Mixed excitation flux switching motor

A technology of magnetic flux switching motor and hybrid excitation, applied in synchronous machine parts, magnetic circuit static parts, magnetic circuit rotating parts, etc., can solve the problem of reducing air gap magnetic density, increasing copper consumption, power density, torque and efficiency reduction, to achieve the effect of high efficiency, easy processing and strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

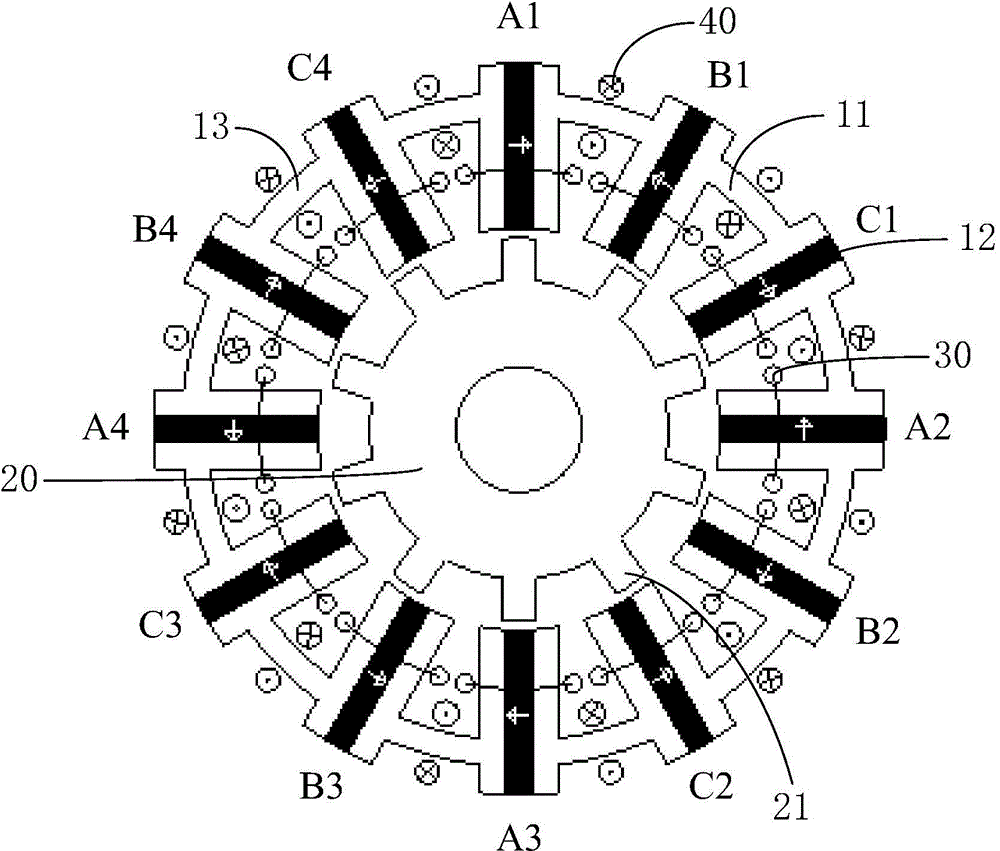

[0022] The present invention provides a hybrid excitation flux switching motor, such as figure 1 As shown, it includes a stator and a rotor 20. Several salient poles 21 are evenly distributed on the rotor 20. The stator includes 12 H-shaped iron cores 11, 12 tangentially magnetized permanent magnets 12, armature coils 30 and excitation coil 40, the H-shaped iron cores 11 and the permanent magnets 12 are alternately arranged, and the magnetization directions of the two adjacent permanent magnets 12 are opposite ( figure 1 The direction shown by the middle white arrow), the excitation coil 40 is wound on the yoke magnetic bridge 13 of the H-shaped iron core 11, and the excitation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com