Patents

Literature

35 results about "Ready to eat cereals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ready-to-eat cereal is one of the most popular breakfast choices in America, according to Clemson University Extension. It’s easy to understand why -- ready-to-eat cereal is convenient, as well as nutritious. Some research suggests regularly consuming ready-to-eat cereal may even help weight management.

High fiber high protein ready-to-eat cereal

Disclosed are cooked dried farinaceous food products such as cooked cereal doughs, ready-to-eat cereals and grain based snacks fabricated from such cooked cereal doughs containing high levels of both insoluble and soluble fiber as well as high levels of protein. The cereals contain about 5 to 15% (dry weight) insoluble fiber; 5% to 15% soluble fiber in an excess of insoluble fiber; 15% to 30% (dry weight) plant protein and the balance cereal ingredients especially rice and wheat flour. The soluble fiber is preferably provided at least in part by inulin ingredient that can be incorporated into the dough and / or topically applied.

Owner:CREIGHTON DEAN W +4

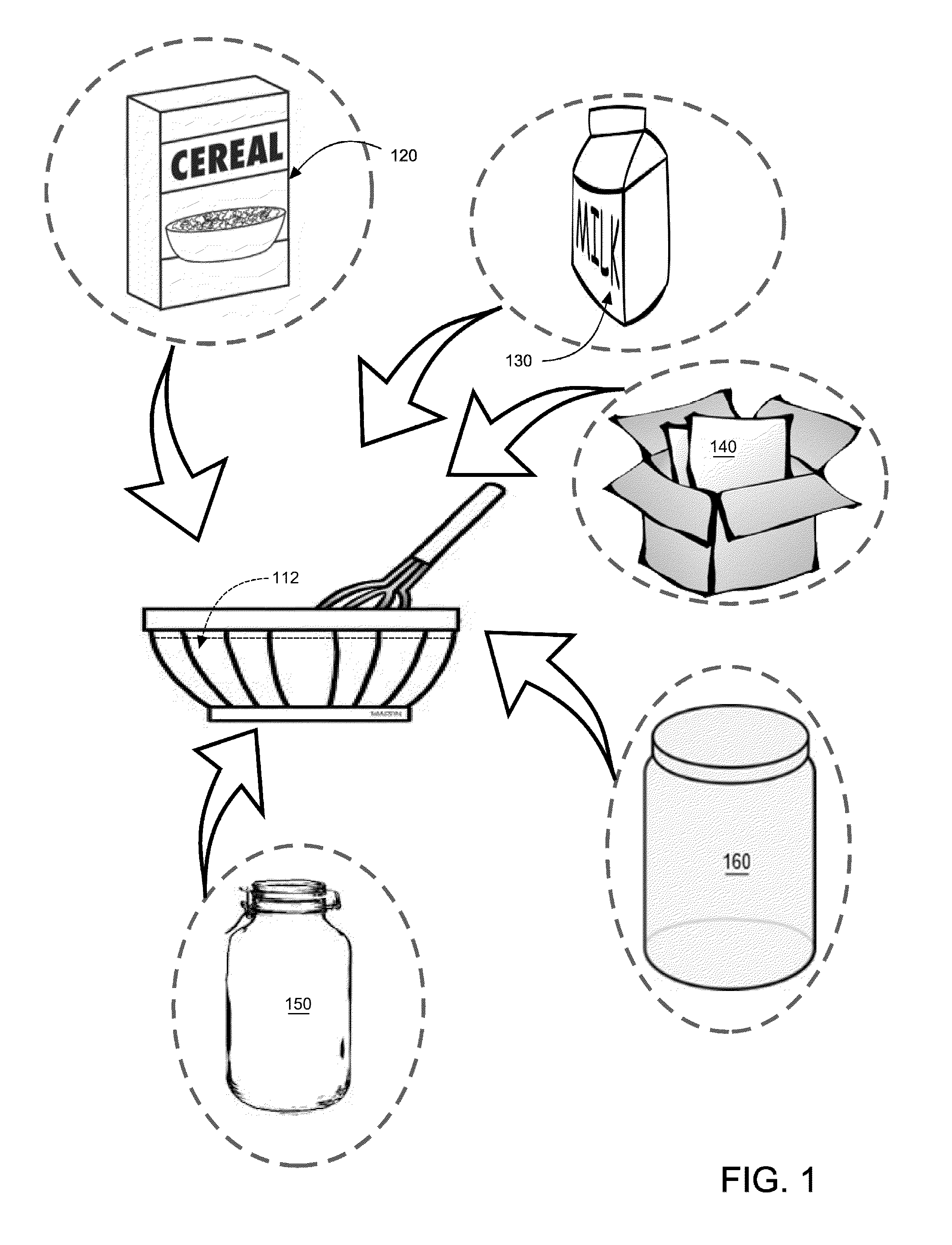

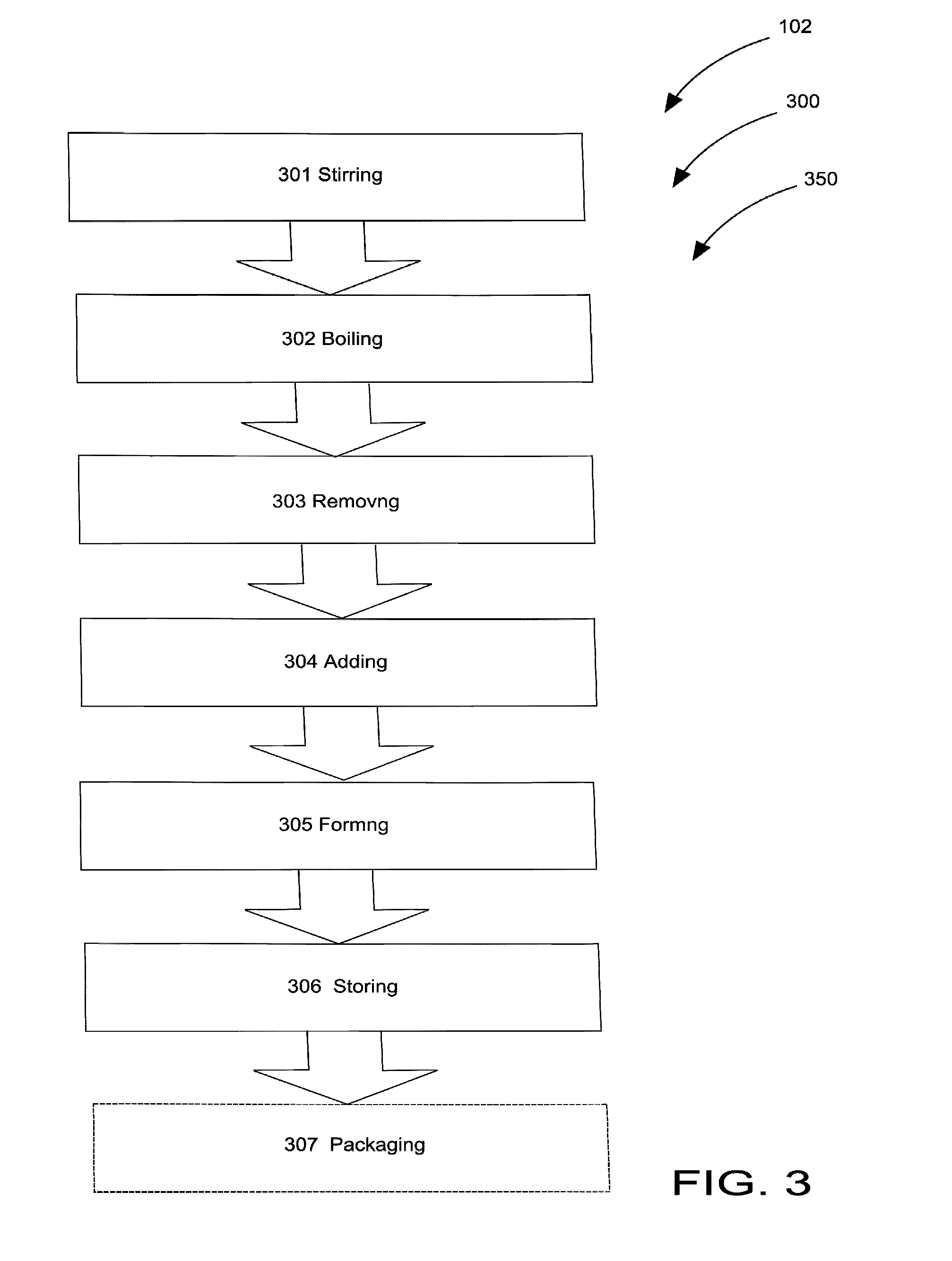

Nutrient clusters for food products and methods of preparation

Nutrient clusters for food products, such as for addition to Ready-To-Eat cereals, are made in the form of aggregates or clusters comprising a first particulate component; a nutrient powder blend, and sufficient binder to adhere the powder to the particulates. The nutrient clusters are in the form of pieces each weighing from about 0.3 to 5 g. and having a moisture content of about 2% to 10%. Such nutrient clusters are prepared by applying a liquid binder to the particulates to form sticky particulates, adding a powdered nutrient blend, and curing the mixtures to form hardened dried nutrient clusters. The nutrient cluster can contain 100% US recommended daily allowance of essential vitamins and minerals and can contain added macronutrients such as soy proteins, soluble fiber, and / or calcium in nutritionally dense form in as little as 5 to 15 g of nutrient clusters. The clusters find particular suitability for use in providing to-order customized cereal products in response to particular customer requirements for nutrition.

Owner:GENERAL MILLS INC

Omega-3 Fatty Acids Encapsulated In Zein Coatings and Food Products Incorporating the Same

Disclosed are processes for stabilizing omega-3 fatty acids for use in food products. The processes permit creation of a variety of food forms and food ingredients that contain omega-3 fatty acids like docosahexaenoic acid and eicosapentaenoic acid wherein these foods and food forms are stable for months without developing fishy aromas or tastes. This stability enables the incorporation of omega-3 fatty acids into food forms such as ready to eat cereals, trail mixes, chips, granola bars, toaster pastries, baked goods, cookies, crackers, fruit pieces and fruit leathers. The processes utilize a zein coating to protect and stabilize the omega-3 fatty acids.

