Medical components having coated surfaces exhibiting low friction and methods of reducing sticktion

A technology of inner surface and outer surface, applied in other medical devices, coatings, medical science, etc., can solve problems such as high starting and/or loosening force, incomplete effectiveness, expensive materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0085] The coated chamber and / or the coated sealing element is subjected to an oxidation treatment, eg plasma treatment. Plasma treatment can be performed in any common vacuum or atmospheric plasma generating equipment. Any suitable ionizing plasma may be used, such as plasma generated by glow discharge or corona discharge. Plasma can be generated from various gases or mixtures thereof. Commonly used gases include air, hydrogen, helium, ammonia, nitrogen, oxygen, neon, argon, krypton, and xenon. Any gas pressure may be used, such as atmospheric pressure or less than or equal to 5 mmHg, such as about 0.1 to about 1.0 mmHg. In some embodiments, such as atmospheric oxidation methods, the ionized plasma is introduced directly within the chamber through a small port or an opening that is subsequently sealed by a sealing element. The outer surface of the coated sealing element can be treated directly similar to corona or plasma treatment methods. In other embodiments, such as va...

Embodiment

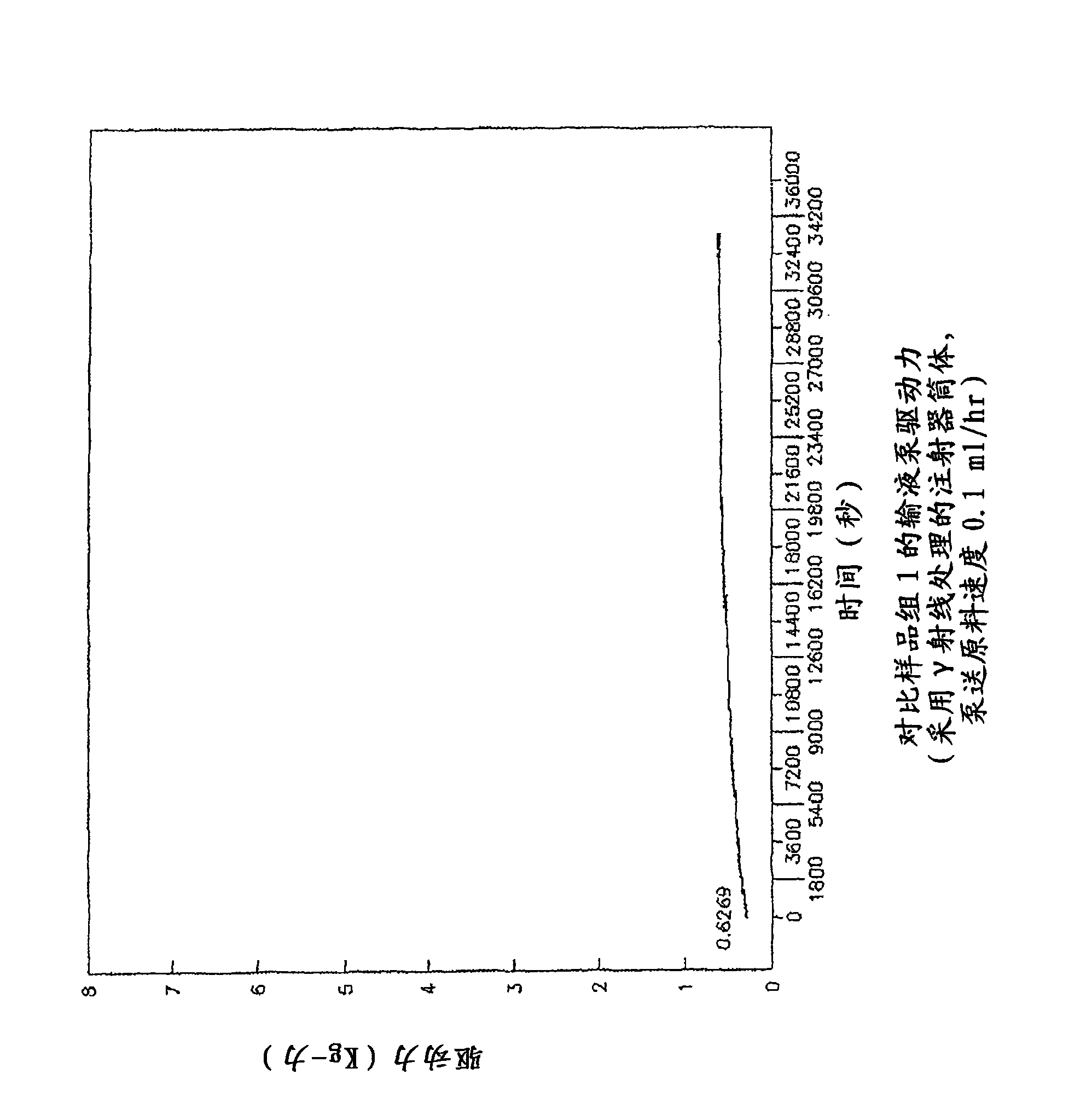

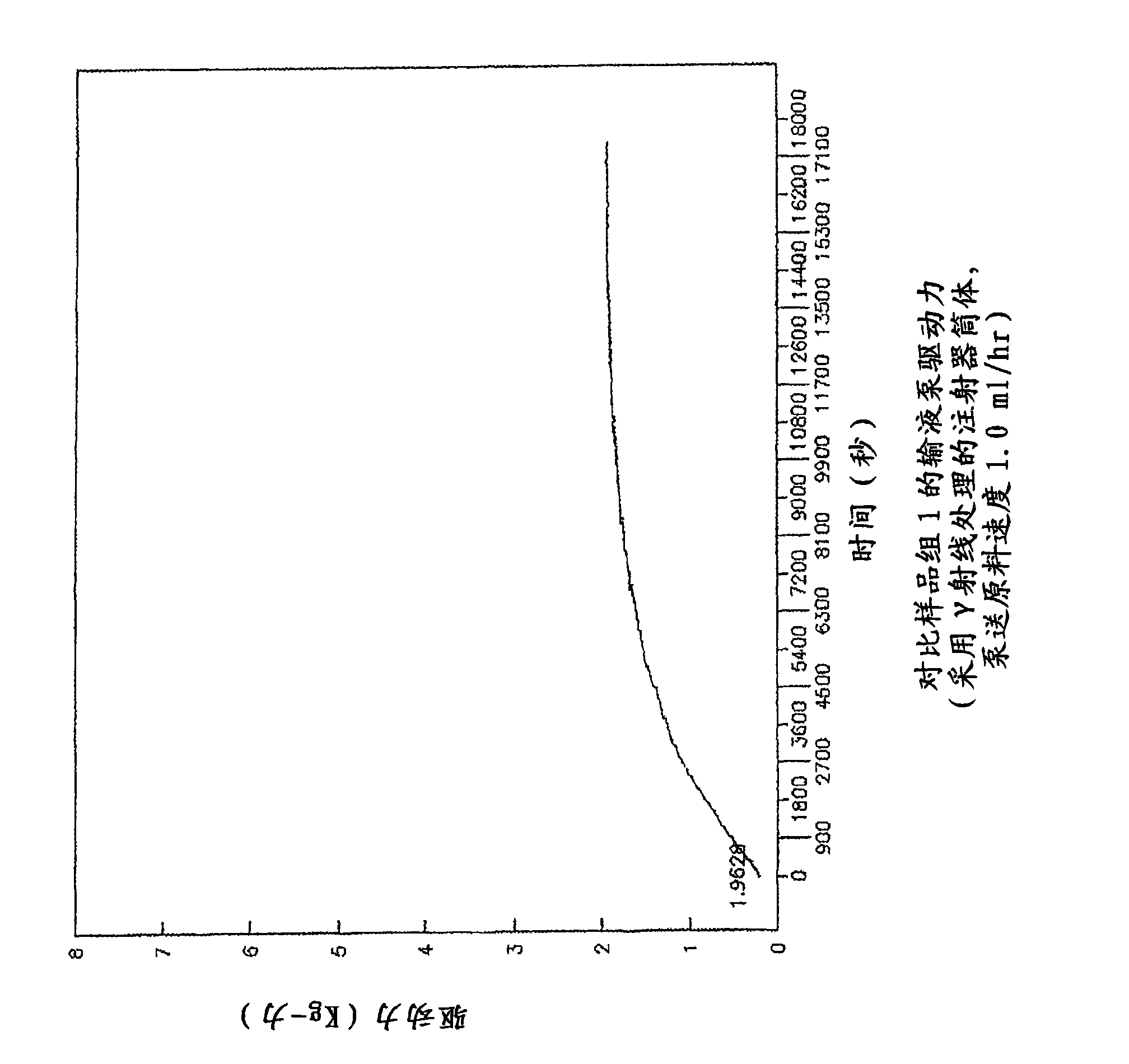

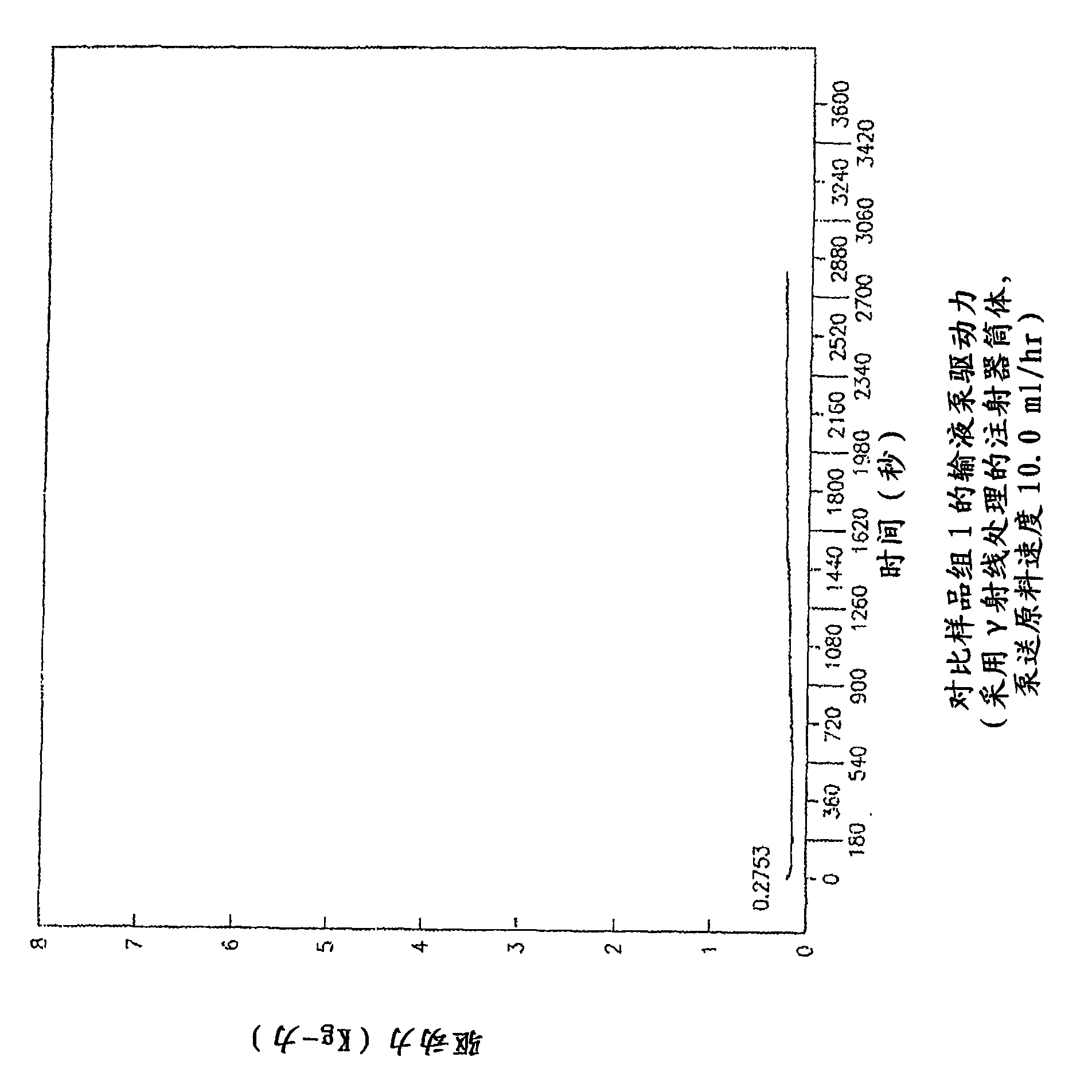

[0098] Syringe barrels of 10 and 50 ml syringes were coated with the coating composition of the present invention. Syringe barrels were formed from cyclic polyolefin, and the inside surface of each barrel was coated with DC360 dimethicone, viscosity 12,500 cst, available from Dow Corning. Pretreat selected barrels with argon plasma from the injection end of the barrels for the time periods specified in Table 1. Plasma treatment was performed using a conventional atmospheric pressure plasma treatment apparatus as described above.

[0099] Helvoet FM460 (Butyl-A) and FM457 (Butyl-B) butyl rubber and Kokoku SBR syringe stoppers were coated with conventional polydimethylsiloxane with a viscosity of 100,000 cst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com