Oyster juice manufacturing method

A production method and technology of oyster juice, which is applied in the field of oyster juice production, can solve the problems of oyster juice losing its characteristic flavor and being unsuitable for industrial production, and achieve the effects of reducing the generation of fishy substances, low production cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

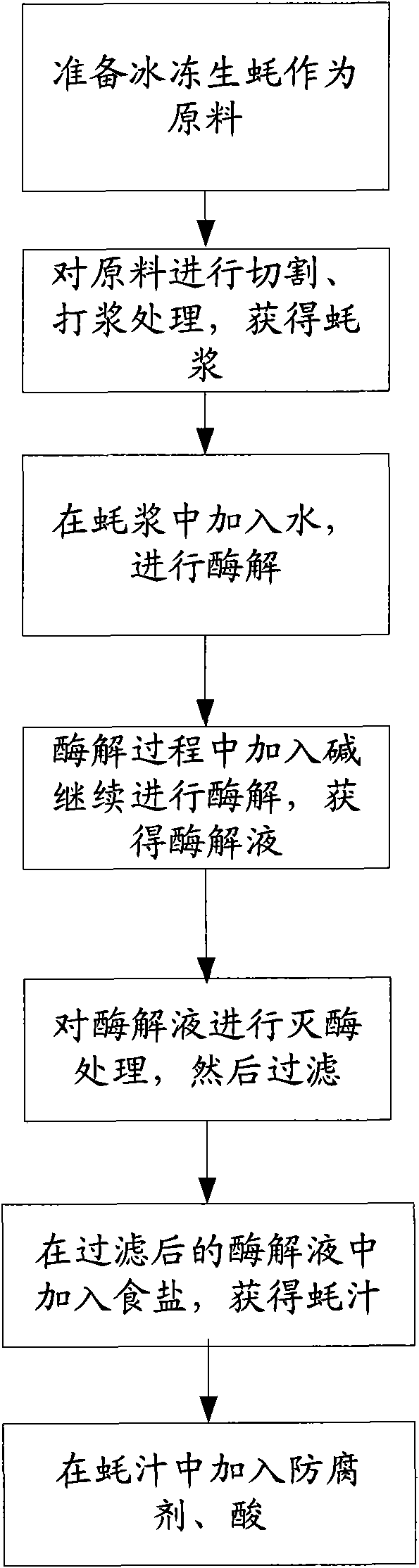

Image

Examples

Embodiment 1

[0031] 1) Cut the frozen oysters at -15°C directly with a cutting machine, and then beat them with a beater to obtain oyster pulp. Add water to the oyster pulp to make oyster water. The weight ratio of the added water to oyster pulp is 1 : 1;

[0032] 2) Add edible alkali to obtain a mixed solution, make the alkali account for 0.01% by weight of the mixed solution, adjust the pH of the mixed solution to 6.5, and react at 40°C for 10 hours to obtain an enzymolysis solution;

[0033] 3) Heat the enzymolysis solution to 100°C, keep it warm for 30 minutes, and filter;

[0034] 4) adding salt to the enzymolysis solution, the weight percentage of the added salt to the enzymolysis solution is 1:5, to obtain oyster juice with a weak fishy smell;

[0035] 5) Add preservatives and edible acids to the oyster juice, the weight of the added preservatives accounts for 0.01% of the total weight of the preservatives and oyster juice, the weight of the added acid accounts for 0.3% of the tota...

Embodiment 2

[0037] 1) Cut the frozen oysters at -18°C directly with a cutting machine, and then beat them with a beater to obtain oyster pulp. Add water to the oyster pulp to make oyster water. The weight ratio of the added water to oyster pulp is 1 : 4;

[0038] 2) adding edible alkali to obtain a mixed solution, so that the alkali accounts for 0.05% by weight of the mixed solution, adjusting the pH of the mixed solution to 7.5, and reacting at 60° C. for 7 hours to obtain an enzymolysis solution;

[0039] 3) Heat the enzymolysis solution to 90°C, keep it warm for 80min, and filter;

[0040] 4) adding salt to the enzymolysis solution, the weight percentage of the added salt to the enzymolysis solution is 3:20, to obtain oyster juice with a weak fishy smell;

[0041] 5) Add preservatives and edible acids to the oyster juice, the weight of the added preservatives accounts for 0.1% of the total weight of the preservatives and oyster juice, the weight of the added acid accounts for 0.2% of ...

Embodiment 3

[0043] 1) Cut the frozen oysters at -20°C directly with a cutting machine, and then beat them with a beater to obtain oyster pulp. Add water to the oyster pulp to make oyster water. The weight ratio of the added water to oyster pulp is 1 : 2;

[0044] 2) adding edible alkali to obtain a mixed solution, so that the alkali accounts for 0.1% by weight of the mixed solution, adjusting the pH of the mixed solution to 8.0, and reacting at 70° C. for 4 hours to obtain an enzymolysis solution;

[0045] 3) Heat the enzymolysis solution to 95°C, keep it warm for 90min, and filter;

[0046] 4) adding salt to the enzymolysis solution, the weight percentage of the added salt to the enzymolysis solution is 1:4, to obtain oyster juice with a weak fishy smell;

[0047] 5) Add preservatives and edible acids to the oyster juice. The weight of the added preservative accounts for 0.05% of the total weight of the preservative and oyster juice, and the weight of the added acid accounts for 0.01% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com