Roll teeth with wear-resisting metal for toothed roll crusher

A wear-resistant metal, toothed roller technology, applied in grain processing and other directions, can solve the problems of complicated use and adjustment, consumption of precious metals, and large machine wear, etc., and achieve the effect of convenient adjustment and maintenance, less consumption of precious metals, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

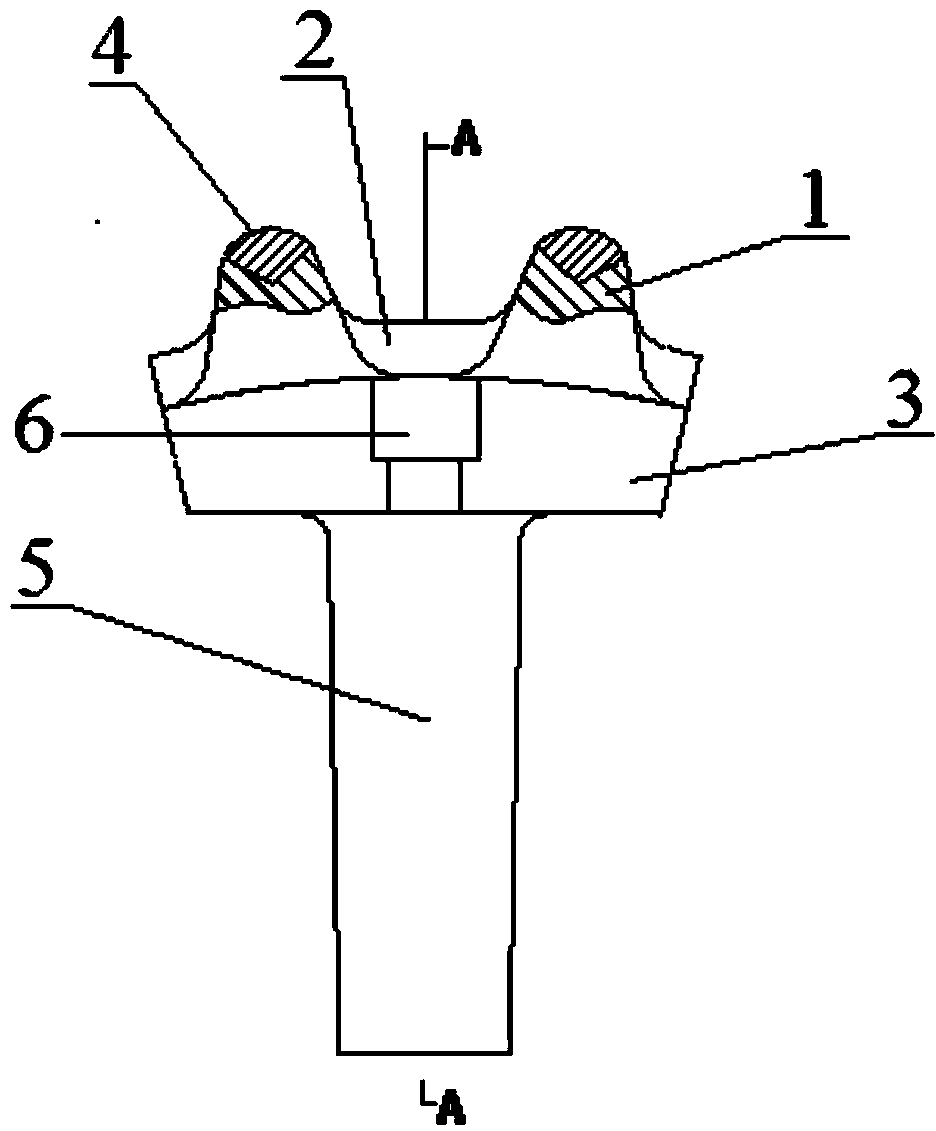

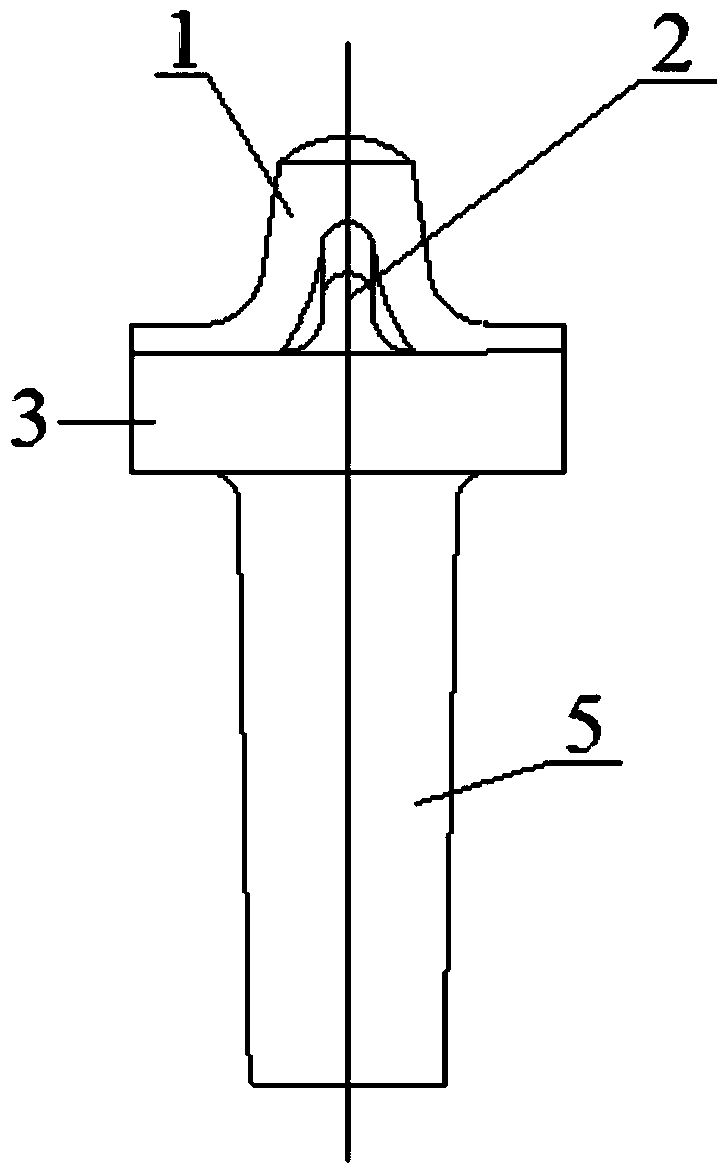

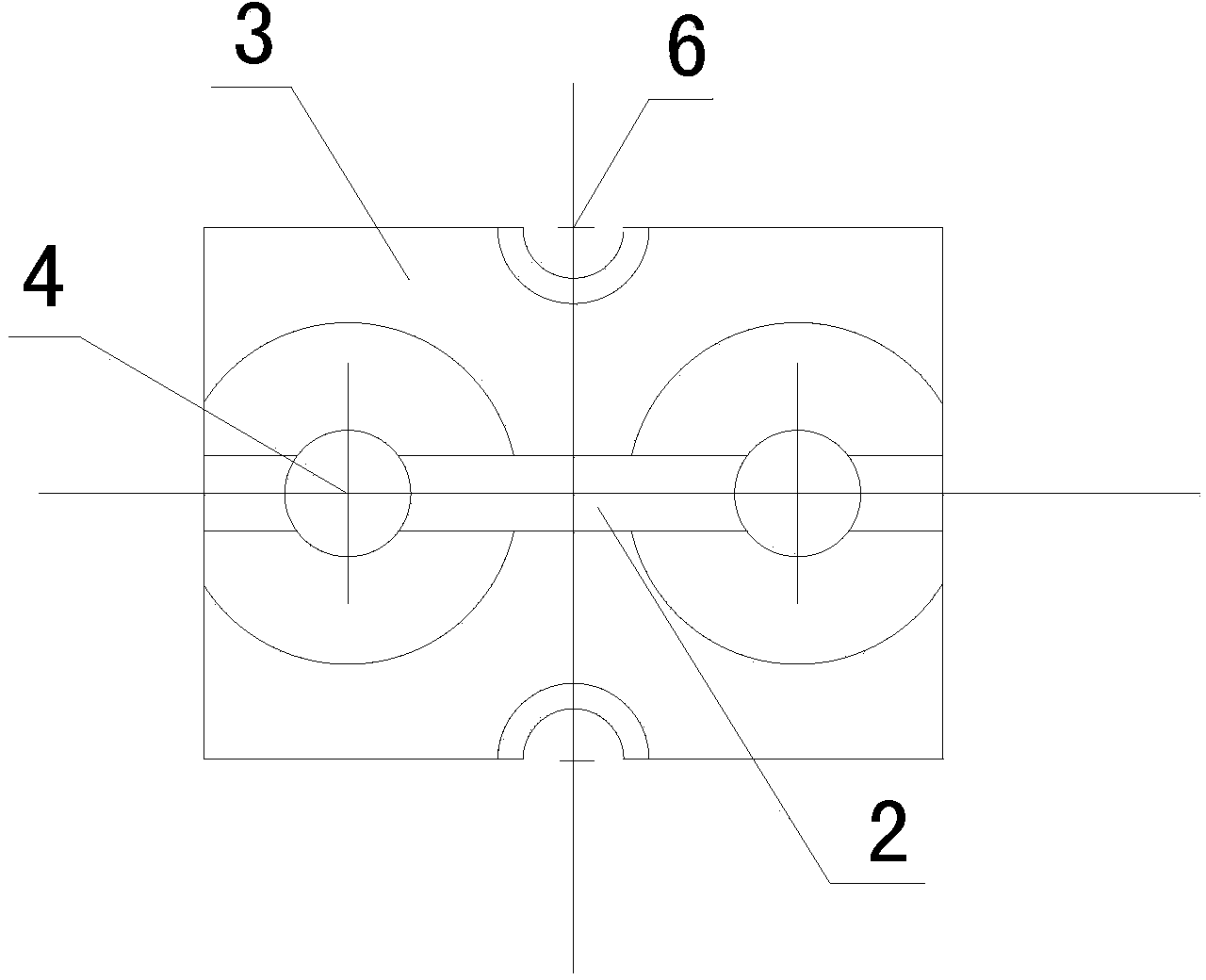

[0015] see figure 1 , 2 , 3, 4, a toothed roller crusher roller teeth with wear-resistant metal, including a guard platform 3 and a tooth handle 5, the guard platform 3 has integrally connected teeth 1 and ribs 2 distributed at intervals, the teeth The top of 1 has wear-resistant metal 4 integrally connected, is provided with installation hole 6 on the apron 3, and tooth handle 5 is integrally connected in the bottom of apron 3.

[0016] In the present invention, the mounting hole is a U-shaped stepped hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com