Method for preparing microcapsules from A-type crystalline structure starch entrapped resveratrol and L-alpha-phosphatidylcholine

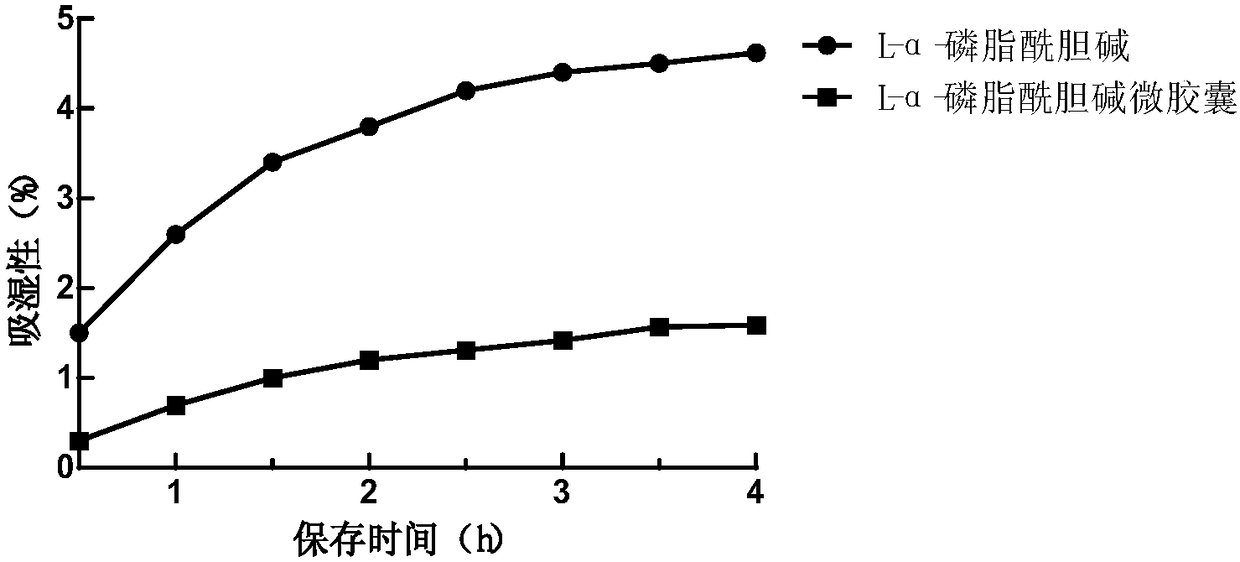

A technology of phosphatidylcholine and crystalline structure, which is applied in the field of preparing microcapsules by embedding resveratrol and L-α-phosphatidylcholine in A-type crystalline structure starch, can solve the problem of low embedding rate, high cost and non-green color and other problems, to achieve the effects of high nutritional value, reduced hygroscopicity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The application provides a method for preparing microcapsules by embedding resveratrol and L-α-phosphatidylcholine in type A crystalline structure starch, and the specific steps are as follows:

