Simple method for quickly improving functional properties of whey isolated protein

A technology of whey protein isolate and protein function, which is applied in the fields of peptide preparation methods, animal protein processing, chemical instruments and methods, etc., can solve the problems of high emulsification, antioxidant activity, and functional properties of whey protein isolate. Ideal, limited antioxidant activity of whey protein isolate, etc., to achieve the effect of shortening the required time, shortening the reaction time, and improving high emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of lactose-whey protein isolate mixed solution:

[0039] Weigh 25g of whey protein isolate, add 500mL of distilled water to fully dissolve to obtain a whey protein isolate solution, and weigh 25g of lactose into the whey protein isolate solution, stir until fully dissolved, add 1mol / L sodium hydroxide, 1mol / L Adjust the pH to 8.5 with hydrochloric acid to obtain a lactose-whey protein isolate mixed solution.

Embodiment 2

[0041] Optimization of parameters for microwave heating of lactose-whey protein isolate mixed solution:

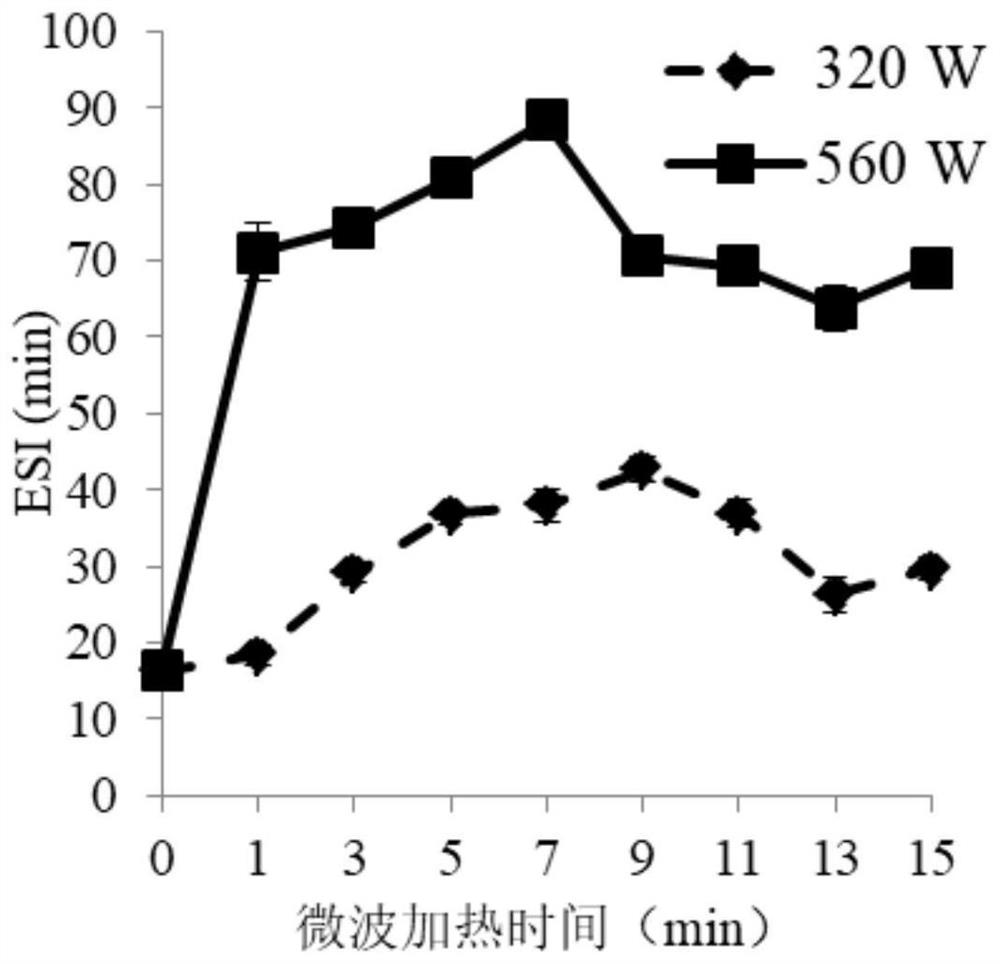

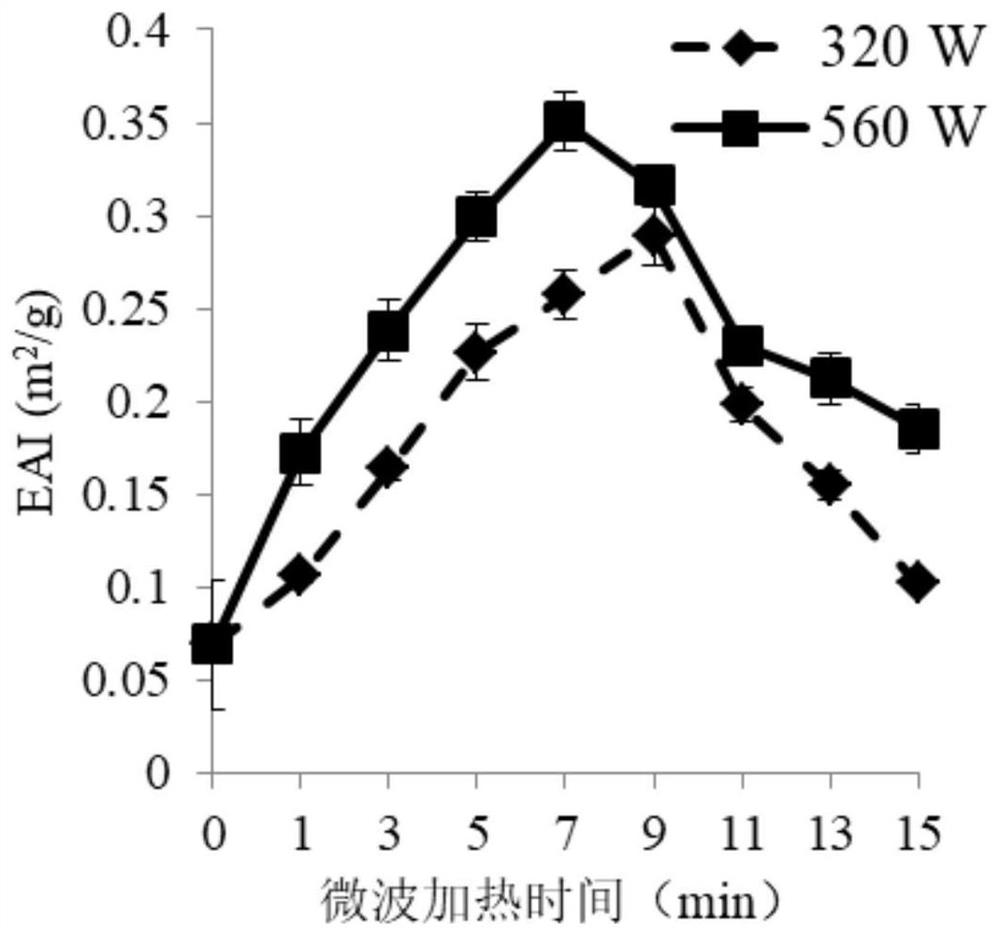

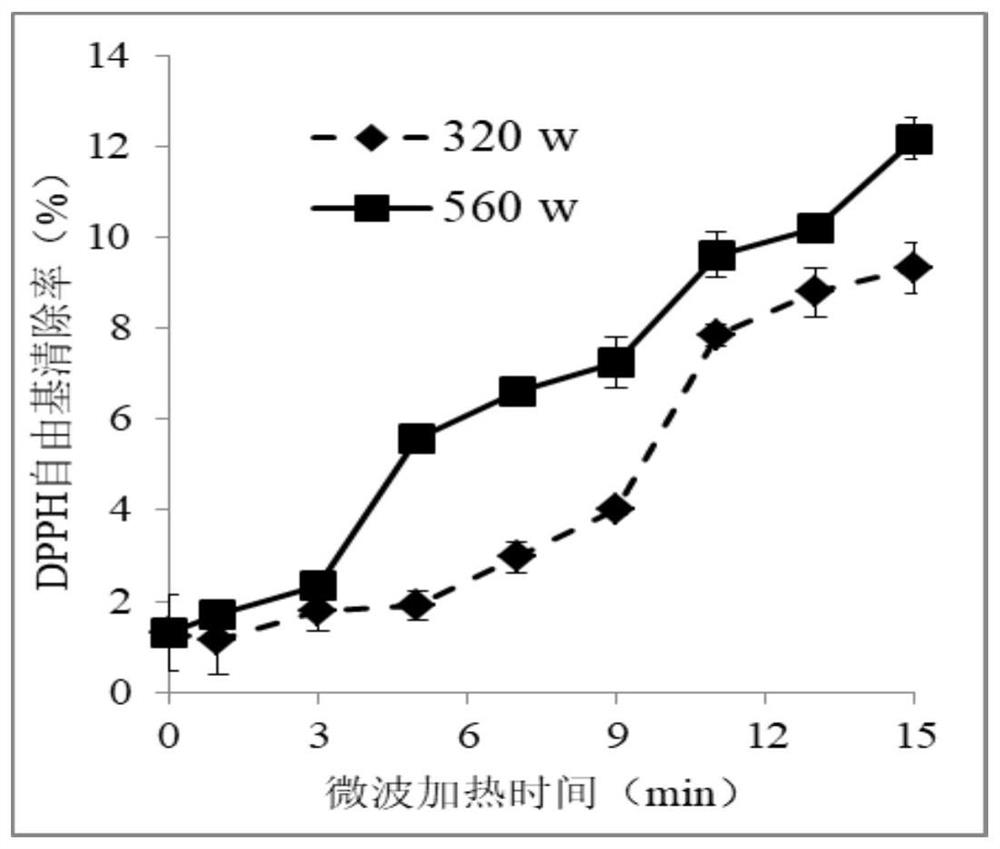

[0042] (1) 560W microwave heating: take 9 parts of the lactose-whey protein isolate mixed solution with pH = 8.5 prepared in Example 1, each 10 mL, put it in a microwave oven, set the microwave heating power to 560W, microwave heating 0, After 1, 3, 5, 7, 9, 11, 13, and 15 minutes, take it out immediately, and cool it with ice water to 10°C or below within 10 minutes to obtain a modified whey protein isolate reaction solution, and the modified whey protein isolate The reaction solution was freeze-dried to obtain 9 parts of modified whey protein isolate.

[0043] (2) 320W microwave heating: Take 9 parts of the lactose-whey protein isolate mixed solution with pH = 8.5 prepared in Example 1, each 10 mL, put it in a microwave oven, set the microwave heating power to 320W, microwave heating 0, After 1, 3, 5, 7, 9, 11, 13, and 15 minutes, take it out immediately, and cool it wi...

Embodiment 3

[0046] Optimum Lactose-Whey Protein Isolate Mass Ratio Determination:

[0047] Weigh 6 parts of 0.5g whey protein isolate respectively, add 10mL distilled water to fully dissolve respectively to obtain whey protein isolate solution, and the mass ratio of whey protein isolate to lactose is 5:3, 5:4, 5:5, 5: 6. Weigh lactose into the whey protein isolate solution at 5:7 and 5:8, stir until fully dissolved, adjust the pH to 8.5 with 0.01mol / L sodium hydroxide and 0.01mol / L hydrochloric acid, and obtain lactose-whey Put the protein isolate mixed solution in a microwave oven, heat it in a microwave at 560W for 7 minutes, take it out immediately, and cool it to 10°C or below with ice water within 10 minutes to obtain a modified whey protein isolate reaction solution. The modified whey The protein isolate reaction solution is freeze-dried to obtain the modified whey protein isolate.

[0048] The emulsion stability (ESI), emulsification activity (EAI) and DPPH free radical scavenging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com