Flowing friction welding method and tool thereof

A technology of flow friction and welding method, which is applied in the direction of welding equipment, manufacturing tools, non-electric welding equipment, etc., which can solve the problems of lap interface distortion and incomplete penetration, and achieve the effect of material performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

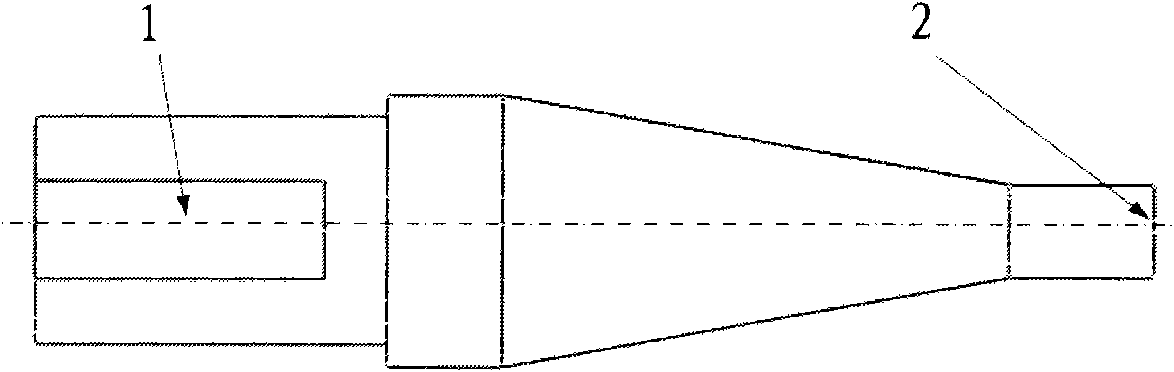

[0032] Embodiment 1 Flow friction spot welding (Friction Flow Spot Welding, referred to as FFSW)

