Machining system for milling cutter and machining method of machining system

A processing system and milling cutter technology, applied in milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problems of low degree of automation and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

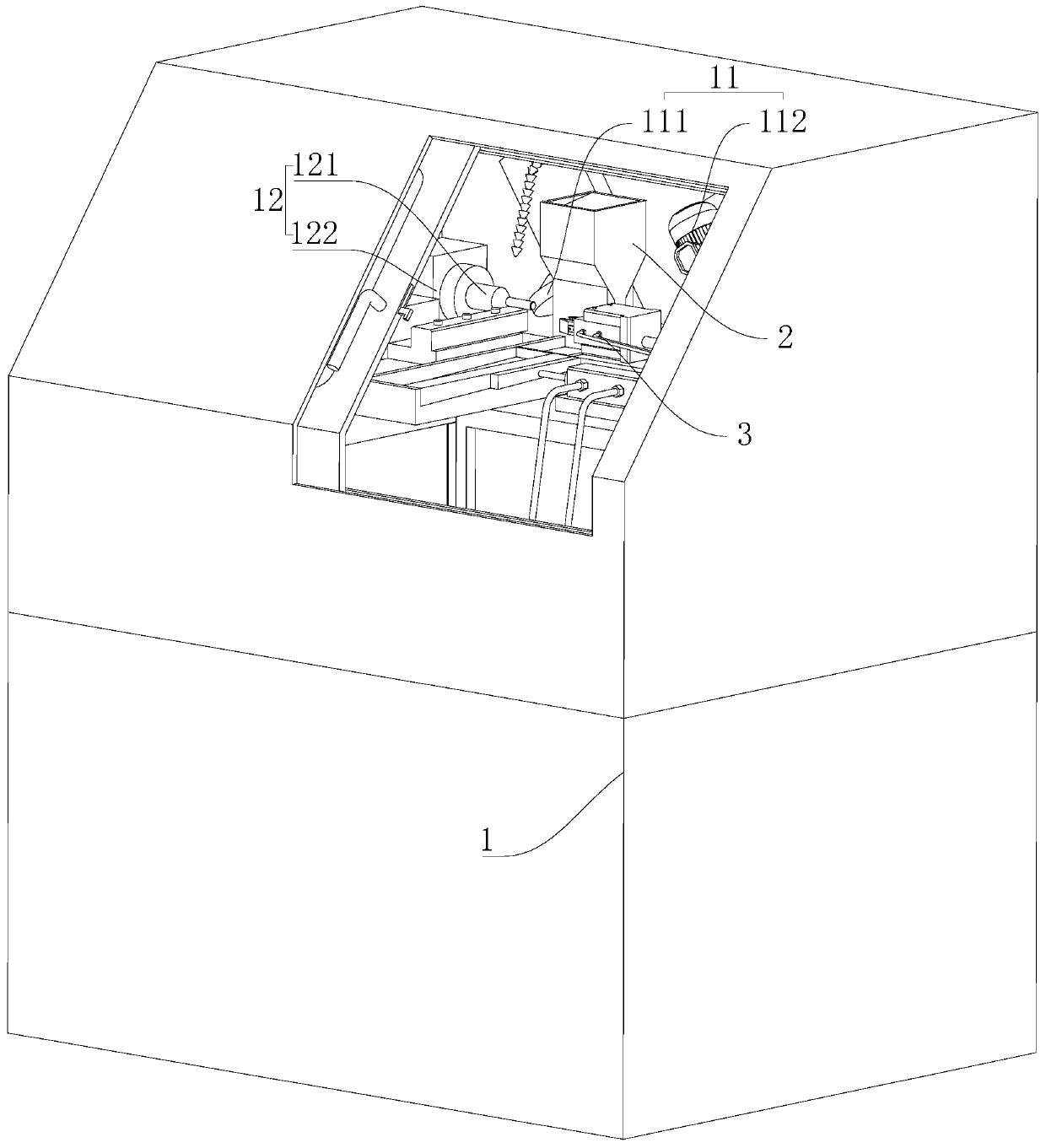

[0049] A kind of processing system and processing method thereof for milling cutter, refer to figure 1 , which includes a frame 1 , a grinding mechanism 11 and a clamping mechanism 12 . The clamping mechanism 12 is slidably connected inside the frame 1 along the direction approaching or away from the grinding mechanism 11. The clamping mechanism 12 can move along the length direction or the width direction inside the frame 1. The bottom of the clamping mechanism 12 is provided with a driving clamp The oil cylinder that mechanism 12 moves. The clamping mechanism 12 includes a clamping clamp 121 and a rotating motor 122 for driving the clamping clamp 121 to rotate. The blank is inserted into the clamping clamp 121 and clamped by the finger clamp cylinder in the clamping clamp 121 . The grinding mechanism 11 is fixedly connected inside the frame 1 , and the grinding mechanism 11 includes a grinding wheel 111 and a driving motor 112 for driving the grinding wheel 111 .

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com