Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

An inner surface, micro-texture technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as increasing manufacturing costs, inability to take into account lubrication and wear resistance, etc., to improve service life, improve lubricity and resistance. Wear performance, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

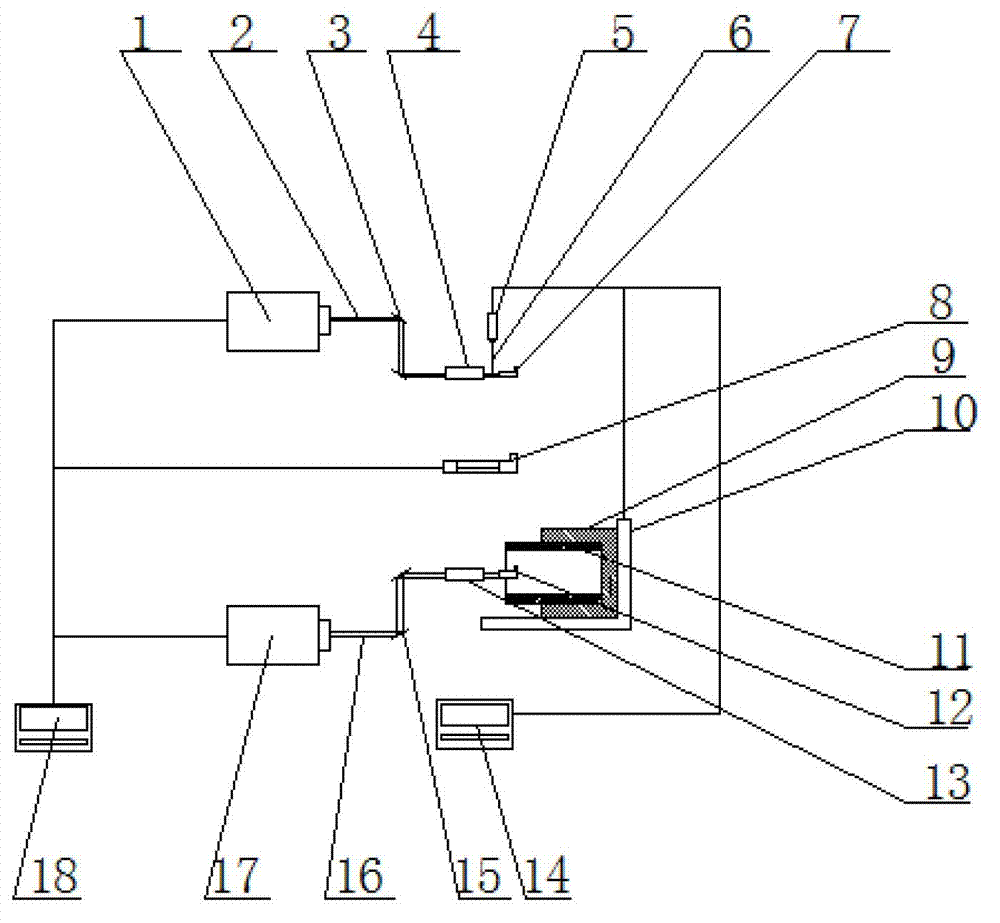

[0027] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The method described in the present invention first uses a femtosecond laser to prepare a regular microscopic geometric shape with a certain density (spacing), width, depth, angle and shape on the surface of the cylinder liner, and then uses laser shock waves to intensify the treatment of the microscopic geometric shape area. The inner surface of the cylinder liner is machined into the microstructure of the required shape and arrangement.

[0029] figure 1 Shown is a schematic diagram of the device on the inner surface of the laser composite micro-textured cylinder liner, including a laser micro-textured optical path part, a laser shock strengthening optical path part, a control part and a workbench 10; the laser micro-textured optical path part includes a femtosecond laser 17, 45° total re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com