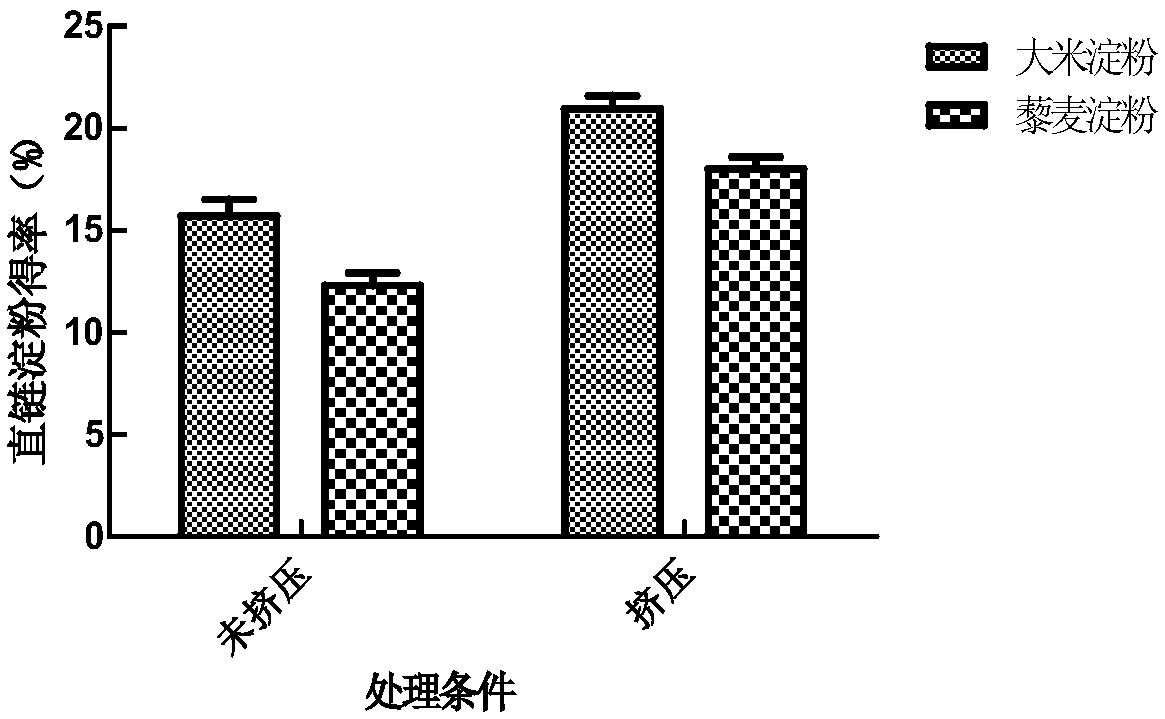

[0029] (1) Activation of raw materials: Grind quinoa / rice and activate it with a twin-screw extrusion cooking machine. The extrusion process parameters are: 40°C in zone I, 50°C in zone II, and 60°C in zone III. The screw speed is 200rpm, the solid feed rate is 15kg / h, and the moisture content of the material is 30%. The quinoa flour after extrusion is dried in an oven at 45°C for 12h, and when the moisture content is 10%, it is crushed through a 100-mesh sieve to obtain Whole Quinoa / Rice Flour

[0030] (2) Extraction of amylose: use alkaline method to extract the original starch in quinoa / rice whole powder, wet the original starch with a small amount of absolute ethanol, add NaOH solution, put it into a boiling water bath, heat and stir until completely dispersed, cool After ...

Embodiment 2

[0033] The application provides a method for preparing microcapsules by embedding resveratrol and L-α-phosphatidylcholine in type A crystalline structure starch, and the specific steps are as follows:

[0034] (1) Activation of raw materials: Grind quinoa / rice and activate it with a twin-screw extrusion cooking machine. The extrusion process parameters are: 40°C in zone I, 50°C in zone II, and 60°C in zone III. The screw speed is 300rpm, the solid feed rate is 20kg / h, and the moisture content of the material is 35%. The quinoa flour after extrusion is dried in an oven at 45°C for 12h, and when the moisture content is 10%, it is crushed through a 100-mesh sieve to obtain Whole Quinoa / Rice Flour.

[0035] (2) Extraction of amylose: use alkaline method to extract the original starch in quinoa / rice whole powder, wet the original starch with a small amount of absolute ethanol, add NaOH solution, put it into a boiling water bath, heat and stir until completely dispersed, cool After...

Embodiment 3

[0038] The application provides a method for preparing microcapsules by embedding resveratrol and L-α-phosphatidylcholine in type A crystalline structure starch, and the specific steps are as follows:

[0039] (1) Activation of raw materials: Grind quinoa / rice and activate it with a twin-screw extrusion cooking machine. The extrusion process parameters are: 40°C in zone I, 50°C in zone II, and 60°C in zone III. The screw speed is 400rpm, the solid feed rate is 25kg / h, and the moisture content of the material is 40%. The quinoa flour after extrusion is dried in an oven at 45°C for 12h, and when the moisture content is 10%, it is crushed through a 100-mesh sieve to obtain Whole Quinoa / Rice Flour.

[0040] (2) Extraction of amylose: use alkaline method to extract the original starch in quinoa / rice whole powder, wet the original starch with a small amount of absolute ethanol, add NaOH solution, put it into a boiling water bath, heat and stir until completely dispersed, cool After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com