High-hardness self-lubricating polyurethane elastomer and preparation method thereof

A polyurethane elastomer and polyurethane prepolymer technology, which is applied in the field of polyurethane elastomers, can solve the problems of the ineffectiveness of polyurethane materials, the inability to fully reflect the excellent wear resistance of polyurethane elastomers, and the excessive wear and tear, and achieve excellent flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

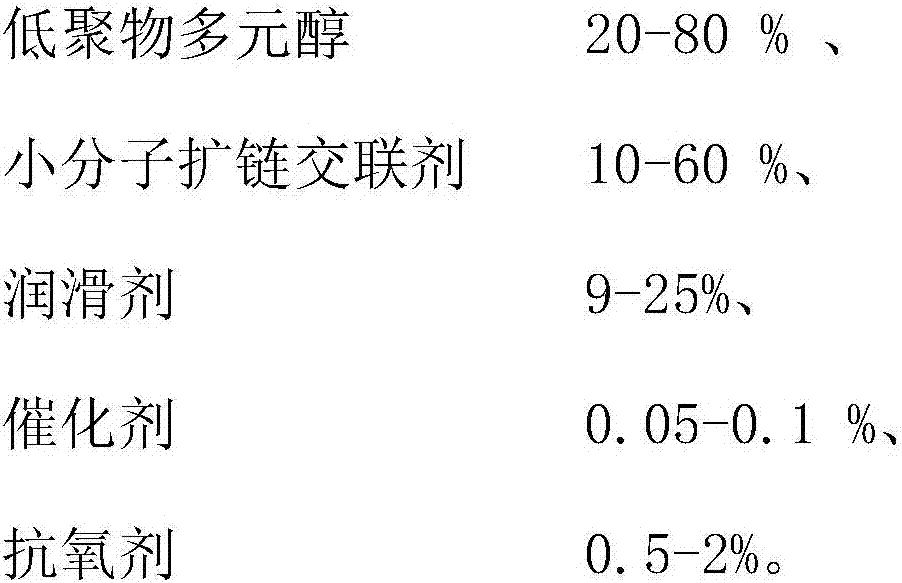

Method used

Image

Examples

Embodiment 1

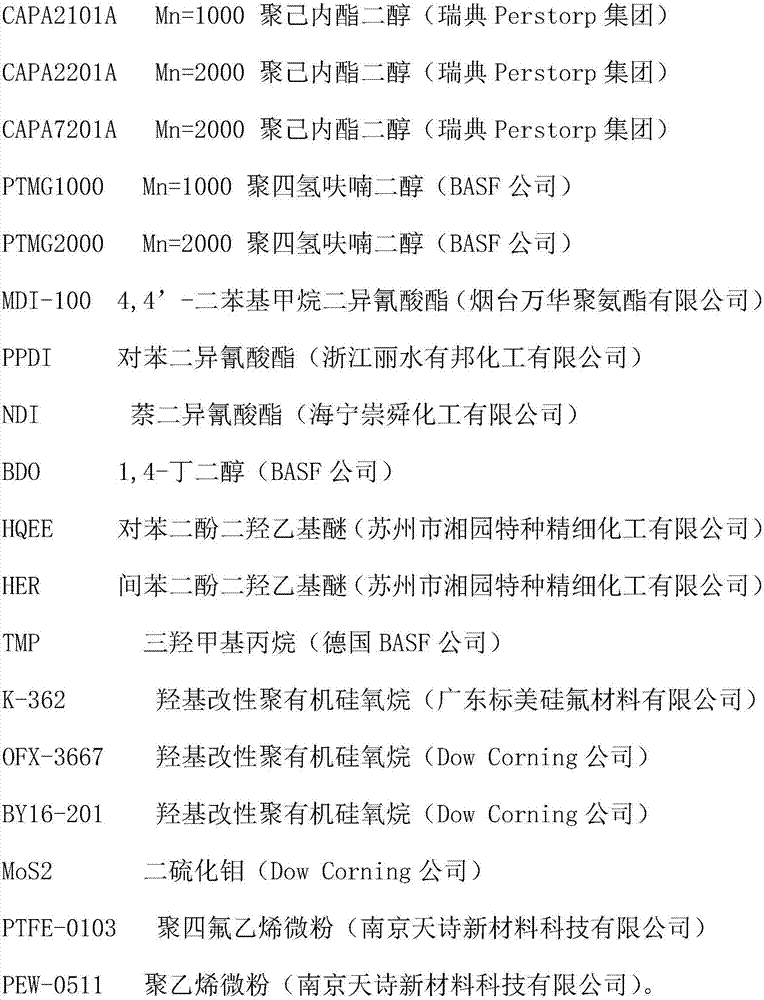

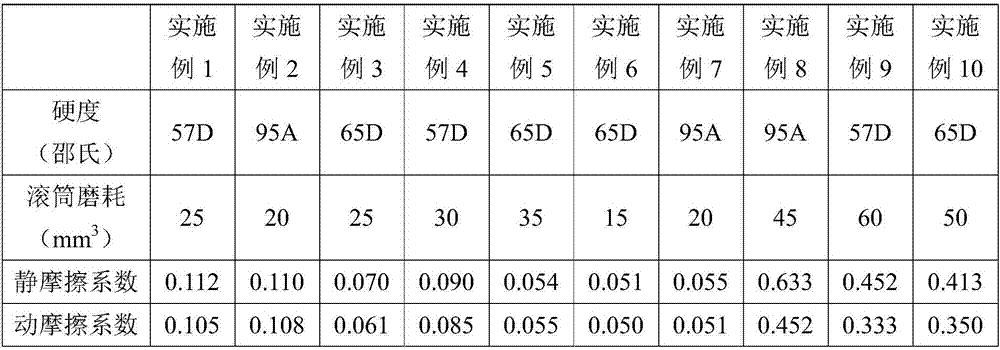

[0048] Embodiment 1: Preparation of high hardness self-lubricating polyurethane elastomer

[0049] 1. Preparation of polyurethane semi-prepolymer: Add 800 parts by weight of completely melted MDI-100 into a dry flask, protect it with dry nitrogen, add 200 parts by weight of dry BY16-201 dropwise, and control the temperature not to exceed 70 ° C. ℃ for 1 hour, then add 300 parts by weight of dry CAPA2101A, continue to react for 2 hours at 70 ℃, test the residual NCO content reaches 16wt% to stop the reaction, cool down and discharge.

[0050]2. Preparation of active hydrogen-containing polymer: Add 250 parts by weight of CAPA2101A and 180 parts by weight of BDO into the flask, heat to 80°C and stir for 1 hour, then add 75 parts by weight of MoS2 and 15 parts by weight of simethicone under low-speed stirring. After continuing to stir for 30 minutes, heat to 110° C. and vacuum dehydrate at -0.1 MPa for 2 hours. When the water content is lower than 0.05 wt %, cool down and dischar...

Embodiment 2

[0052] Embodiment 2: Preparation of high hardness self-lubricating polyurethane elastomer