Owner:KELLOGG CO

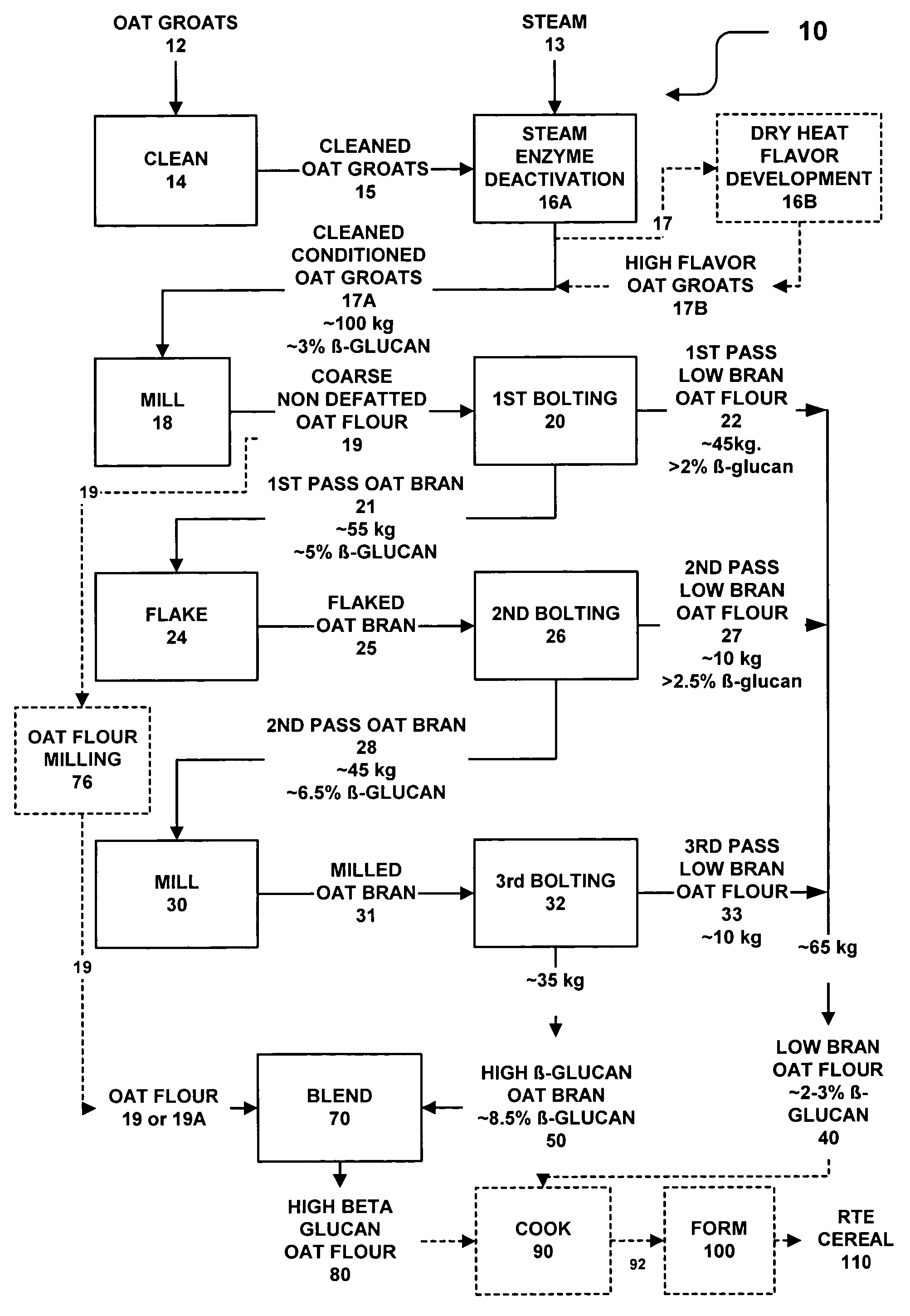

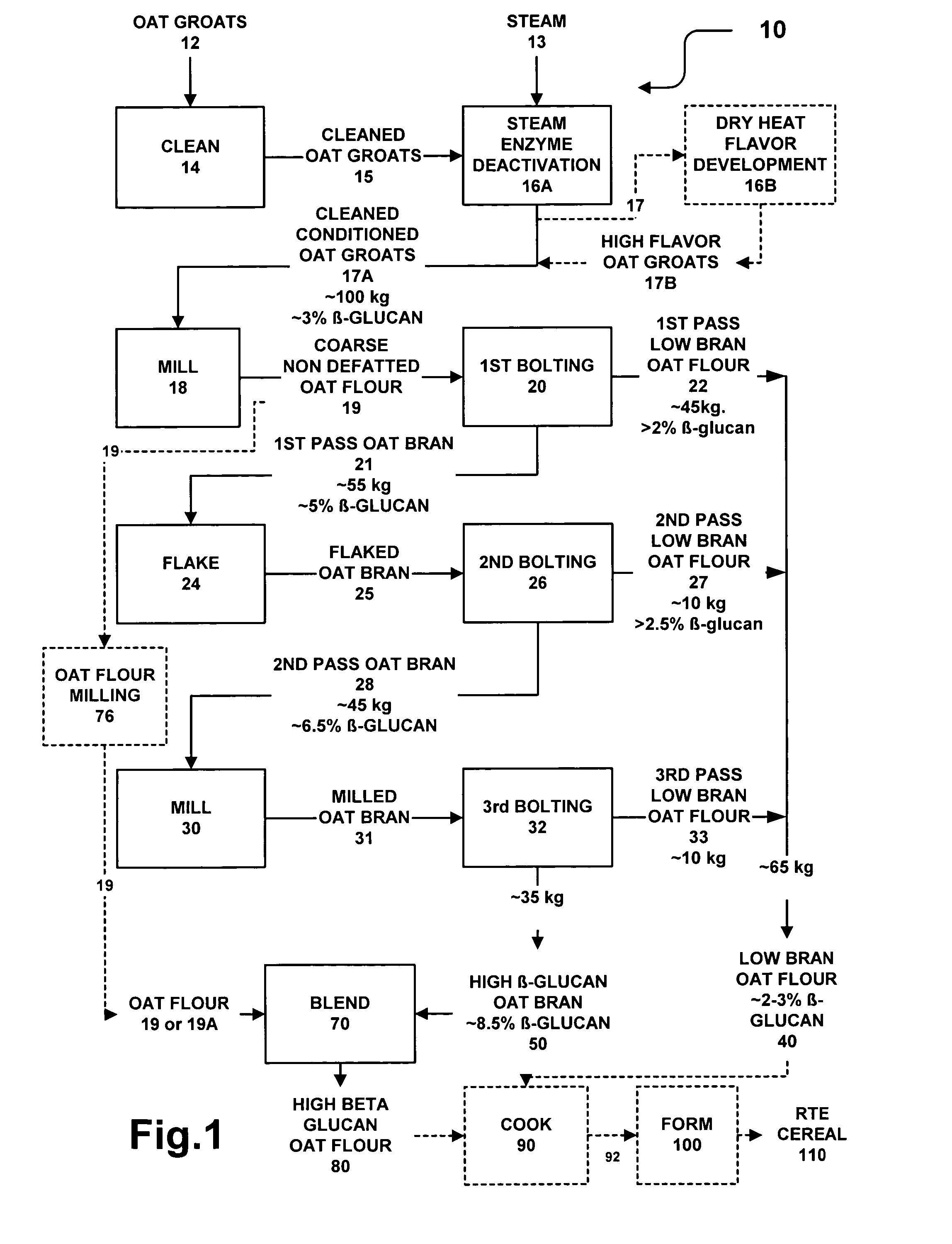

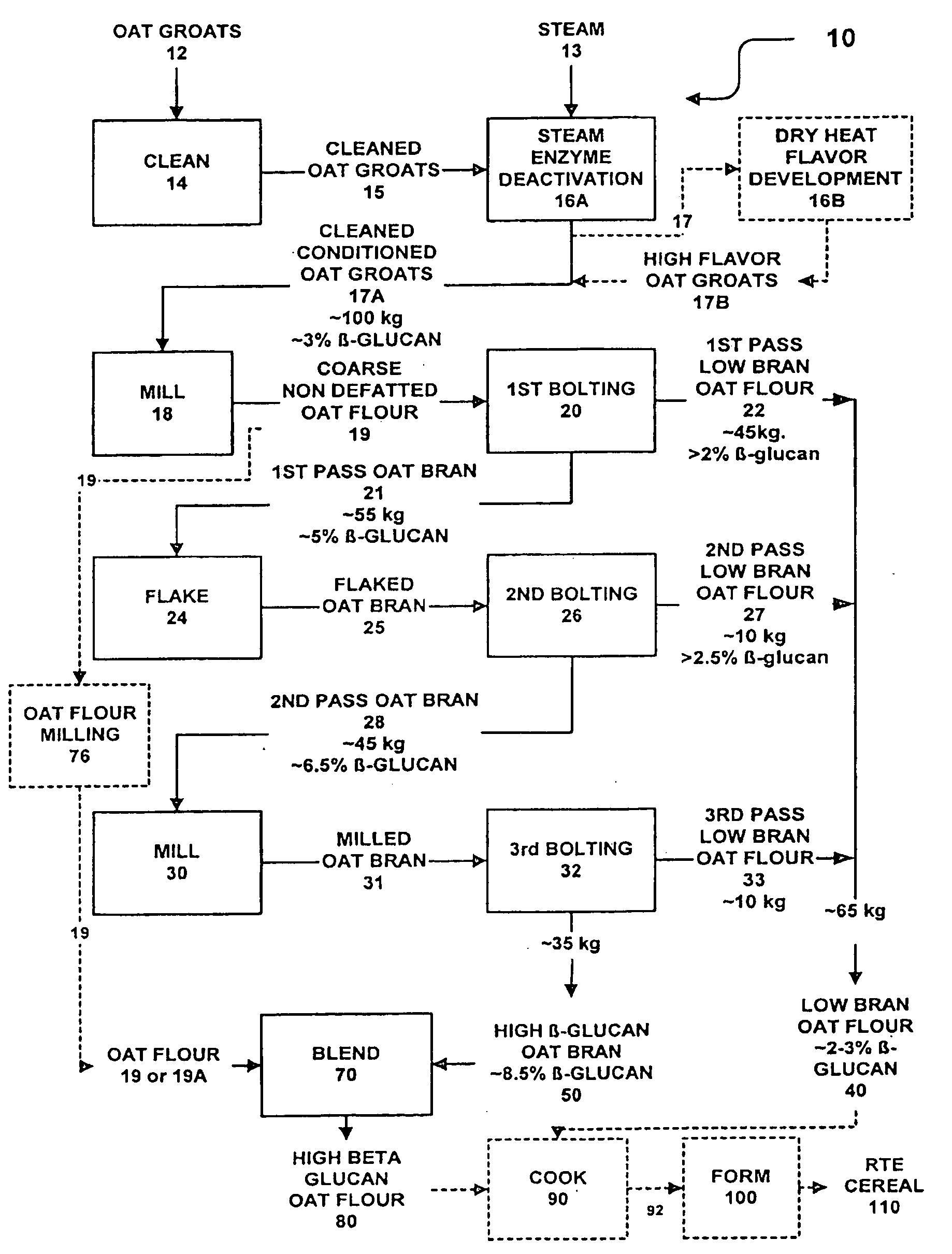

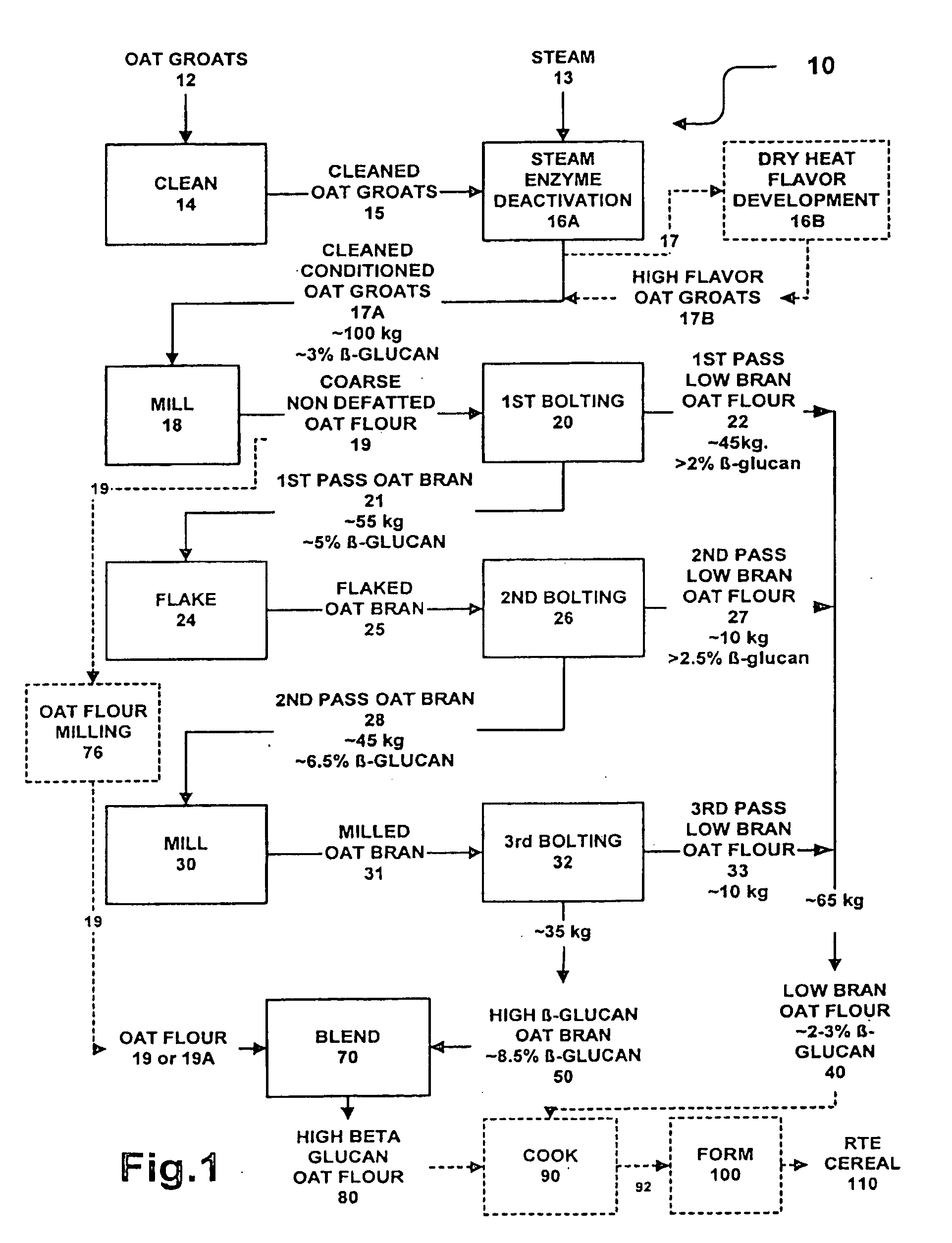

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS20050153044A1Add flavorEnhance cooking characteristicsDough treatmentBaking mixturesFood flavorCereal grain

