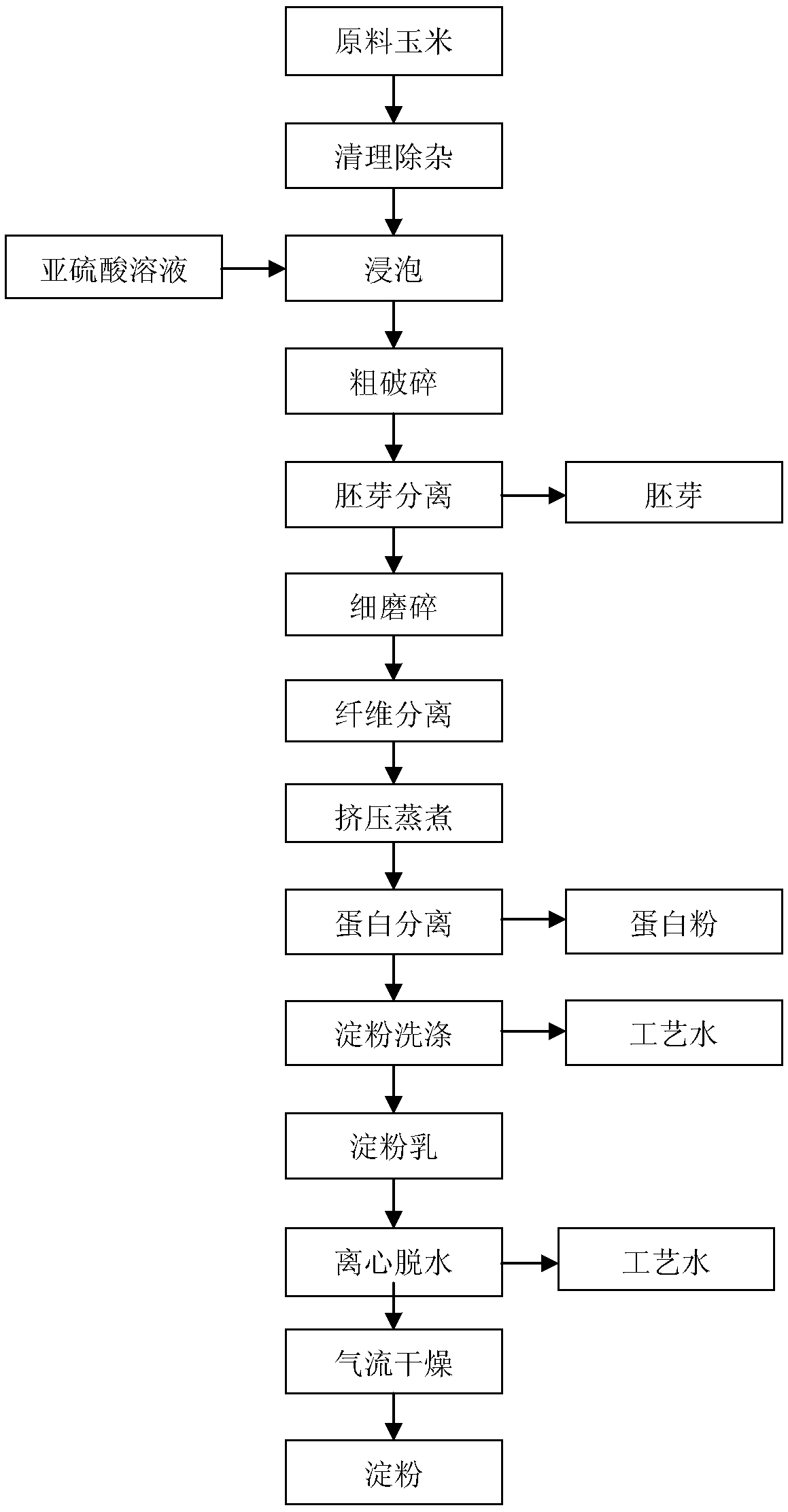

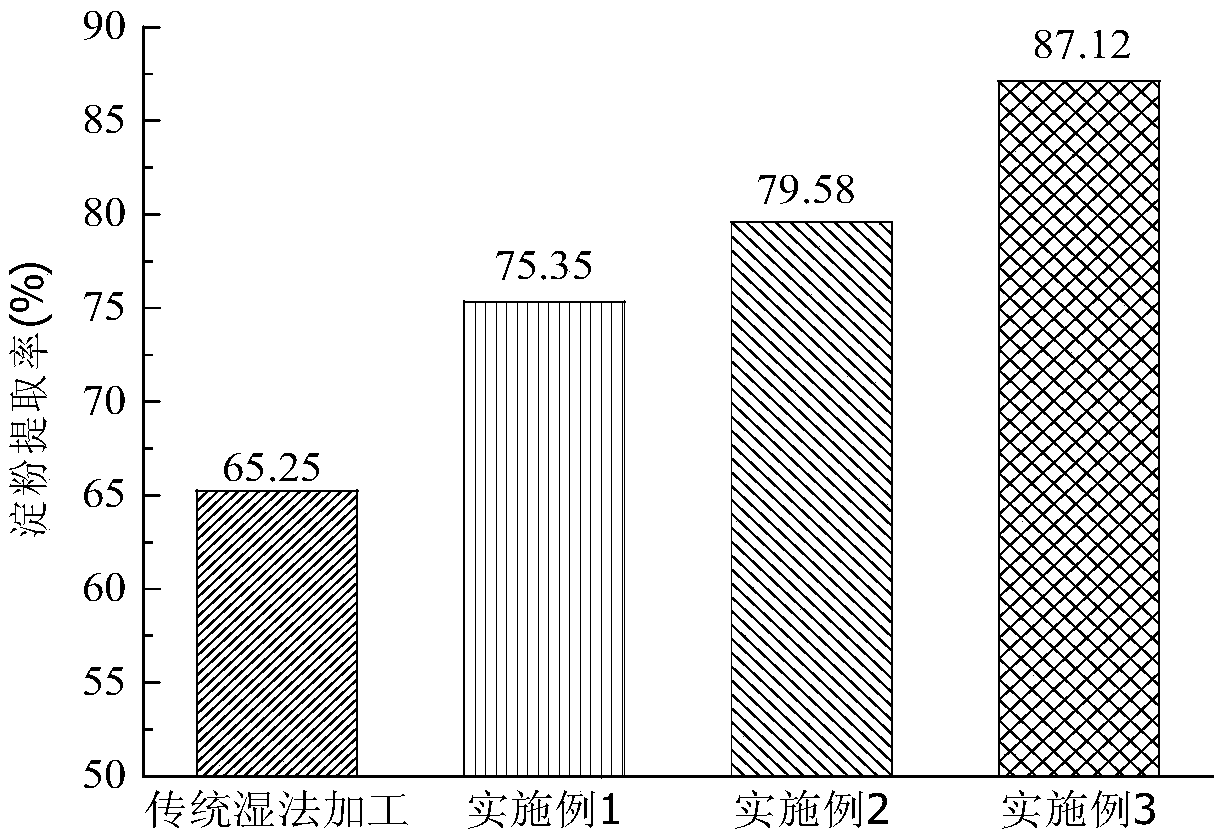

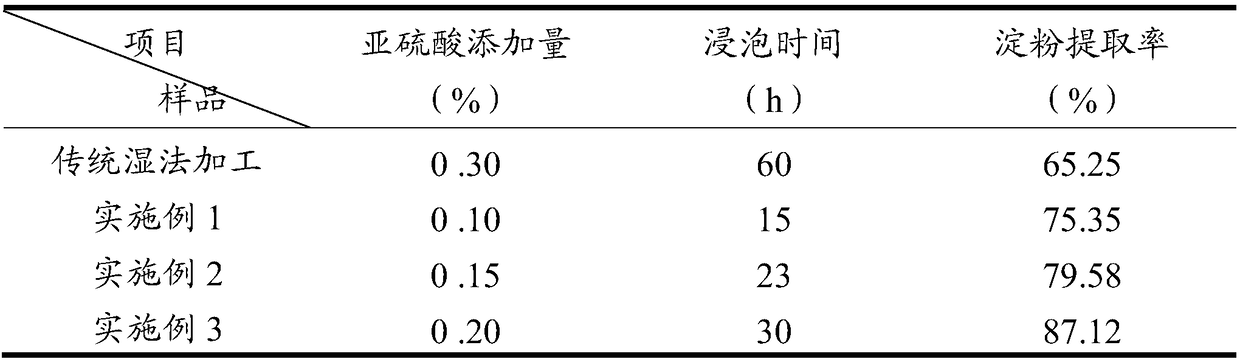

Method for improving extraction rate of corn starch by virtue of extrusion and cooking

The invention relates to a method for improving the extraction rate of corn starch by virtue of extrusion and cooking. The method adopts an extrusion and cooking technology to process the corn starch.The temperature of six sections of an extruder is as follows: the temperature of section I is 25 to 35 DEG C, the temperature of the section II is 30 to 40 DEG C, the temperature of the section III is 35 to 45 DEG C, the temperature of the section IV is 40 to 50 DEG C, the temperature of the section V is 45 to 55 DEG C, the temperature of the section VI is 50 to 60 DEG C, the screw revolution is150 to 350 rpm, the material water content is 20 to 40 percent, and an aperture of a grinding head of the extruder is in a circular shape or a rectangular shape. Compared