Method for preparing red and square probiotic fermented bean curds by using bean dregs as raw material

A technology of probiotics and bean dregs, applied in the field of fermented food, can solve the problems of rough texture, environmental pollution, and poor formability of fermented bean curd, and achieve the effects of increasing value, increasing protein digestibility, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

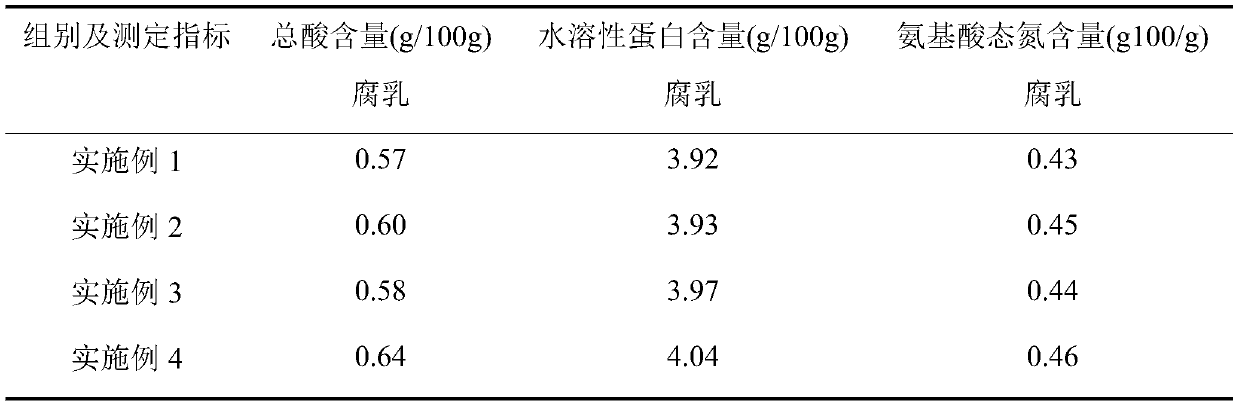

Examples

specific Embodiment approach 1

[0029] A method for preparing fermented fermented bean curd with bean dregs as raw material, comprising the steps of:

[0030] Step 1: using a drum centrifuge to dehydrate the bean dregs, the rotating speed of the drum is 3700-4000 rpm, the dehydration time is 15-20 minutes, and the water content of the bean dregs after dehydration is 21%-25%;

[0031] Step 2: Extruding and expanding the dehydrated bean dregs to obtain expanded materials, the screw speed of the extruder is 330-350 rpm, and the extrusion temperature is 150-170°C;

[0032] Step 3: The puffed material is coarsely pulverized by a high-speed pulverizer, passed through a 50-mesh sieve to obtain a coarse powder of bean dregs, and then the coarse powder of bean dregs is ultrafinely pulverized by a low-temperature ultrafine pulverizer to obtain an ultrafine pulverized bean dregs powder, and the pulverization time is 15 to 20 minutes; the temperature of the low-temperature ultrafine pulverizer for ultrafine pulverizatio...

Embodiment 1

[0044] A method for preparing fermented fermented bean curd with bean dregs as raw material, comprising the steps of:

[0045] Step 1: using a drum dehydration device to dehydrate the bean dregs, the rotating speed of the drum is 3700 rpm, the dehydration time is 15 minutes, and the water content of the bean dregs after dehydration is 25%;

[0046] Step 2: Extruding and expanding the dehydrated bean dregs to obtain expanded materials, the screw speed of the extruder is 330 rpm, and the extrusion temperature is 150°C;

[0047] Step 3: The puffed material is coarsely crushed with a high-speed pulverizer, passed through a 40-mesh sieve to obtain coarse bean dregs powder, and then ultrafinely pulverized the bean dregs coarse powder with a low-temperature ultrafine pulverizer to obtain ultrafine pulverized bean dregs powder, and the time for ultrafine pulverization It was 15 minutes; the temperature at which the low-temperature ultrafine pulverizer carried out ultrafine pulverizati...

Embodiment 2

[0055] A method for preparing fermented fermented bean curd with bean dregs as raw material, comprising the steps of:

[0056] Step 1: using a drum dehydration device to dehydrate the bean dregs, the rotating speed of the drum is 3900 rpm, the dehydration time is 17 minutes, and the water content of the bean dregs after dehydration is 23%;

[0057] Step 2: Extruding and expanding the dehydrated bean dregs to obtain expanded materials, the screw speed of the extruder is 340 rpm, and the extrusion temperature is 160°C;

[0058] Step 3: The puffed material is coarsely crushed with a high-speed pulverizer, passed through a 50-mesh sieve to obtain coarse bean dregs powder, and then ultrafinely pulverized the bean dregs coarse powder with a low-temperature ultrafine pulverizer to obtain ultrafine pulverized bean dregs powder, and the time for ultrafine pulverization It was 17 minutes; the temperature at which the low-temperature ultrafine pulverizer carried out ultrafine pulverizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com