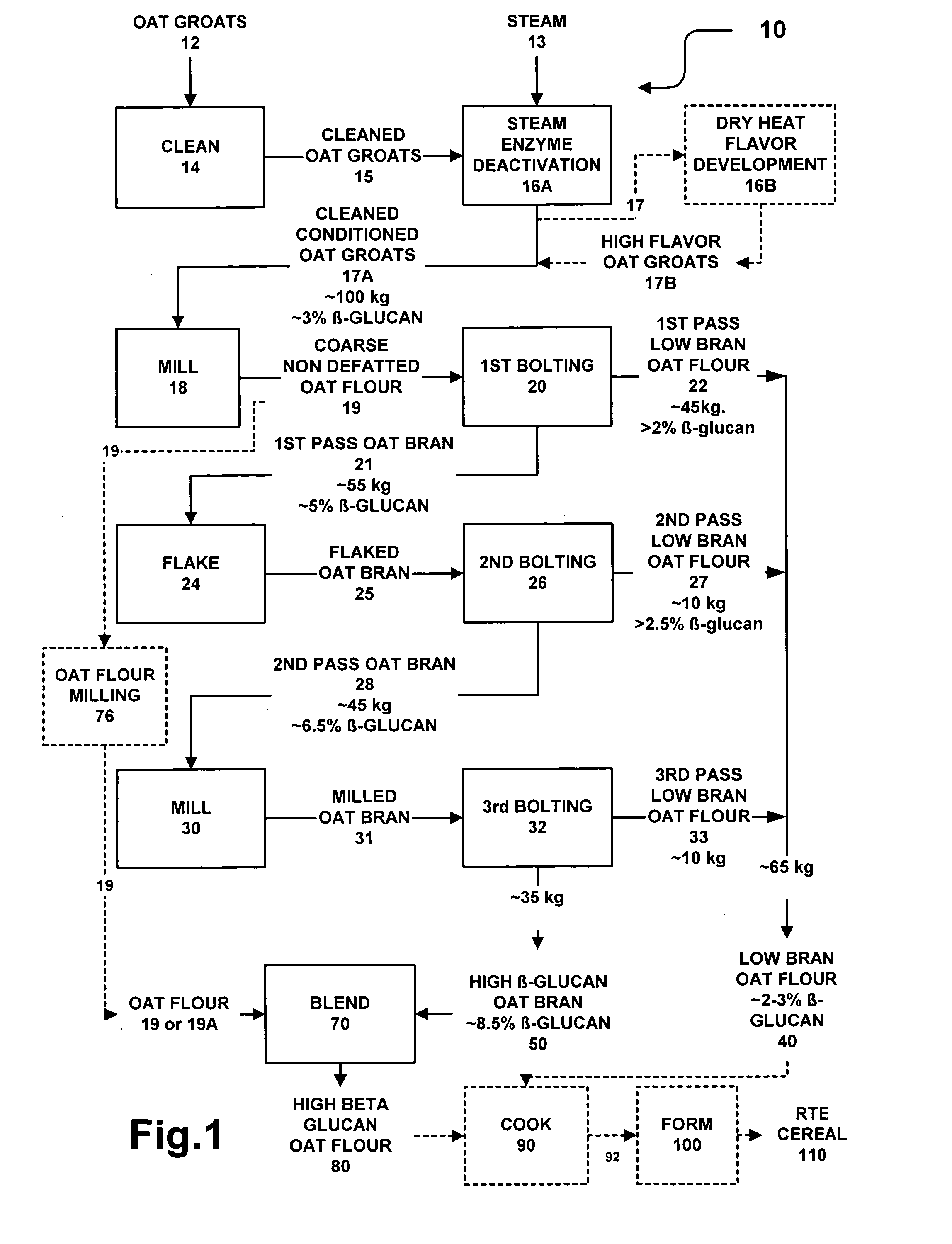

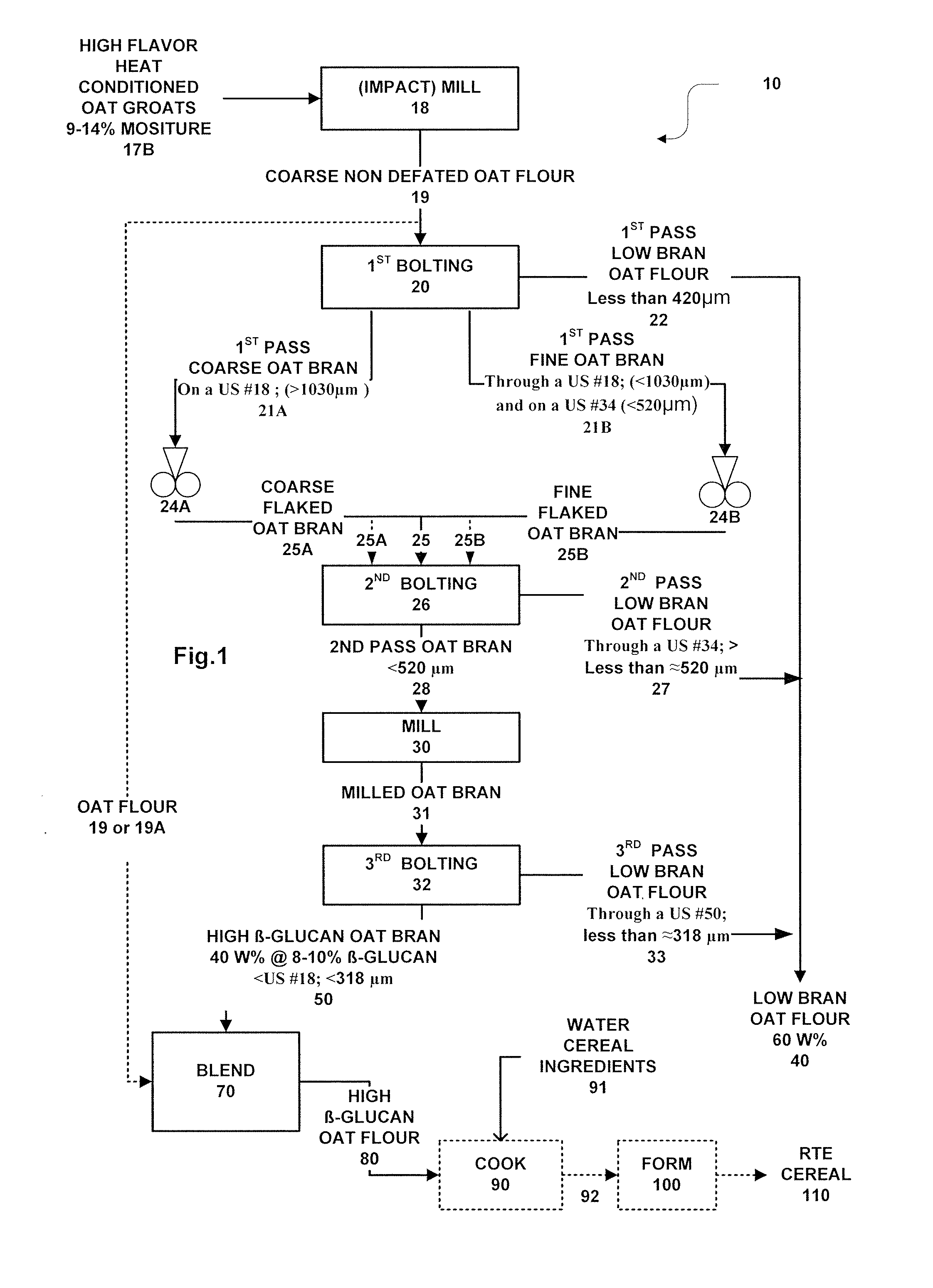

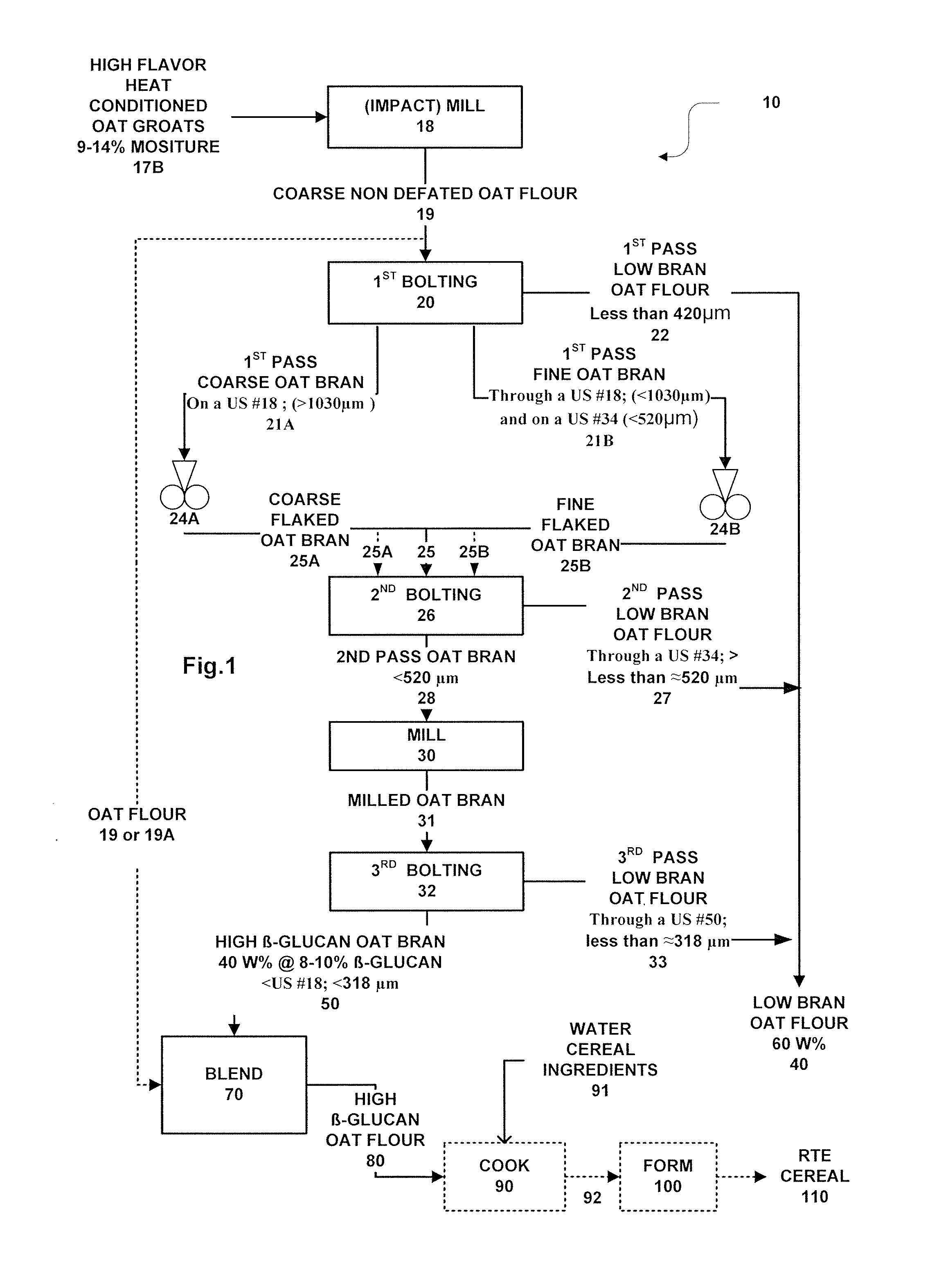

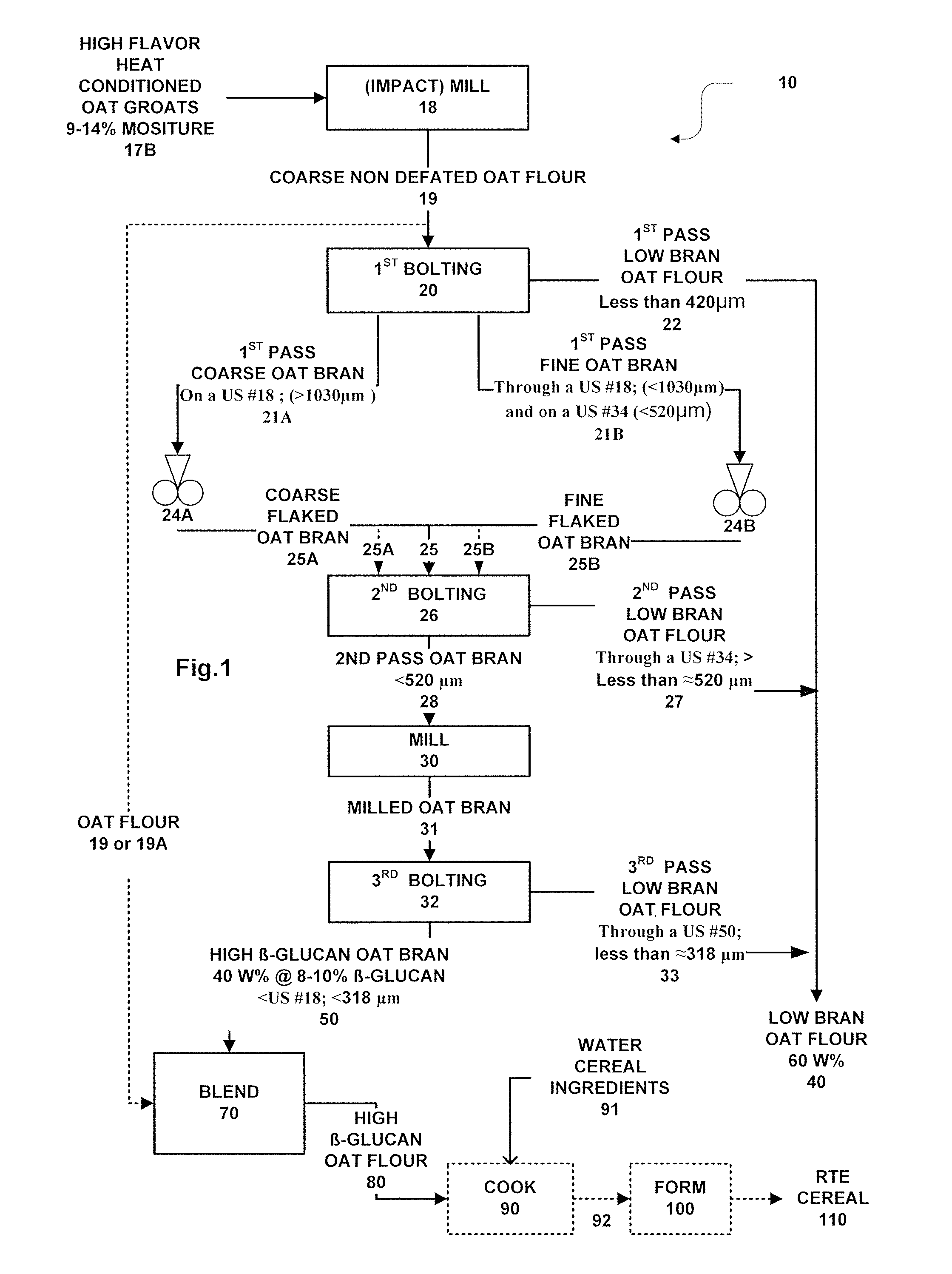

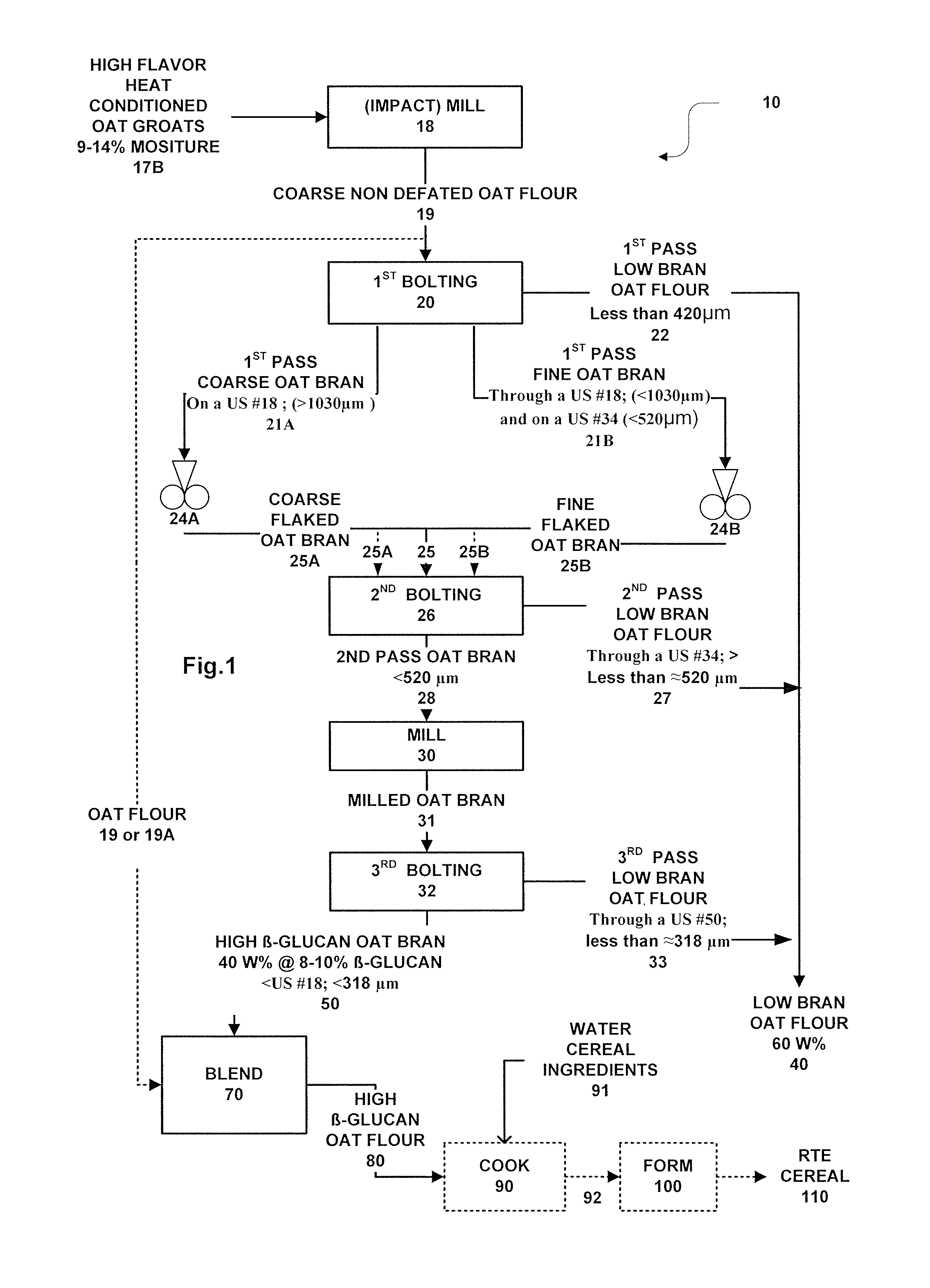

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is subjected to second and third rounds of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

