Emulsified oil composition and use thereof

A technology of composition and emulsified oil, applied in lubricating composition, petroleum industry and other directions, can solve the problems of poor stability of emulsified oil, difficult to filter, clogging of iron soap, etc. good synergistic effect

Inactive Publication Date: 2015-02-11

CHINA PETROLEUM & CHEM CORP

View PDF6 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

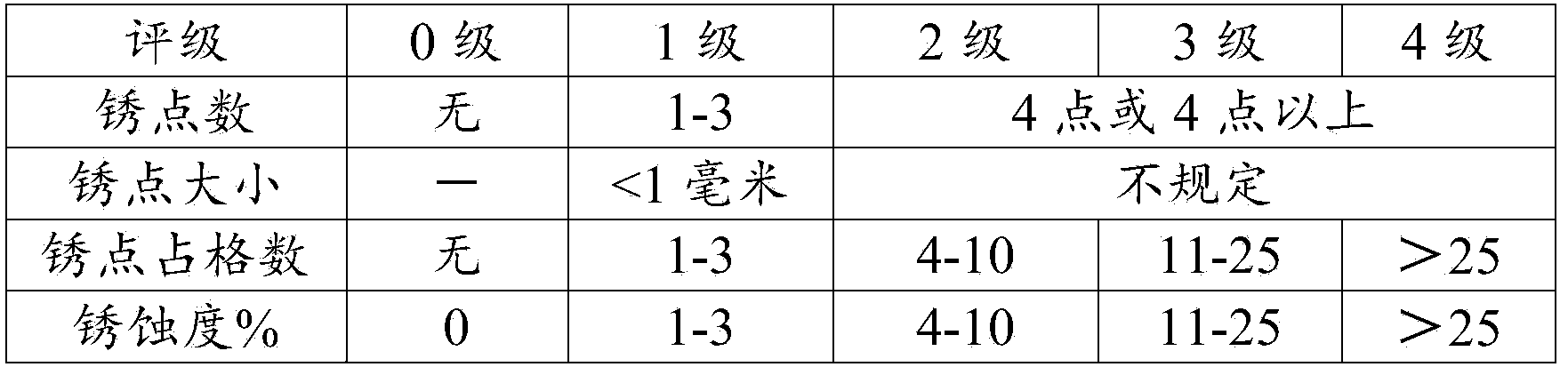

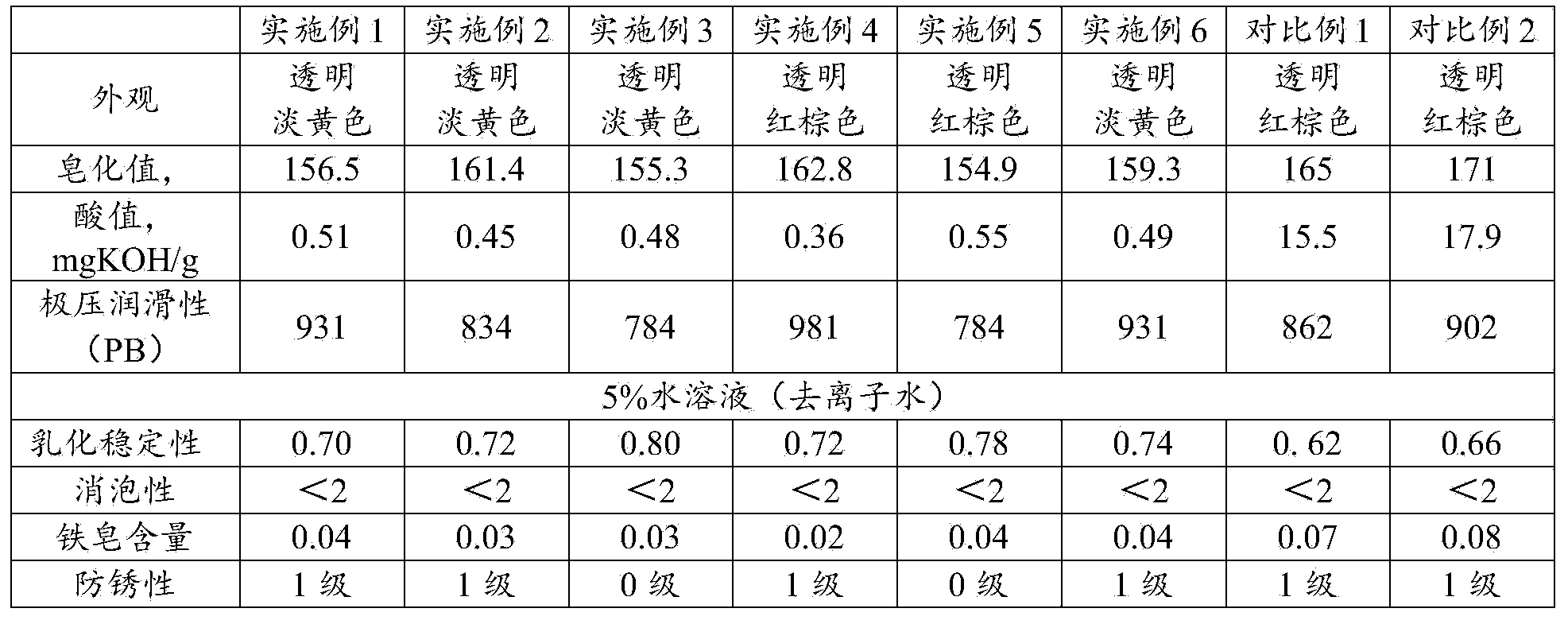

[0004] One of the technical problems to be solved by the present invention is that in the prior art, the free fatty acid of the emulsified oil is high, the acid value is relatively large, and a large amount of iron soap is produced during rolling, resulting in poor stability of the emulsified oil, iron soap clogging pipes, and difficulty in filtering problem, providing a new emulsified oil composition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~6

[0043] Heat the base oil to 45-50°C, add the required amount of non-fatty acid lubricant, extreme pressure agent, rust inhibitor, surfactant and antioxidant in turn during stirring, stir well, stop heating after 1.5 hours, Add defoamer and bactericide, stir well, stop stirring after 0.5 hours, let stand for 1.5 hours, filter and fill.

Embodiment 2

[0048] components

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an emulsified oil composition and use thereof. The emulsified oil composition is mainly used for solving the problem that the quality of plate faces and the use performance of emulsified liquid are affected due to the fact that iron soaps are excessive, block pipelines and are difficultly filtered during the use of the existing emulsified liquid technologies. By adopting the technical