Abrasion resistant dental composition product and process

a technology of dental composition and abrasion resistance, which is applied in the field of abrasion resistance dental composition products, can solve the problems of excessive wear of enamel and dentin, the cost of most noble metals, and the cost consideration, and achieve the effect of superior physical and aesthetic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0122] Prior Art Tooth

[0123] A precursor blend is prepared having the following composition.

2 Weight Percent Methyl Methacrylate 37.33 Bisphenol A Dimethacrylate 8.43 Benzoyl peroxide 0.24 Polymethyl methacrylate 54.00

[0124] All ingredients of the precursor blend composition except polymer are added to a planetary mixer and stirring until a homogeneous solution is produced. The polymer is then added and stirred to form a uniform dough. Prosthetic teeth are molded from the precursor blend composition in heated metal molds after the precursor blend composition is aged at ambient temperature for seven days. The teeth are clear and comply with ADA / ANSI Specification 15.

example 3

[0125] Prior Art Interpenetrating Network Tooth C

[0126] A precursor blend is prepared having the following composition:

3 Weight Percent of blend 35.35% methyl methacrylate 0.21% benzoyl peroxide 7.44% 2,2-bis(4-methacryloxyphenyl)propane 38.00% poly(methyl methacrylate-co-ethylene dimethacrylate) (99.2:0.8) 19.00% poly(methyl methacrylate) 100.00%

[0127] The crosslinked polymer is in the form of particles, 46% by weight of which were below 74 microns in size, the balance being below about 500 microns in size. The poly-(methyl methacrylate) have an average molecular weight of 800,000 g / mole.

[0128] The benzoyl peroxide and 2,2-bis(4-methacryloxy-phenyl)propane are dissolved in the methyl methacrylate at ambient temperature to form a monomer solution. The polymers and pigment are charged to a planetary dough mixer containing the monomer solution and the charge is stirred until visibly homogeneous. Prosthetic teeth (C) are molded from the resultant precursor blend mixture after it is age...

example 4

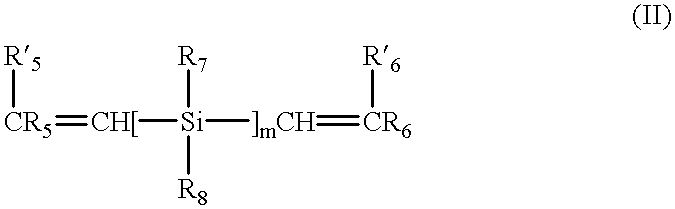

[0129] Abrasion Resistant Silane Monomer Containing IPN Tooth D

[0130] A precursor blend is prepared having the following composition:

4 Weight Percent of Blend methyl methacrylate 34.55 benzoyl peroxide 0.22 2,2-bis (4-methacryloxyphenyl)propane 7.08 poly(methyl methacrylate-co-ethylene dimethacrylate) (99.2:0.8) 37.00 poly(methyl methacrylate) 19.00 divinyl dimethyl silane 2.15 100.00

[0131] The crosslinked polymer is in the form of particles, 46% by weight of which were below 74 microns in size, the balance being below about 500 microns in size. The poly-(methyl methacrylate) have an average molecular weight of 800,000 g / mole.

[0132] The benzoyl peroxide and divinyl dimethyl silane, and 2,2-bis(4-methacryloxy-phenyl)propane are dissolved in the methyl methacrylate at ambient temperature to form a monomer solution. The polymers and pigment are charged to a planetary dough mixer containing the monomer solution and the charge is stirred until visibly homogeneous. Prosthetic teeth (D) ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com