A Redundant Excitation Double Armature Winding Multiphase Flux Switching Motor with Fault Tolerant Teeth

A double-armature winding and flux switching technology, which is applied to the shape/style/structure of windings, electric components, and winding conductors, can solve the problem that single-motor systems cannot guarantee reliability requirements, cannot meet acceleration performance and maximum speed, Increased motor size and system mass, etc., to improve reliability and fault-operating capability, overcome non-adjustable permanent magnetic field, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

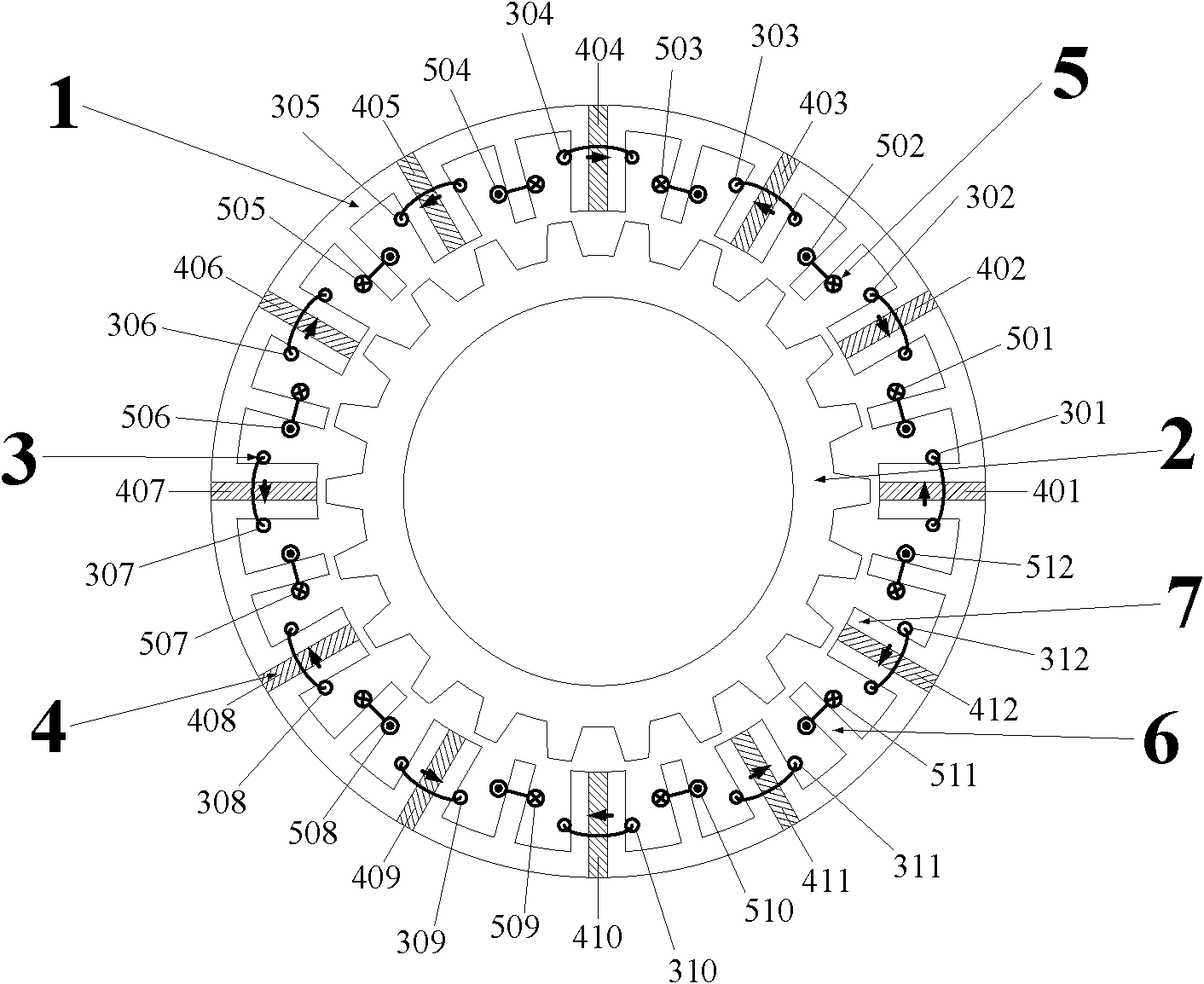

[0022] Such as figure 1 Shown is a redundant excitation dual armature winding multi-phase flux switching motor with fault-tolerant teeth, specifically a dual three-phase stator 24-slot / rotor 22-pole motor, the number of phases of the motor is m, the number of stator slots for P s , the number of rotor poles is P r ; where m=3.

[0023] The motor comprises a stator core 1, a rotor core 2 located in the stator core 1, 4m armature coils 3 and 4m field coils 5, the stator core 1 and the rotor core 2 are salient pole structures; the stator core 1 is composed of 4m E-shaped iron core units and 4m permanent magnets 4 for magnetization are staggered and spliced. The magnetization direction of the permanent magnets 4 is tangential, and the magnetization directions of adjacent permanent magnets 4 are opposite. The E-shaped The protruding teeth in the middle of the core unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com