scheme that the emulsified oil composition contains the following ingredients in parts by weight: (a) 30-40 parts of base oil, (b) 40-50 parts of non fatty acid type lubricant, (c) 2-5 parts of extreme pressure agent, (d) 1-5 parts of anti-rust agent, (e) 5-10 parts of surfactant and (f) 0.1-5 parts of antioxidant, the problem is better solved, the requirements of a straight carbon steel cold-rolling rolling process are met, and the emulsified oil composition can be applied to a rolling process of a modern large-sized multi-rack continuous-rolling rolling mill and a rolling process of a multi-roller mono-rack reversible rolling mill.

Description

technical field [0001] The invention relates to an emulsified oil composition and its application. Background technique [0002] Steel plate rolling is widely used in the iron and steel machinery industry as a non-loss forming processing method for metals. As a high-tech cold rolling process, its processing method is highly valued by people. In the steel plate rolling process, a lubricating cooling medium is usually required, that is, steel plate rolling oil, which is mainly divided into two types: pure oil type and emulsified steel plate rolling oil. Pure oil-type rolling oil has good lubricating extreme pressure performance, but its cooling performance is poor, and it cannot take away the heat generated during the rolling process in time, resulting in large oil mist on site and affecting the working environment on site. At the same time, with the advancement of modern rolling technology, the rolling speed required by the current rolling technology is getting faster and fa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N40/24

Inventor 杨兰王士庭吴滨杨志东张旭李谨

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com