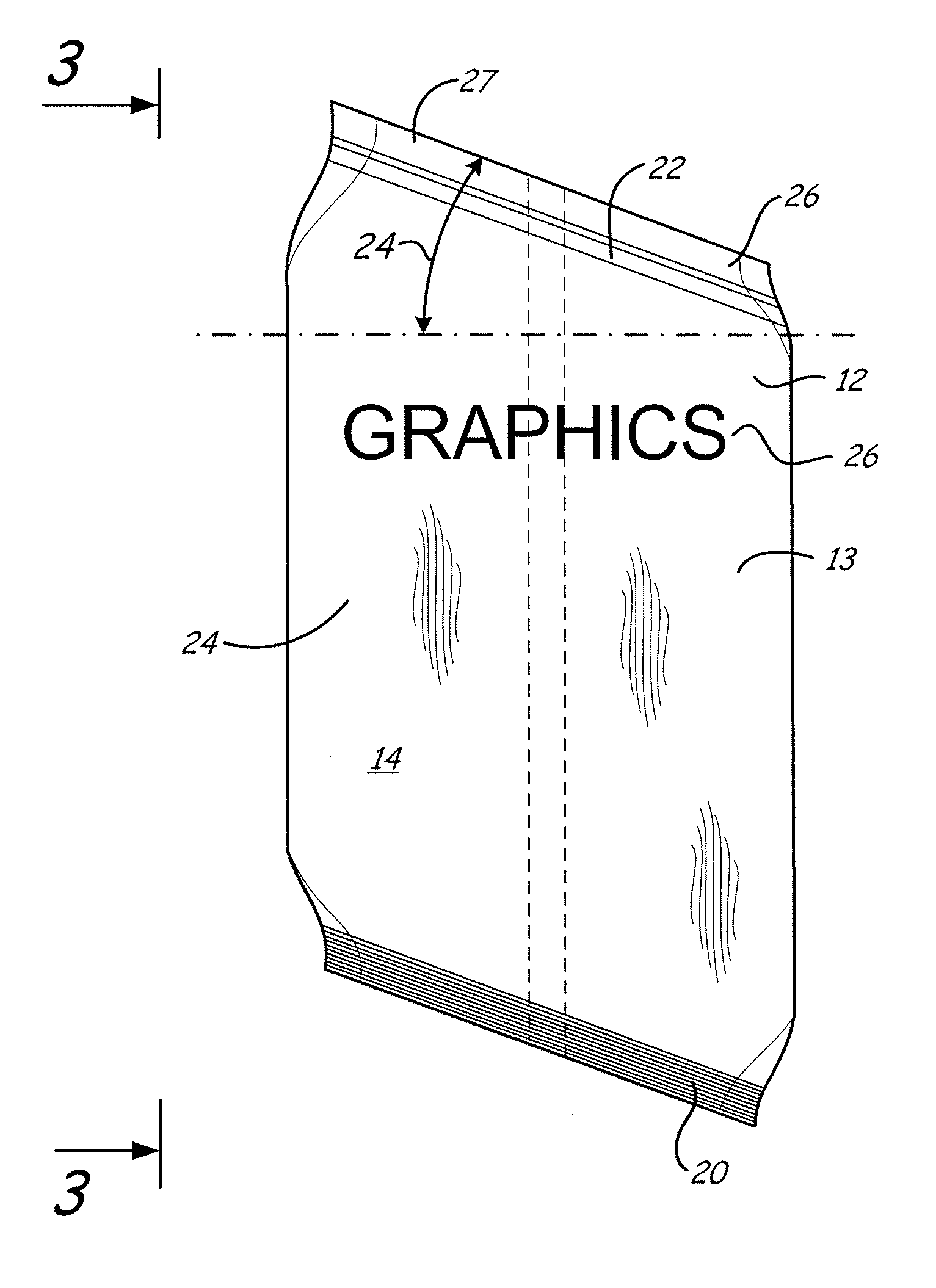

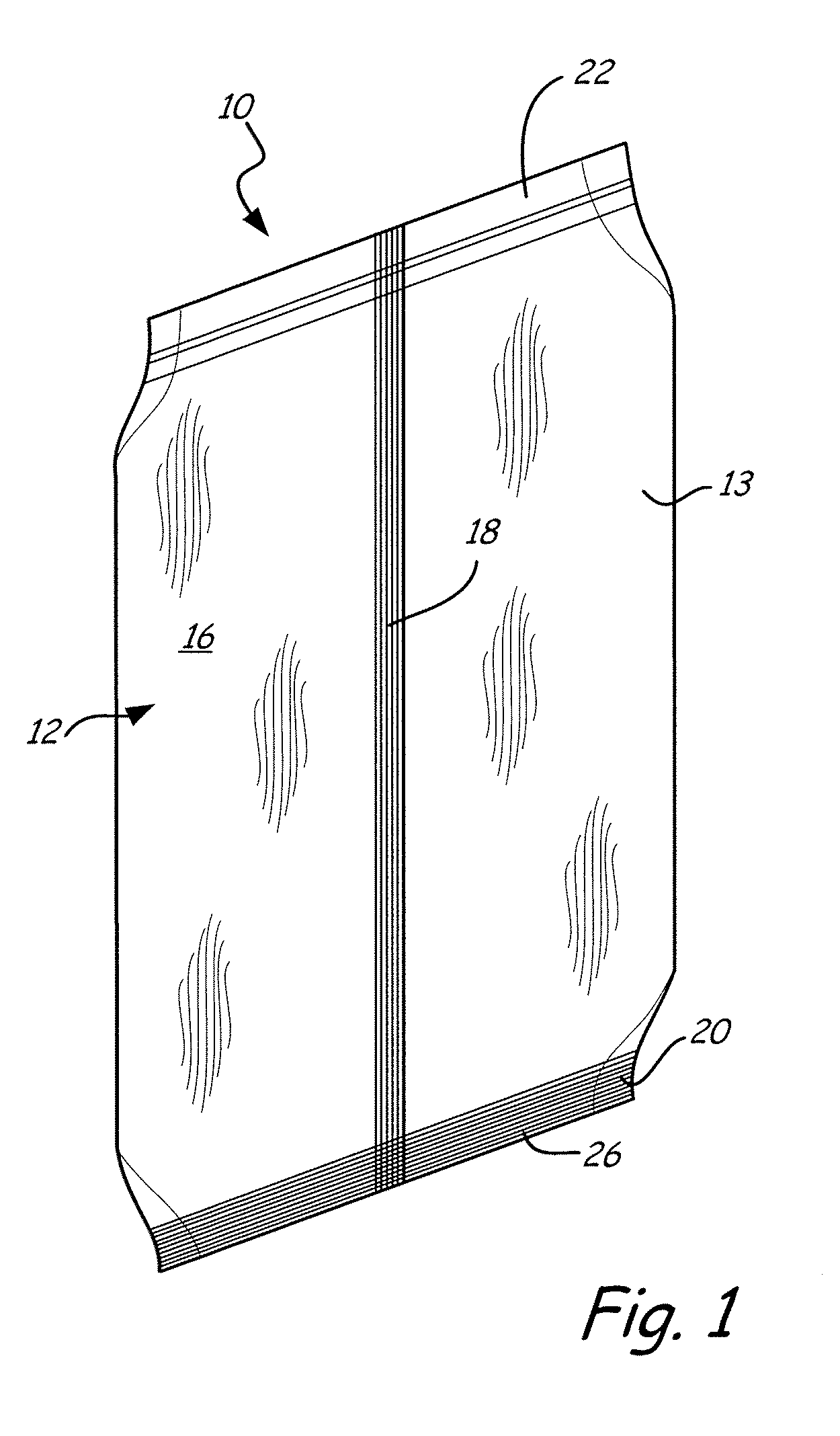

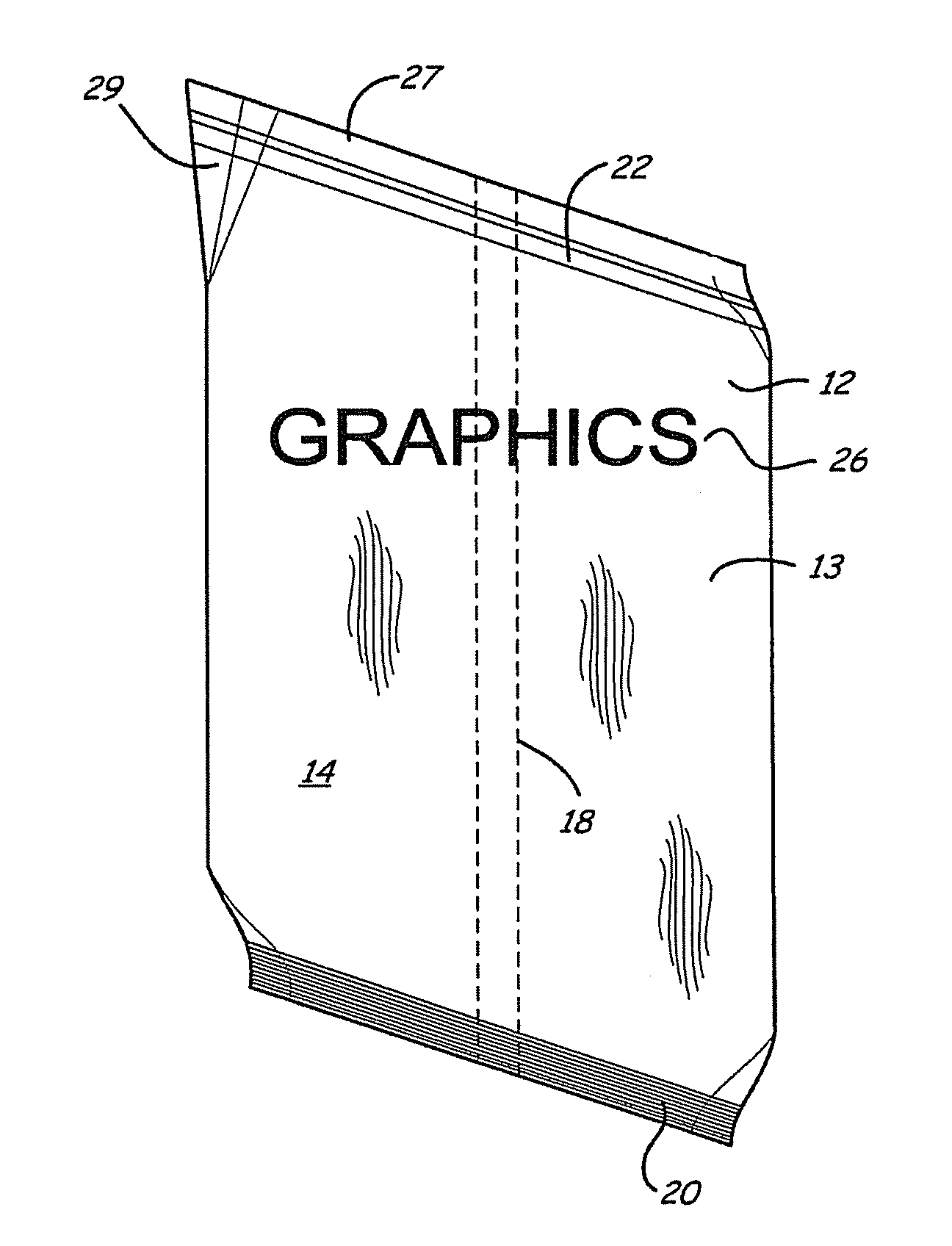

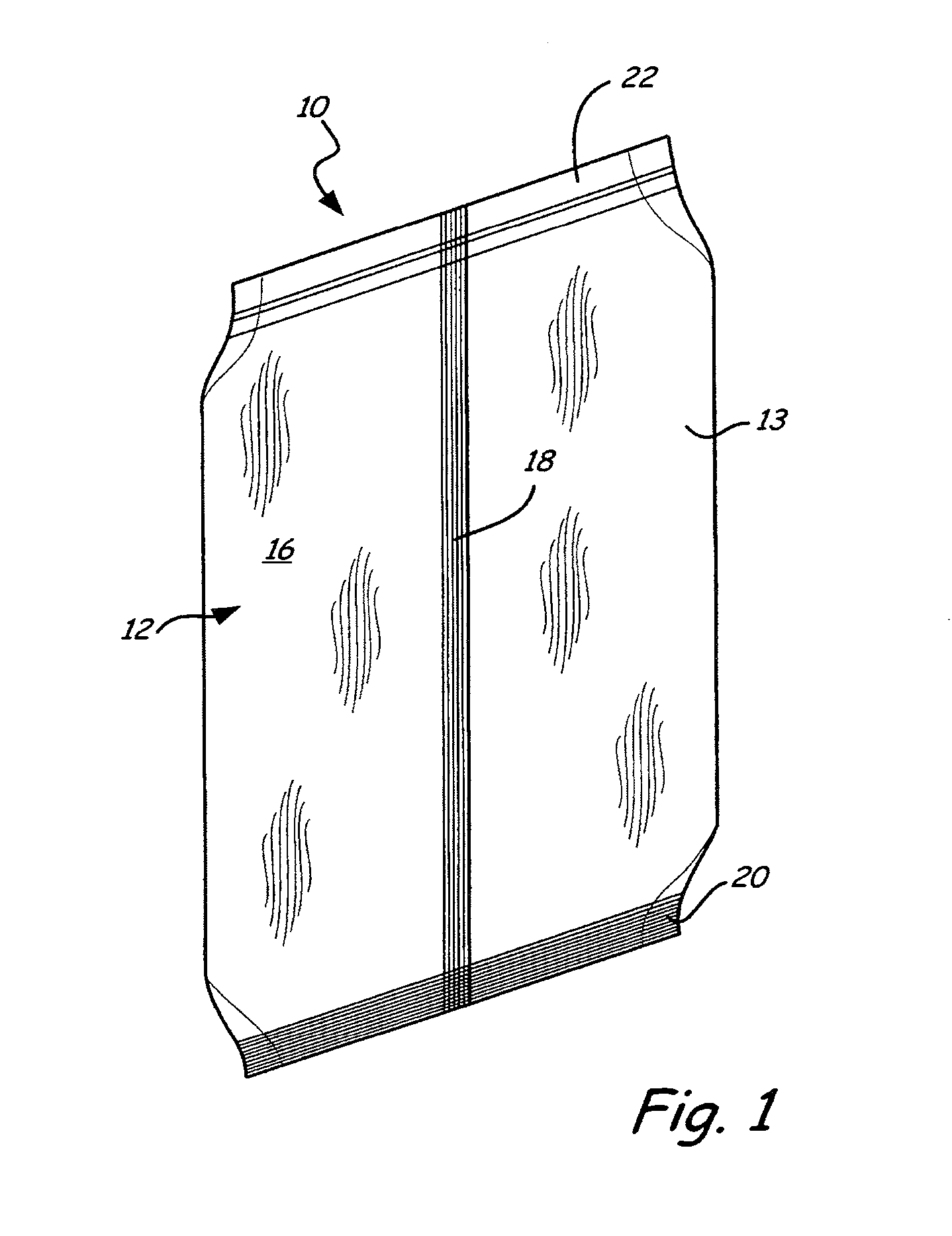

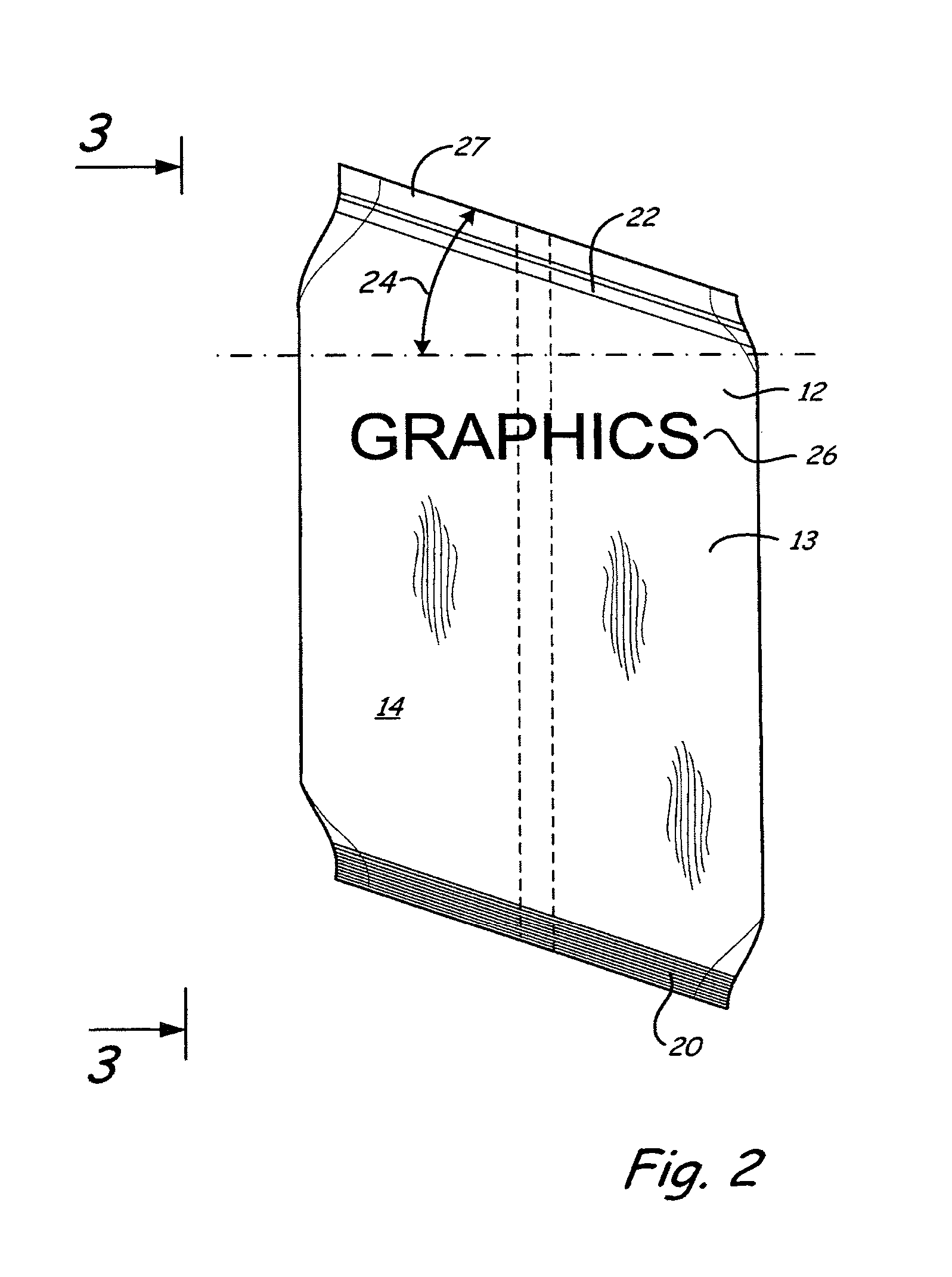

Easy pour bag

Vertical fill and form bags fabricated from flexible packaging film are provided with at least one transverse seal at an oblique angle. Upon opening, the oblique angled seal provides a natural use easy pour dispensing feature. The bag is intuitively and ergonomically easy to use to facilitate controlled pouring without spilling. The bag are especially useful for bulk particulate contents especially consumer food products such as ready-to-eat cereals for use in food service venues such as universities and hospitals. Apparatus and method of preparation for the productions of the easy pour bulk bags are described including using transverse sealers at least one of which is oriented at an angle such as to impart the oblique angled transverse seal.

