Double eccentric wheel type push-pull pulsed wire feeding method and device

A technology of pulsating wire feeding and eccentric wheel type, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of fast wear, complex and heavy mechanism, difficult semi-automatic welding operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

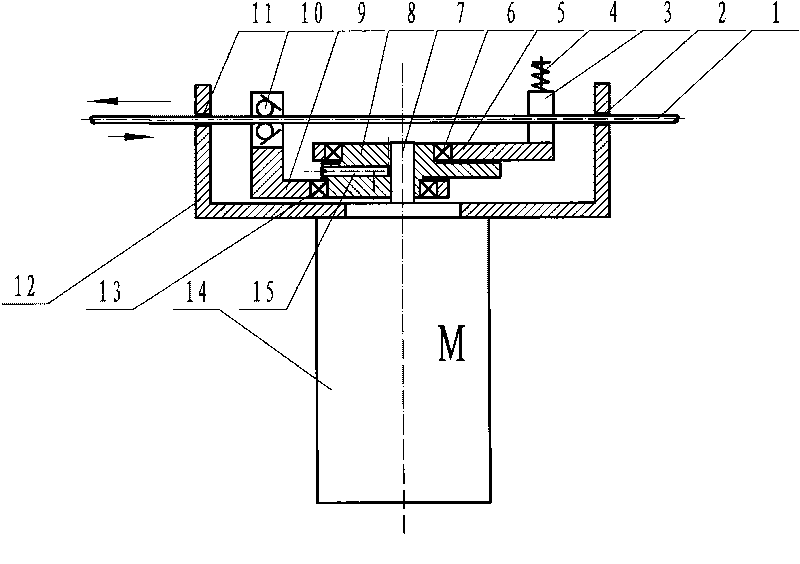

[0019] With reference to the drawings, the specific implementation method of the present invention will be further described below.

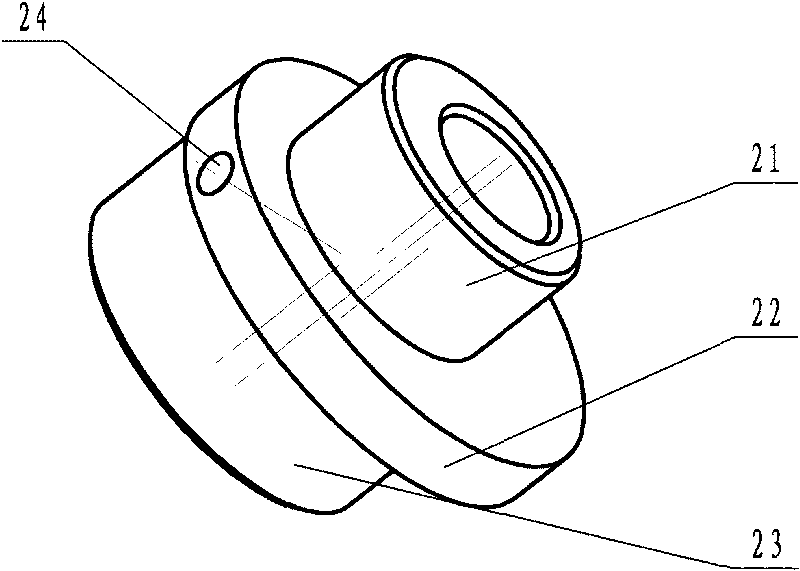

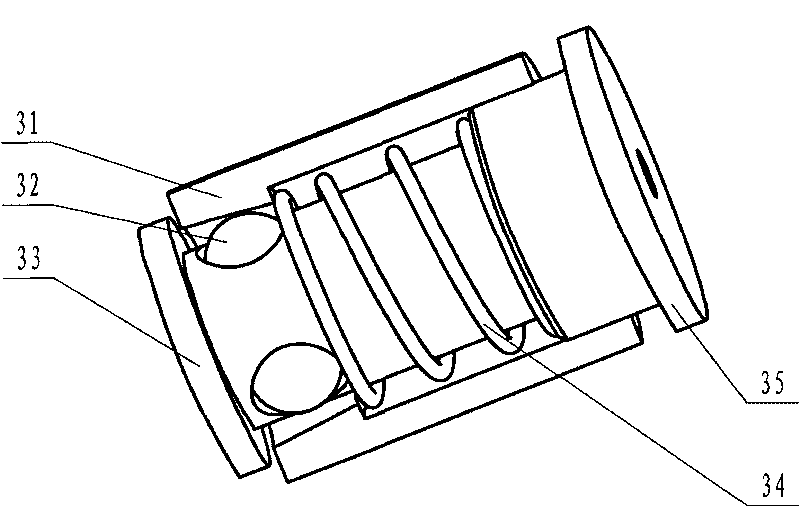

[0020] figure 1 It is the structural principle diagram of the double eccentric wheel push-pull pulsating wire feeding method and device of the present invention. The feeding chuck 10 is fixed on the feeding eccentric sleeve 9, and the retracting chuck 3 is fixed on the retracting eccentric sleeve 5. The lower half of the eccentric shaft 8 is fed into the eccentric 23 through the feeding bearing 13 and the feeding eccentric sleeve 9 is connected, the upper part of the eccentric shaft 8 withdrawing eccentric 21 is connected with the withdrawing eccentric sleeve 5 through the withdrawing bearing 6 and the middle part of the eccentric shaft 8 is a balanced eccentric 22 for balancing vibration. The eccentric shaft 8 and the motor shaft 7 are fixed by a set screw 15. The welding wire 1 passes through the channel 2 on the right side of the base 12, enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com