Turbocharger sealing ring subjected to laser surface texturing and machining method

A turbocharger and surface texture technology, which is applied in the sealing of engines, laser welding equipment, metal processing equipment, etc., can solve problems such as the inability to form effective lubrication on smooth surfaces, increase processing costs, and adhere to abrasive particles, etc., to achieve Improve friction and wear characteristics, reduce abrasive wear, and reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

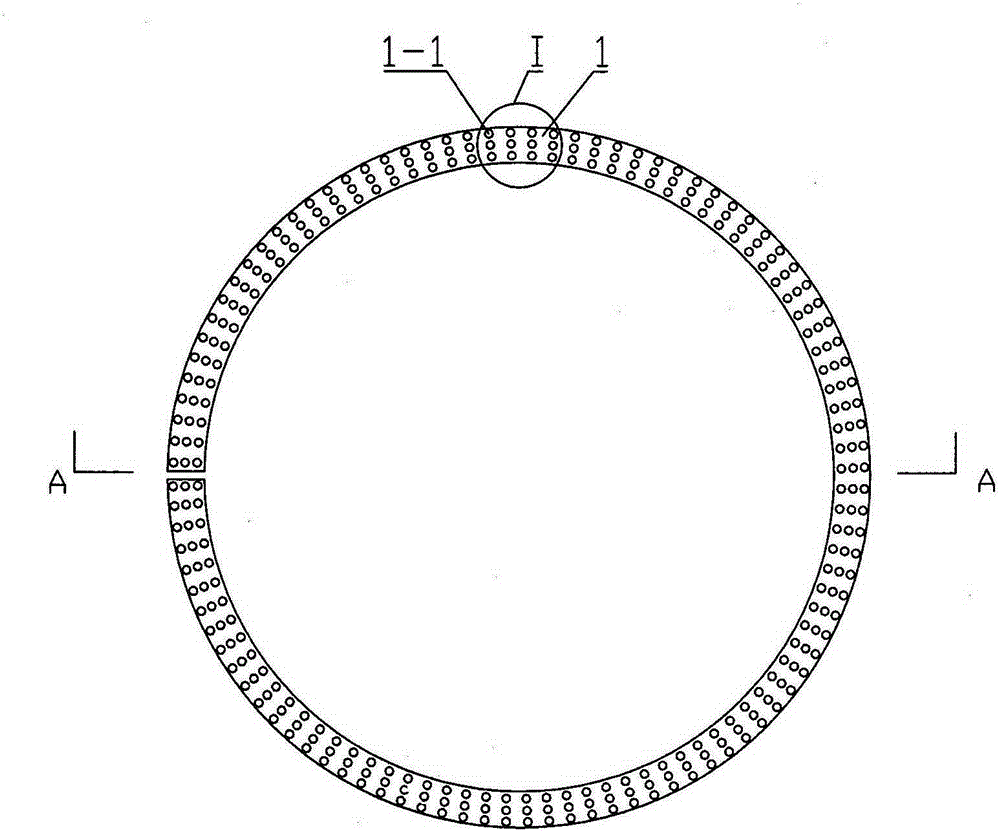

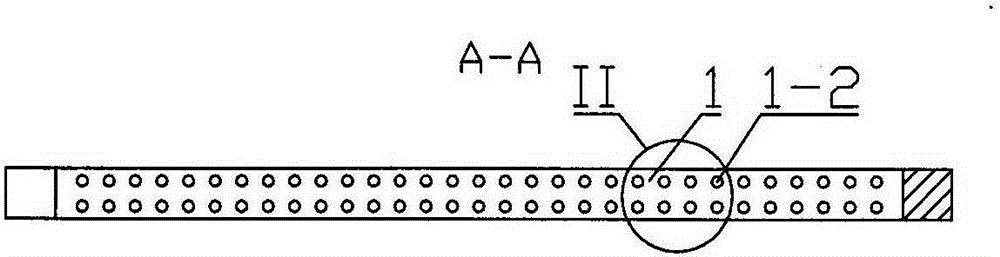

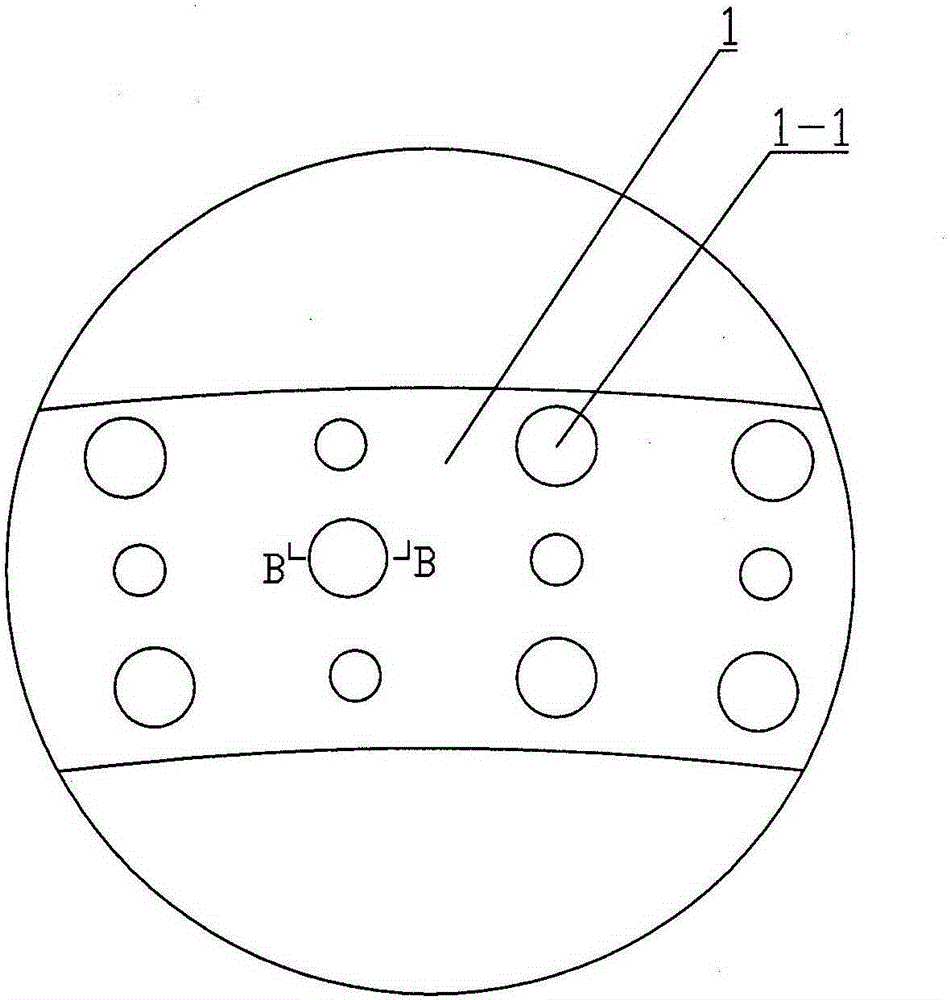

[0028] A turbocharger sealing ring that has undergone laser surface texturing. After laser surface texturing, arcs with different diameters and depths are formed on the left and right end faces and the inner surface of the turbocharger sealing ring 1. The arc-shaped micro-cavities are distributed in a random order, and the geometric parameters of the formed micro-cavities are:

[0029] The diameter d1 of the arc-shaped micro-recessed cavity 1-1 formed on the left and right end faces is 60-400um, the depth h1 is 3-30um respectively, and the area occupancy ratios of the arc-shaped micro-recessed cavity 1-1 on the left and right end faces are respectively 3%-20%;

[0030] The diameter d1 of the arc-shaped micro-recessed cavity 1-2 formed on the inner circular surface is 100-400um, the depth h2 is 3-30um, and the area occupancy of the arc-shaped micro-recessed cavity 1-2 is 3%-20% on the inner circular surface .

[0031] This embodiment also provides a method for laser texturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com