Owner:GENERAL MILLS INC

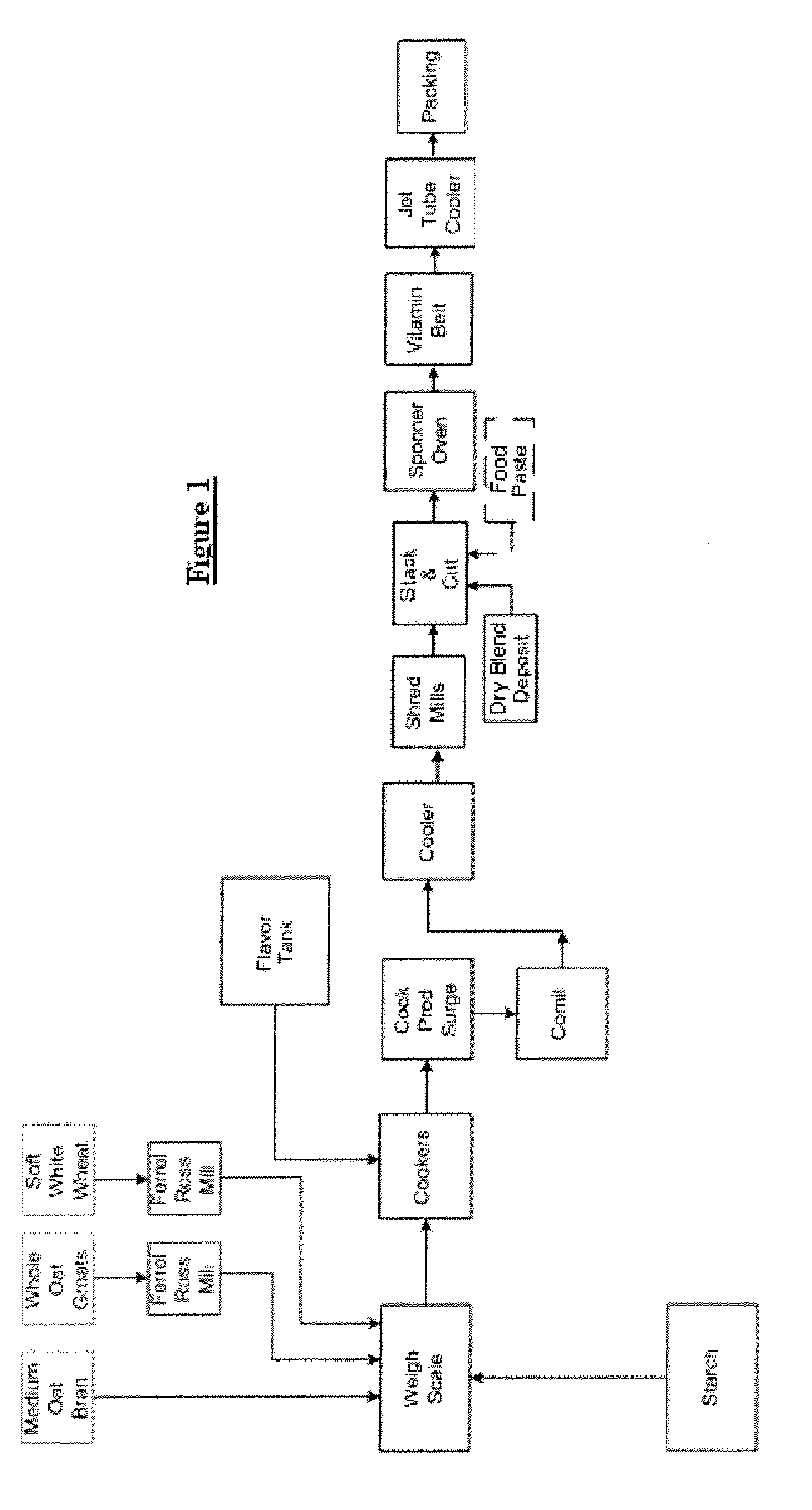

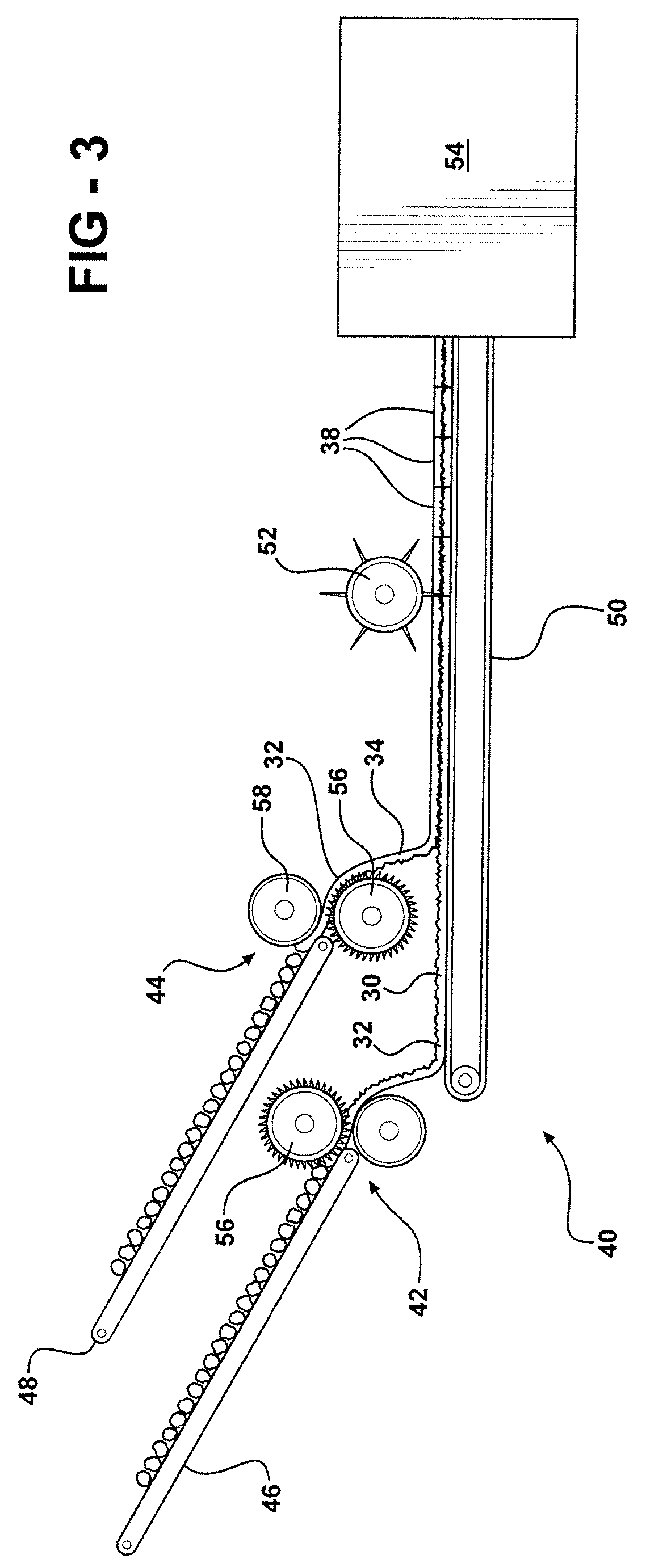

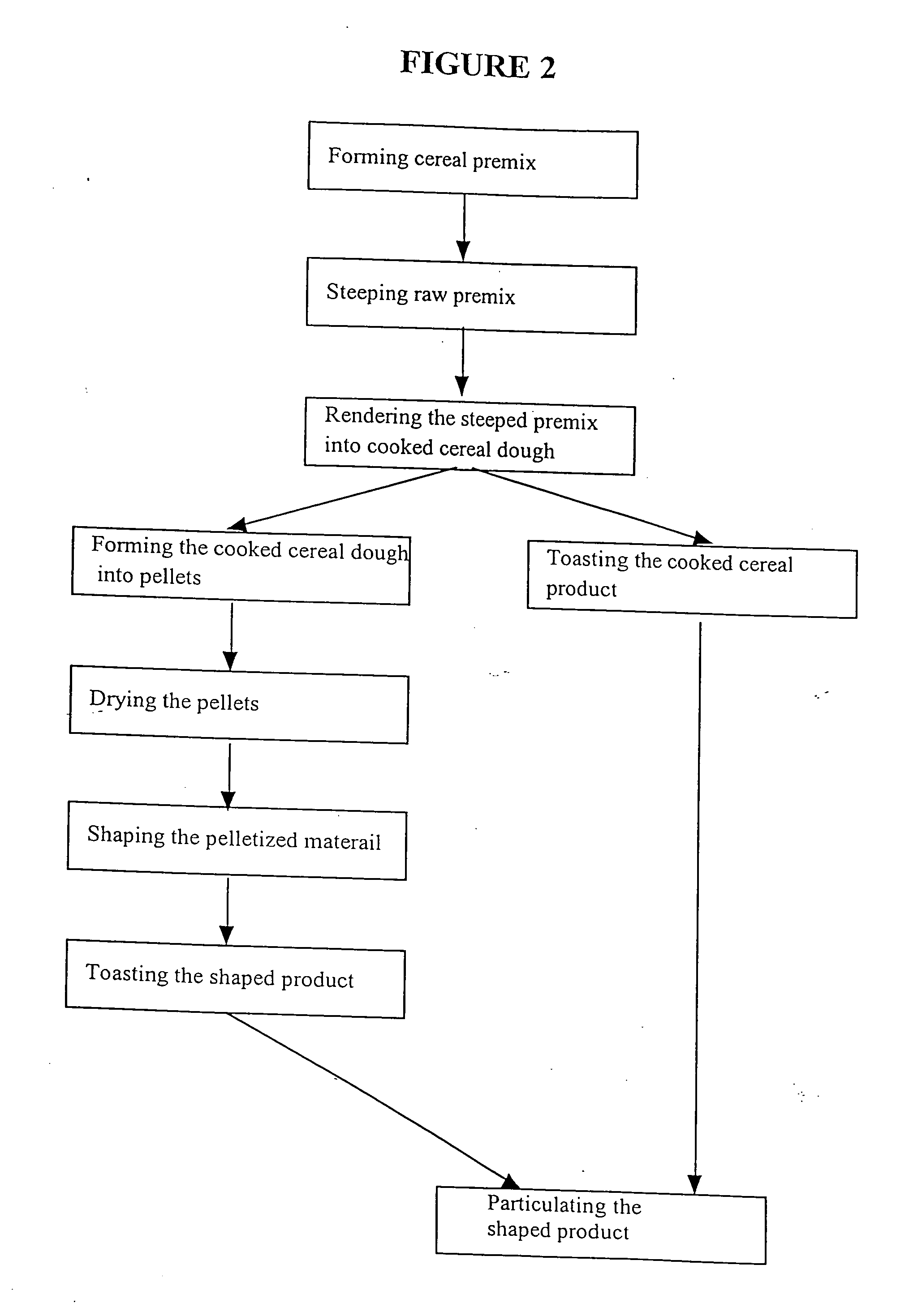

Production of whole grain shredded products

InactiveUS20060246195A1Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsSnack food

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 135° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS

Low water activity food binder and methods related thereto

The present invention provides a binder syrup comprising polydextrose, crystalline fructose and glycerin. The binder syrup has a low water activity of less than 0.55 and provides a significant amount of fiber. The binder syrup is disposed on particulates, such as whole grains, rolled oats, and fruit pieces, to form food products, such as ready-to-eat cereals and granola bars. The binder syrup also provides a desirable taste and maintains a chewy texture when used in the food products.

