Production method of special soybean protein powder for tofu pudding

A technology of soybean protein powder and production method, which is applied in the direction of protein food processing, plant protein processing, protein food ingredients, etc., can solve the problems of low extraction rate of soybean protein, affect the application of soybean protein, and poor taste of bean curd, etc., and achieve remarkable Economic benefits, solve the effect of poor flavor and taste, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

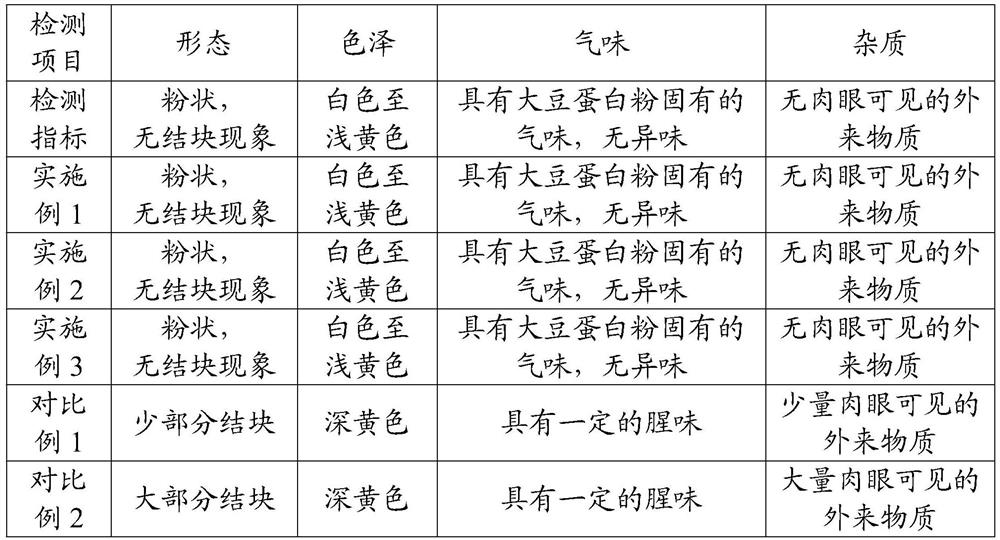

Examples

Embodiment 1

[0024] The production method of special soybean protein powder for bean curd specifically comprises the following steps:

[0025] (1) Put 1 kg of soybeans into 6 kg of water at a temperature of 15°C and soak for 14 hours, then crush and refine the pulp and filter to remove the slag. ℃, to obtain soybean milk;

[0026] (2) Add citric acid dropwise to the soymilk to adjust the pH value to 5.0, then add 40 g of neutral protease, heat up to 40° C. for 4 hours, and filter to obtain the soymilk enzymatic hydrolyzate;

[0027] (3) Heat the soymilk enzymatic hydrolysis solution to 85°C to deactivate the enzyme for 20 minutes, then set the spray drying inlet temperature to 180°C and the outlet temperature to 60°C and spray dry for 10-20s to obtain soybean protein powder for bean curd.

Embodiment 2

[0029] The production method of special soybean protein powder for bean curd specifically comprises the following steps:

[0030] (1) Put 1 kg of soybeans into 10 kg of water at a temperature of 25°C and soak for 16 hours, then crush and refine the pulp and filter to remove the slag. ℃, to obtain soybean milk;

[0031] (2) Add dropwise citric acid to the soymilk to adjust the pH value to 6.0, then add 60 g of neutral protease, heat up to 60° C. for 6 hours, and filter to obtain the soymilk enzymatic hydrolyzate;

[0032] (3) Heat the soymilk enzymatic hydrolysis solution to 95°C to deactivate the enzyme for 40 minutes, then set the spray drying inlet temperature to 220°C and the outlet temperature to 80°C and spray dry for 20 seconds to obtain soybean protein powder for bean curd.

Embodiment 3

[0034] The production method of special soybean protein powder for bean curd specifically comprises the following steps:

[0035] (1) Soak 1 kg of soybeans in 8 kg of water at a temperature of 20°C for 15 hours, then crush and refine the pulp and filter to remove slag. ℃, to obtain soybean milk;

[0036] (2) Add citric acid dropwise to the soybean milk to adjust the pH value to 5.5, then add 50 g of neutral protease, heat up to 50° C. for enzymolysis reaction for 5 hours, and filter to obtain the soybean milk enzymatic hydrolysis solution;

[0037] (3) Heat the soymilk enzymatic hydrolyzate to 90°C to deactivate the enzyme for 30 minutes, then set the spray drying inlet temperature to 200°C and the outlet temperature to 70°C and spray dry for 15 seconds to obtain soybean protein powder for bean curd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com