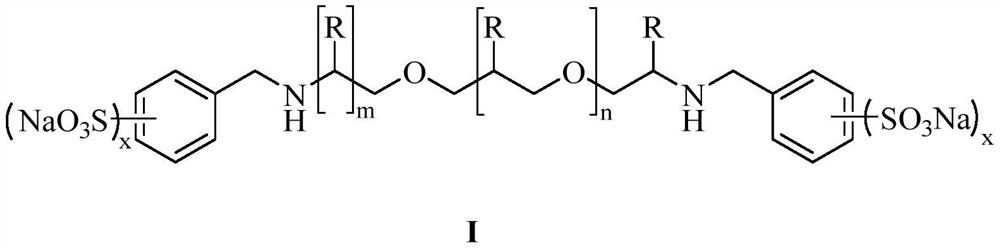

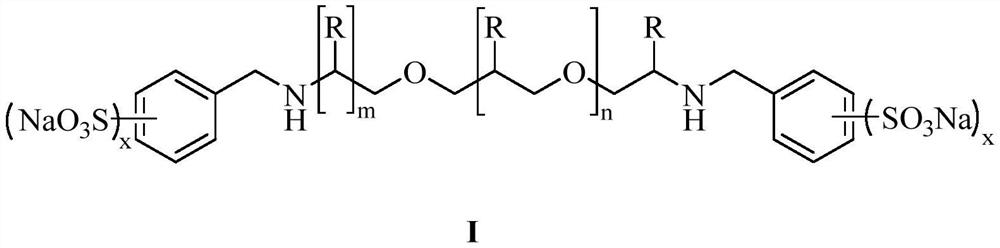

Flexible sulfonic acid type hydrophilic chain extender as well as preparation method and application thereof

A hydrophilic chain extender and sulfonic acid-type technology, which is applied in the field of polyurethane materials, can solve the problems of the water resistance of polyurethane films, hinder the industrial application of water-based polyurethane, and restrict the practical application of water-based polyurethane, so as to increase water resistance and ensure emulsification performance And long-term stability, beneficial to the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

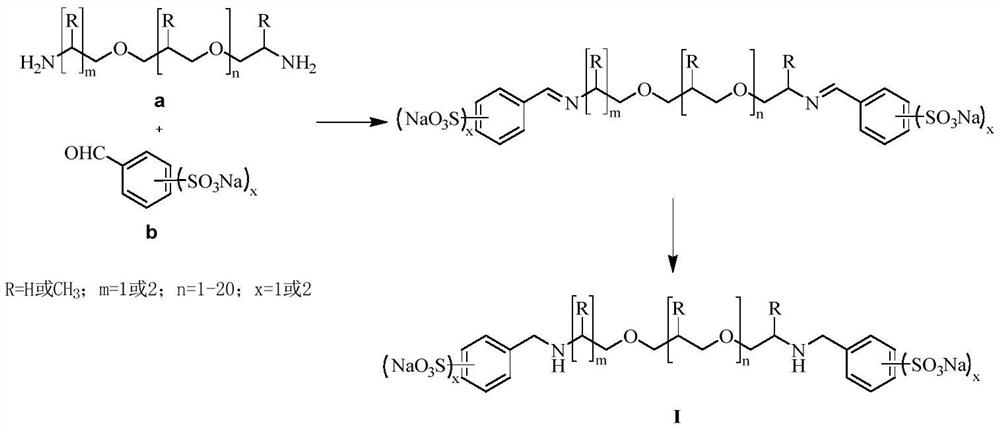

[0039]Add 8.1 g of ether diamine a-1, 22.9 g of sodium benzaldehyde-2-sulfonate, 0.1 g of p-toluenesulfonic acid, and 50 mL of dimethyl sulfoxide into the reaction flask, and react at room temperature with stirring for 5 hours; add sodium borohydride 6.1 g, react at room temperature for 5 hours; precipitate the reaction mixture system in acetone twice, wash the obtained solid with a large amount of acetone, and obtain 26.5 g of chain extender I-1 after vacuum drying.

[0040]The reaction formula is as follows:

[0041]

Embodiment 2

[0043]Add 11.1 g of ether diamine a-2, 21.8 g of sodium benzaldehyde-4-sulfonate, 0.11 g of p-toluenesulfonic acid, and 50 mL of dimethyl sulfoxide into the reaction flask, and react at room temperature with stirring for 5 hours; add sodium borohydride 5.9 g, react at room temperature for 5 hours; precipitate the reaction mixture system in acetone twice, wash the obtained solid with a large amount of acetone, and obtain 29.2 g of chain extender I-2 after vacuum drying.

[0044]The reaction formula is as follows:

[0045]

Embodiment 3

[0047]Add 28.0 g of ether diamine a-3, 2.08 g of sodium benzaldehyde-4-sulfonate, 0.56 g of p-toluenesulfonic acid, and 80 mL of dimethyl sulfoxide into the reaction flask, and react at room temperature with stirring for 5 hours; add cyanoborohydride Sodium 1.0g, reaction at room temperature for 5h; the reaction mixture system was precipitated in acetone twice, the obtained solid was washed with a large amount of acetone, and after vacuum drying, 27.2g of chain extender I-3 was obtained.

[0048]The reaction formula is as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com