Owner:KELLOGG CO

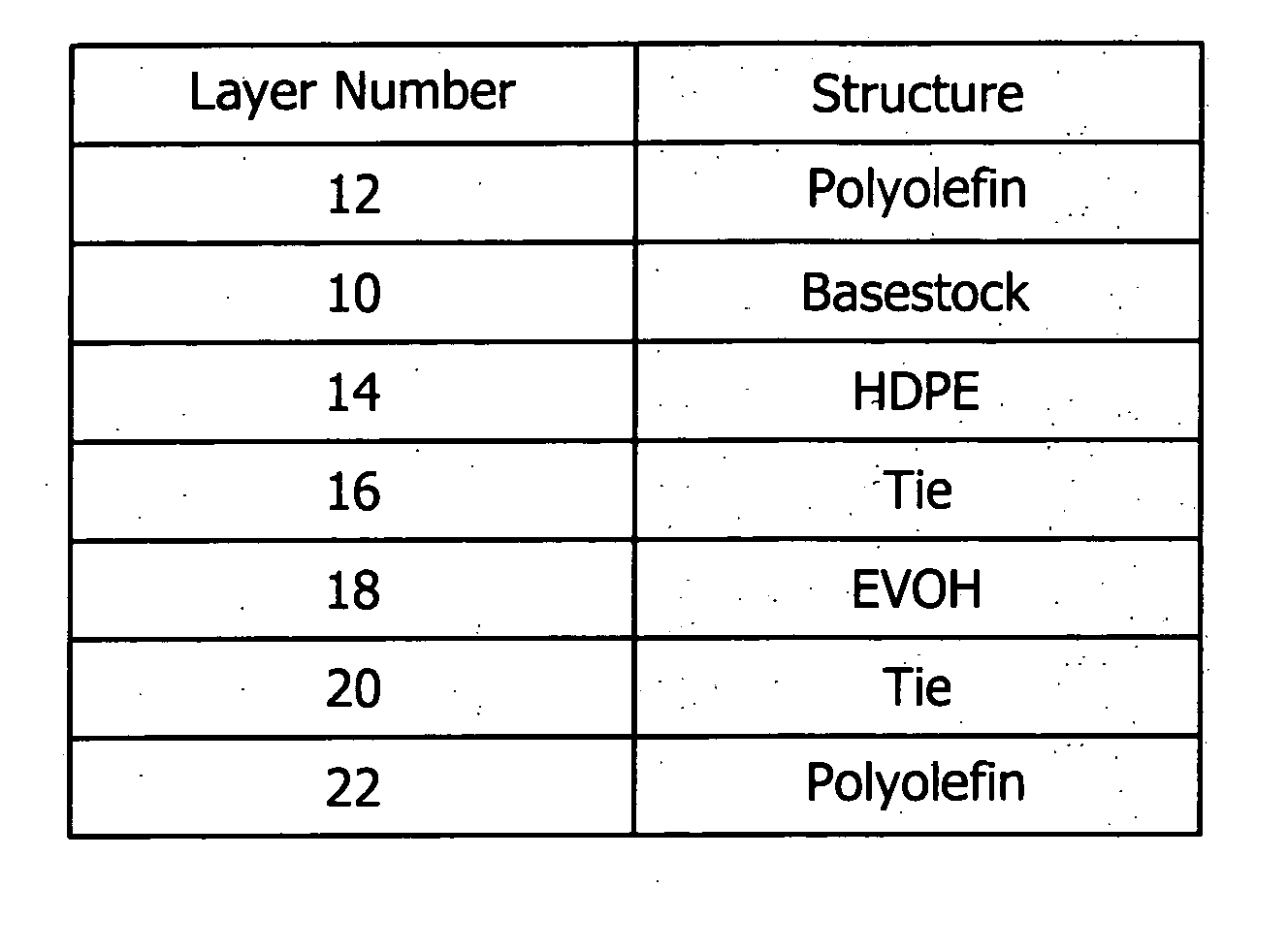

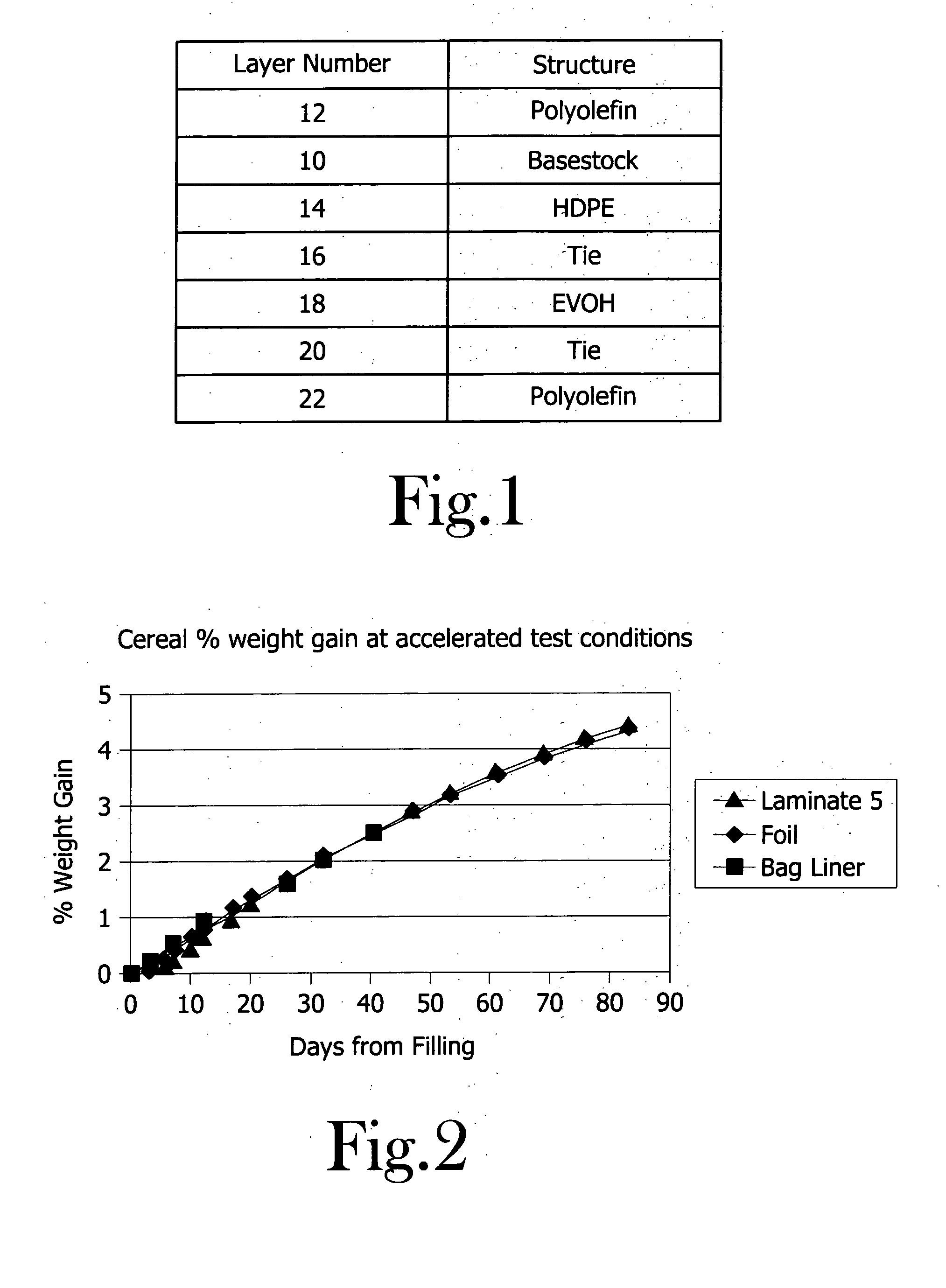

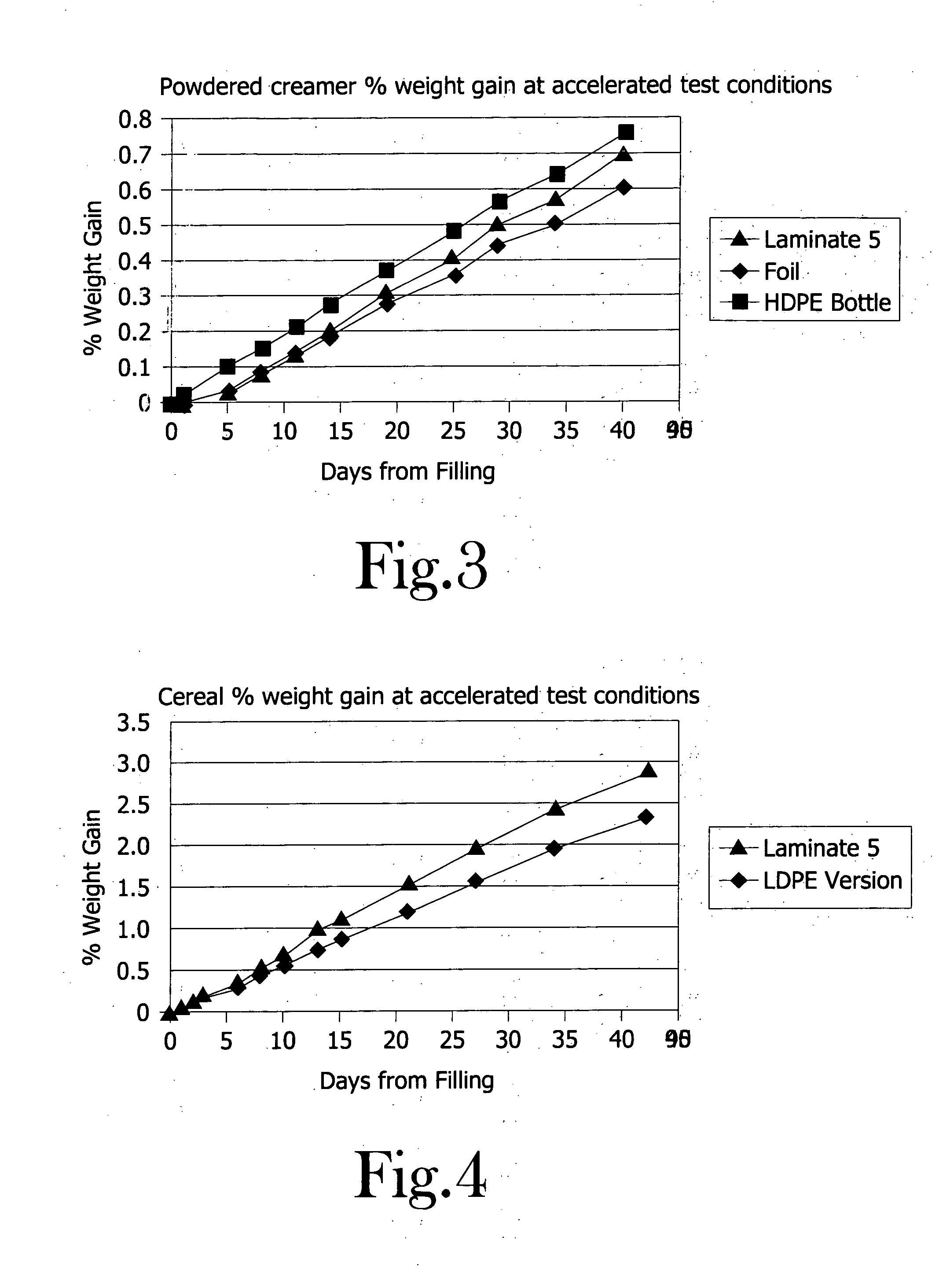

Moisture vapor barrier laminate

InactiveUS20050074621A1Synthetic resin layered productsCellulosic plastic layered productsPolymer sciencePolyolefin

A paperboard laminate comprising a paperboard substrate, having an interior surface and an exterior surface, a layer of high density polyethylene on the interior surface of the paperboard substrate, a tie layer interior to the high density polyethylene layer, a barrier layer interior to the high density polyethylene layer, a second tie layer interior to the barrier layer, and a polyolefin layer interior to the second tie layer. The laminate is useful for packaging dry food products such as ready-to-eat cereals, powdered drink mixes, baking goods, and non-food products such as dry laundry detergent, fertilizer pellets, and powdered air fresheners.

Owner:INT PAPER CO

Production of whole grain shredded products

InactiveUS20060246193A1Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 120° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method of bleaching cereal grains

InactiveUS7101580B2White colorIncrease volumeDough treatmentEdible seed preservationFiberFood flavor

The present invention describes bleached grain products such as bleached whole wheat flour that are obtained having the color and taste of white flour by bleaching whole wheat kernels prior to conventional flour milling. The wheat kernels are treated with a peroxide solution to lighten the color of the bran layers. The bleached grain kernels can be tempered and milled into whole grain flours having 10% to 12% dietary fiber from the bran but which are white in color and bland in flavor. The whitened, high fiber whole wheat flours can be used to prepare good tasting, and nutritious products such as baked goods such as breads and pastries as well as pasta product, and ready-to-eat cereals or grain based snacks.

Owner:GENERAL MILLS INC

Ready-to-eat cereal with reduced sugar coating

Disclosed is a reduced sugar coating for coating a variety of food products including ready-to-eat cereals, granola, trail mix, energy bars, granola bars, cookies, cakes, pies, crackers, and muffins. The reduced sugar coating provides a frosted appearance to the food products and permits up to 50% reduction of the sugar in a coating composition while maintaining the taste, texture and function of a full sugar coating composition. The removed sugar is replaced by a type 4 resistant starch in an amount of from 0.1 to 1.0 parts of type 4 resistant starch per every 3 parts of removed sugar. Preferably the source of the type 4 resistant starch is potato, however the source can also comprise wheat, corn, rice, tapioca, quinoa, a legume, barley, banana, sorghum, oat, millet, sweet potato, or mixtures thereof.