[0053] 1. Preparation of polyurethane semi-prepolymer: Add 630 parts by weight of completely melted MDI-100 into a dry flask, protect it with dry nitrogen, add 150 parts by weight of dry BY16-201 dropwise, control the temperature not to exceed 70°C, and React at ℃ for 1 hour, then add 350 parts by weight of dry CAPA2201A, continue to react at 70 ℃ for 2 hours, and stop the reaction when the residual NCO content reaches 16wt%, then cool down and discharge.

[0054] 2. Preparation of active hydrogen-containing polymer: add 720 parts by weight of CAPA2201A, 114 parts by weight of BDO and 16 parts by weight of TMP into the flask, heat to 80°C and stir for 1 hour, then add 72 parts by weight of MoS2 and 18 parts by weight of Dimethicone oil, after continuing to stir for 30 minutes, heated to 110° C. and dehydrated in vacuum at -0.1 MPa for 2 hours. When the water content was lower than 0.05 ...

Embodiment 3

[0056] Embodiment 3: Preparation of high hardness self-lubricating polyurethane elastomer

[0057] 1. Preparation of polyurethane semi-prepolymer: Add 700 parts by weight of completely melted MDI-100 into a dry flask, protect it with dry nitrogen, add 150 parts by weight of dry K-362 dropwise, react at 70°C for 1 hour, then add 350 parts by weight of dry PTMG1000, continue to react at 70°C for 2 hours, and stop the reaction when the residual NCO content reaches 16wt%, and cool down to discharge.

[0058] 2. Preparation of active hydrogen-containing polymer: Add 180 parts by weight of PTMG1000 and 320 parts by weight of HQEE into the flask, heat to 120°C and stir for 1 hour, then add 100 parts by weight of PTFE-0103 and 14 parts by weight of dimethyl Silicone oil, after continuing to stir for 30 minutes, vacuum dehydrate at 110° C. at -0.1 MPa for 2 hours, and cool down and discharge when the water content is lower than 0.05 wt%.

[0059] Mix 100 parts by weight of the polyure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com