Laser micro-texturing self-lubricating treatment method for friction pairs

A treatment method and friction pair technology, applied in the field of friction pair self-lubrication, can solve problems such as increasing process difficulty and cost, affecting lubrication effect, and limiting machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

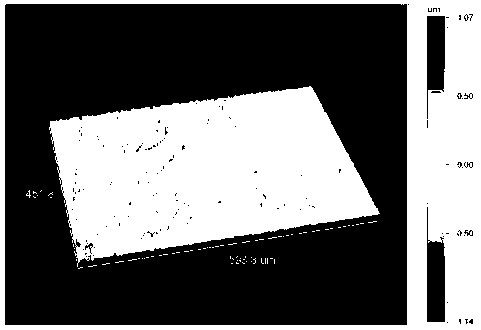

[0024] The laser texturing equipment adopts diode-pumped Nd:YAG laser processing system, the laser wavelength is 532nm, the current is 16-17A, the frequency is 1600Hz, the number of pulses is 8-9 times, nitrogen is used as the auxiliary gas, and the gas pressure is 0.15Mpa. After GCr15 steel was textured, the surface of the sample was polished with metallographic sandpaper until the slag around the micro pits disappeared, and the measured surface hardness was still about 62-64HRC. Using the WYKO-NT1100 three-dimensional measuring instrument for surface micro-geometric topography produced by Veeco, the diameter of a single micro-pit in the sample is measured to be about 110 μm, and the depth is about 18 μm.

[0025] Weigh the polyimide and molybdenum disulfide according to the mass ratio of 1:4, then fully mix them at room temperature, spread them evenly on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com