with the traditional wet-method corn starch extraction process, on the premise of ensuring the purity of the starch, the soaking time of the corn can be reduced by 50.00 percent, the addition amount of the sulfinic acid is reduced by 33.33 percent, the starch extraction rate is increased by 33.52 percent, and the extraction rate of the corn starch is significantly improved. The equipment used in the method is single, the processing method is simple and easy, the production cost is low, the time consumption is short, and the industrialized production is facilitated.

Owner:SHENYANG NORMAL UNIV

Processing method of normal temperature stored and transported mashed potato

The invention belongs to the technical field of food processing, and concretely relates to a processing method of normal temperature stored and transported mashed potato. The method comprises the following steps: cleaning fresh potatoes, peeling the cleaned potatoes, cutting the peeled potatoes to form 3-5 mm square blocks, carrying out extruding steaming cooking on the square blocks, allowing the sterilized and cooled cooked mashed potato to go through a closed aseptic filling machine, and filling and sealing the machine to realize normal temperature storage, transportation and selling. The processing method of the mashed potato, combining a double screw extruding boiling technology with an aseptic filling and sealing technology, changes the present production technologies of the mashed potato, is a high-efficiency processing method of the aseptic, cooked and normal temperature stored and transported mashed potato with long shelf life, and can solve the problems of flavor substance loss, high energy consumption and large logistics cost of present mashed potato production methods.

Owner:HENAN ACAD OF AGRI SCI

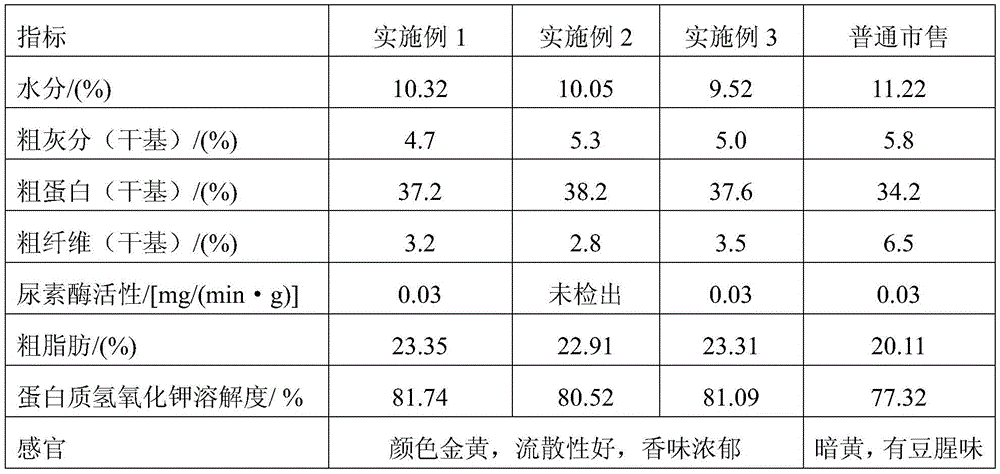

Preparing method for peeled puffing full-fat soybean meal capable of substituting fish meal

