Wind generating set yawing device and wind generating set

A wind turbine, yaw technology, applied in wind turbines, wind turbine control, wind power generation, etc., can solve problems such as economic loss, easy jamming, deformation, etc., and achieve the effect of avoiding secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

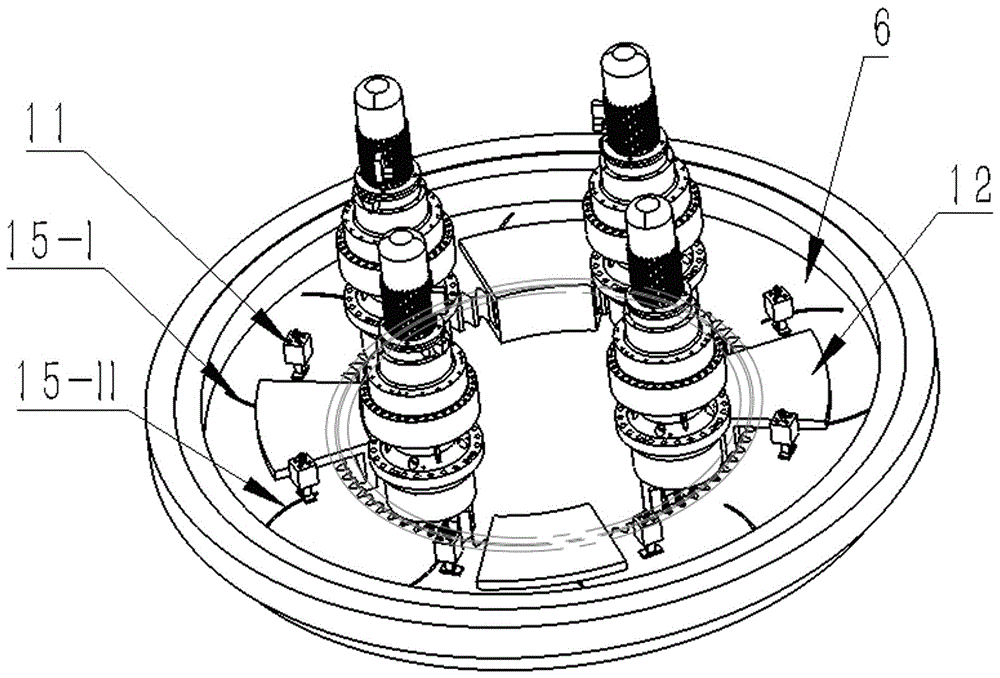

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

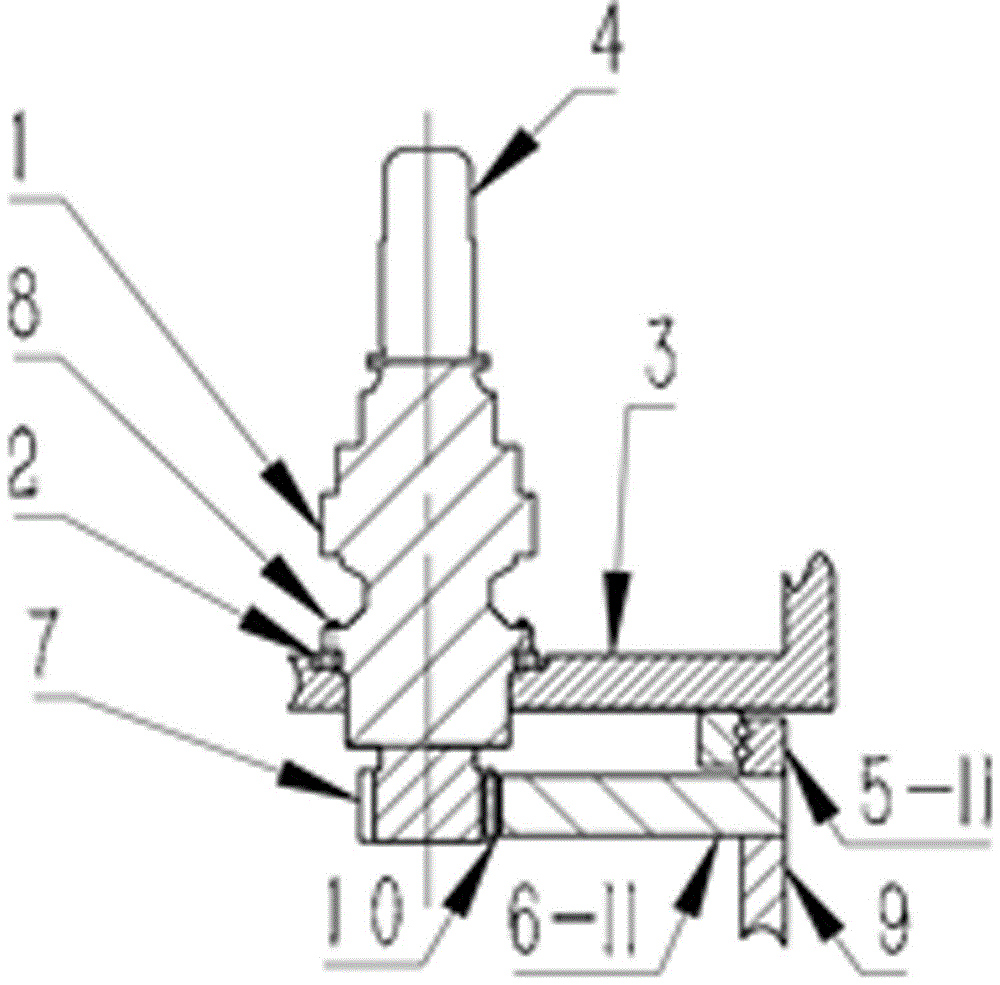

[0019] The present invention specifically provides two embodiments: a wind power generating set suitable for rotating the outer ring of the yaw bearing 5-I and a rotating inner ring of the yaw bearing 5-II when yawing.

