Processing method for improving digestibility and reconstituability of instant brown rice powder

A processing method and technology of brown rice flour, applied in the field of grain deep processing, can solve the problems of high viscosity of paste liquid, low digestibility, rough taste, etc., to simplify the process, improve digestion and absorption rate and brewability, and fine taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

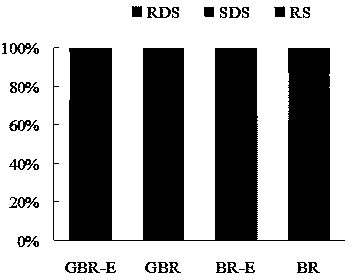

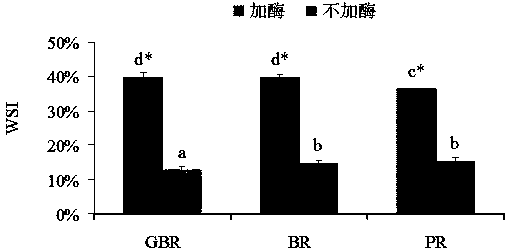

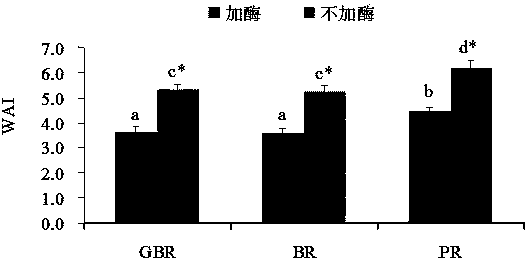

Image

Examples

Embodiment 1

[0026] After removing impurities, the rice was rinsed with tap water for 3 times, and then soaked with 1% NaClO solution at 30°C for 20 minutes at a concentration of 1% by volume. The ratio of NaClO solution to rice was 1:1. Soak for 10 hours at ℃, the solid-liquid ratio of NaClO solution to rice is 1:0.6. Wash the soaked rice once with sterile water, transfer it to a porcelain plate sterilized by ultraviolet light for 30 minutes, germinate in a constant temperature incubator at 30°C and 95% humidity until the bud length is 0.2mm, and then dry it at 50°C for 10 hours until Moisture content 8%. The dried germinated rice is husked by an electric husker to obtain germinated brown rice. The electric husker is TR-200 model produced by Japan KETT. The germinated brown rice is crushed through a 60-mesh sieve, and sprayed into the brown rice flour with a high-temperature α-amylase dilution solution. The α-amylase is diluted to the required volume with a pH 5.8-7.8 phosphate buffer so...

Embodiment 2

[0028] After removing impurities, the rice was rinsed twice with tap water, then soaked in 1% NaClO solution at 25°C for 30 minutes, the ratio of NaClO solution to rice was 1:2; after rinsing once, soaked in 0.05% NaClO solution at 25°C for 15 hours, NaClO The ratio of solution to rice is 1:1. The treated rice was transferred to a porcelain plate sterilized by ultraviolet light for 30 minutes, germinated in a constant temperature incubator at 25°C and 90% humidity until the bud length was 0.3mm, and then dried at 45°C for 8 hours to reach a moisture content of 10%. The dried germinated rice is dehulled by an electric huller to obtain germinated brown rice. The germinated brown rice is crushed through a 60-mesh sieve, and sprayed into the brown rice flour with a high-temperature α-amylase dilution solution. The α-amylase is diluted to the required volume with a pH 5.8-7.8 phosphate buffer solution, and the spraying amount is sprayed per gram of brown rice flour. 40 U units of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com