Making process and product of high-butterfat-content crisp pralines and device

A preparation process and high milk fat technology, applied in the confectionery industry, oily food ingredients, confectionery, etc., can solve the problems of short shelf life, sweetness, stickiness, etc., and achieve the effect of compact structure and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

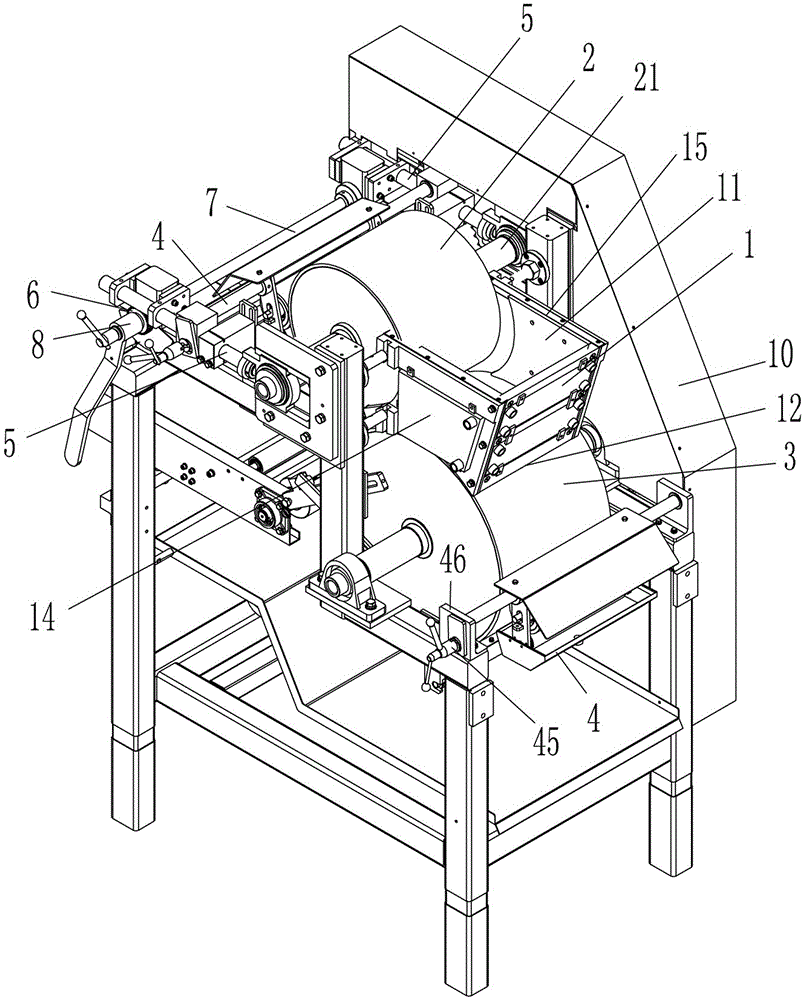

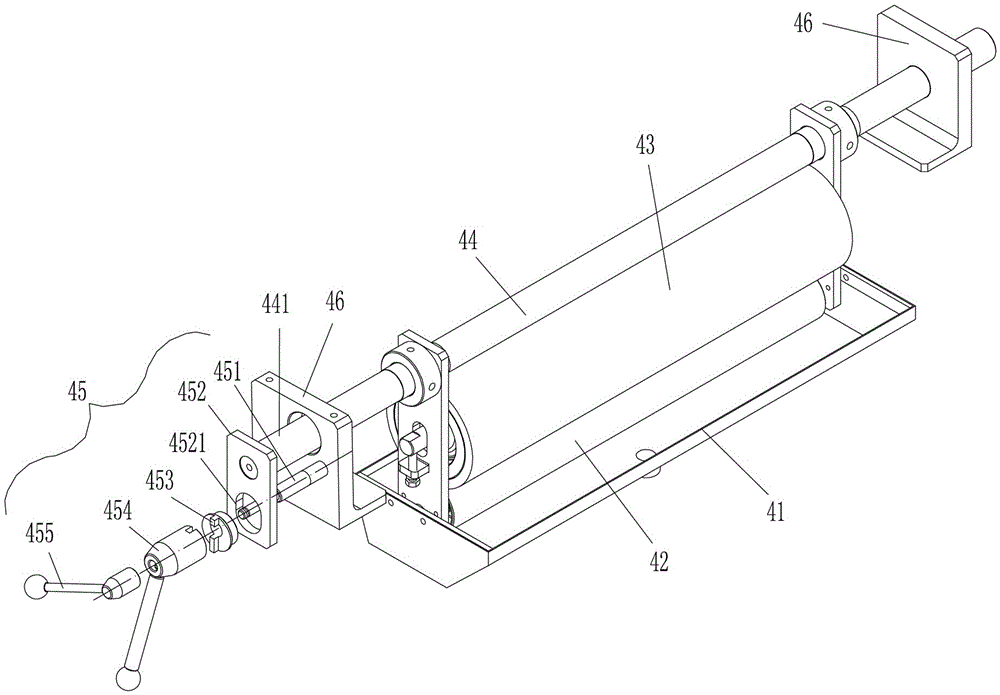

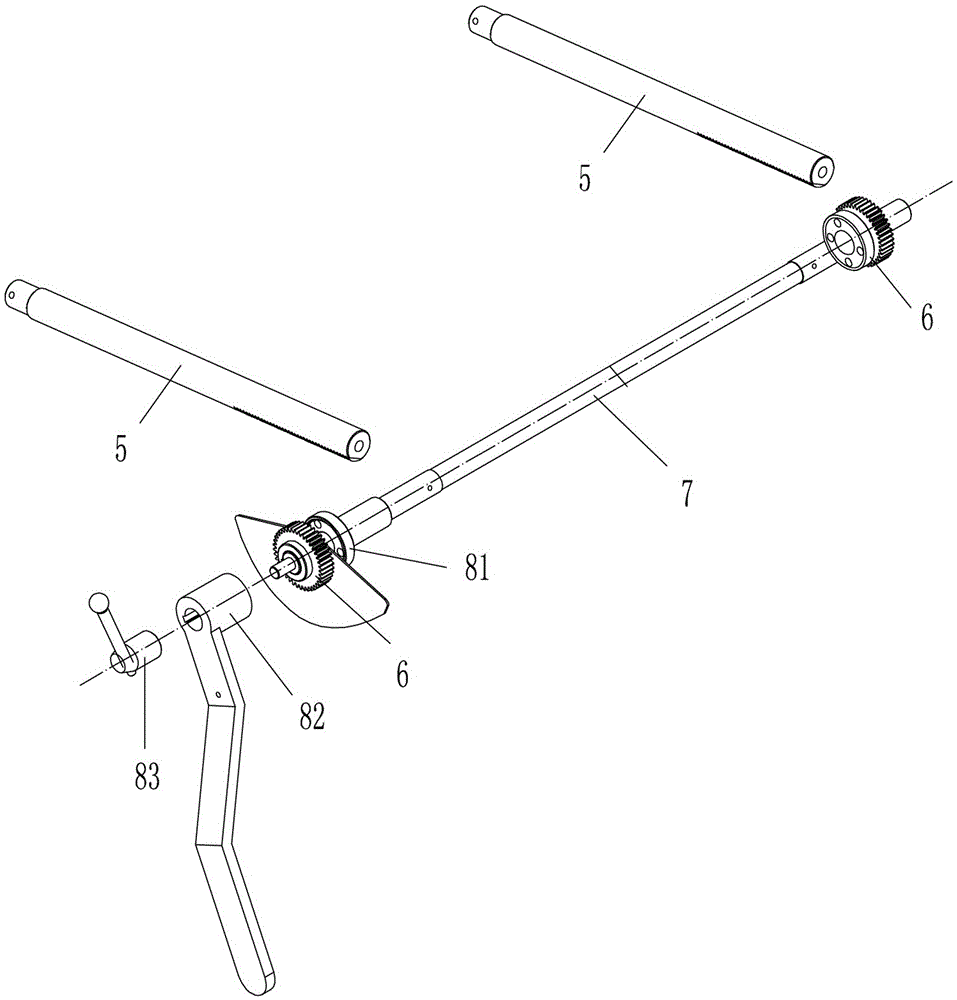

Image

Examples

Embodiment 1

[0053] A kind of preparation technology of high milk fat crisp praline, it comprises the following steps:

[0054] 1) Ingredients (unit / kg):

[0055] water 12;

[0056] white sugar 34;

[0057] Glucose syrup 34;

[0058] cream 9;

[0059] coconut oil 33;

[0060] Full-fat sweetened condensed milk8;

[0061] Sucrose fatty acid ester S3700.3;

[0062] Sucrose fatty acid ester S5700.2;

[0063] Sucrose fatty acid ester S7700.2;

[0064] Soy lecithin 1.2;

[0065] 2) Dissolving sugar: Mix the water, sugar and glucose syrup weighed in step 2) evenly and filter them into the pre-cooking pot storage tank as the syrup liquid. The sugar content of the syrup liquid is 84-85%; open the pre-cooking pot, Pre-boiling temperature is set at 110°C;

[0066] 3) Emulsification: prepare a compound emulsifier, the compound emulsifier consists of sucrose fatty acid lipid S370 weighed in step 1),

[0067] Sucrose fatty acid ester S770, sucrose fatty acid ester S570 mixed with soybean leci...

Embodiment 2-4

[0079] Embodiment 2-4 adopts the process identical with embodiment 1, and difference is the weight difference of batching and temperature difference in the reaction process, and concrete data is as shown in table 1:

[0080] Table 1:

[0081]

[0082] The praline worthy of the preparation process of the high-butterfat crispy praline of the present invention combines fragrant and crispy butterscotch and crispy nuts into a whole with a unique flavor.

[0083] The amount of the compound emulsifier of the present invention accounts for 1.5-2.5% of the mass percentage of the solid massecuite in the prepared syrup liquid in step 2), coconut oil, cream and sweetened condensed milk, wherein the formula for calculating the solid massecuite is (glucose syrup mass*75 %+white sugar quality) / brix value, if the amount of emulsifier is too much, it will affect the taste, if the amount of emulsifier is too low, it will not be emulsified; the amount of coconut oil and cream is 55% of the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com