Automatic high-shear emulsifying machine

A high-shear emulsification machine, automatic technology, applied in the field of emulsification machine, can solve the problems of waste of manpower and time, material loss, cumbersome operation, etc., to prevent damage to the container, save manpower and time, and ensure the effect of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

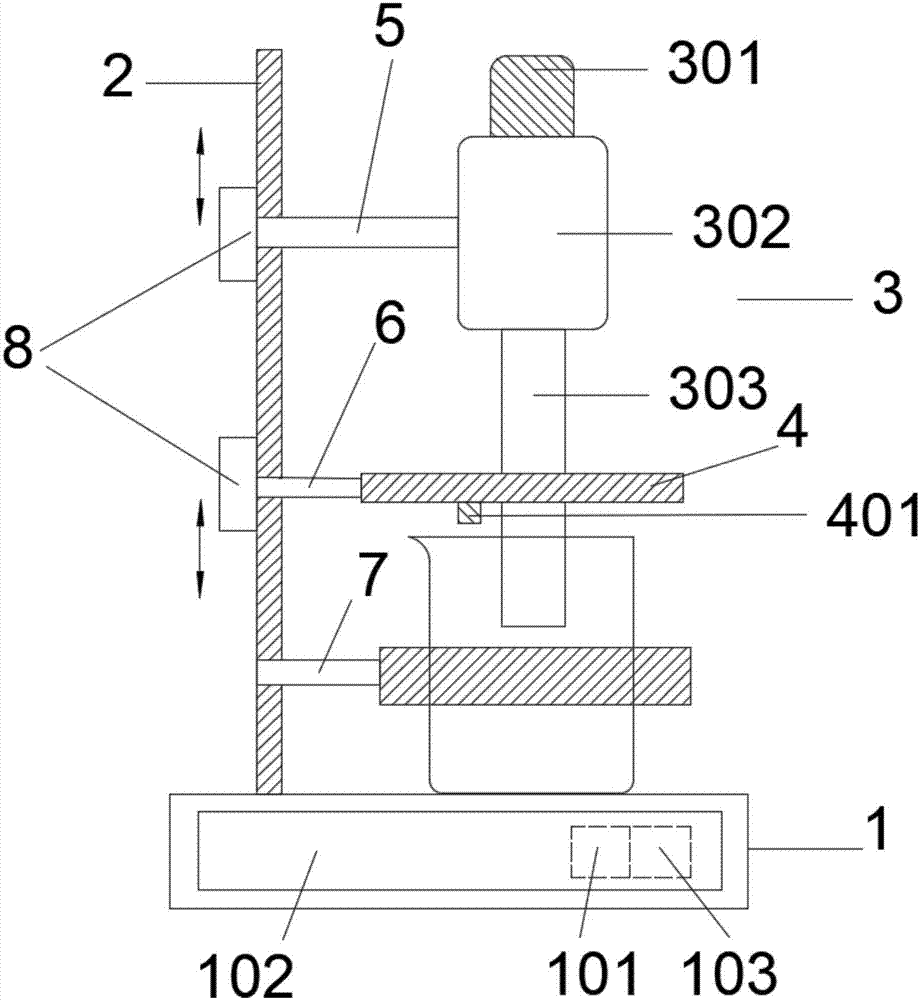

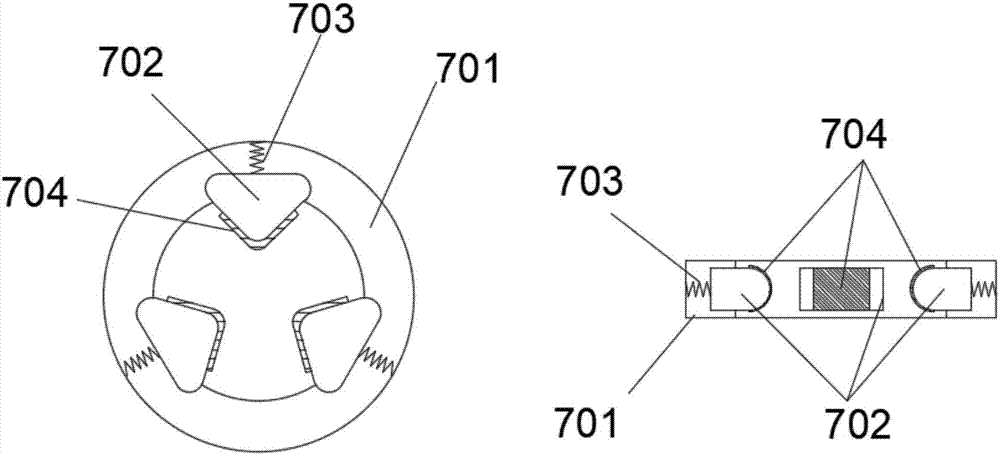

[0023] Such as Figure 1 to Figure 4 As shown, an automatic high-shear emulsification machine includes a console 1, a bracket 2, an emulsification device 3, and an annular cover plate 4; the console 1 includes a micro-control chip 101 electrically connected to each other, a touch screen 102, a timing module 