A ratchet wrench

A technology of ratchet wrench and ratchet wheel, which is applied in the field of ratchet wrench, and can solve the problems of losing the fulcrum, slipping and breaking of the ratchet wheel 3, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

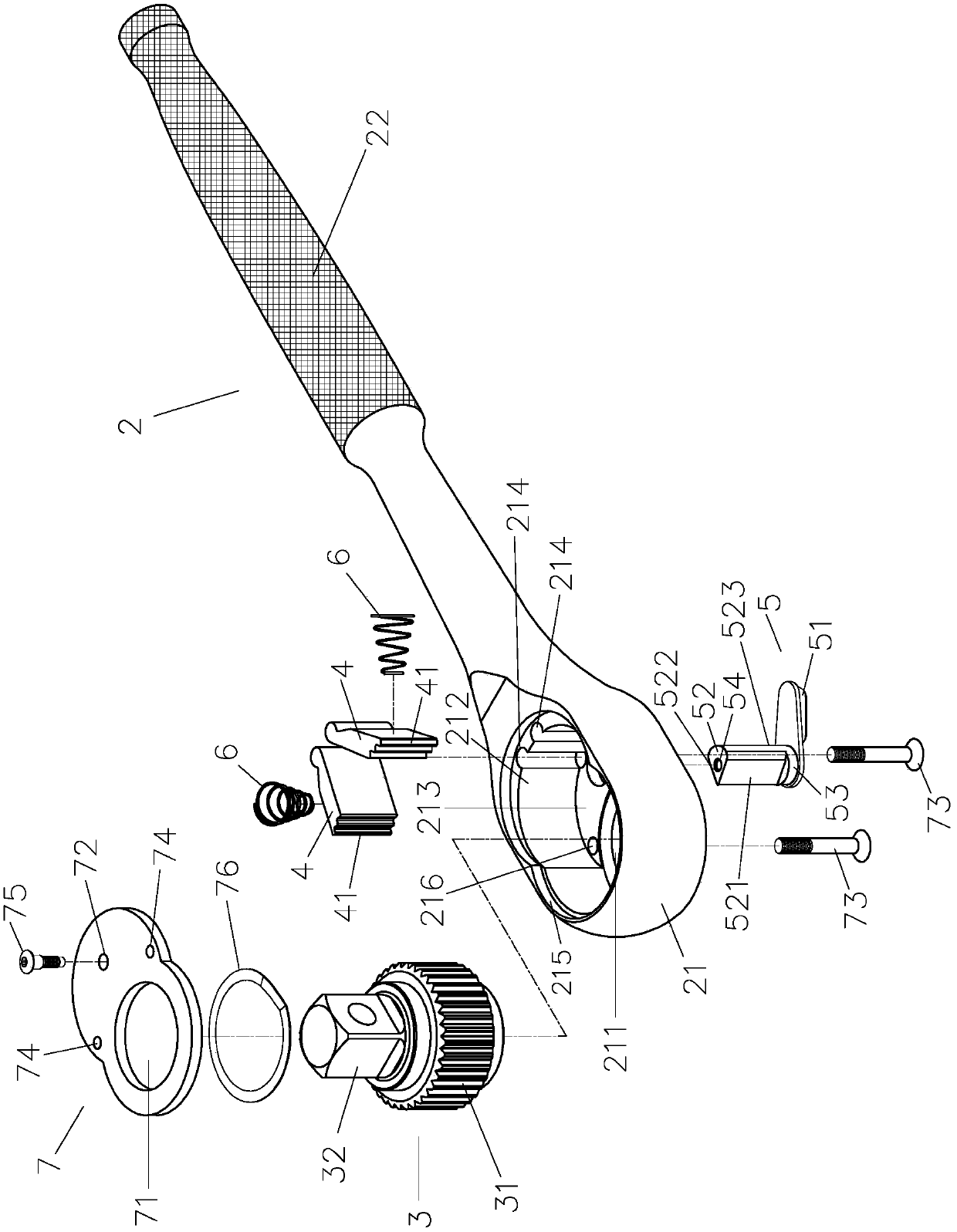

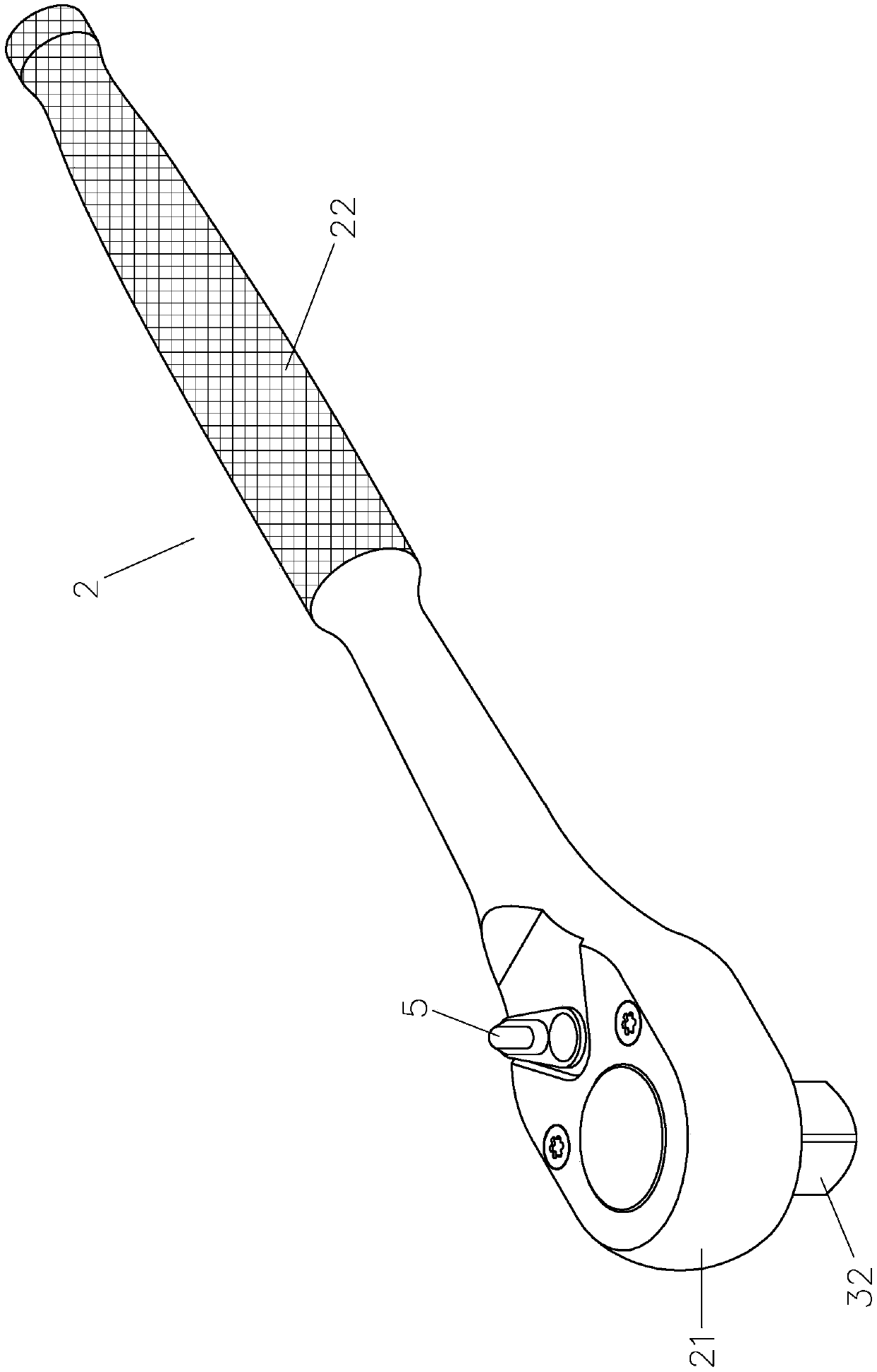

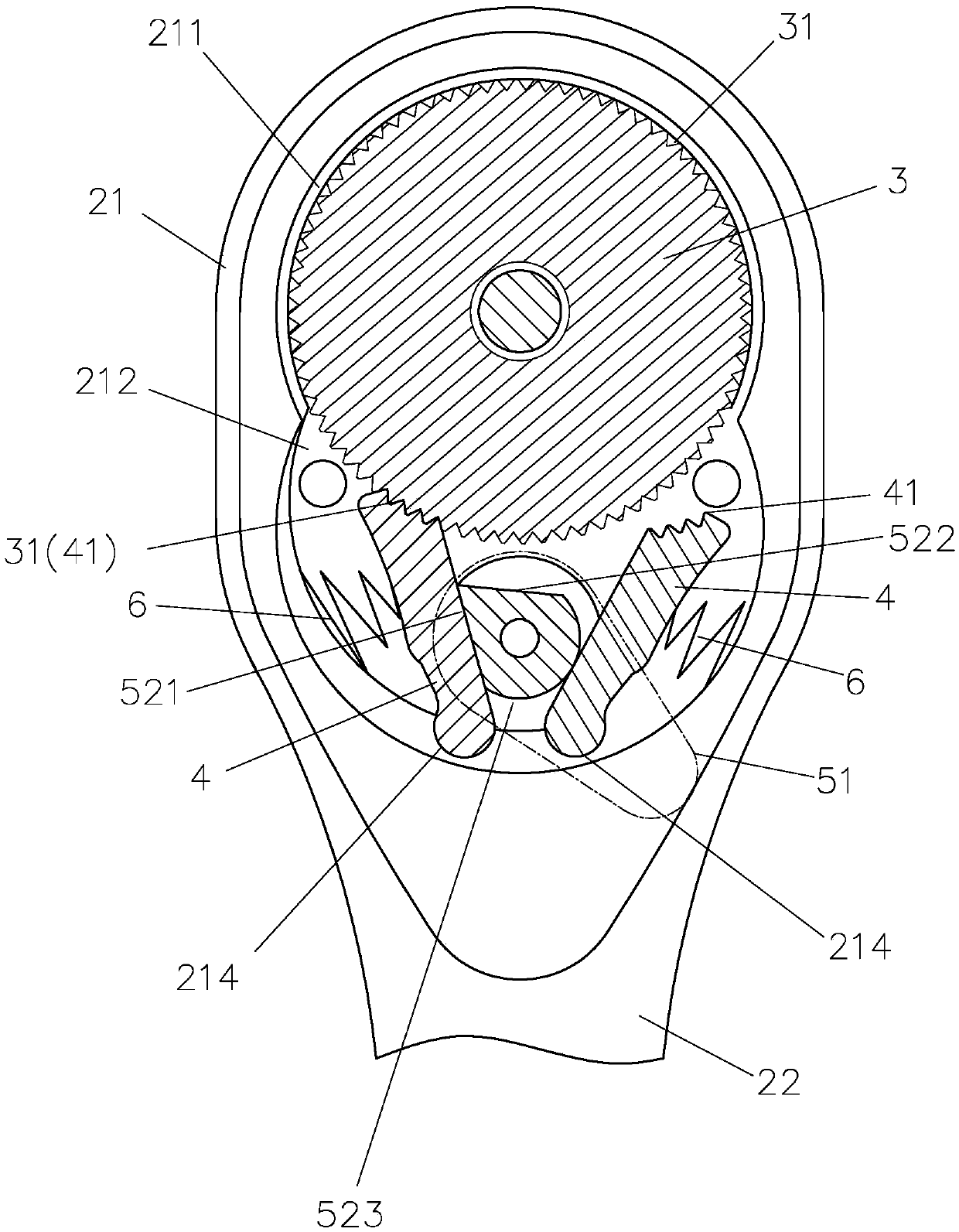

[0057] In order to describe in detail the structural features and effects of the present invention, preferred embodiments are listed hereafter in conjunction with the drawings.

[0058] See Figure 6 to Figure 10 Shown is the first embodiment of the ratchet wrench of the present invention, which includes: a body 20, a ratchet 30, two detent blocks 40, a reversing member 50, two elastic members 60 and a cover 70; among them,

[0059] The body 20 has a head 201 and a handle 202. The head 201 extends from one end of the handle 202. The head 201 has a first accommodating groove 2011 and a communicating second accommodating groove 2012. The accommodating groove 2011 and the second accommodating groove 2012 are open on both sides of the head 201, and the first accommodating groove 2011 and the second accommodating groove 2012 have a connecting portion 2013 on one side of the head 201, and the second accommodating groove The wall surface of the groove 2012 different from the first receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com