InactiveCN105595193AReduced activityReduce anti-nutritional factorsWorking-up animal fodderFood scienceFodderSoybean meal

The invention discloses a preparing method for peeled puffing full-fat soybean meal capable of substituting fish meal and belongs to the field of processing methods for soybean feed to solve the problem that the demanding amount of fish meal is increased day by day, and a substitutable product urgently needs to be sought in market. The preparing method comprises the steps of peeling, air sorting, grinding, conditioning, extrusion cooking, cold air cooling, finished product packaging and the like. The preparing method is used for preparing the peeled puffing full-fat soybean meal capable of substituting fish meal.

Owner:SHANDONG SANWEI OIL GRP CO LTD

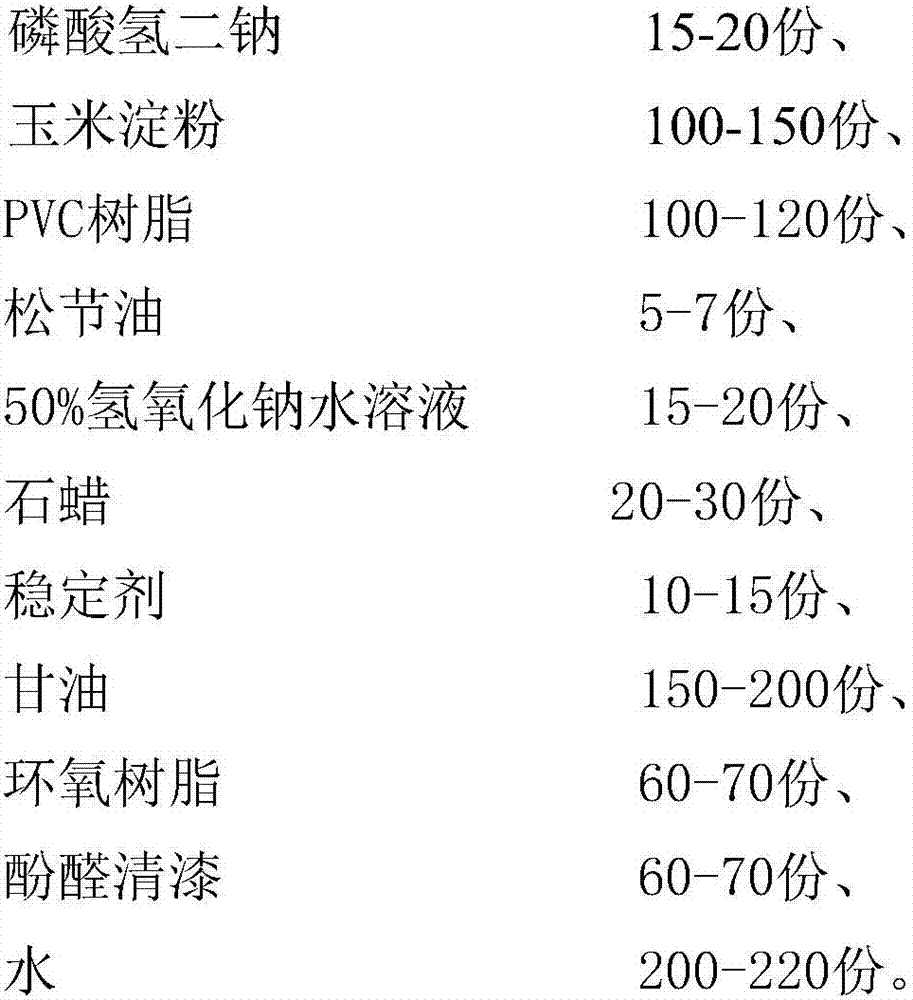

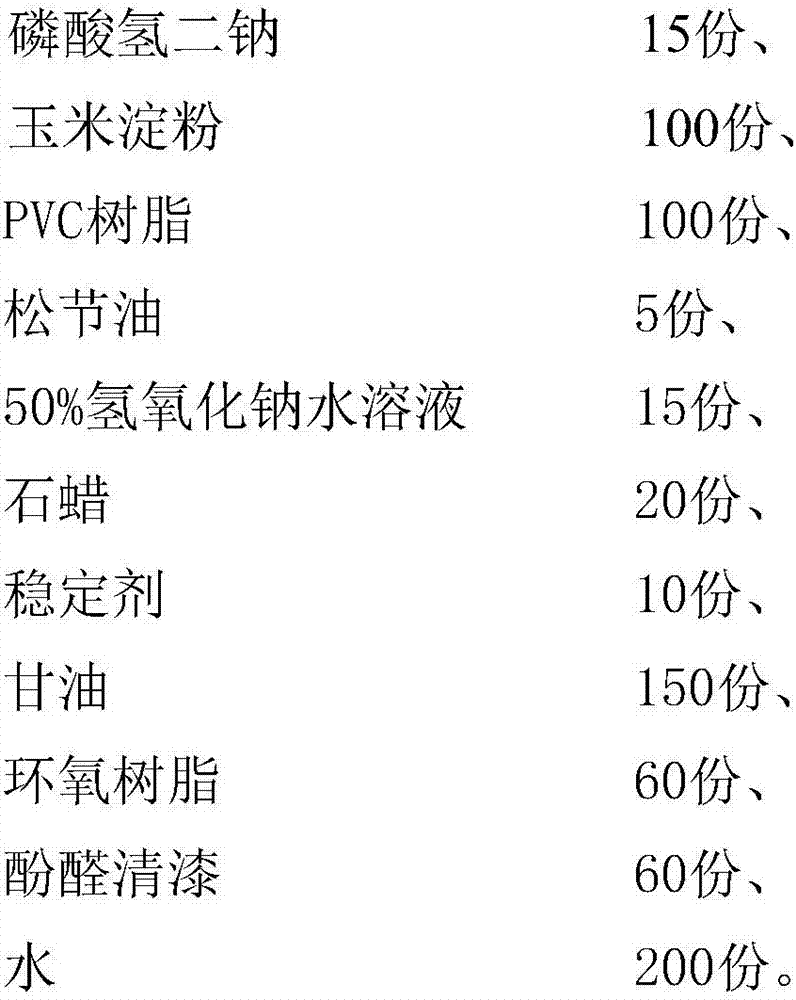

Extrusion molding process for pore-free PVC pipe

InactiveCN107498828AFill up quicklyImprove insulation performancePlastic/resin/waxes insulatorsTubular articlesEpoxyThermal expansion

An extrusion molding process for a pore-free PVC pipe is characterized in that according to a pipe formula, a PVC resin and epoxy resin copolymer, an impact modifier, a stabilizer, a processing modifier, a filling agent, a pigment and an outer lubricant are adopted, and the extrusion molding process specifically comprises the following steps of preparing of various materials, weighing, kneading, extrusion pelleting, extrusion molding, cooling molding, cutting, checking and obtaining of a finished product. The plastic pipe has remarkable beneficial effects that the relative density is small and is 1 / 4-1 / 7 that of metal; the electric insulation property and the chemical stability are excellent; installation and construction are convenient, and maintaining is easy; the unit energy consumption is low, in the process of extrusion, conditions are provided for molding through constant changing for the temperature, expanding with heat and contracting with cold are carried out several times, and the materials can be combined more tightly through contracting and expanding; and cooling is carried out through cooling liquid, paraffin in the cooling liquid can rapidly fill up pores, and after molding, a pore-free state is achieved.

Owner:安徽博泰塑业科技有限公司

Method for producing psudo-meats (artificial meats) by thermo-extruding, steaming and boiling tech.

InactiveCN1559294AChewyRational development and utilizationFood preservationFood preparationBiotechnologyMuscle tissue

A thermoplastic squeezing and steaming and boiling technique for preparing simulative meat from the leftover of different kinds of animal meat or the muscle tissue of aquatic animals is disclosed.

Owner:刘俊荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com