103, the touch screen 102 is embedded on the side of the console 1, and the touch screen 102 sets and displays emulsification parameters; the bracket 2 is fixed on the console 1, and the emulsification device 3 automatically A motor 301, a fixed cylinder 302, and a rotor 303 are arranged from top to bottom, the motor 301 passes through the fixed cylinder 302 and is connected to the rotor 303, and a bearing is arranged between the fixed cylinder 302 and the rotor 303,

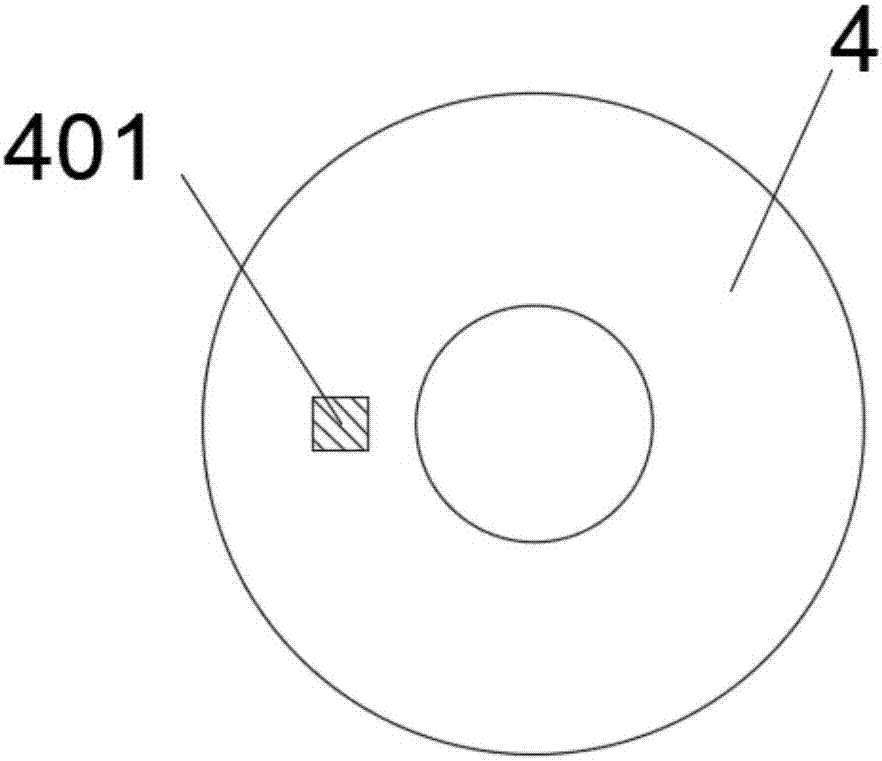

[0024] The rotor 303 passes through the middle of the annular cover plate 4, and the lower surface of the annular cover plate 4 is provided with a photoelectric sensor 401; the fixed cylinder 302 and the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com