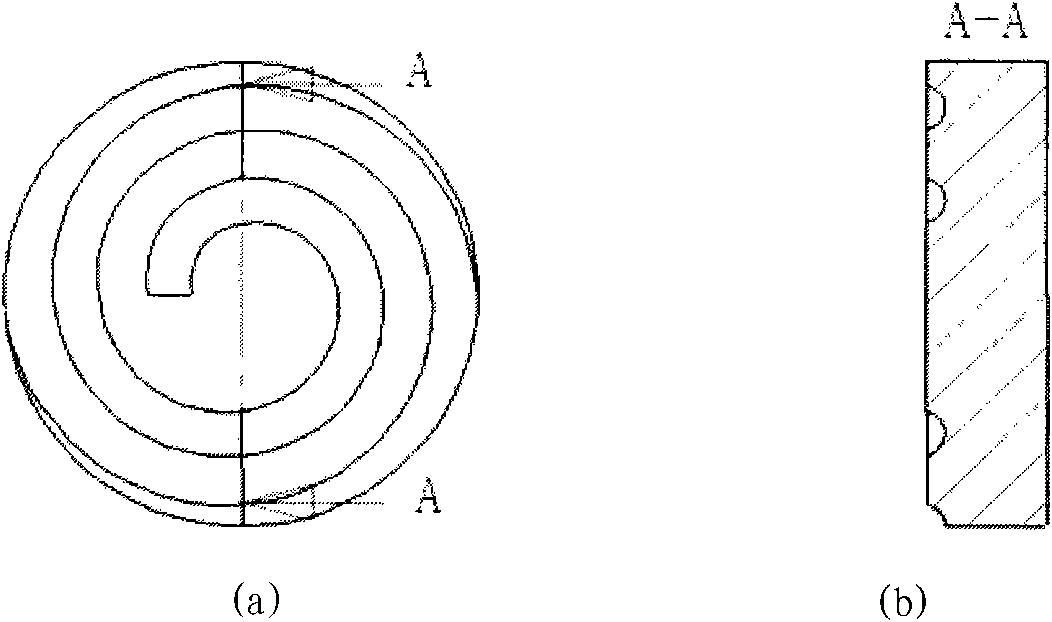

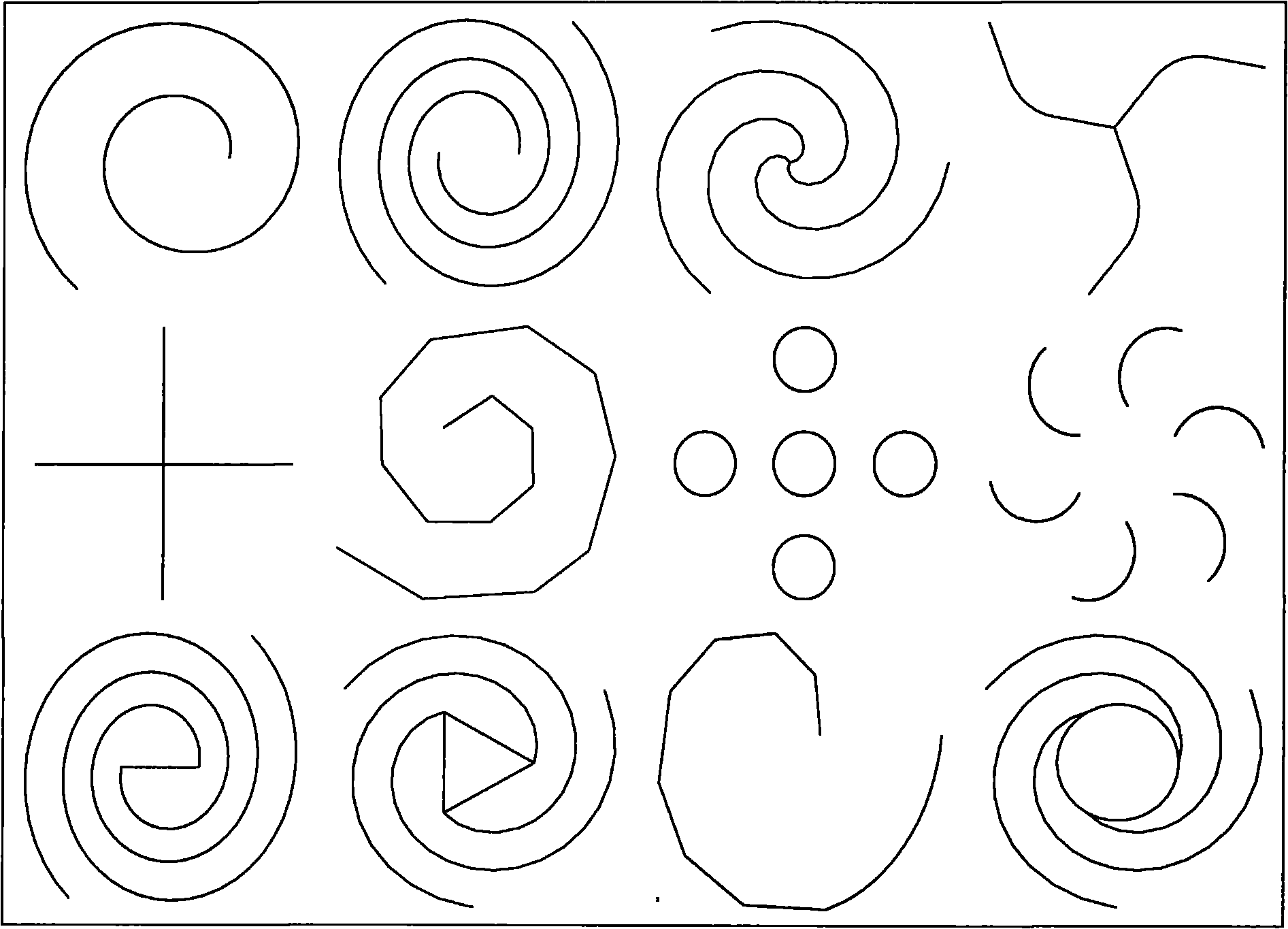

[0033] Spot welding 2mm thick 2524-T3 aluminum alloy, the diameter of the flow friction head is Φ10mm, the macroscopic shape of the end surface groove is helical, 2 helical lines, the cross-sectional shape of the groove is semicircular, the groove depth is 0.3mm, and the grooves everywhere Same deep.

[0034] The flow friction spot welding method is to place the flow friction head on the welding equipment and rotate it at 400 rpm. The axis of the flow friction tool contacts the surface of the workpiece at an angle of 0° with the surface of the workpiece to be welded. After contact, the flow friction The tool applies a normal pressure of 5KN to the workpiece. After the flow friction tool maintains the normal pressure, rotates continuously and stays on the workpiece for 5 seconds, the flow friction tool moves upward, and the end surface of the flow friction tool leaves the upper su...

Embodiment 2

[0035] Embodiment two flow friction spot welding

[0036]Spot welding 3mm thick 6082-T6 aluminum alloy, the diameter of the flow friction head is Φ15mm, the macroscopic shape of the end surface groove is spiral, with 3 helical lines, the cross-sectional shape of the groove is semicircular, and the depth of the groove is the groove opening and the groove tail Between 0.1 ~ 2mm linear gradient. The inclination angle of the flow friction head axis is 3°, the rotation speed is 2400 rpm, the normal force is 30KN, and the residence time is 30 seconds. Finally, a defect-free 3mm thick 6082 aluminum alloy flow friction spot welded joint was obtained.

Embodiment 3

[0037] Embodiment three flow friction butt welding

[0038] Flow friction butt welding of 5mm thick 6082-T6 aluminum alloy, using a flow friction head with a diameter of Φ20mm, the macroscopic shape of the end surface groove is a spiral, four helical lines, the groove depth is 2mm, and the cross-sectional shape of the groove is an inverted triangle.

[0039] The flow friction butt welding method is to place the flow friction tool on the welding equipment and rotate it at 2000 rpm. The axis of the flow friction tool contacts the surface of the workpiece at an angle of 5° with the surface of the workpiece to be welded. After contact, the flow friction The tool applies a normal pressure of 100KN to the workpiece. After the flow friction tool maintains the normal pressure, rotates continuously and stays on the workpiece for 6 seconds, it moves at a speed of 100mm / min in a direction parallel to the surface of the workpiece. After welding, the flow friction tool moves upward Move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com