Use method for anti-adhesion crusher for crushing adhesive oil shale

A viscous oil and crusher technology, which is applied in grain processing and other directions, can solve the problems of feed particle size limitation and crusher inoperability, etc., and achieve the effects of reducing downtime maintenance, improving production efficiency, and ensuring crushing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

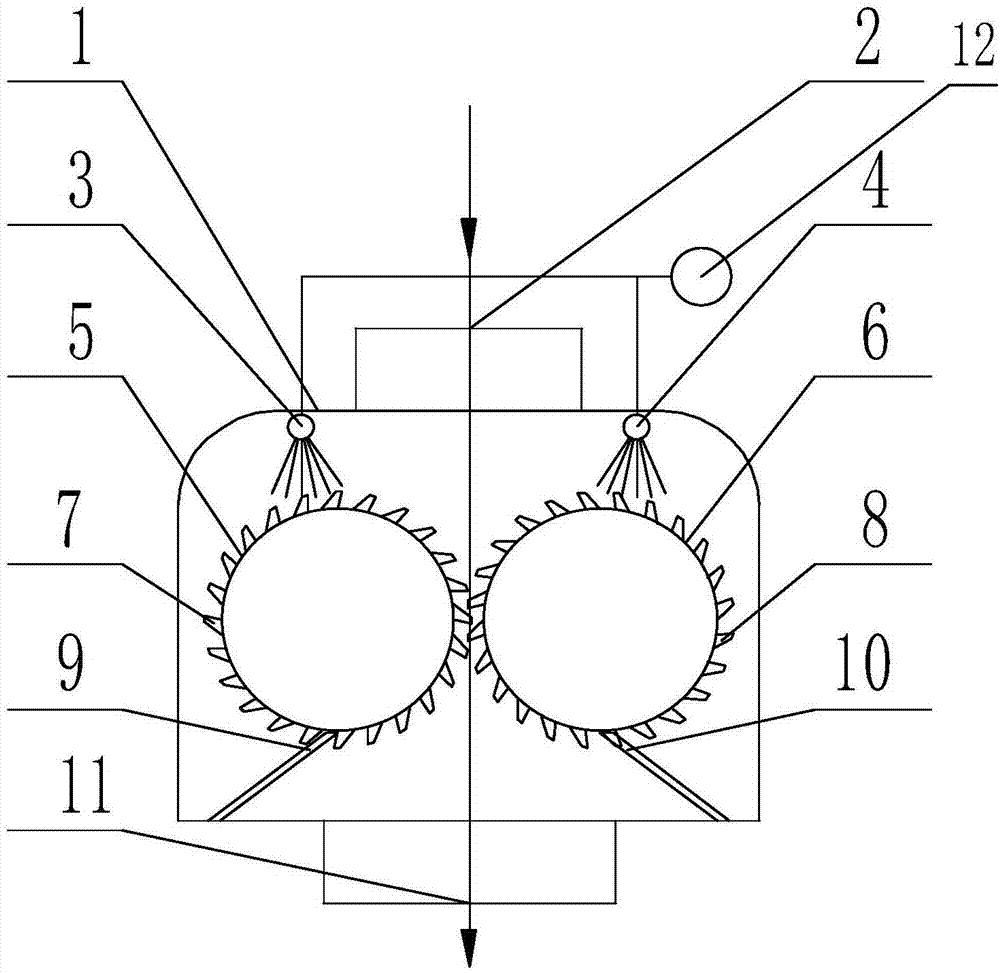

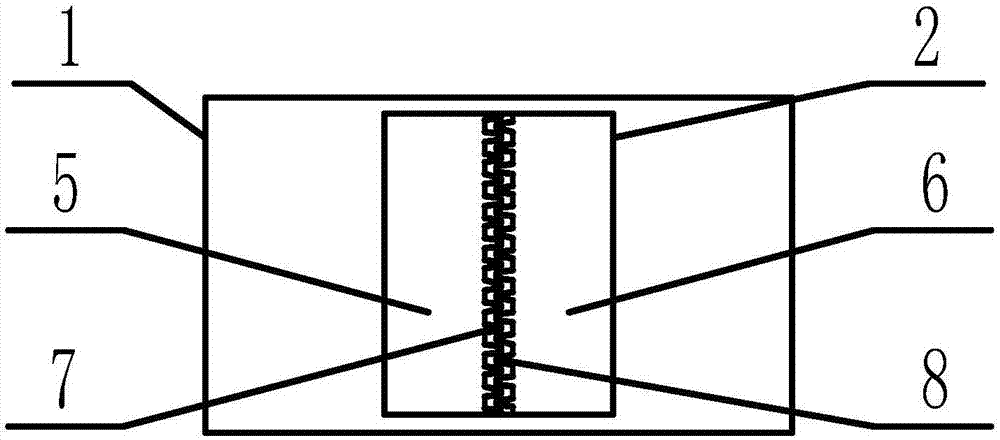

[0017] The upper middle part of the casing 1 is provided with the feeding port 2, the lower part of the casing 1 is provided with the feeding port 11, the left roller 5 is arranged on the left side of the casing 1, and the left crushing teeth are evenly arranged on the outside of the wall of the left roller 5. 7. The right roller 6 is arranged on the right side of the casing 1, and the right crushing teeth 8 are evenly arranged on the outside of the wall of the right roller 6, and the left crushing teeth 7 and the right crushing teeth 8 are correspondingly set; the left roller 5 and the The seams of the right roller 6 are respectively set on the same line as the centers of the feeding port 2 and the feeding port 11;

[0018] The left spreader 3 is set on the left side of the feed port 2 in the casing 1, and the spray port of the left spreader 3 corresponds to the left side of the left roller 5, and the right spreader is set on the right side of the feed port 2 in the casing 1 ...

Embodiment 2

[0022] After the left crushing tooth 7 and the right crushing tooth 8 with the attachment layer rotate and engage, the viscous oil shale is continuously conveyed to the feed port 2 through the conveying device. Crushing is carried out in the occlusal crushing teeth of the crushing teeth 7 and the right crushing teeth 8, and the crushed viscous oil shale and tailings dry powder adhesion layer are separated from the natural fall and discharged through the discharge port 11.

Embodiment 3

[0024] The viscous oil shale falls naturally, while the left crushing tooth 7 and the right crushing tooth 8 rotate, the scraper heads of the left scraper 9 and the right scraper 10 respectively face the gap between the left crushing tooth 7 and the right crushing tooth 8 and the left roller 5, The cylinder wall surface of the right roller 6 is cleaned, and the viscous oil shale that falls after cleaning falls into the discharge port 11, and the pulverized viscous oil shale discharged from the discharge port 11 is transported to the dry distillation furnace for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com