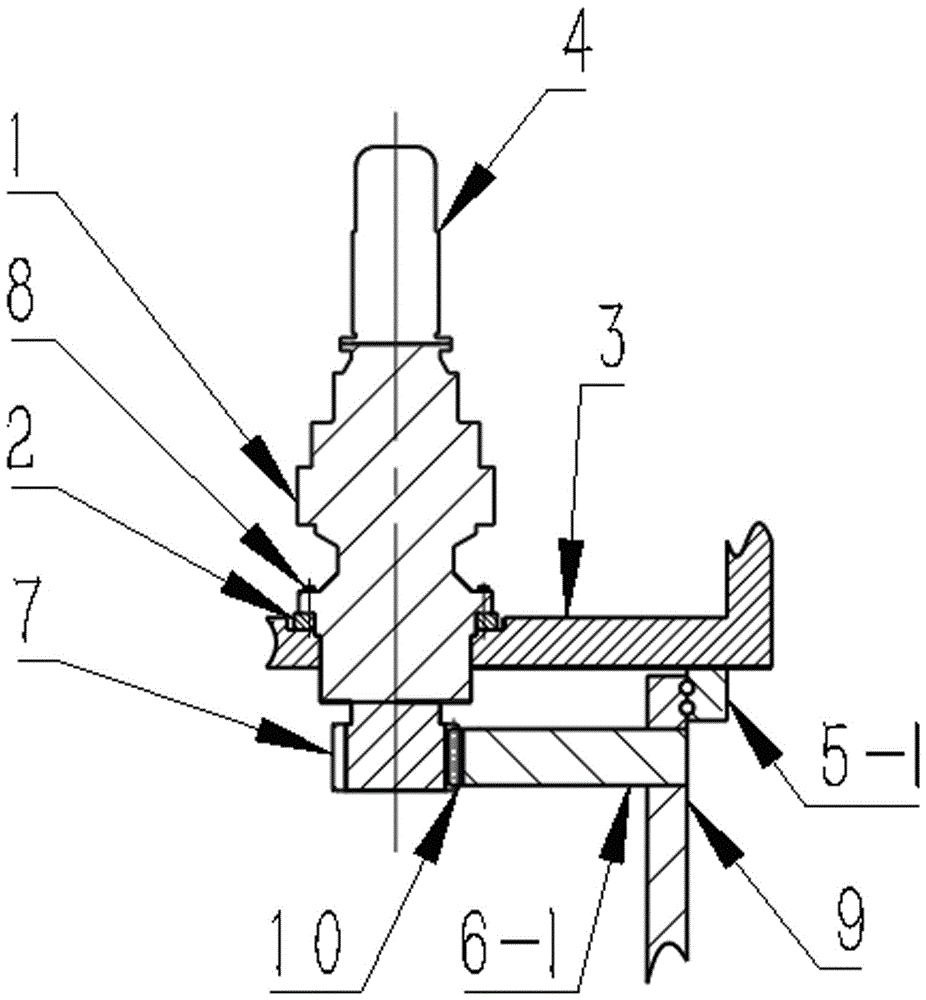

[0020] Refer to attached figure 1 , a kind of wind generator set that is applicable to the rotation of yaw bearing 5-1 outer ring during yaw, its yaw drive system includes: nacelle 3, tower tube 9, yaw motor 4, yaw gearbox 1, yaw bearing 5-I and brake disc 6-I. The brake disc 6-I is located between the upper surface of the tower tube 9 and the lower surface of the yaw bearing 5-I, and is fixedly connected with the inner ring of the yaw bearing 5-I. Preferably, the yaw bearing 5 is a double-row four-point angular contact ball bearing preloaded with negative clearance. The yaw gearbox 1 is fixed with the yaw motor 4 on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com