Owner:KELLOGG CO

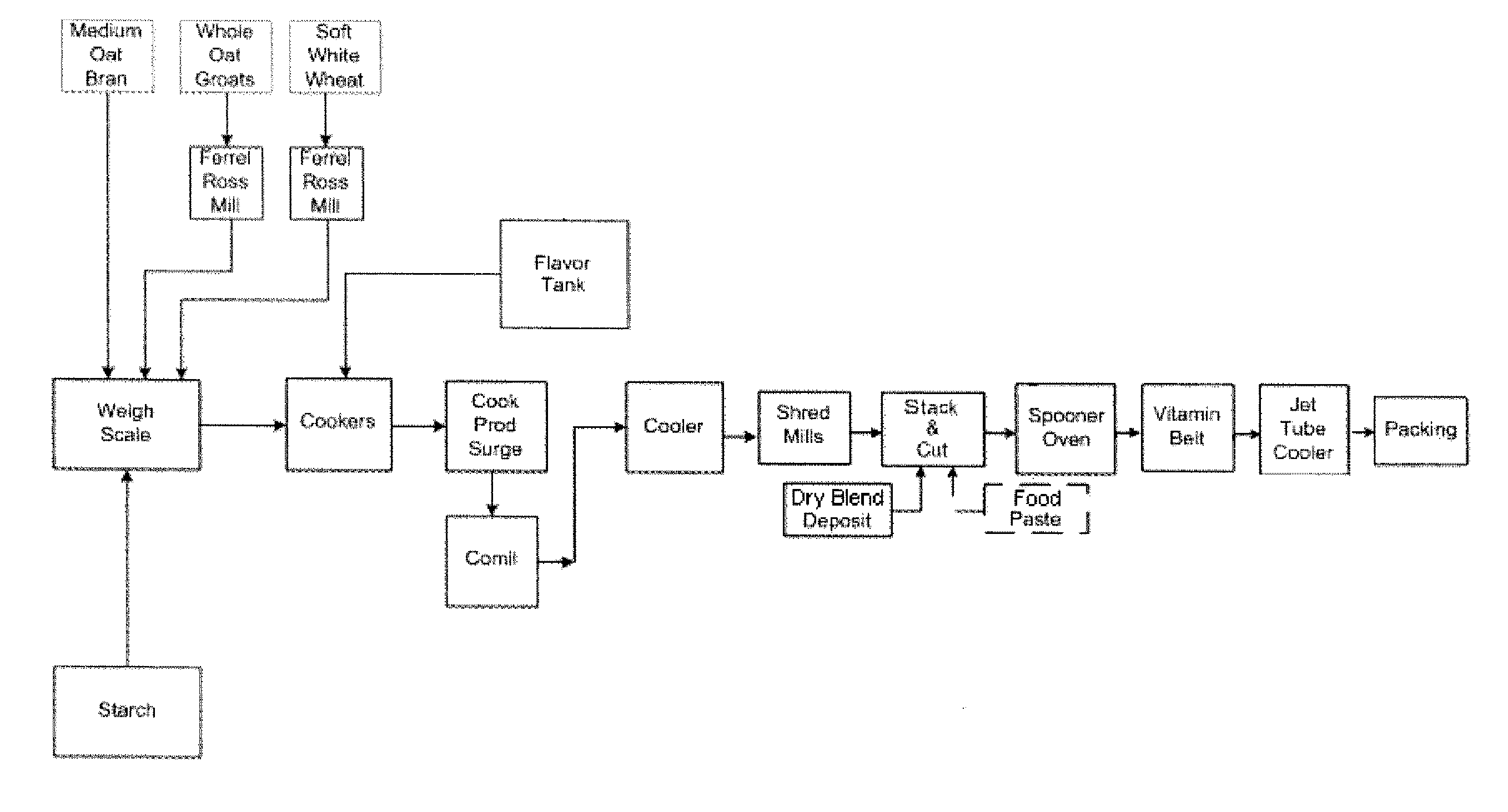

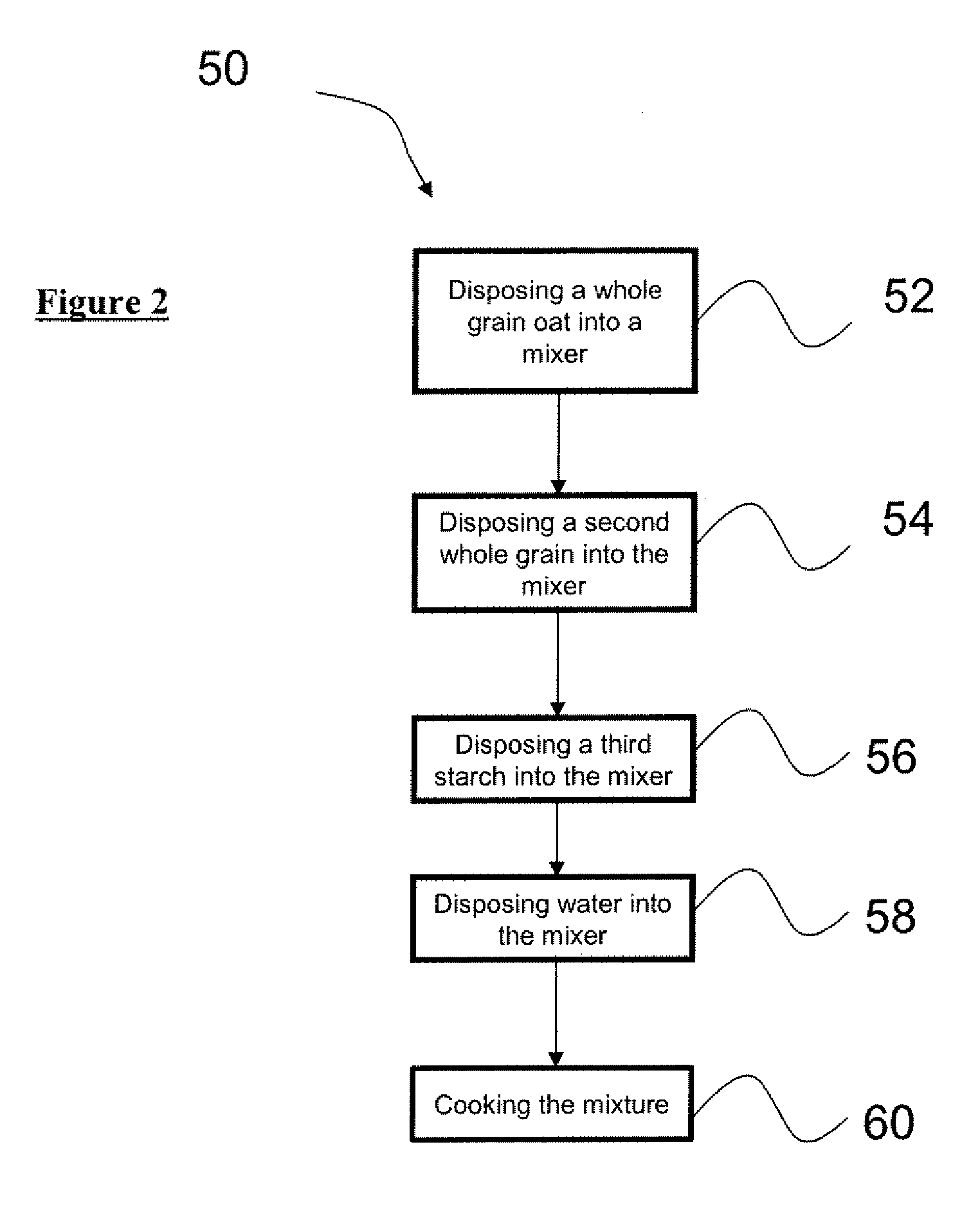

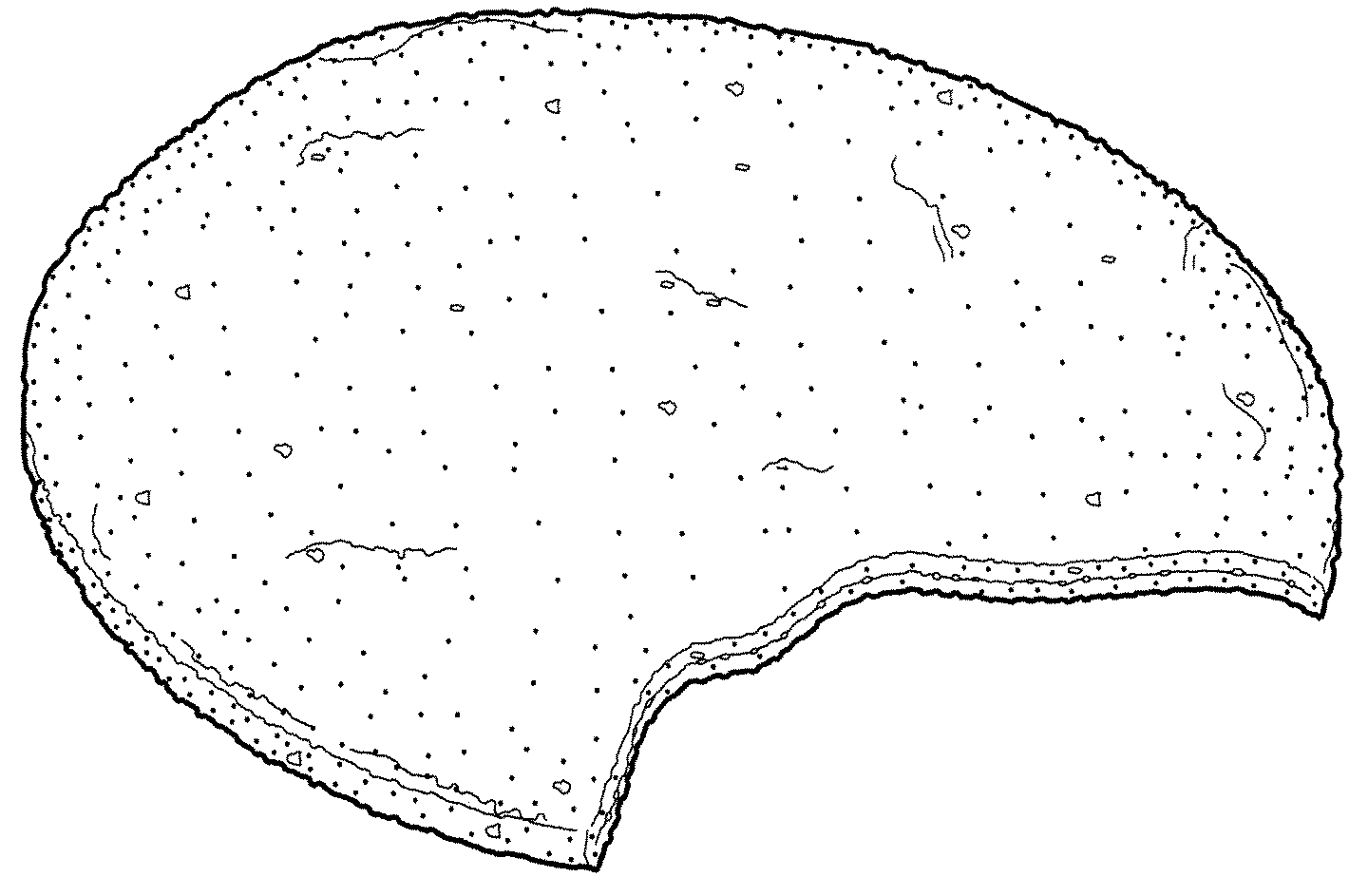

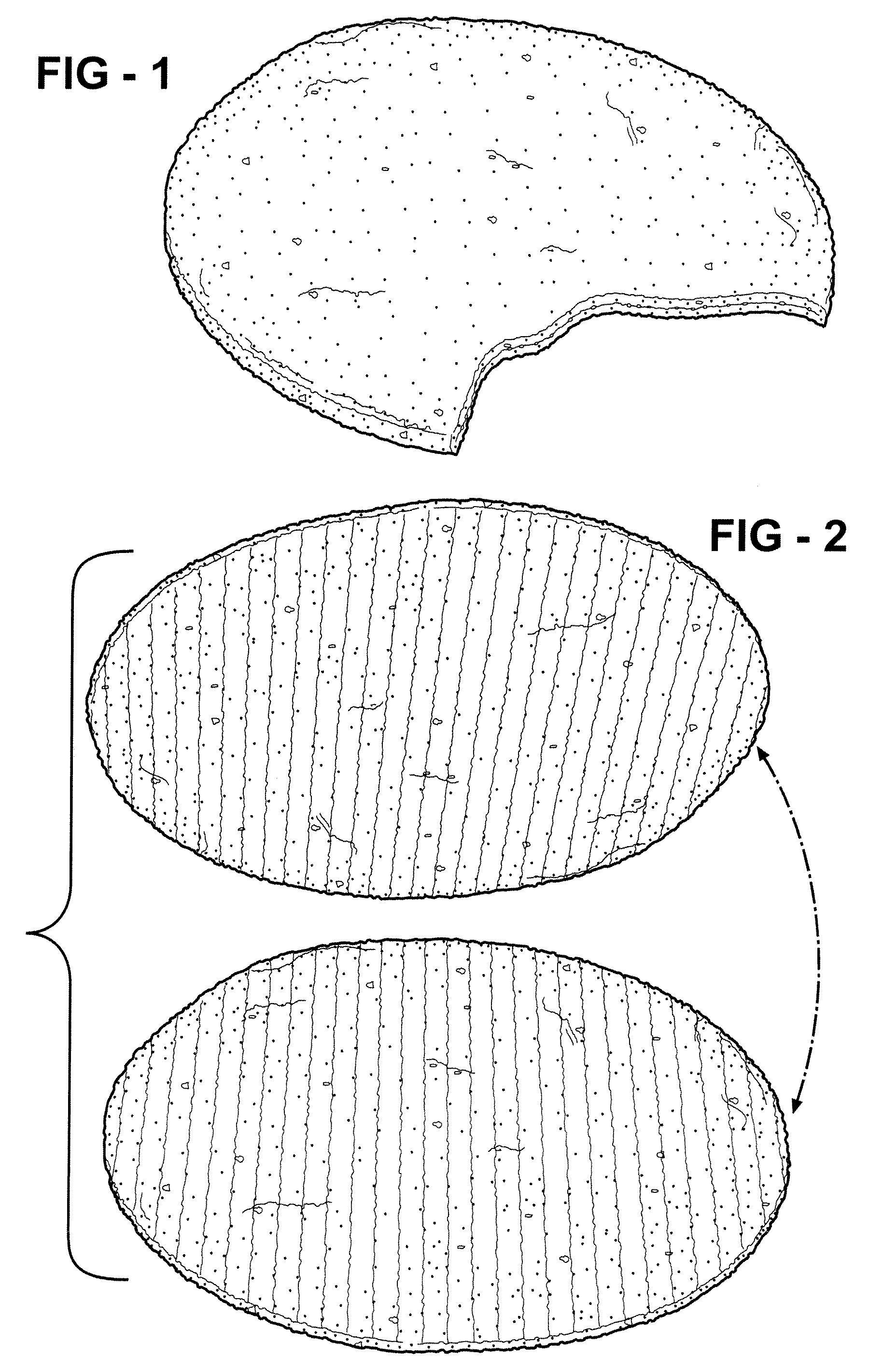

Shredded ready-to-eat cereal with oats

InactiveUS20090087527A1Improve the level ofDough treatmentFood coatingCereal grainReady to eat cereals

A method of producing cooked cereal grains containing a high level of whole oats for a shredded ready-to-eat cereal. The method begins by disposing a whole grain oat into a mixer. The whole grain oat has an exposed first starch. Next, a second whole grain is disposed into the mixer. The second whole grain has an exposed second starch that is different from the first starch. A third starch is disposed into the mixer to act as a binder of the whole grain oat and second whole grain. Water is added to the mixer to form a mixture that is cooked to form cooked cereal grains containing high levels of whole oats. The cooked grains are shredded and layered to form a shredded wheat-like biscuit.

Owner:KELLOGG CO

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS7494683B2Increase contentImprove flavor profileDough treatmentBaking mixturesCereal grainBeta-Glycan

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is subjected to second and third rounds of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

Ready to eat cold cereal cakes with ingredients

InactiveUS20140093620A1Increase nutritionReduce consumptionFood preparationReady to eatAdditive ingredient

Cold and ready to eat cereal cakes, with a variety of ingredient combinations suitable for healthy consumption. Serving size can be a single serving, or a six pack of servings for convenience such that the inherent nutritional aspects of cereals are able to be included in consumer's diets.

Owner:CHANG ALICE

Layered Snacks And Ready-To-Eat Cereals And Methods Related Thereto

InactiveUS20080032005A1Inhibition formationAvoid layeringDough treatmentConfectioneryFlavorReady to eat cereals

The present invention is in the field of layered food products and processes for making them. The present invention provides food items with improved crispy and non-abrasive texture and more abundant flavor, as well as industrially-efficient and cost-effective processes for making food items with the improved crispy and non-abrasive texture and more abundant flavor.

Owner:KELLOGG CO

Bleached grain and grain products and methods of preparation

InactiveUS20070054016A1White colorIncrease volumeDough treatmentEdible seed preservationFiberBaked goods

The present invention describes bleached grain products such as bleached whole wheat flour that are obtained having the color and taste of white flour by bleaching whole wheat kernels prior to conventional flour milling. The wheat kernels are treated with a peroxide solution to lighten the color of the bran layers. The bleached grain kernels can be tempered and milled into whole grain flours having 10% to 12% dietary fiber from the bran but which are white in color and bland in flavor. The whitened, high fiber whole wheat flours can be used to prepare good tasting, and nutritious products such as baked goods such as breads and pastries as well as pasta product, and ready-to-eat cereals or grain based snacks.

