Fishy smell-free difficult-to-break fish rice noodles and production method for same

A production method and rice noodle technology, applied in the food field, can solve problems such as easy spoilage and deterioration of fish meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

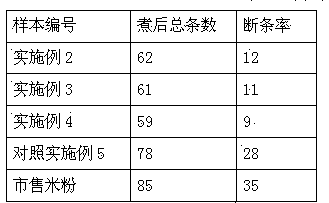

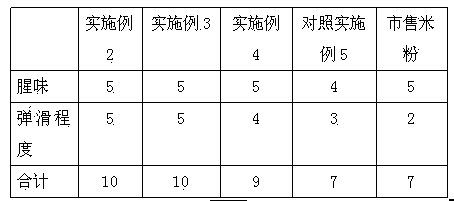

Examples

Embodiment 1

[0031] Treat rice milk with α-amylase at 30-65°C and pH 5-8 for 1-4 hours, then enzymatically hydrolyze it with cyclodextrin glucosyltransferase at 55-65°C and pH 6-9 for 10-300 minutes to obtain Rice milk after enzymatic hydrolysis; mince the fish meat at 0-4°C; mix the minced fish meat and the rice milk after enzymolysis with a pulping machine, and cook it by extrusion cooking at a temperature of 80-90°C Extrude into rice flour by a flour milling machine, freeze the prepared rice flour to a temperature of -10°C, store for 24 hours, then rinse with running water and thaw the rice flour, then age and dry according to conventional methods.

Embodiment 2

[0033] Take by weighing 20kg of fish protein, 50kg of rice and 30kg of water. The rice was then soaked in water at room temperature for 12 hours; the soaked rice was refined with a refiner; the rice slurry was treated with α-amylase at 55°C and pH 6.5 for 2 hours, followed by cyclodextrin glucosyltransferase Enzymolysis at 60°C and pH 7.2 for 120 minutes to obtain enzymolysis rice milk; mince fish at 0-4°C; mix the minced fish and enzymolysis rice milk evenly with a pulper, Extrude it into rice noodles with an extruding cooking type flour making machine at a temperature of 85°C, freeze the prepared rice noodles to a temperature of -10°C, store for 24 hours, then rinse with running water and thaw the rice noodles, then age and dry according to conventional methods. Can.

Embodiment 3

[0035] Take by weighing 20kg of fish protein, the ratio of 50kg of rice and 30kg of water, and weigh raw materials. After powdering, it was frozen to 0°C and stored for 48 hours. Other processes adopt the method of embodiment 2 to carry out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com