Coating vermicelli used for coating food, and production method thereof

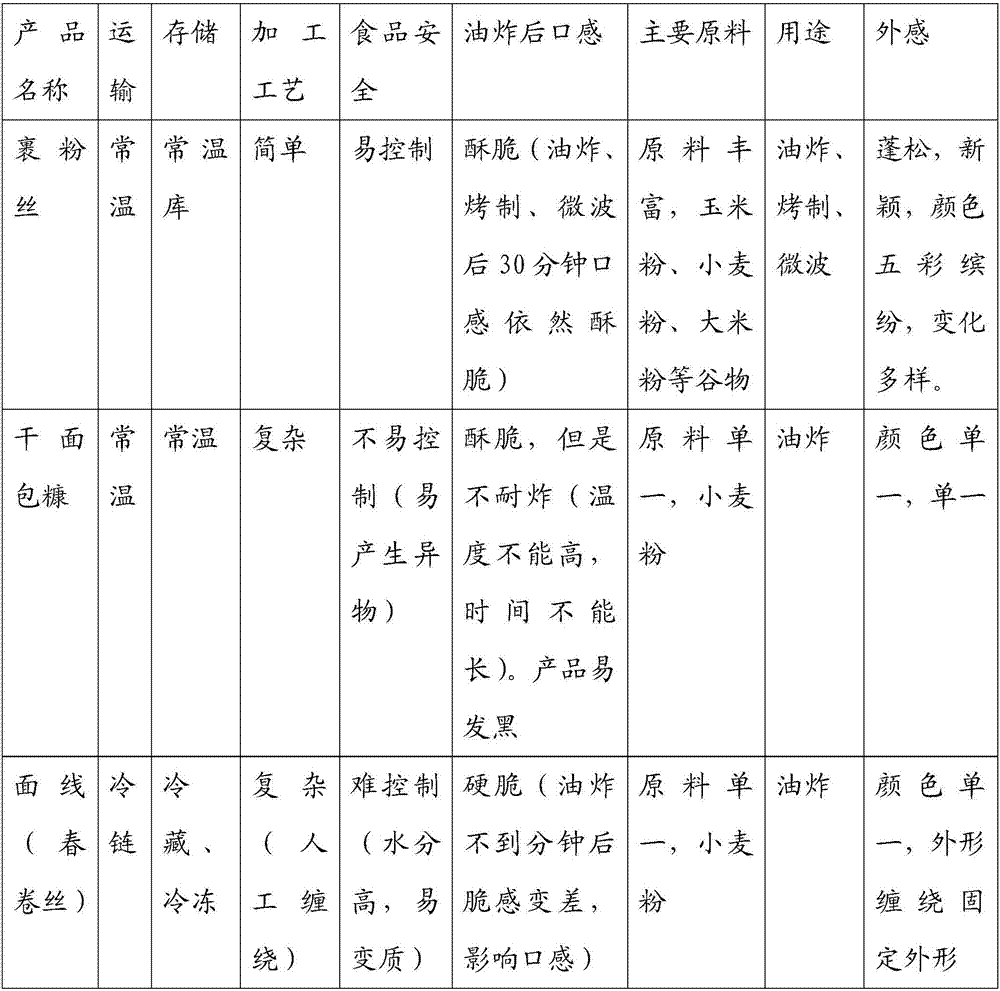

A production method and food technology, which are applied in the forming of food, food ingredients as taste improvers, food ingredients as taste improvers, etc., can solve the problems of manual winding, affecting the preference of coated food, bread crumb shape and single taste, etc. , to achieve the effect of improving production efficiency, wide product use, and colorful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of wrapped vermicelli used for food coating, said wrapped vermicelli is made of rice flour as the main raw material, adding 2.5wt% of vegetable oil and 0.5wt% of sodium bicarbonate; after being extruded and matured, it is first extruded through an extrusion die Instantly use the white filamentous product that rotary cutter cuts again; The long 20~25mm of described filamentous product, silk fineness are 0.3~0.8mm, after drying (dehumidifying), moisture content is 12%.

Embodiment 2

[0042] A wrapped vermicelli used for food coating, the wrapped vermicelli is made of corn flour, adding 2.0wt% of vegetable oil; adding 0.5wt% of cumin powder; adding 0.5wt% of salt and 0.05wt% of monosodium glutamate and 10wt% water; the raw material is extruded through an extrusion die after being extruded and ripened, and then used a rotary cutter to cut into yellow filamentous products in an instant; 0.5-1mm, and the moisture content after drying (dehumidification) is 13wt%.

Embodiment 3

[0044] A kind of wrapped vermicelli used for food coating, said wrapped vermicelli is mixed with wheat flour and millet flour according to the ratio of 3:1, then add 3.0wt% vegetable oil as raw material; mix evenly and add 14wt% water to stir, In the extrusion curing machine, the raw materials are finally heated to a temperature of 160-165°C and extruded under a certain pressure to extrude and puff, extruded through an extrusion die, and then cut into a filamentous product with a rotary cutter in an instant; the filamentous product The length is 15-25mm, the thread fineness is 0.5-1mm, and the moisture content after drying (dehumidification) is 14wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com