Owner:METZGER LLOYD E

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS20090078802A1Increase contentImprove flavor profileGrain huskingGrain polishingAmyrisFood flavor

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is fractionated into a coarse and fine oat bran sub-streams. The oat bran sub-streams are each is subjected to second roller milling step and then bolted. The second bolting of oat bran is then subjected to a third round of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

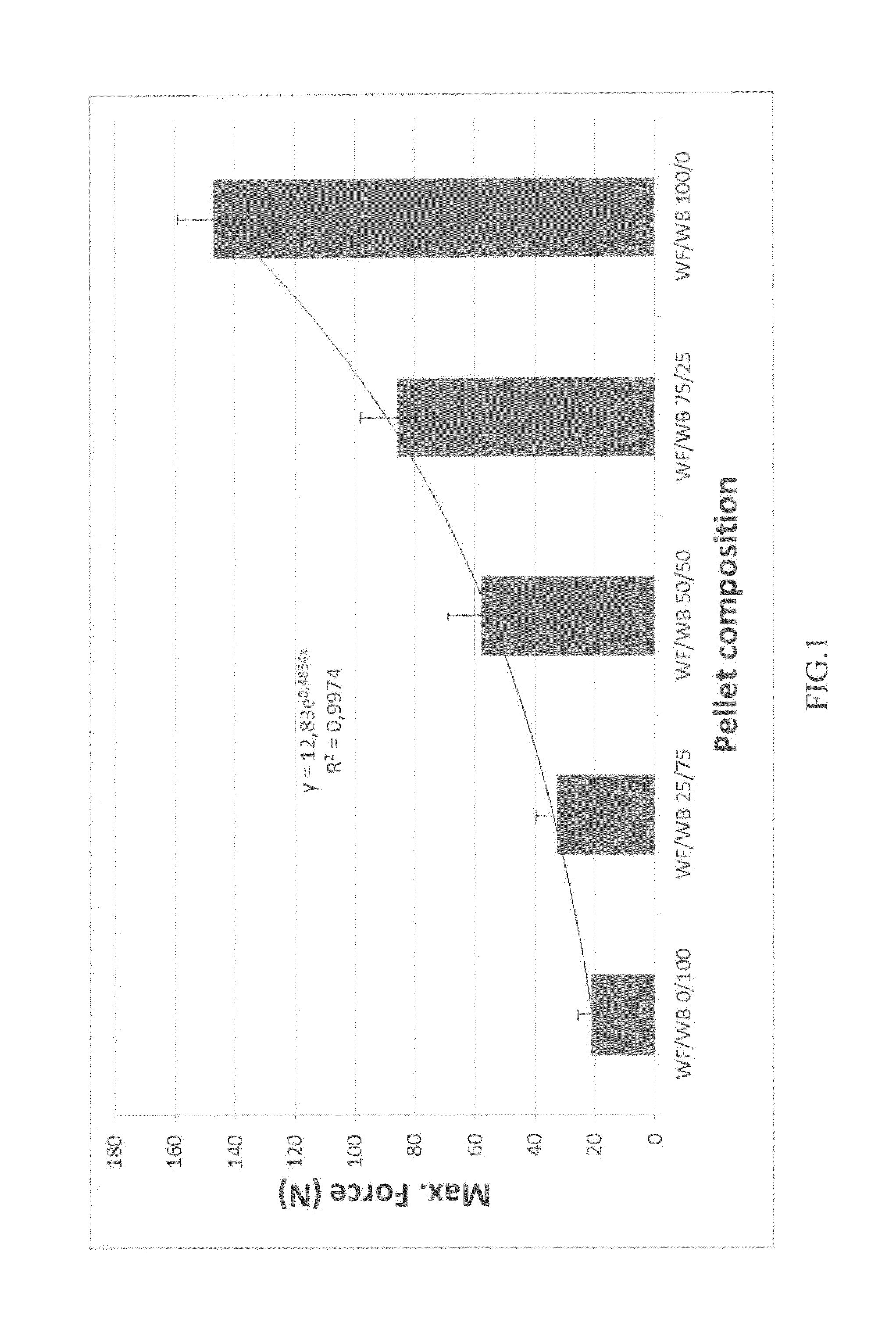

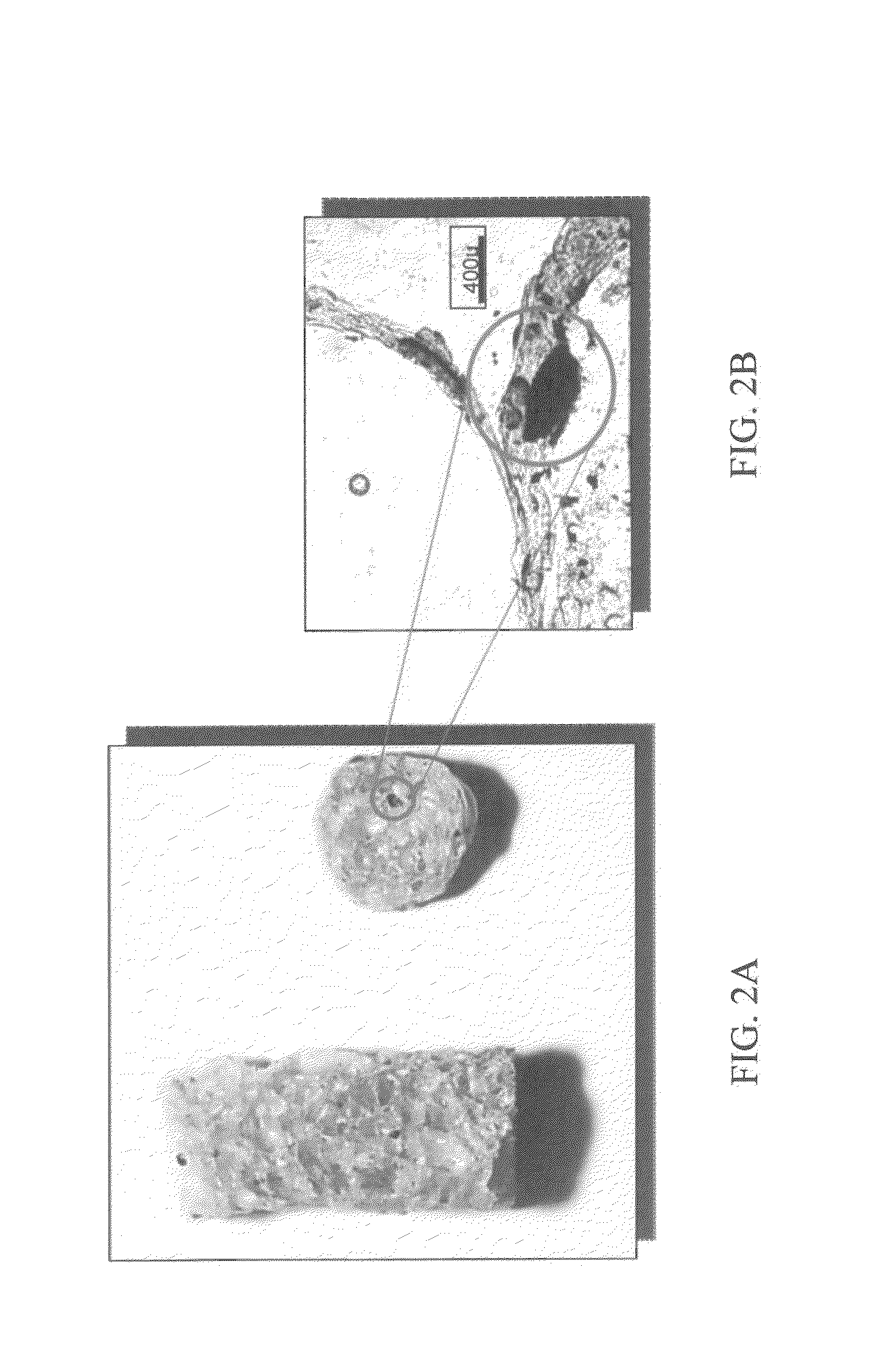

Cereal-Based Product with Improved Eating Quality Fortified with Dietary Fiber and/or Calcium

Inhibition of expansion of a cereal product, such as a ready-to-eat cereal, by a particulate insoluble component such as fiber and / or calcium is avoided by pelletizing the particulate insoluble component. A binder component, such as gelatinized starch, is used to bind particles of the particulate insoluble component into a coherent mass which is formed into non-expanded pellets for fortification of the cereal product. The expanded cereal products, such as extruded puffed RTE cereals which contain the pellets, exhibit a crisp, uniform texture and cell structure, improved, prolonged bowl life, a non-gritty mouthfeel, and a smooth, uniform surface appearance even though they are fortified with high amounts of the solid or particulate insoluble nutritional components.

Owner:GENERAL MILLS INC

Production of whole grain shredded products

InactiveUS7964233B2Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsGlutenCereal grain

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 120° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Production of whole grain shredded products

InactiveUS7939122B2Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 135° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Food products containing rice bran oil

Disclosed are cooked dried farinaceous food products such as cooked cereal doughs, ready-to-eat cereals and grain based snacks fabricated from such cooked cereal doughs containing or fortified with rice bran oil supplied at least in part by non-hydrogenated rice bran oil especially high oryzanol rice bran oil. The cereals contain about 0.1 to 10% added rice bran oil. The rice bran oil ingredient can be incorporated into the dough and / or topically applied. The rice bran oil provides the processing advantages of oil addition during processing with low or now transfatty acids but with extended shelf stability. The finished fortified cereal products are not only organoleptically desirable but almost indistinguishable from their counterparts containing hydrogenated fats.

Owner:GENERAL MILLS INC

Coffee-flavored cereal

Owner:SCHLOSSER DAVID

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS7976888B2Increase contentImprove flavor profileGrain huskingGrain polishingFlavorBeta-glucan

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is fractionated into a coarse and fine oat bran sub-streams. The oat bran sub-streams are each is subjected to second roller milling step and then bolted. The second bolting of oat bran is then subjected to a third round of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

Composition and Method of Preparing Ready-to-Eat Cereal with Konjac Flour as a Main Ingredient

The present invention discloses a method and composition of preparing ready-to-eat (R-T-E) cereal with konjac flour as a main ingredient. Based on the conventional method, innovations are made in mixing konjac flour with other ingredients in the composition as well as in drying the interim product. The appearance and physical property of the finale product are similar to that of the conventional R-T-E cereal, whereas konjac-associated health benefits are retained.

Owner:TANG JILL S

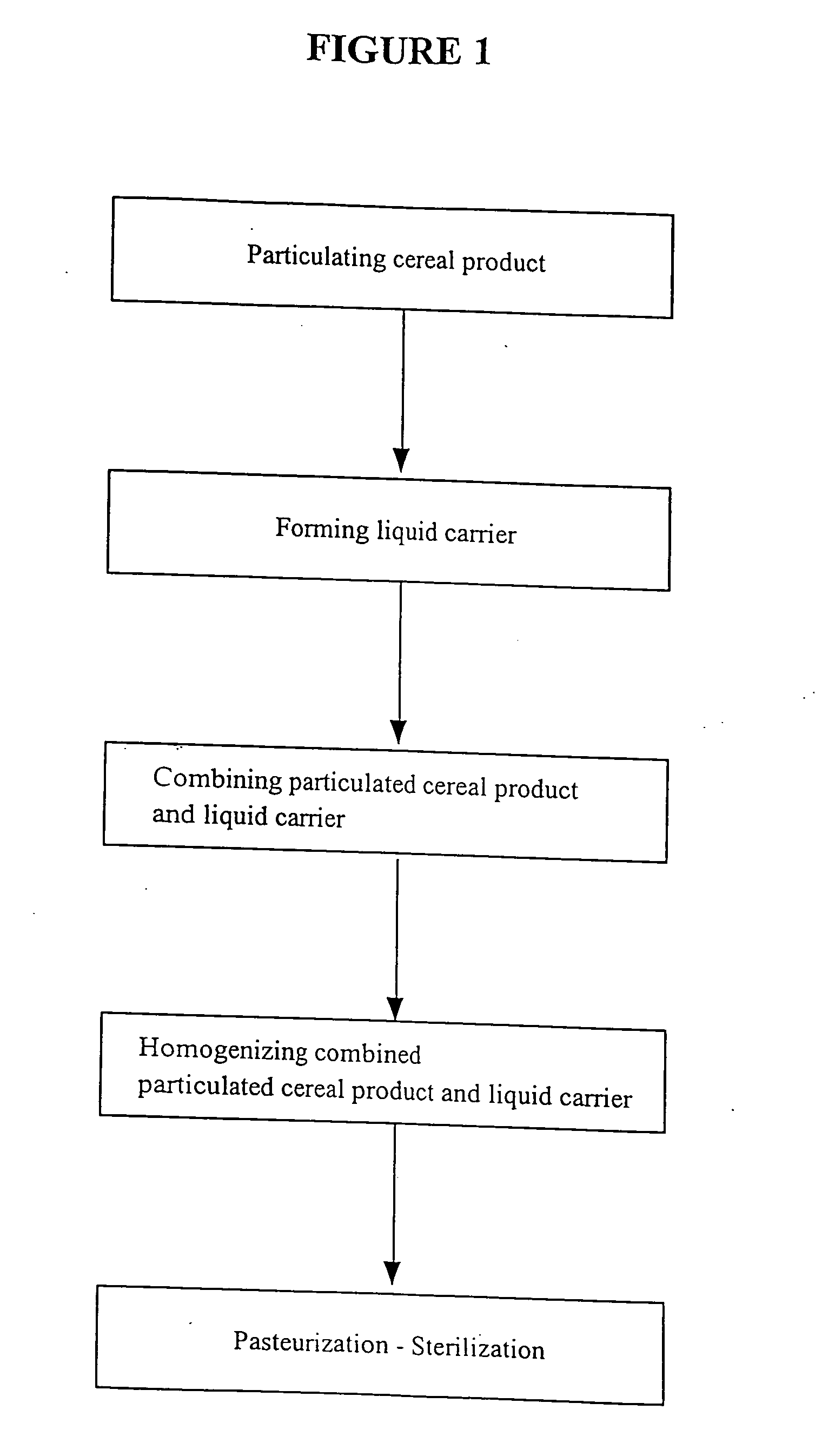

Stable hemogeneous drink composition including particulate cereal product

A ready-to-drink stable and homogeneous drink composition has particulated ready-to-eat cereal product in a liquid carrier. The drink mix composition can incorporate milk or milk-type products as the liquid carrier in either a refrigerated or shelf stable non-refrigerated format, wherein food stabilizers can be added.

Owner:O AT KA MILK PRODS COOP

Food Products Fortified With Omega-3 Fatty Acids and Processes For Making The Same

Disclosed is a process for stabilizing an omega-3 fatty acid containing powder onto a food product. The food product is coated with a coating oil and then the powder containing at least one powdered omega-3 fatty acid comprising at least one of docosahexaenoic fatty acid, eicosapentaenoic fatty acid, or a mixture thereof is applied onto the food product. The coated food product is then packaged and is stable for at least 12 weeks of storage at 70° F. 50% relative humidity as defined by the absence of development of a fishy aroma or taste. The process is widely applicable to a variety of food products including ready to eat cereals, quick cooking oatmeal, cereal bars, granola bars, potato chips, nacho chips, corn chips, cookies, crackers, pretzels, baked cheese curls, fried cheese curls and other food products.

Owner:KELLOGG CO

Easy pour bag

Owner:GENERAL MILLS INC

Soft dried marshmallow and method of preparation

Dried soft aerated confections and methods of their preparation are provided having a water activity of about 0.1 to 0.4 and a glass transition temperature of less than 20° C. The confections comprise sugars, a foaming and a structuring ingredient, preferably each gelatin, and about 5 to 15% softening agent. Preferred softening agents include glycerin, polyglycerols and mixtures thereof. The confections are aerated to densities of about 0.1 to 0.5 g / cc. The soft dried aerated confections are particularly suited for addition to children's Ready-To-Eat cereals in the form of pieces weighing about 0.1 to 2 g each. The dried confection pieces maintain their soft texture over time without causing moisture migration to the cereal.

Owner:GENERAL MILLS INC

Methods for Preparing Oat Bran Enriched in Beta-Glucan and Oat Products Prepared Therefrom

InactiveUS20090148576A1Increase contentImprove flavor profileDough treatmentAnimal feeding stuffBeta-glucanCereal grain

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is subjected to second and third rounds of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

Food products containing rice bran oil

Owner:GENERAL MILLS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com