A kind of preparation method of aluminum silicon carbide water-cooled tooth plate

A technology of aluminum silicon carbide and porous silicon carbide, which is applied in the field of preparation of aluminum silicon carbide water-cooled tooth plates, to achieve the effects of yield and performance improvement, stable thermal expansion coefficient, and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

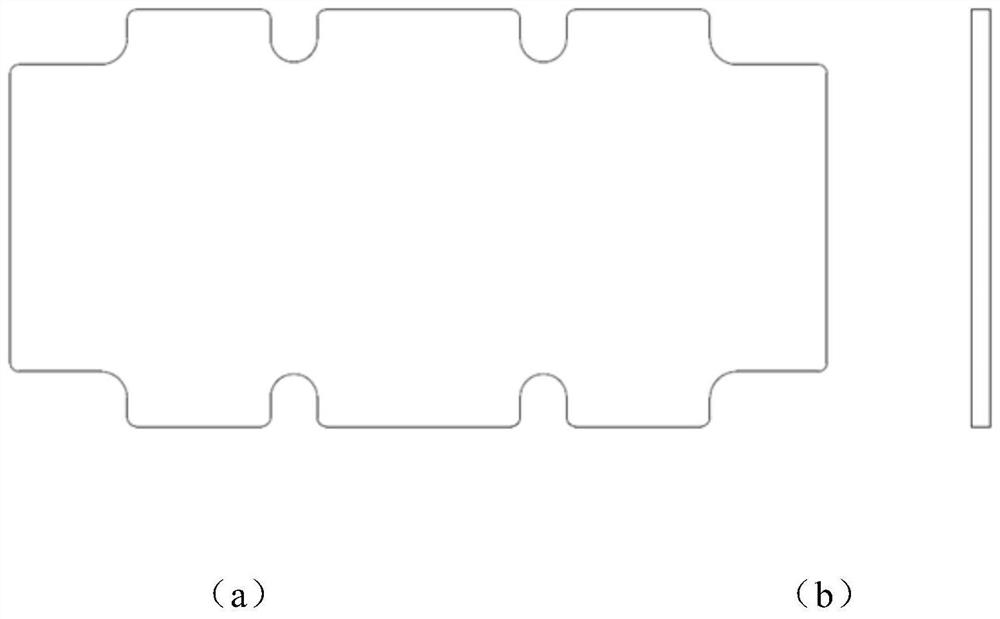

[0039] The invention discloses a method for preparing an aluminum silicon carbide water-cooled tooth plate. The aluminum silicon carbide composite and the main surface of the aluminum alloy tooth are connected by a metal welding method, and the welding interface is connected by the same metal, which can prevent the aluminum silicon carbide main surface from The main surface of the tooth part is peeled off, and the specific steps are as follows:

[0040] S1. Using a high-pressure forging method, the porous silicon carbide prefabricated body is soaked in the molten metal of aluminum alloy under high temperature and high pressure to obtain an aluminum-silicon carbide composite body;

[0041] Put the aluminum alloy in the crucible and heat it to 720-760°C, put the porous silicon carbide preform into the mold and heat it to 700-740°C; put the heated aluminum liquid crucible and the porous silicon carbide preform mold in the order of top and bottom In the high-pressure airtight equi...

Embodiment 1

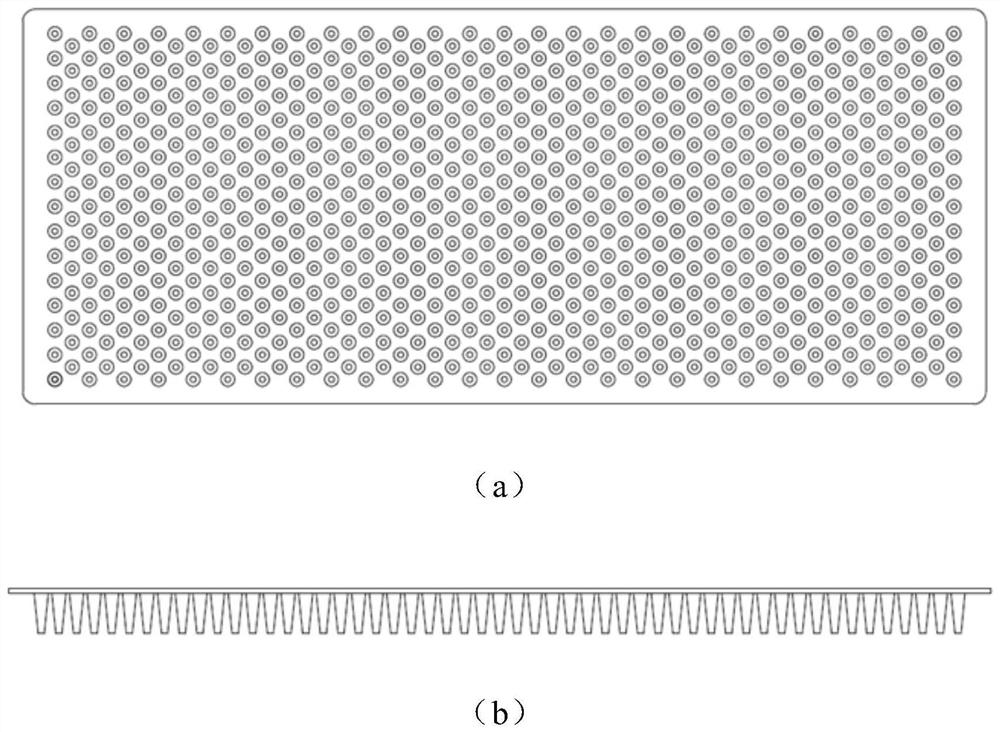

[0053] Put an aluminum alloy containing 0.5% by mass of magnesium into a crucible and heat it to 720°C, put a porous silicon carbide preform with a volume ratio of 55% into a mold and heat it to 700°C; The silicon preform mold enters the high-pressure airtight equipment in the order of top and bottom, the infiltration pressure is controlled at 1Mpa, and the holding time is 30 minutes. After the mold is cooled, the aluminum-silicon carbide composite body with a thickness of 3mm is removed from the mold. , the average thickness of the aluminum alloy layer in the aluminum-silicon carbide composite is 50 μm, and the flatness of the welding surface of the aluminum-silicon carbide composite is less than 50 μm;

[0054] Select an aluminum alloy containing 0.5% by mass of magnesium, control the temperature of aluminum water smelting to 680°C, the mold temperature to 220°C, the injection pressure to 20Mpa, the pressure holding time to 10s, and mold cooling to obtain a die-cast aluminum ...

Embodiment 2

[0057] Put an aluminum alloy containing 0.8% by mass of magnesium into a crucible and heat it to 730°C, put a porous silicon carbide preform with a volume ratio of 58% into a mold and heat it to 705°C; The silicon prefabricated mold enters the high-pressure airtight equipment according to the upper and lower order, the infiltration pressure is controlled at 2Mpa, and the holding time is 35 minutes. After the mold is cooled, the aluminum-silicon carbide composite body with a thickness of 4mm is removed from the mold. , the average thickness of the aluminum alloy layer in the aluminum silicon carbide composite is 80 μm, and the flatness of the welding surface of the aluminum silicon carbide composite is less than 50 μm;

[0058] Select an aluminum alloy containing 0.8% by mass of magnesium, control the melting temperature of aluminum water to 690°C, the mold temperature to 230°C, the injection pressure to 22Mpa, the pressure holding time to 10s, and mold cooling to obtain a die-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com